Preparation method of noble metal catalyst

A precious metal catalyst, precious metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Surface, complex operation process and other problems, to achieve the effect of short reaction time, small particle size and low reaction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

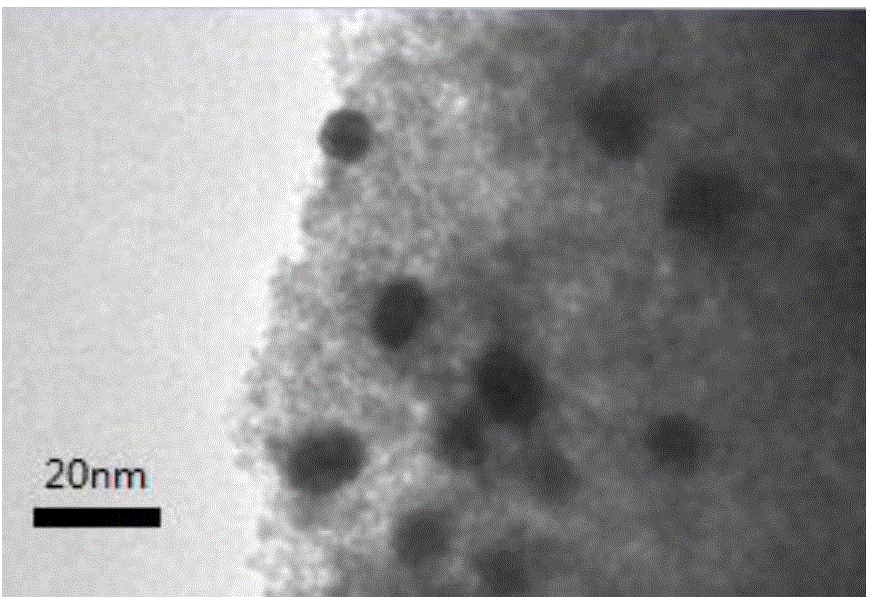

[0025] 5g activated carbon, 13ml, 0.2mol / L RuCl 3 The solution was mixed with 4 mL of 5% sodium dodecylsulfonate, dispersed under the action of ultrasonic waves, and the ultrasonic frequency was set to 40KHz, and the ultrasonic time was set to 0.5h. Add 20ml of the mixture obtained after ultrasonication, and reduce with 0.25mol / L sodium borohydride solution under microwave radiation, set the microwave radiation power to 20w, time to 1h, and reduction reaction temperature to 70°C. The obtained solid product was washed 5 times with distilled water, and then dried at 80° C. for 10 h to obtain a 5% Ru / C catalyst.

[0026] from figure 1 The metal Ru of the Ru / C catalyst has good dispersion, the dispersion is relatively uniform, and the metal particle size is small.

