Copper smelting smoke dust arsenic removal method

A technology for copper smelting and soot, applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of hidden safety hazards, high cost, low energy consumption, etc., and achieve the effects of no secondary pollution, flexible operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

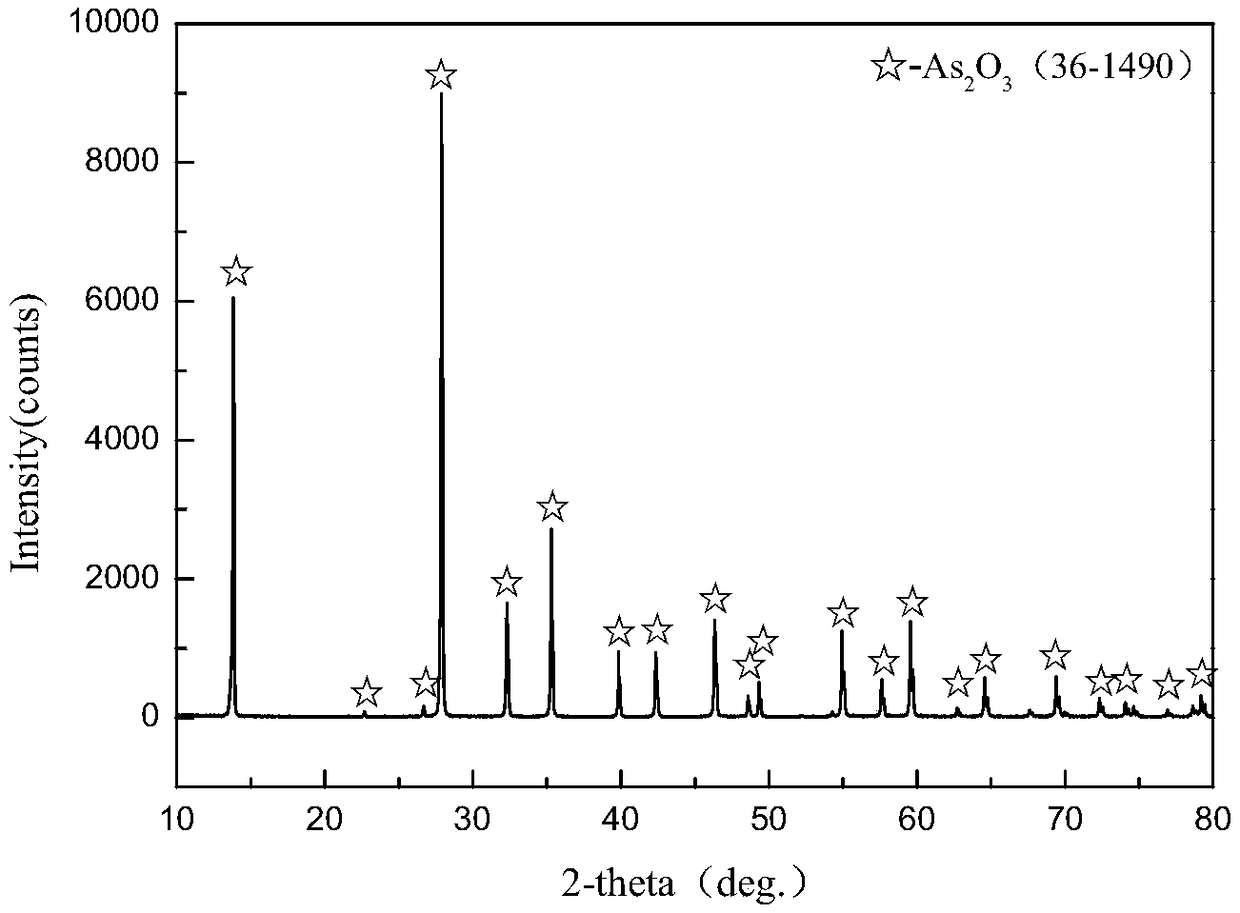

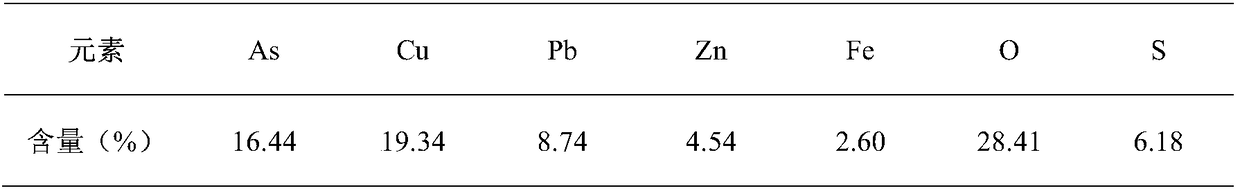

[0027] In this example, a copper smelting plant in Hunan Province is selected for smelting electric dust collection. Its main element composition is shown in Table 1, and the additive is pyrite. The specific implementation steps are as follows:

[0028] Table 1 Composition of main elements of electric dust collection in a copper smelting plant in Hunan Province (%)

[0029]

[0030] Step 1: Take copper smelting electric dust collector and pyrite respectively, dry at low temperature, crush until the particle size is less than 2mm, and mix the copper smelting dust and pyrite evenly according to the pyrite addition amount of 30%, to obtain a mixed material.

[0031] Step 2: Weigh 5g of the above-mentioned mixture into the ark crucible, place the ark crucible in a tube furnace for roasting, set the roasting temperature to 700°C, set the roasting time to 60min, and set the heating rate to 20°C / min. The sample was digested and sent to an inductively coupled plasma optical emissi...

Embodiment 2

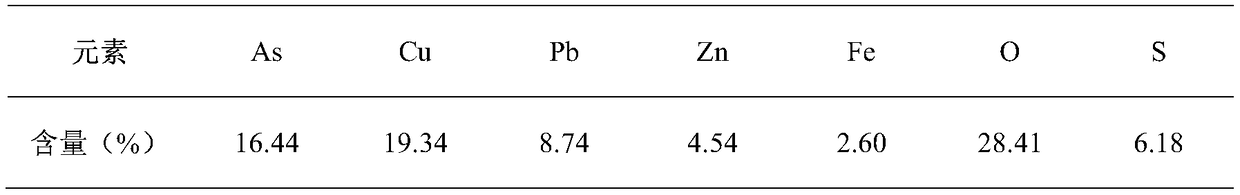

[0034] In this example, a copper smelting plant in Hunan Province is selected for smelting electric dust collection. Its main element composition is shown in Table 2, and the additive is pyrite. The specific implementation steps are as follows:

