Method for removing palladium from silver electrolyte by using multifunctional silica gel adsorbent

A silica gel adsorption and multi-functional technology, applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problem of increasing Ag separation process, etc., and achieve the effect of low cost, simple operation and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

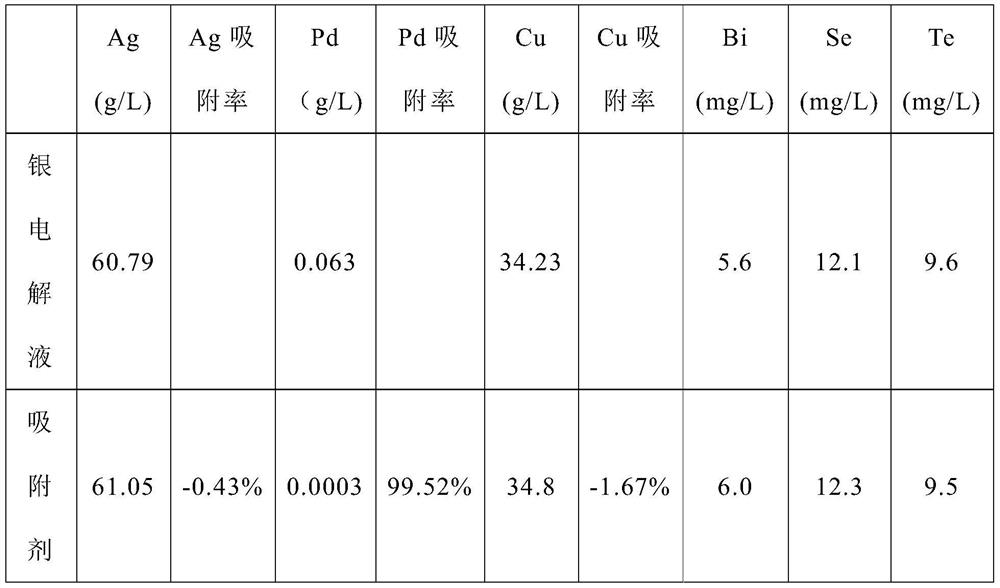

Embodiment 1

[0034] Example 1 Method for removing palladium from the silver electrolyte by multi-function silica adsorbent, including steps:

[0035] 1) Preparation of multifunctional silica gel adsorbents

[0036] Tetrate-free pentamine (13.68 kg, 72 mol) is added to 100 L reactor (CH 3 O) 3 Si (CH) 2 ) 3 After CL (48 mol) was stirred at 120 ° C for 6 hours, it was cooled to 60 ° C, and then ethanol (10L) was refluxed for 2 hours until the liquid became transparent, and the cooling was transferred to a 200l reaction kettle, and xylene (80.0L) and Silica gel (32.0kg, 37-500 μm, ), Place the oil bath cope at 150 ° C, when the oil bath temperature reaches the set value and begins to collect ethanol, the entire process lasts for 3 hours. The liquid removal was removed, the solids (100 L) were stirred after 30min, and more water (100 L) was added to the solid, stirring the mixture for 30 min and filtered, dried to the silica gel adsorbent; multifunctional silica gel adsorbent The chemical formula...

Embodiment 2

[0050] Example 2 Methods of removing palladium from the silver electrolyte by multi-function silica adsorbent, including steps:

[0051] 1) Preparation of multifunctional silica gel adsorbents

[0052] Diethylene triamine (7.49 kg, 72 mol) and (CH) were added to 100 L reactor 3 O) 3 Si (CH) 2 ) 3 After CL (48 mol) was stirred at 160 ° C for 8 hours, it was cooled to 60 ° C, and then ethanol (10L) was refluxed to flow until the liquid became transparent, cooled into 200L reactor, and pell xylene (80.0L) and Silica gel (32.0kg, 37-500 μm, ), Place the oil bath cope at 150 ° C, when the oil bath temperature reaches the set value and begins to collect ethanol, the entire process lasts for 3 hours. The liquid removal was removed, and the solid was stirred for 30 min and then filtered, and more water (100 L) was added to the solid, stir filtered after 30min, dried, and the polyfunctional silica gel absorbent. Chemical formation [(O 3 / 2 ) Si (CH 2 ) x NH (CH) 2 CH 2 NH) y H] a [Si (O " ...

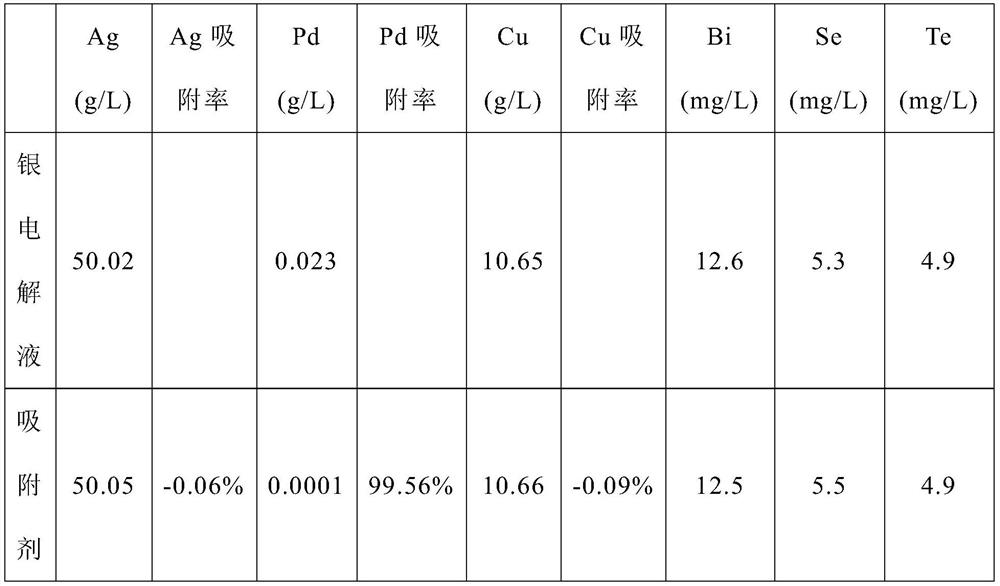

Embodiment 3

[0064] Example 3 Methods of removing palladium from the silver electrolyte by multi-function silica gel adsorbent, including steps:

[0065] 1) Preparation of multifunctional silica gel adsorbents

[0066] Polyethylene polyamine (27.36 kg, 72 mol) is added to 100 L reactor (CH) 3 O) 3 Si (CH) 2 ) 3 After CL (48 mol) was stirred at 160 ° C for 8 hours, it was cooled to 60 ° C, and then ethanol (10L) was refluxed to flow until the liquid became transparent, cooled into 200L reactor, and pell xylene (80.0L) and Silica gel (32.0kg, 37-500 μm, ), Place the oil bath cope at 150 ° C, when the oil bath temperature reaches the set value and begins to collect ethanol, the entire process lasts for 3 hours. The liquid removal was removed, and the solid was stirred for 30 min and then filtered, and more water (100 L) was added to the solid, stir filtered after 30min, dried, and the polyfunctional silica gel absorbent. Chemical formation [(O 3 / 2 ) Si (CH 2 ) x NH (CH) 2 CH 2 NH) y H] a [Si (O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com