Resource utilization technology of drilling well wastes

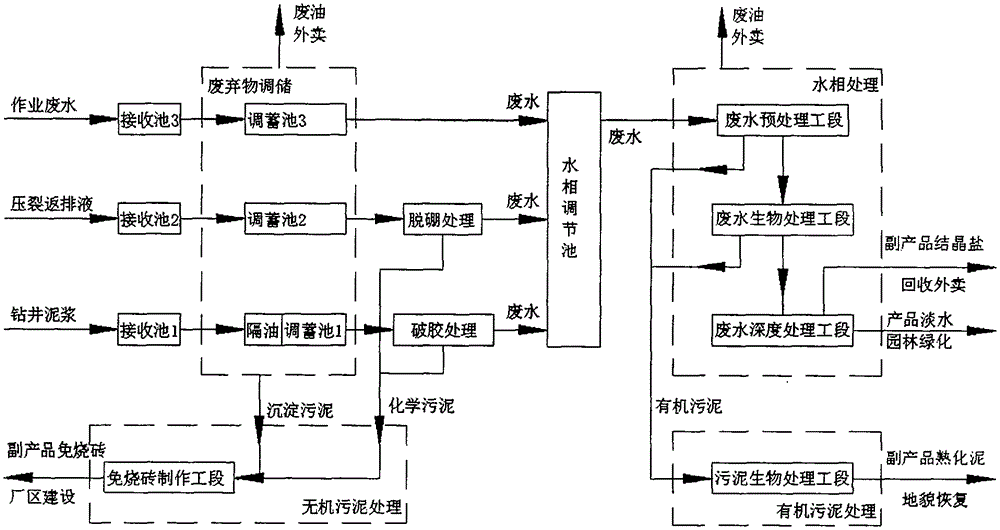

A drilling waste and recycling technology, which is applied in the field of drilling waste recycling technology, can solve the problems to be further improved, and achieve the effects of excellent environmental protection benefits, broad social benefits, and strengthening demonstration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

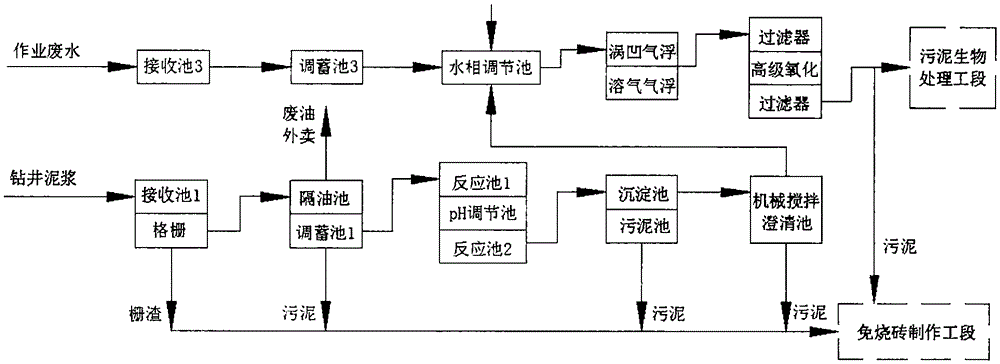

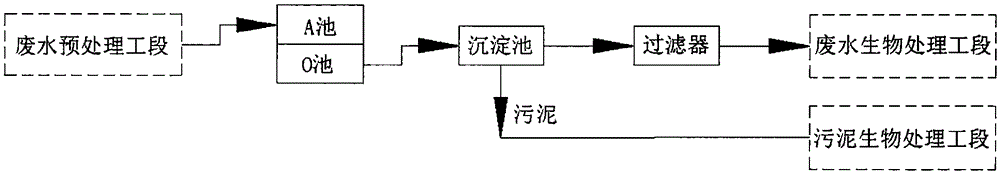

Method used

Image

Examples

Embodiment 1

[0039] Taking the treatment of drilling mud, fracturing flowback fluid and gas test operation wastewater in Sulige Gas Field as an example, the comprehensive influent water quality of various drilling waste pollutants in the water quality monitoring report is as follows:

[0040] Table 1 Comprehensive influent water quality indicators of drilling waste pollutants

[0041]

[0042] It can be seen from the test results that the three streams of wastewater that make up the drilling waste in the Sulige oil and gas field have seriously exceeded the standard in terms of COD, BOD5, inorganic salt content, oil content, etc., and the wastewater from the gas removal operation has good biodegradability In addition, the biodegradability of the other two streams of wastewater is very low, and the salt content is high, which belongs to high-salt organic wastewater that is difficult to degrade. Reliable treatment process to reduce the overall operating cost and operating load of the syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Shrinkage value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com