Production process of decaffeination tea

A technology for decaffeination and production process, which is applied to the technical field of producing decaffeinated tea by supercritical carbon dioxide extraction, can solve the problems of strong adsorption of activated carbon, long process extraction period, damage to tea characteristics, etc., and achieves high extraction rate. , the effect of short extraction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

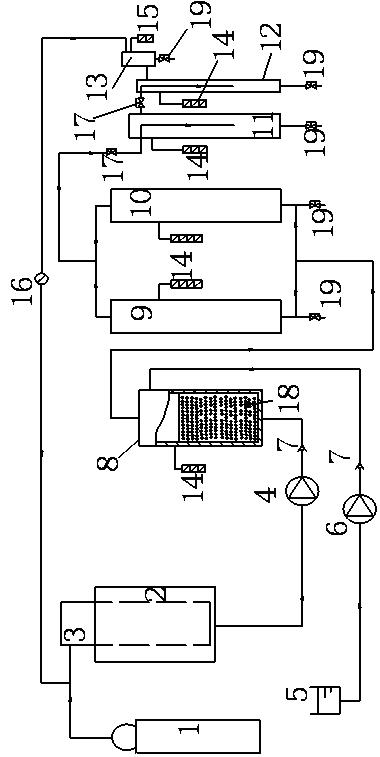

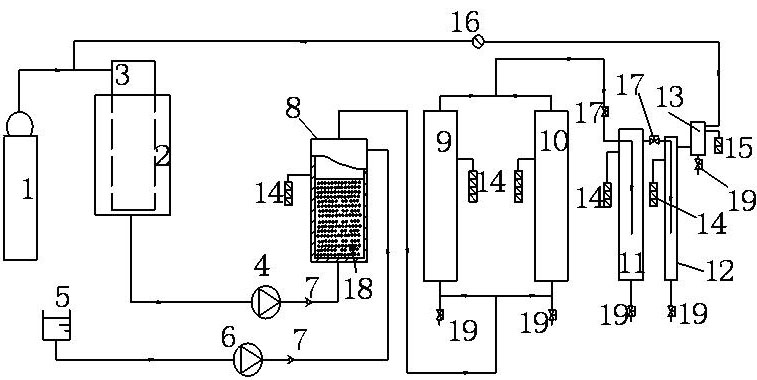

[0018] Embodiment: choose the weight ratio of tea, water and carbon dioxide to be 1:0.2:10; first use the fumigation method to pretreat the tea leaves to make the water content reach 20%-30% and then put them into the extraction kettles 9 and 10; The temperature of the section: the mixer 8 is at 50°C-80°C, the extraction kettles 9 and 10 are at 30°C-60°C, the separation kettles 11 and 12 are at 50°C-55°C, and the water vapor separation kettle 13 is at -5°C-0°C; After the temperature of each section is reached, turn on the entrainer pump 6, pass the water in the distilled water tank 5 into the mixer 8, open the gas cylinder 1 at the same time, turn on the main pump 4, and pass the carbon dioxide stored in the storage tank 3 in the freezer 2 into the mixer 8. In the mixer 8, the supercritical carbon dioxide is fully contacted with the filler and water in the mixer 8 to achieve saturation. Then the saturated supercritical carbon dioxide and water are passed into the extraction ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com