Sodium polyacrylate in situ growth of Prussian blue nanocrystal composites and preparation method and application thereof

A technology of sodium polyacrylate and Prussian blue, which is applied in the field of nanocomposite materials and its preparation, can solve the problems of low Prussian blue content, easy aggregation of nanoparticles, complex preparation process, etc., and achieve easy recyclability, not easy to fall off, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: In this embodiment, the sodium polyacrylate in-situ growth Prussian blue nanocrystalline composite material is made of polyacrylic iron and Prussian blue, wherein the mass percentage of polyacrylic iron is 40% to 90%. The mass percentage of blue is 10% to 60%.

[0024] The beneficial effects of this embodiment:

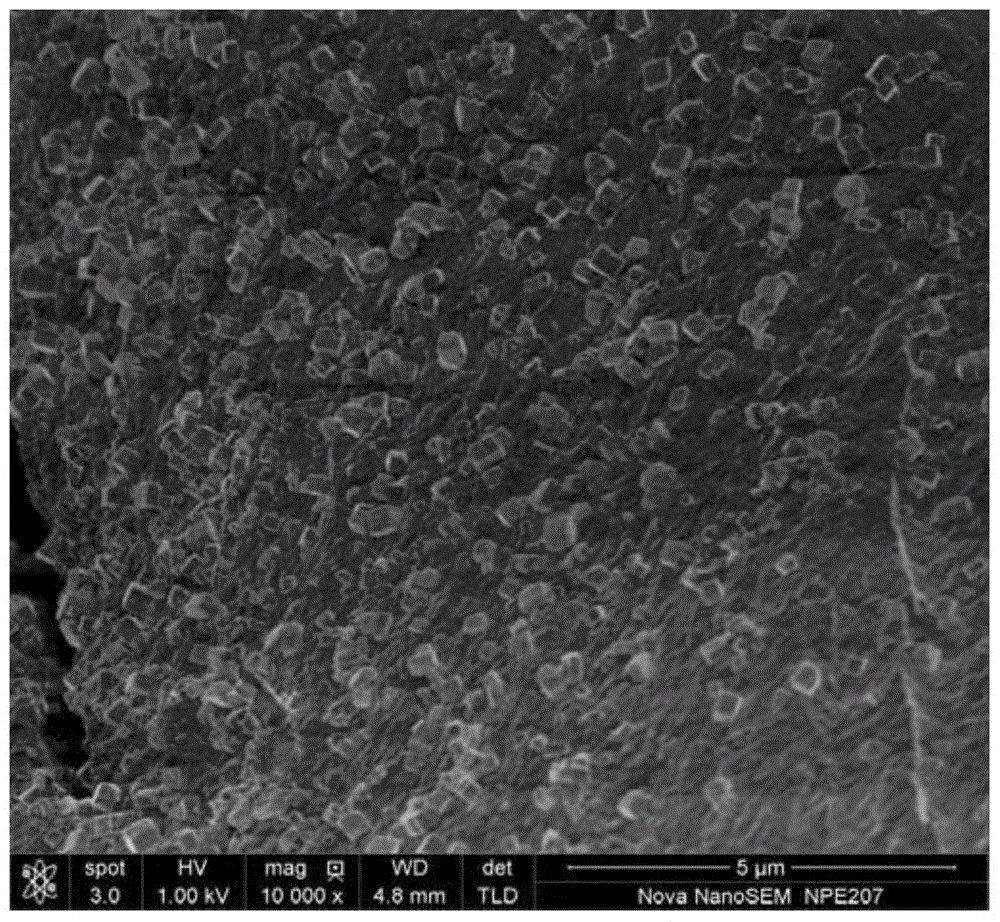

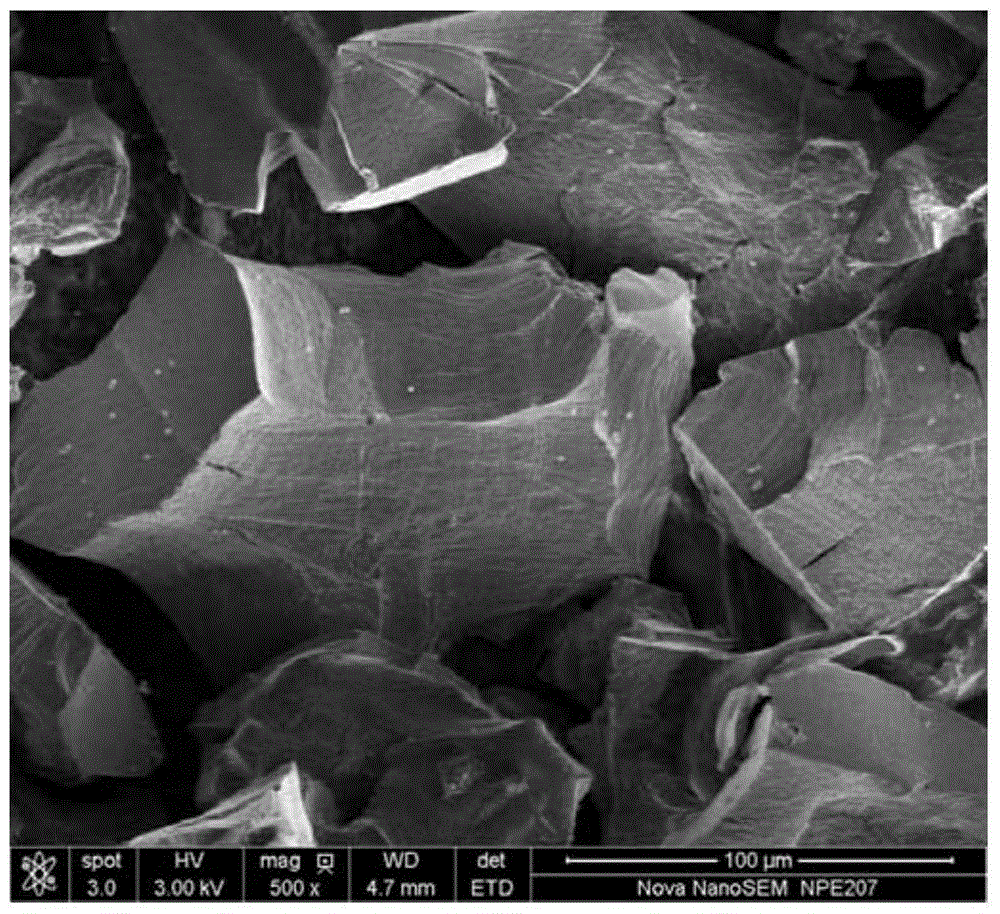

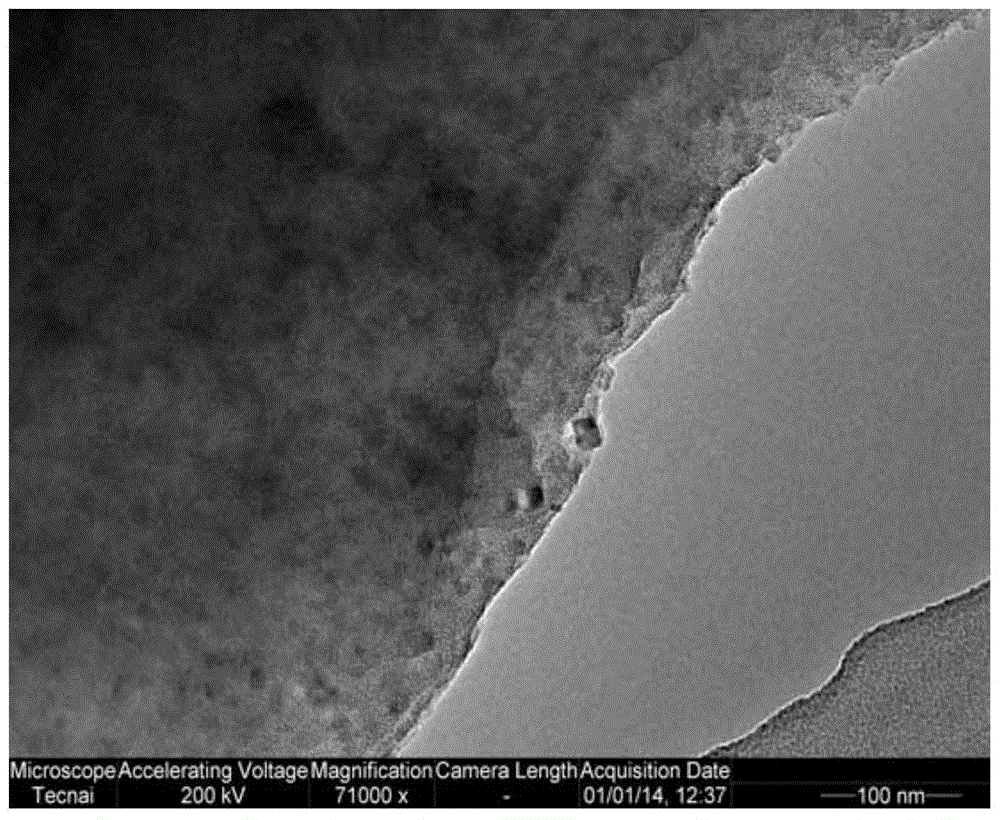

[0025] The in-situ growth of Prussian blue nanocrystalline composite material prepared by sodium polyacrylate in this embodiment is based on the three-dimensional network polymer of sodium polyacrylate as the matrix, and the rich oxygen-containing groups of sodium polyacrylate are used to reduce Fe 3+ Capture in the polymer network structure, and synthesize Prussian blue nanocrystal multi-level structure composite material in situ inside the polymer by in-situ growth self-assembly technology. The synthesized sodium polyacrylate / Prussian blue composite material has a size between 1-10 μm. Prussian blue nanocrystals are between 10 and 200nm, t...

specific Embodiment approach 2

[0026] Specific implementation manner 2: In this embodiment, the method for preparing sodium polyacrylate in-situ growth Prussian blue nanocrystalline composite material is carried out according to the following steps:

[0027] 1. Dissolve the ferric salt in a mixed solution of deionized water and glacial acetic acid in the ratio of mole to volume ratio of 1mmol: (15mL~35mL) under stirring conditions, and stir for 0.5h~2h to obtain a solution; where deionization The volume ratio of water to glacial acetic acid is 1mL: (0.5mL~1mL);

[0028] 2. Add sodium polyacrylate to the solution obtained in step 1, so that Fe 3+ With Na + The molar ratio of is 1:(2~3), continue to stir for 48h~96h and then stand for separation, collect the solid powder, then wash the solid powder with deionized water 3-6 times, and then collect the solid powder after filtration;

[0029] 3. Add the same volume of deionized water as the mixed solution of deionized water and glacial acetic acid in step one to the so...

specific Embodiment approach 3

[0032] Specific embodiment three: This embodiment is different from the specific embodiment two in that as described in step one, the ferric salt is dissolved in deionized water at a molar to volume ratio of 1mmol: (20mL-30mL) under stirring conditions. In a mixed solution of water and glacial acetic acid. Others are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com