Light source device

A light source device, visible light technology, applied in the direction of light source, electric light source, projection device, etc., to achieve the effects of enhanced damage resistance, good cooling effect, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

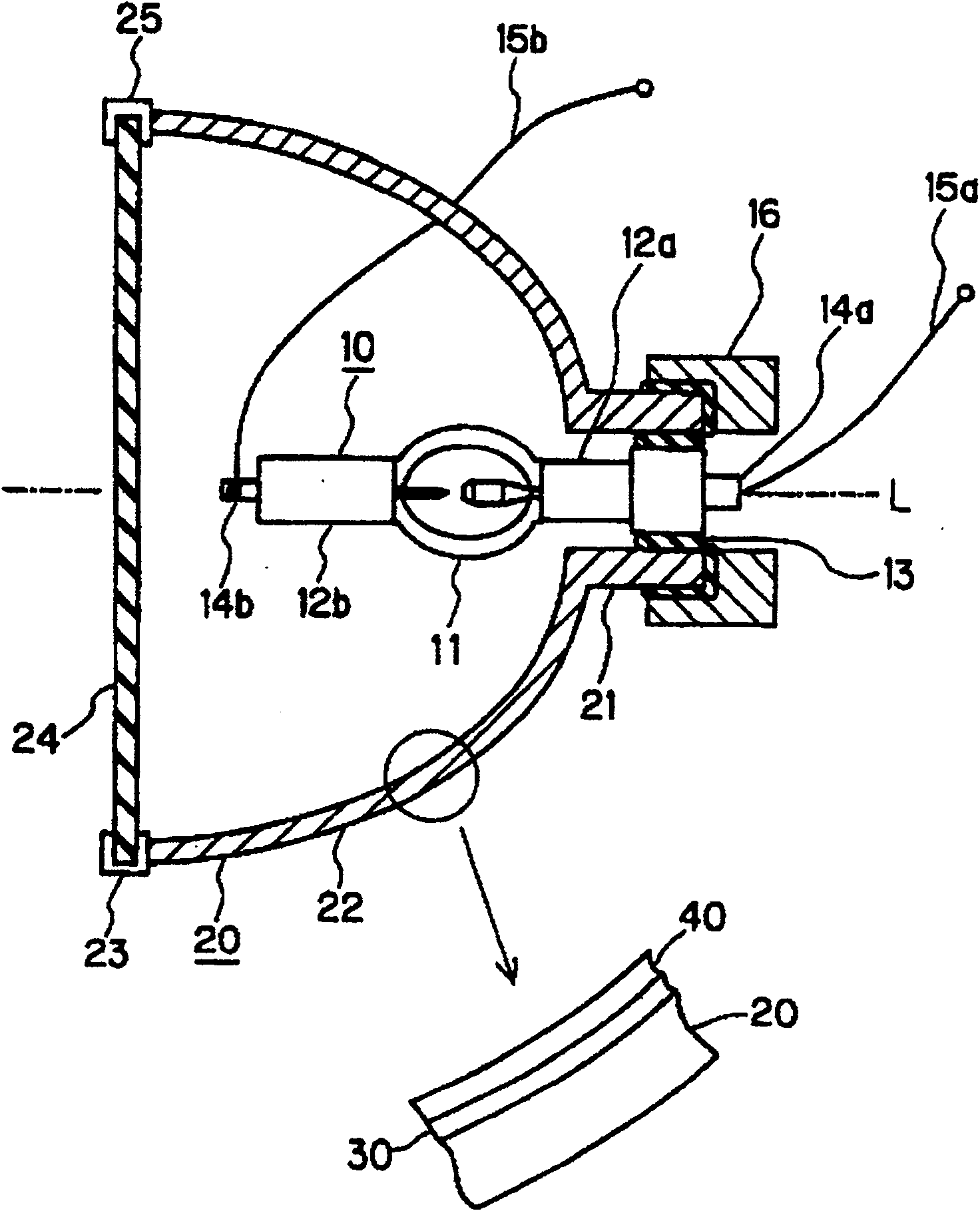

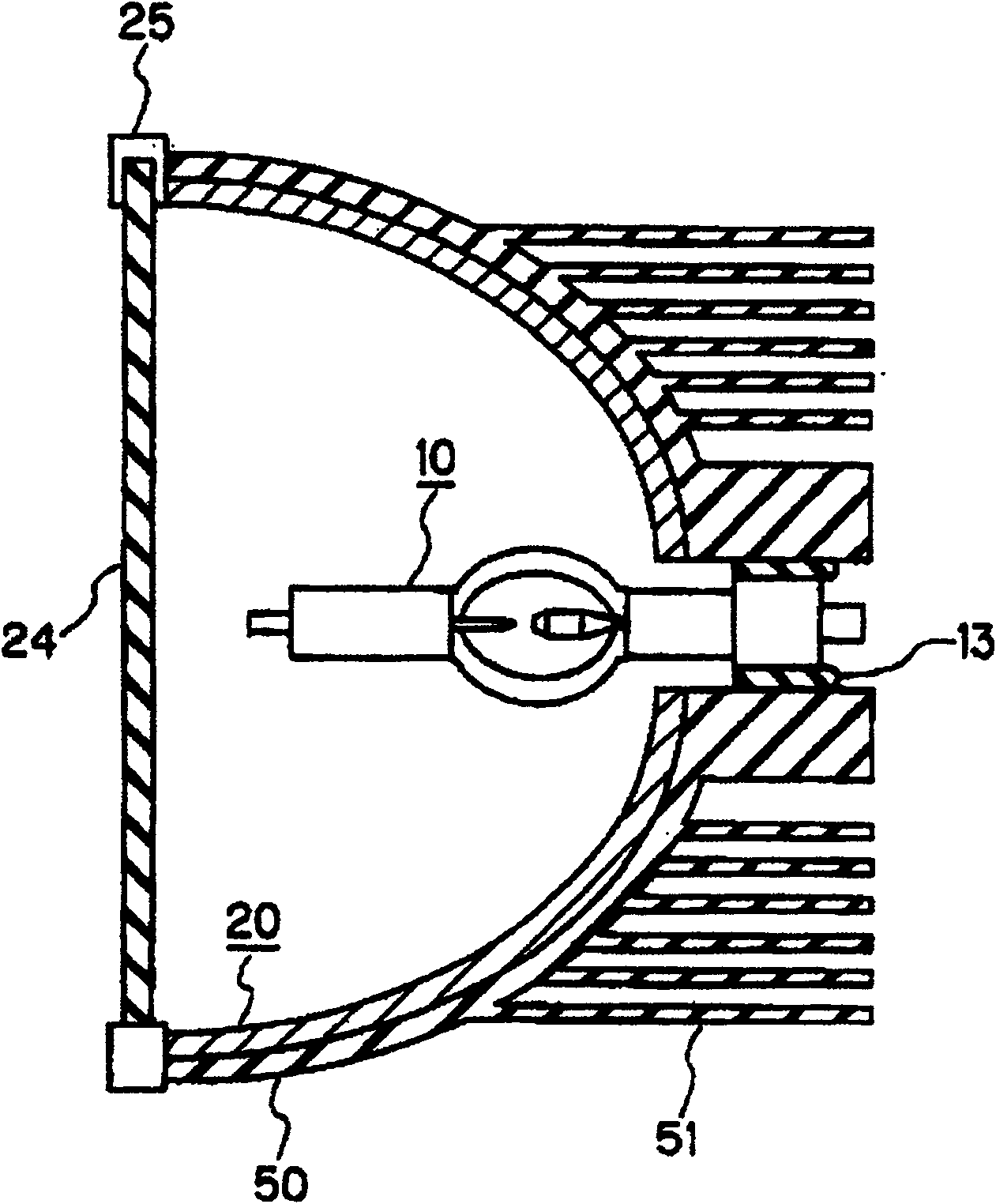

[0027] figure 1 A schematic configuration diagram illustrating a light source device of the present invention is shown.

[0028] The light source device is composed of a short-arc ultra-high pressure discharge lamp 10 (hereinafter also referred to as "discharge lamp") and a concave reflector 20 surrounding the discharge lamp 10. The optical axis L of the concave reflector 20 and the arc direction of the discharge lamp 10 are approximately Consistently, the arc bright spot of the discharge lamp 10 and the first focal point of the concave reflector 20 are configured to be consistent at the same time.

