Recycling method for anode graphite material for invalid prismatic lithium-ion battery

A technology for lithium-ion batteries and graphite materials, which is applied in the field of recovery and reuse of negative electrode graphite materials of invalid square lithium-ion batteries, can solve the problems of high reaction energy consumption, low recovery efficiency, poor graphite performance, etc., and achieve low reaction energy consumption, Recycling efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

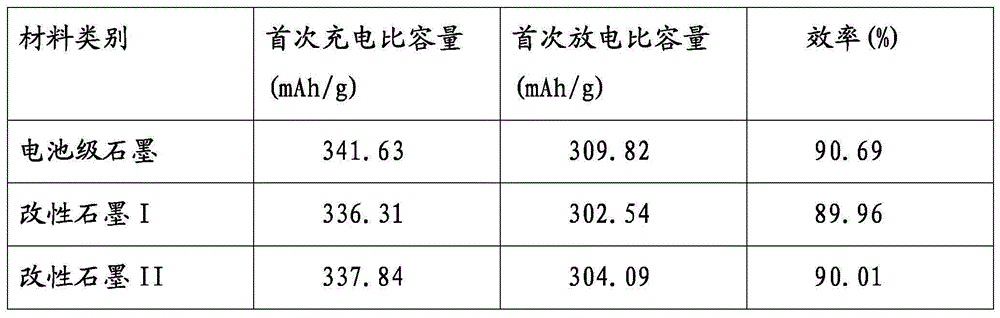

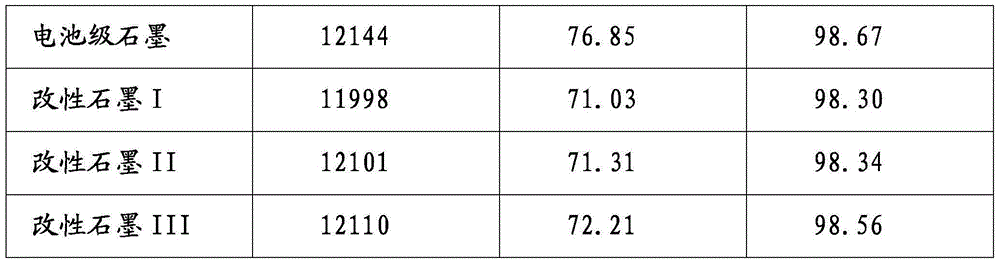

Embodiment 1

[0022] The failed prismatic lithium-ion battery is completely discharged and dissected. The resulting negative pole piece is ultrasonically dissolved in a 0.01mol / L dilute hydrochloric acid solution. The ultrasonic power is 60W. After the graphite sheet is completely separated from the current collector, the ultrasonic is stopped. , Take out the current collector, wash it with water, and dry it to complete the recovery of the current collector. At this time, the remaining graphite slurry is filtered, dried under vacuum at 50℃, and then sieved to separate the thickener to obtain the first purified graphite material The obtained first-purified graphite material is placed in an oxidizer solution in a water bath at 35°C for ultrasonic treatment with an ultrasonic power of 40W, and then centrifuged, washed, and dried in vacuum at 50°C, and then obtained after sieving to separate the binder Secondary purified graphite material; the obtained secondary purified graphite material is imme...

Embodiment 2

[0024] The failed prismatic lithium-ion battery is completely discharged and dissected. The resulting negative pole piece is ultrasonically dissolved in a 0.01mol / L dilute hydrochloric acid solution. The ultrasonic power is 40W. After the graphite sheet is completely separated from the current collector, the ultrasonic is stopped. , Take out the current collector, wash it with water, and dry it to complete the recovery of the current collector. At this time, the remaining graphite slurry is filtered, vacuum-dried at 60℃, and then sieved to separate the thickener to obtain the first purified graphite material The obtained first-purified graphite material is placed in an oxidant solution in a water bath at 45°C for ultrasonic treatment with an ultrasonic power of 50W, then centrifuged, washed and dried in vacuum at 60°C, and then obtained after sieving to separate the binder Secondary purified graphite material; the obtained secondary purified graphite material is immersed in a re...

Embodiment 3

[0026] The failed prismatic lithium-ion battery is completely discharged and dissected. The resulting negative pole piece is ultrasonically dissolved in a 0.01mol / L dilute hydrochloric acid solution. The ultrasonic power is 100W. After the graphite sheet is completely separated from the current collector, the ultrasonic is stopped. , Take out the current collector, wash it with water and dry it to complete the recovery of the current collector. At this time, the remaining graphite slurry is filtered, dried in vacuum at 80℃, and then sieved to separate the thickener to obtain the first purified graphite material The obtained first-purified graphite material is placed in an oxidant solution in a water bath at 25°C for ultrasonic treatment with an ultrasonic power of 30W, then centrifuged, washed, and dried in a vacuum at 80°C, and then obtained after sieving to separate the binder Secondary purified graphite material; the obtained secondary purified graphite material is immersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com