Preparation method for nano-carbon material having graphene-like structure

A nanocarbon material, graphene technology, applied in nanocarbon, nanotechnology for materials and surface science, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a graphene-like nano-carbon material, comprising the following steps:

[0023] 1) Put 2g of bentonite into 5 L of wastewater containing crystal violet at a concentration of 200 mg / L, absorb for 1 hour and then settle for 2 hours, and the wastewater becomes clear;

[0024] 2) Dry and pulverize the precipitated waste bentonite, then place it in a muffle furnace, raise the temperature to 600°C for 2 hours under the protection of nitrogen, and then use hydrofluoric acid with a volume concentration of 10%, hydrochloric acid with a volume concentration of 10% Alternately washing 4 times, each washing time is 4 h, and the amount of acid is 40 mL; after the product is dried, a graphene-like structure nano-carbon material is obtained.

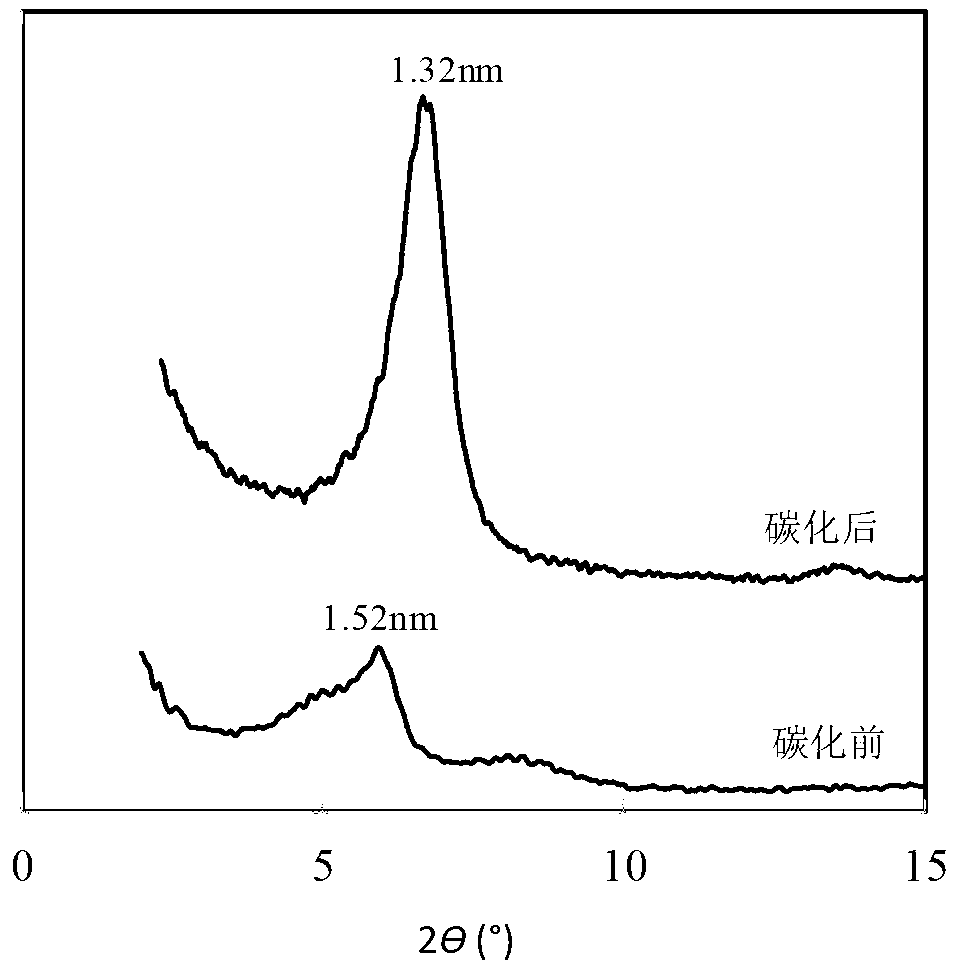

[0025] The XRD characterization results show that ( figure 1 ), the distance between the bottom surfaces of bentonite before and after carbonization was 1.52 nm and 1.32 nm, respectively; since the thickness of the benton...

Embodiment 2

[0027] A preparation method of a graphene-like nano-carbon material, comprising the following steps:

[0028] 1) Put 2g of bentonite into 5 L of wastewater containing methylene blue at a concentration of 200 mg / L, and after 1 hour of adsorption, precipitate for 2 hours, and the wastewater becomes clear;

[0029] 2) Separate, dry, and pulverize the above bentonite that has absorbed the cationic dye methylene blue, and then place it in a muffle furnace and heat it up to 600°C for 3 hours under the protection of nitrogen. Fluoric acid and hydrochloric acid with a volume concentration of 12% were washed 4 times alternately, each washing time was 3 h, and the acid dosage was 30 mL. The product is dried to obtain a nano-carbon material with a graphene-like structure.