Embodiment 2

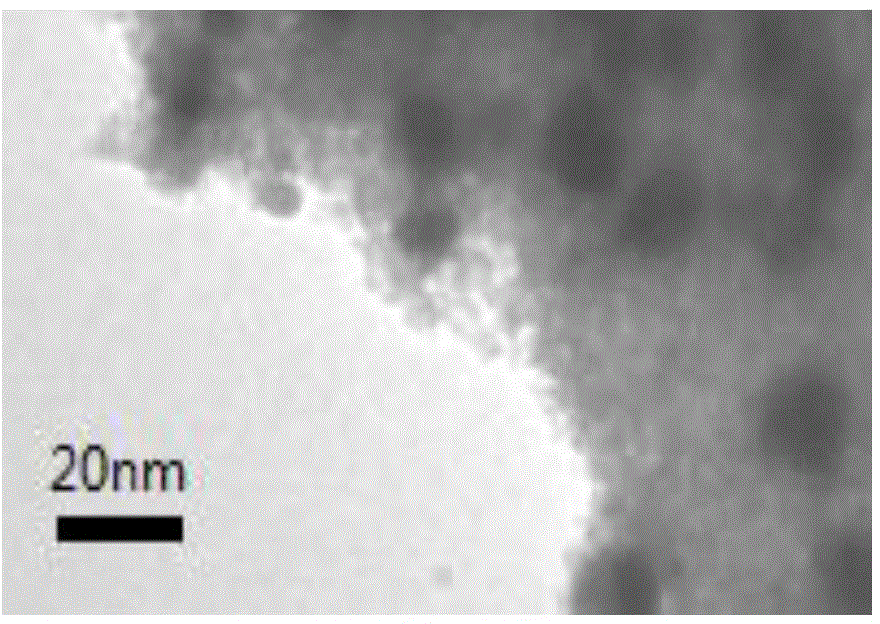

[0028] 1g activated carbon, 5ml, 0.0376mol / L Pd(NO 3 ) 2 The solution was mixed with 2mL, 3% sodium dodecylbenzenesulfonate, dispersed under the action of ultrasonic waves, and the ultrasonic frequency was set to 60KHz, and the ultrasonic time was set to 0.5h. Add 10ml of the mixture obtained after ultrasonication, and reduce with 0.3mol / L sodium borohydride solution under microwave radiation. The obtained solid product was washed 5 times with distilled water, and then dried at 80° C. for 10 h to obtain a 2% Pd / C catalyst.

[0029] from figure 2 The metal Pd of the Pd / C catalyst has good dispersion, the dispersion is relatively uniform, and the metal particle size is small.

Embodiment 3

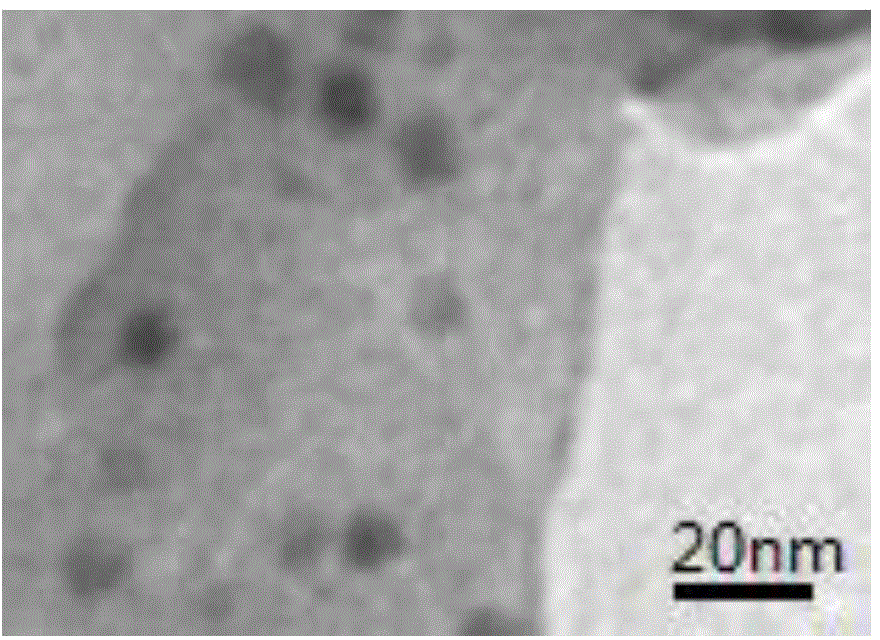

[0031] 1g activated carbon, 2ml, 0.0125mol / L K 2 PtCl 4 The solution was mixed with 5 mL of 4% sodium dodecylsulfonate, dispersed under the action of ultrasonic waves, the ultrasonic frequency was set to 80 KHz, and the ultrasonic time was 1 h. Add 10ml of the mixture obtained after ultrasonication, and reduce with 0.15mol / L sodium borohydride solution under microwave radiation. The obtained solid product was washed 5 times with distilled water, and then dried at 80° C. for 10 h to obtain a 0.5% Pt / C catalyst.

[0032] from image 3 The metal Pt of the Pt / C catalyst has good dispersion, the dispersion is relatively uniform, and the metal particle size is small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com