[0035] Table 2 Composition of main elements of electric dust collection in a copper smelting plant in Hunan Province (%)

[0036]

[0037] Step 1: Take copper smelting electric dust collector and pyrite respectively, dry at low temperature, crush until the particle size is less than 2mm, and mix the copper smelting dust and pyrite evenly according to the pyrite addition amount of 30%, to obtain a mixed material.

[0038] Step 2: Weigh 5g of the above-mentioned mixture into the ark crucible, place the ark crucible in a tube furnace for roasting, set the roasting temperature to 700°C, set the roasting time to 5min, and set the heating rate to 20°C / min. It was digested and sent to an inductively coupled plasma optical emission spectr...

Embodiment 3

[0041] In this example, a copper smelting plant in Hunan Province is selected for smelting electric dust collection. Its main element composition is shown in Table 3, and the additive is pyrite. The specific implementation steps are as follows:

[0042] Table 3 Composition of main elements of electric dust collection in a copper smelting plant in Hunan Province (%)

[0043]

[0044]Step 1: Take copper smelting electric dust collector and pyrite respectively, dry at low temperature, crush until the particle size is less than 2mm, and mix the copper smelting dust and pyrite evenly according to the pyrite addition amount of 30%, to obtain a mixed material.

[0045] Step 2: Weigh 5g of the above-mentioned mixed materials into the ark crucible, place the ark crucible in a tube furnace for roasting, set the roasting temperature to 400°C, set the roasting time to 60min, and set the heating rate to 20°C / min, and put the roasted The sample was digested and sent to an inductively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com