[0030] The results of XRD characterization showed that the distance between the bottom surfaces of bentonite after carbonization was 1.33 nm; after acid washing, a nano-carbon material with a graphene-like structure ...

Embodiment 3

[0032] A preparation method of a graphene-like nano-carbon material, comprising the following steps:

[0033] 1) Put 2g of bentonite into 5 L of wastewater containing crystal violet at a concentration of 250 mg / L, absorb for 1 hour and then settle for 2 hours, and the wastewater becomes clear;

[0034] 2) Dry and pulverize the precipitated waste bentonite, then place it in a muffle furnace, heat up to 500°C for 5 hours under nitrogen protection, and carbonize the bentonite after carbonization with hydrofluoric acid with a volume concentration of 20% and a volume concentration of 6 % hydrochloric acid alternately washed 3 times, each washing time was 4 h, the acid dosage was 30 mL, and dried to obtain a graphene-like structure nano-carbon material.

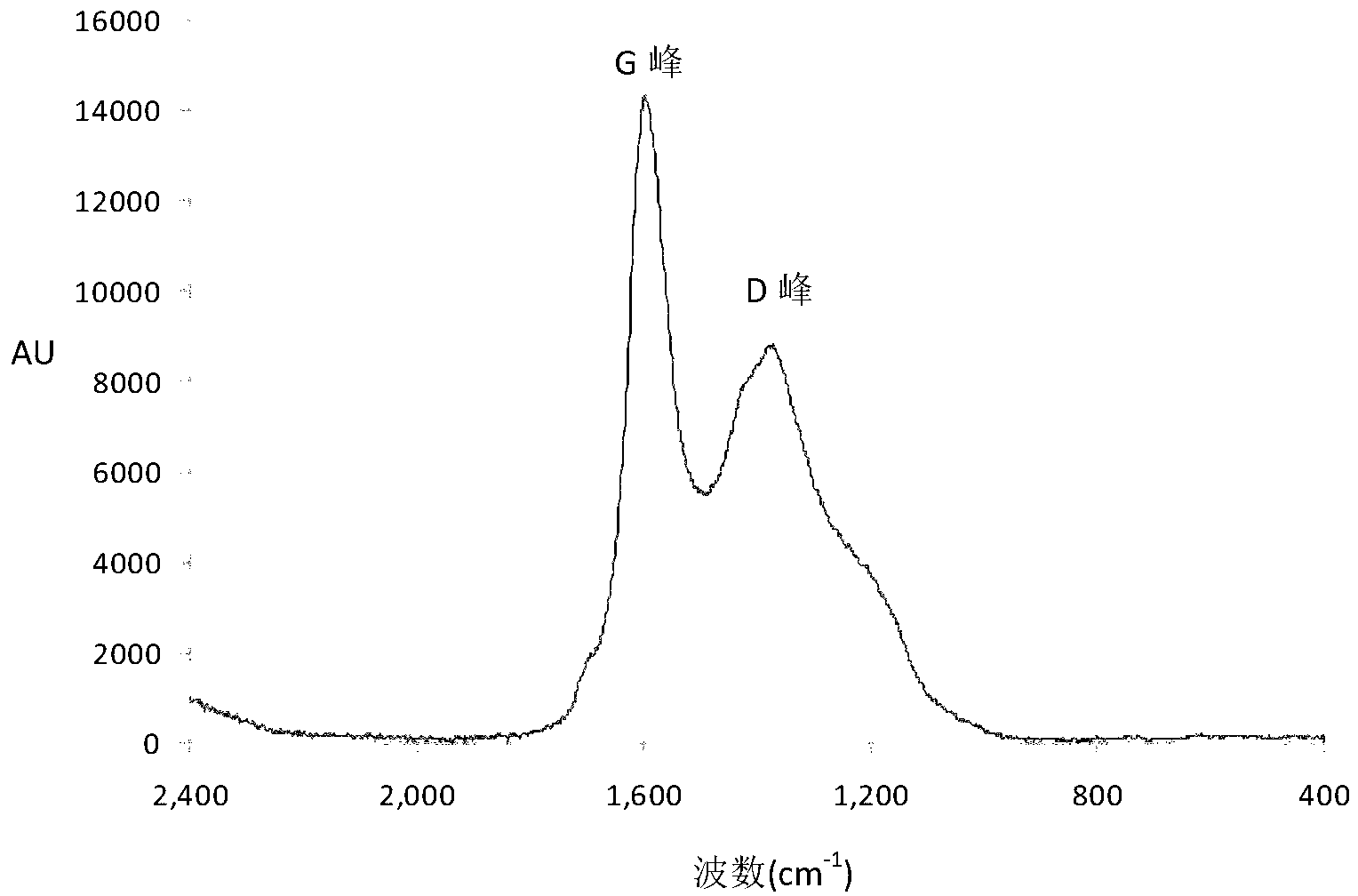

[0035] The XRD characterization results show that the distance between the bottom surfaces of the carbonized bentonite is 1.32 nm; the product after acid washing has the structural characteristics of graphene, and the Raman spectru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com