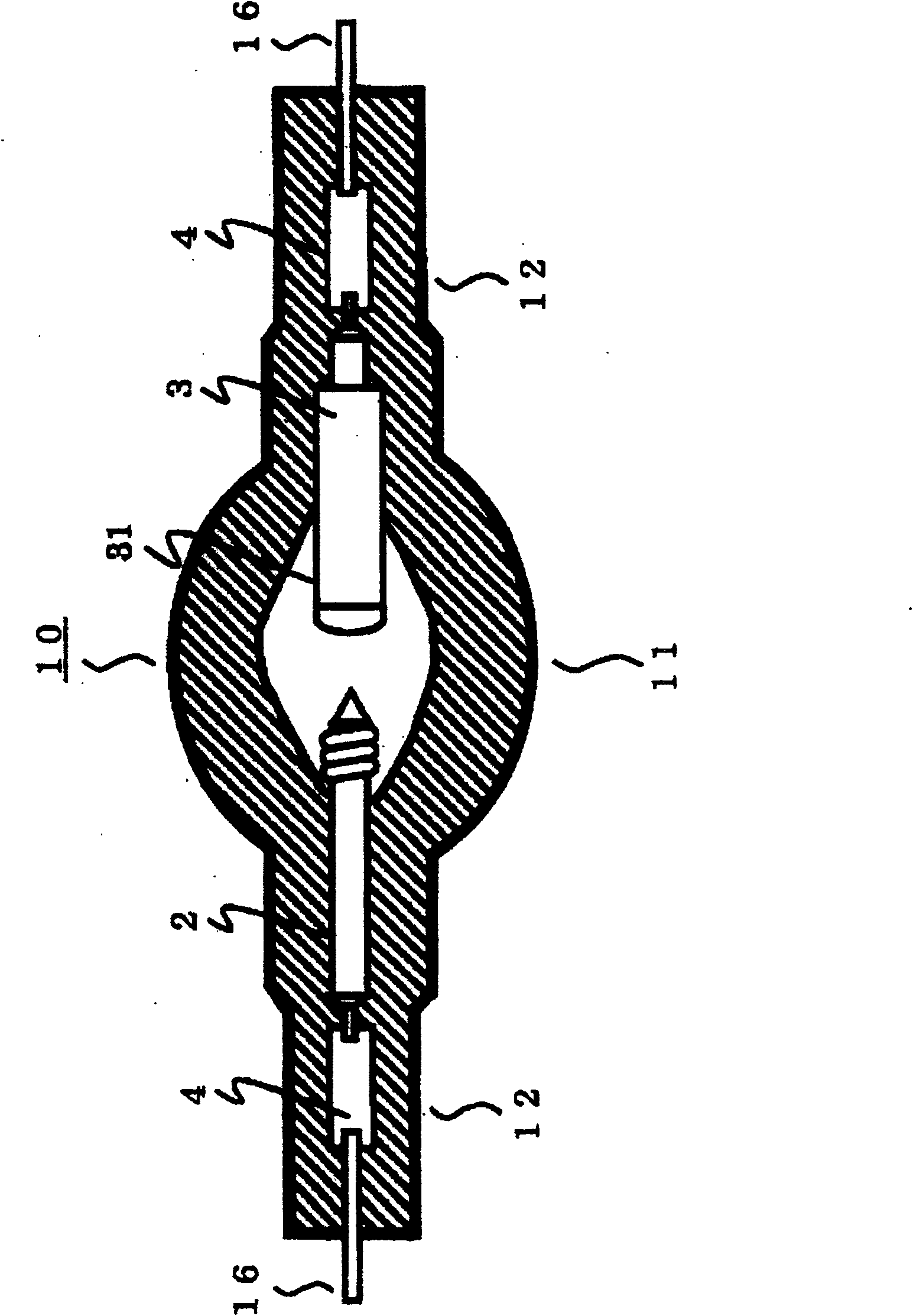

[0029] The discharge vessel of the discharge lamp 10 is composed of a substantially spherical light emitting portion 11 and rod-shaped sealing portions 12a and 12b extending along both ends of the light emitting portion 11 , and a pair of opposing electrodes are arranged inside the light emitting portion 11 . The sealing portion 12 a of the discharge lamp 10 is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com