Re-injection process and equipment for poured resin adhesive solution when discharging air bubbles during composite material RTM molding process

A technology for resin glue and composite materials, applied in the field of re-injection process and special equipment, can solve problems such as pollution of the environment, waste of resin glue, etc., and achieve the effects of reducing emissions, reducing production costs, and being easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

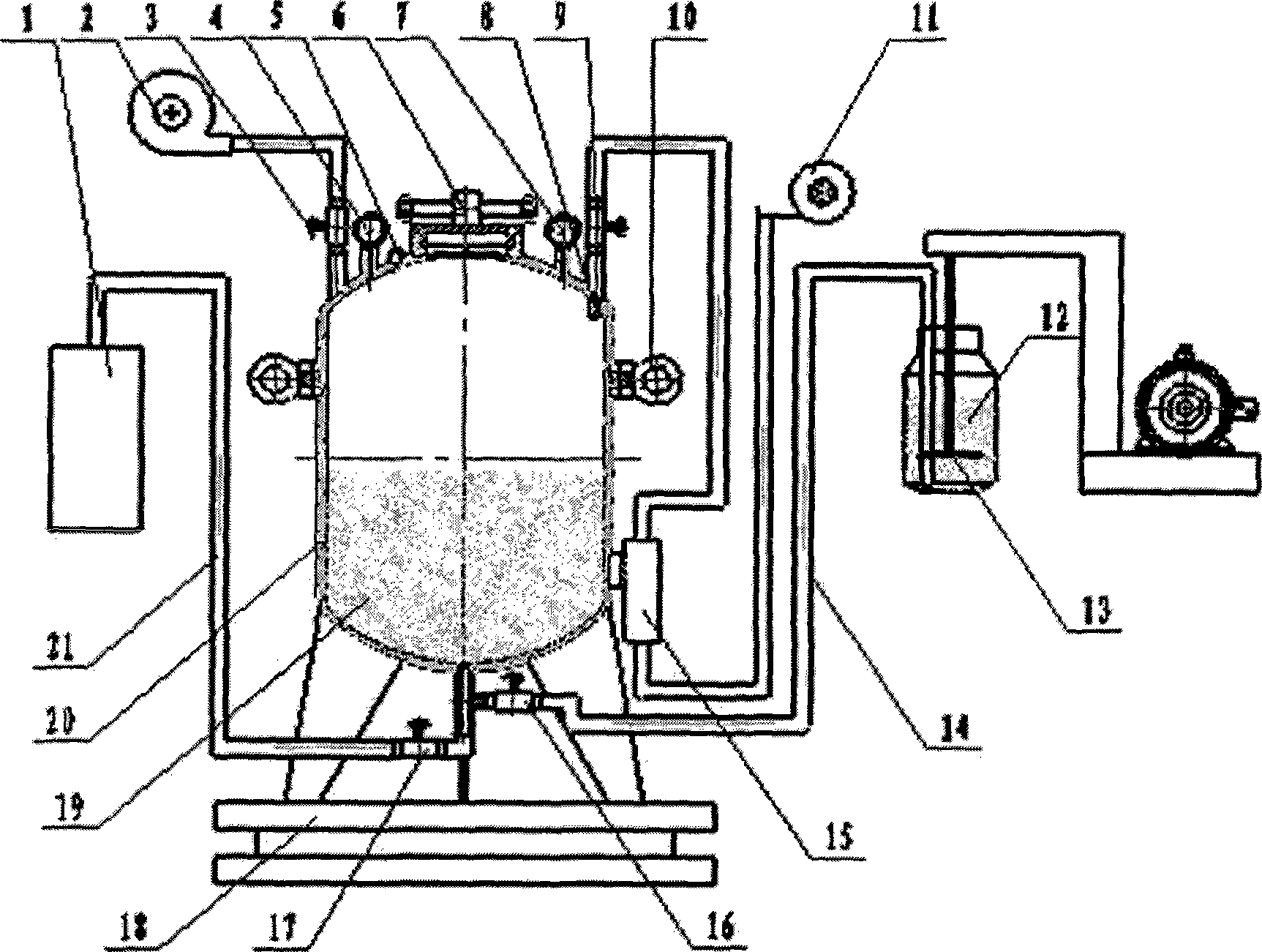

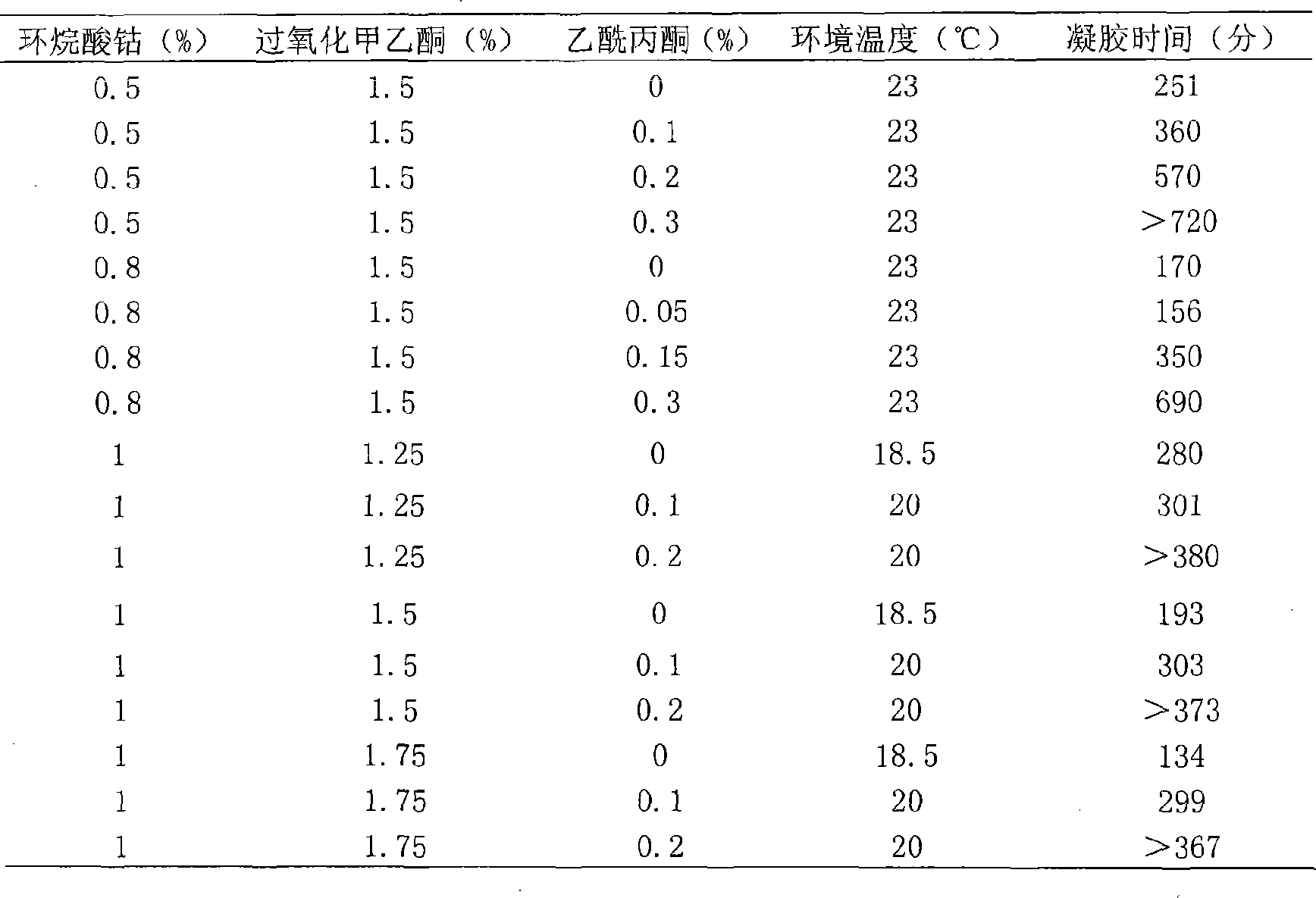

[0064] Example 1: use technology of the present invention and special equipment, realize its following steps:

[0065] 1) During RTM production, the accelerator ratio of the resin system is 0.5%, the curing agent ratio is 1.5%, and the retarder acetylacetone is quantitatively added in the raw material barrel 12 according to the ratio of 0.1% of the total amount according to the amount of resin glue to be collected Finally, the resin glue liquid flowing out during the RTM production process is filtered through a 60-mesh screen and collected in the raw material barrel 12, and stirred evenly with the agitator 13. The mold for the first production of the product should be clean and use semi-permanent demoulding agent, the resin will not be polluted when flowing through the pipeline, and ensure that the release agent and the like are not mixed into the resin glue;

[0066] 2) Start the vacuum pump 2, open the vacuum valve 3 and the feed valve 16, and use vacuum suction to suck the ...

example 2

[0072] Example 2: use process technology and special equipment described in the present invention, concrete steps are identical with example 1, do not repeat them here, and its difference is:

