Recycling method of retired lithium iron phosphate battery positive-electrode materials

A lithium iron phosphate battery, lithium iron phosphate technology, applied in the direction of battery recycling, recycling technology, waste collectors recycling, etc., can solve the problems of limited development space, high energy consumption, fast decay of electrochemical performance, etc. good chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

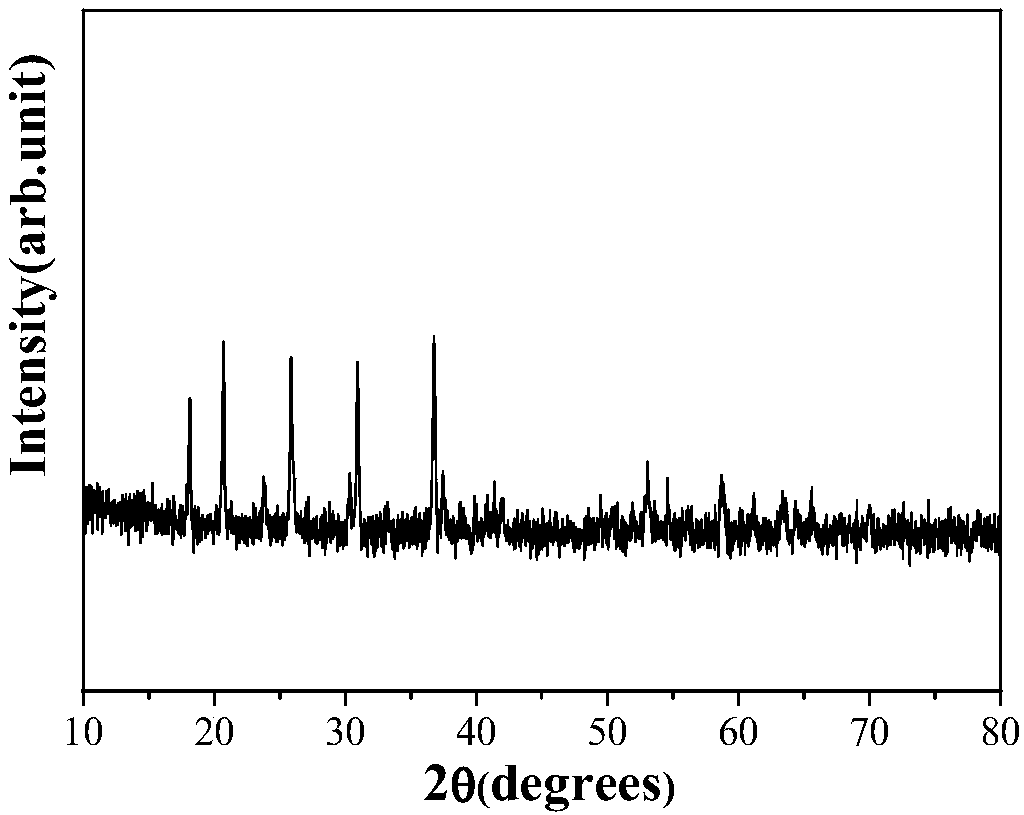

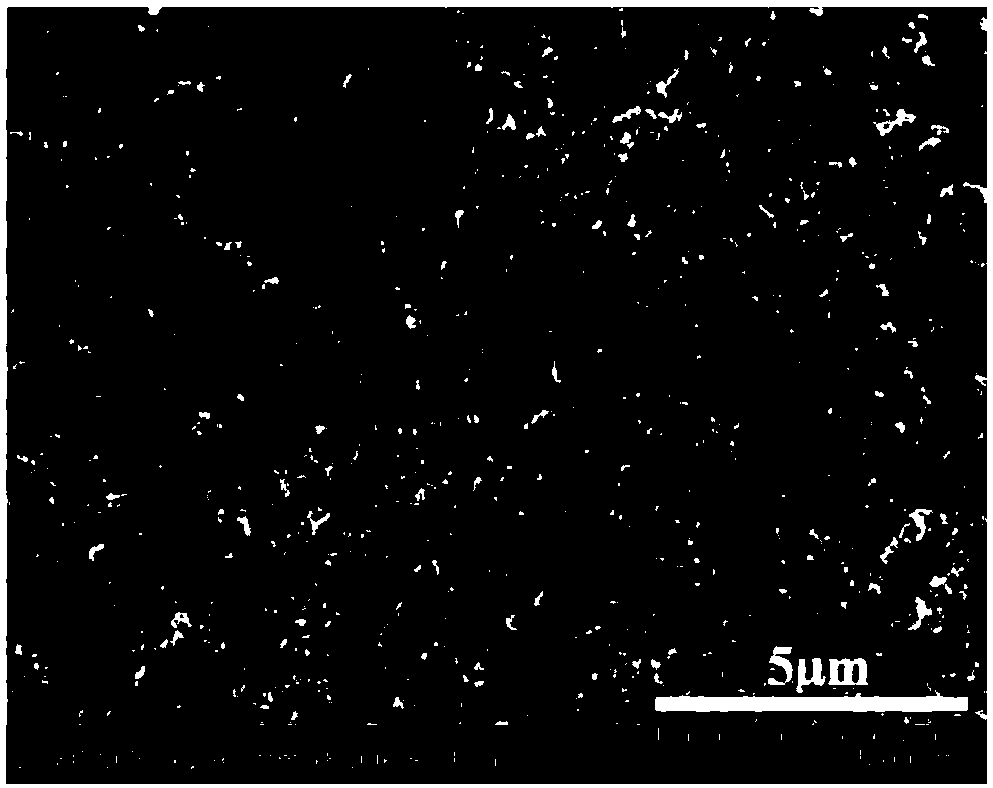

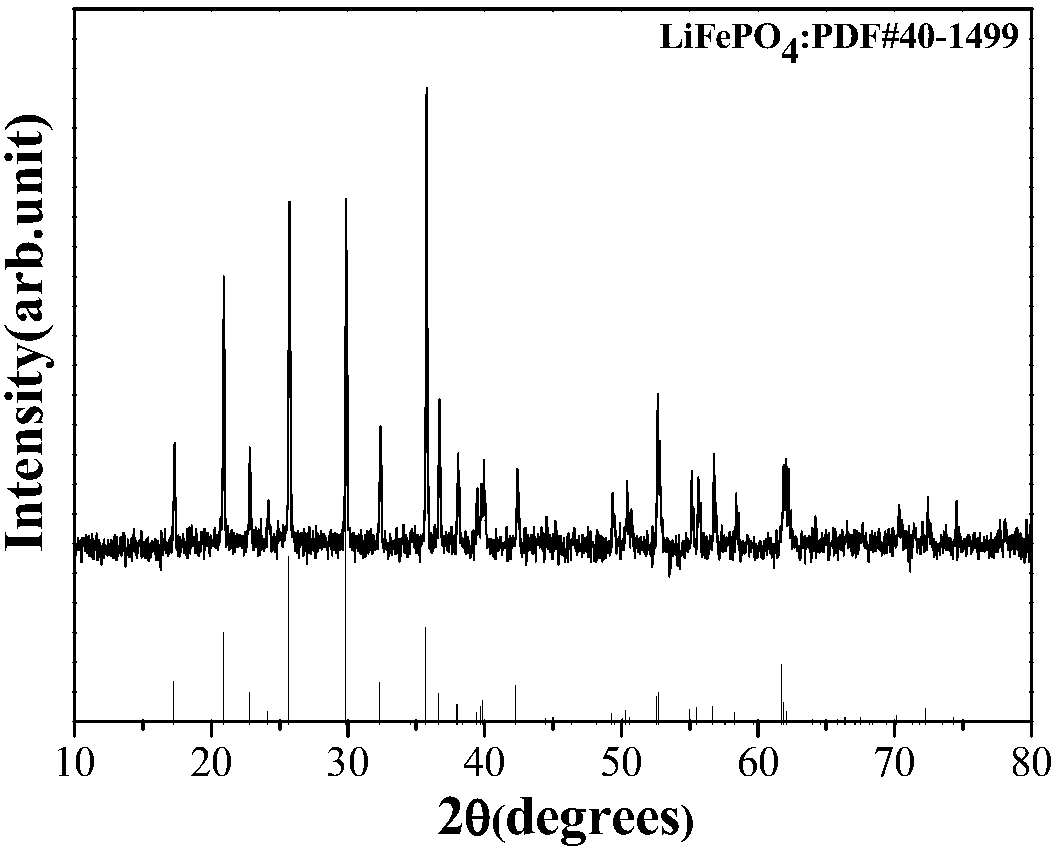

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further analyzed and illustrated through specific examples below.

[0031] The recycling method of the cathode material of the decommissioned lithium iron phosphate battery of the present invention comprises the following steps:

[0032] 1. Recycling and processing of waste lithium iron phosphate electrode materials

[0033] Discharge the waste lithium iron phosphate battery, then disassemble it, sort out the positive electrode, negative electrode, separator, etc., soak the waste lithium iron phosphate positive electrode with N-methylpyrrolidone solvent, and dissolve the binder (PVDF ), then the LiFePO 4 The electrode material is stripped from the aluminum foil current collector, and the stripped waste LiFePO 4 The electrode material is mixed with a binder (polyvinylidene fluoride PVDF or polytetrafluoroethylene PTFE) and coated on carbon cloth or titanium mesh, heated to 120°C under vacuum drying conditions and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com