Device and method for removing sulphur dioxide and dioxin from sintering flue gas

A technology of sulfur dioxide and sintering flue gas, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems that by-products can only be landfilled, and desulfurization by-products cannot be used as building materials, etc. Small, reduced impact, easy to handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

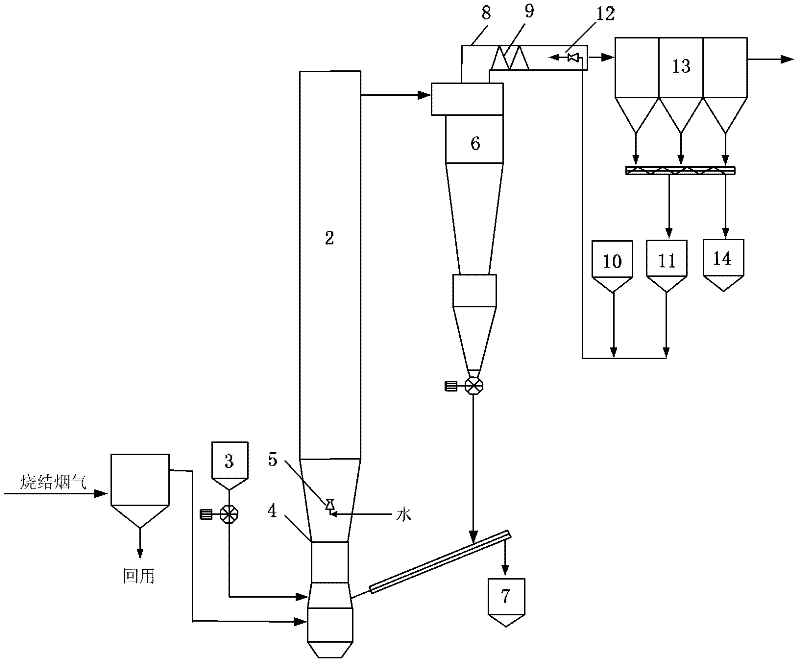

[0049] Using this process to treat 400,000 m 3 / h sintering machine flue gas, flue gas temperature is about 140°C, flue gas SO 2 Content 860mg / m 3 , the content of dioxin-like pollutants is 5ngTEQ / m 3 . After the sintering flue gas is pre-dusted by the electrostatic precipitator 1, it enters the circulating fluidized bed absorption tower 2, and the Ca(OH) in the desulfurizer bin 3 2 The desulfurizing agent enters the absorption tower 2 through the Venturi 4, and at the same time, the atomized water sprayed from the water nozzle 5 is sprayed to the entire flue gas flow section, and the flue gas, desulfurizing agent, and water move upward in the absorption tower 2 together. The molar ratio of Ca to S is controlled at 1.3, and the temperature of the flue gas in the absorption tower 2 is controlled at about 75°C by using the amount of water sprayed. 2 A chemical reaction occurs with the desulfurizer, and the SO in the flue gas 2 was removed. After the desulfurization agent r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com