[0073] When RTM is produced, the accelerator ratio of the resin system is 0.8%, the curing agent ratio is 1.25%, and the retarder acetylacetone is added in the raw material barrel 12 to be 0.05%; the resin glue liquid flowing out during the RTM production process is passed through a 40-mesh screen Collected in the raw material bucket 12 successively after filtering;

[0074] The temperature of the resin glue in step 2) and the room temperature are both 23°C;

[0075] Step 3) The degassing time for the resin glue is 20 minutes; the temperature of the tank body 19 is 26°C;

[0076] Step 4) inject the pressure into the tank body 19 to an initial injection pressure of 0.1 MPa;

[0077] Step 5) start injection into the mold 1, and the mold temperature is 23°C; the pressure in the tank body 1...

example 3

[0078] Example 3: use process technology and special equipment of the present invention, concrete steps are identical with example 1, do not repeat them here, and its difference is:

[0079] When RTM is produced, the accelerator ratio of the original resin system is 1%, the curing agent ratio is 1.75%, and the retarder acetylacetone is added in the raw material barrel 12 to be 0.2%; Collected in succession in the raw material bucket 12 after sieve filtering;

[0080] The resin glue solution and room temperature of step 2) are both 15°C;

[0081] Step 3) The degassing time for the resin glue is 30 minutes, and the temperature of the tank body 19 is 20°C;

[0082] Step 4) inject the pressure into the tank body 19 to an initial injection pressure of 0.15MPa;

[0083] Step 5) Start injection into the mold 1, the temperature of the mold 1 is 15°C; the pressure in the tank body 19 can be adjusted in the range of 0.15-0.6Mpa as required, so as to control the feed rate at 20-2000g / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com