Preparation method of columnar bamboo activated carbon

An activated carbon and columnar technology, which is applied in the field of preparation of columnar bamboo activated carbon, can solve the problems of poor mechanical strength of bamboo activated carbon, affect the use of bamboo activated carbon, and complicated preparation process, so as to improve the gas atmosphere, ensure strength, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

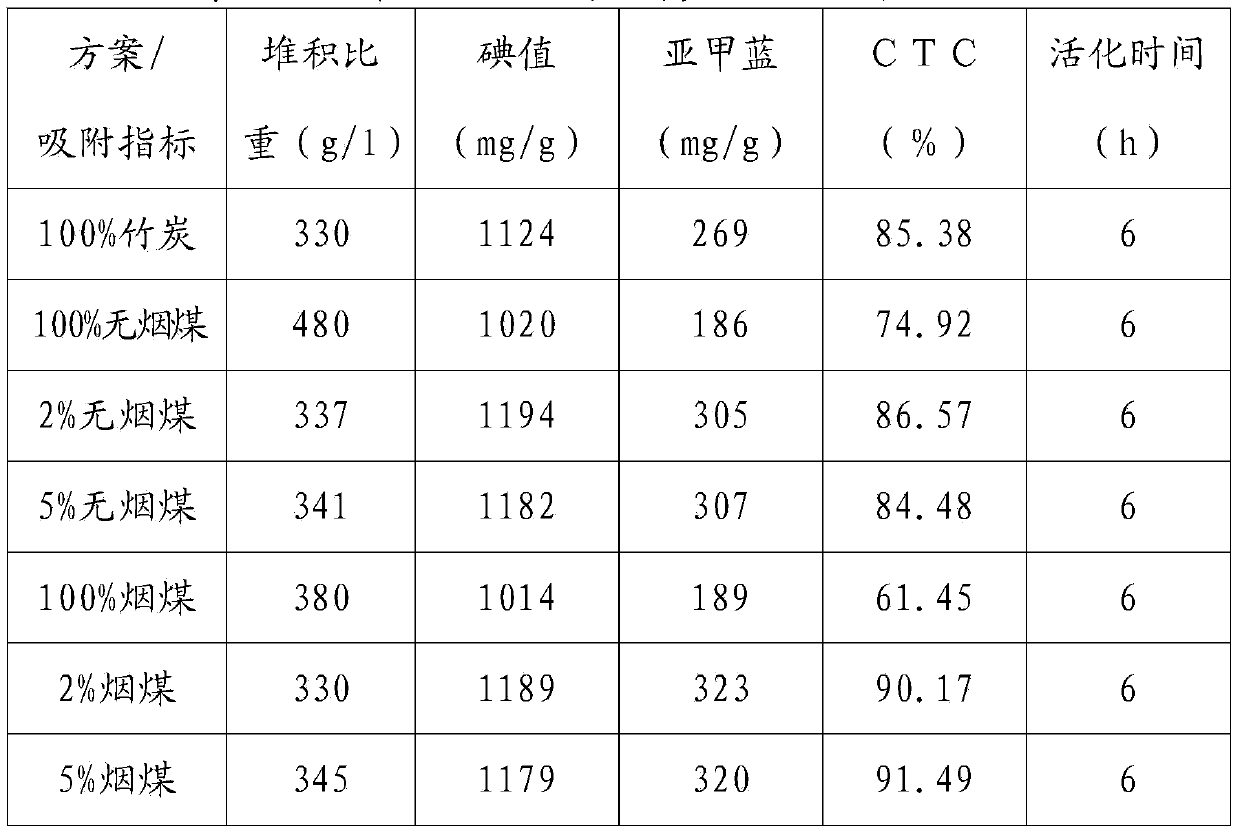

Examples

Embodiment 1

[0030] Bamboo charcoal raw materials are obtained by anaerobic carbonization at 270°C for 16 hours through selected bamboo or bamboo processing wastes and scraps in a retort, and the bamboo charcoal raw materials obtained by an anaerobic retort process are dried until the water content is 1%, and then pulverized. Weigh 10g of bamboo charcoal powder, select 200 mesh national standard sieve to sieve for 3min, accurately weigh the bamboo charcoal powder weight under the sieve, the percentage of the weight under the sieve to the total weight is 96.7%, that is, the 200 mesh pass rate is 96.7%, stop milling, and get Bamboo charcoal powder, measure the bamboo charcoal powder technical parameter that anaerobic dry distillation process makes be volatile matter 16.67%, ash content 1.87%, moisture content 1.15%, fixed carbon 80.31%; Select the product coal tar that 1000 ℃ coal dry distillation obtains, its Asphalt content is 60%, dehydrated to 0.6% moisture, accurately weigh 30kg of dehyd...

Embodiment 2

[0032] Bamboo charcoal raw materials are obtained by anaerobic carbonization at 310°C for 16 hours through selected bamboo or bamboo processing wastes and scraps in a retort, and the bamboo charcoal raw materials obtained by an anaerobic retort process are dried to a moisture content of 3% and then pulverized. Weigh 10g of bamboo charcoal powder, select 200 mesh national standard sieve to sieve for 3min, accurately weigh the bamboo charcoal powder weight under the sieve, the percentage of the weight under the sieve to the total weight is 96.2%, that is, the 200 mesh pass rate is 96.2%, stop milling, and get Bamboo charcoal powder, measure the bamboo charcoal powder technical parameter that anaerobic dry distillation process makes be volatile matter 11.63%, ash content 2.92%, moisture content 0.8%, fixed carbon 85.3%; Select the product coal tar that 1000 ℃ of coal dry distillation obtains, its Asphalt content is 56%, dehydrated to 2.5% moisture, accurately weigh 30kg of dehydra...

Embodiment 3

[0034]Bamboo charcoal raw materials are obtained by anaerobic carbonization at 350°C for 16 hours through selected bamboo or bamboo processing wastes and scraps in a retort, and the bamboo charcoal raw materials obtained by an anaerobic retort process are dried until the water content is 5%, and then pulverized. Weigh 10g of bamboo charcoal powder, select 200 mesh national standard sieve to sieve for 3 minutes, accurately weigh the weight of the bamboo charcoal powder under the sieve, the percentage of the weight under the sieve to the total weight is 95.1%, that is, the 200 mesh pass rate is 95.1%, stop milling, and get Bamboo charcoal powder, measure the bamboo charcoal powder technical parameter that anaerobic dry distillation process makes be volatile matter 13.65%, ash content 3.91%, moisture content 1.8%, fixed carbon 75.27%; Select the product coal tar that 1000 ℃ coal dry distillation obtains, its Asphalt content is 54%, dehydrated to 4% moisture, accurately weigh 30kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com