Cysteine modified SBA-15 mesoporous material and preparation method thereof

A technology of NH2-SBA-15 and cysteine, applied in chemical instruments and methods, silicate, aluminum silicate, etc., can solve secondary pollution and other problems, achieve strong adsorption capacity and good environmental compatibility , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

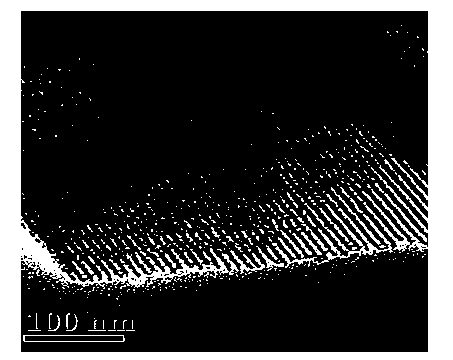

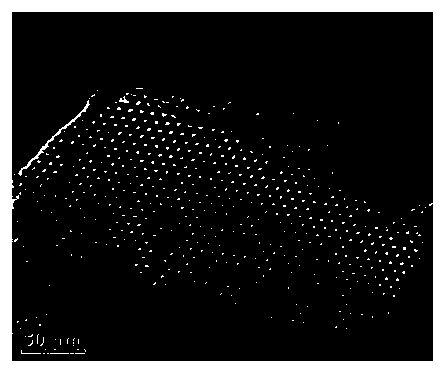

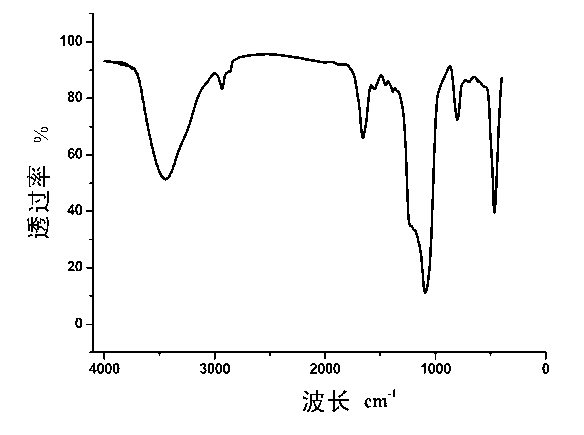

[0053] Weigh 4.0g of triblock copolymer surfactant P123 and dissolve it in 120mL of 2mol / L hydrochloric acid and 30mL of deionized water. Place the mixed solution in a 38℃ water bath and stir until the solution is clear. Then slowly add TEOS and continue. Stir for 10 minutes and then stand for 24 hours. Hydrothermal treatment at 100°C for 24 hours. After cooling, it was repeatedly filtered and washed with deionized water. After drying treatment at 100°C, the powder was placed in a muffle furnace and slowly heated to 550°C for 5 hours to remove surfactants. Obtain white mesoporous material SBA-15;

[0054] Activate the obtained SBA-15 in boiling water for 3 hours, filter, and dry; dissolve 2.2 g of the above product and 5 mL of APTES in 250 mL of dry toluene, reflux for 20 hours at 110°C under a nitrogen atmosphere, and repeatedly filter with dry toluene and absolute ethanol Wash the powder; finally weigh the above dry powder 3.9g, cysteine 2.0g, DCC: 3.4g, DMAP: 2.0g, using 25...

Embodiment 2

[0056] Weigh 4.0g of triblock copolymer surfactant P123 and dissolve it in 120mL of 2mol / L hydrochloric acid and 30mL of deionized water. Place the mixed solution in a 38℃ water bath and stir until the solution is clear. Then slowly add TEOS and continue. Stir for 24 hours. Hydrothermal treatment at 100°C for 24 hours. After cooling, it was repeatedly filtered and washed with deionized water. After drying treatment at 100°C, the powder was placed in a muffle furnace and slowly heated to 550°C for 5 hours to remove surfactants. Obtain white mesoporous material SBA-15;

[0057] Activate the obtained SBA-15 in boiling water for 3 hours, filter, and dry; dissolve 1 g of the above product and 5 mL APTES in 100 mL of dry toluene, reflux for 20 hours at 110°C under a nitrogen atmosphere, and repeatedly filter and wash with dry toluene to obtain a powder; Finally, weigh 2.0g of the above powder, 1.0g of cysteine, 2.02g of DCC, 0.12g of DMAP, 200mL of dry DMF (dimethylformamide) as a sol...

Embodiment 3

[0059] Weigh 4.0g of triblock copolymer surfactant P123 and dissolve it in 120mL of 2mol / L hydrochloric acid and 30mL of deionized water. Place the mixed solution in a 38℃ water bath and stir until the solution is clear. Then slowly add TEOS and stir. 24 hours. Hydrothermal treatment at 100°C for 24 hours. After cooling, it was repeatedly filtered and washed with deionized water. After drying treatment at 100°C, the powder was placed in a muffle furnace and slowly heated to 550°C for 5 hours to remove surfactants. Obtain white mesoporous material SBA-15;

[0060] Activate the obtained SBA-15 in boiling water for 3 hours, filter, and dry; dissolve 1.5 g of the above product and 8 mL APTES in 150 mL dry toluene, reflux for 20 hours at 110°C under a nitrogen atmosphere, and repeatedly filter and wash with dry toluene to obtain a powder ; Finally, weigh the above powder 1.6g, cysteine 0.8g, DCC: 0.8g, DMAP: 0.015g, with 160mL dry DMF (dimethylformamide) as the solvent, reflux at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com