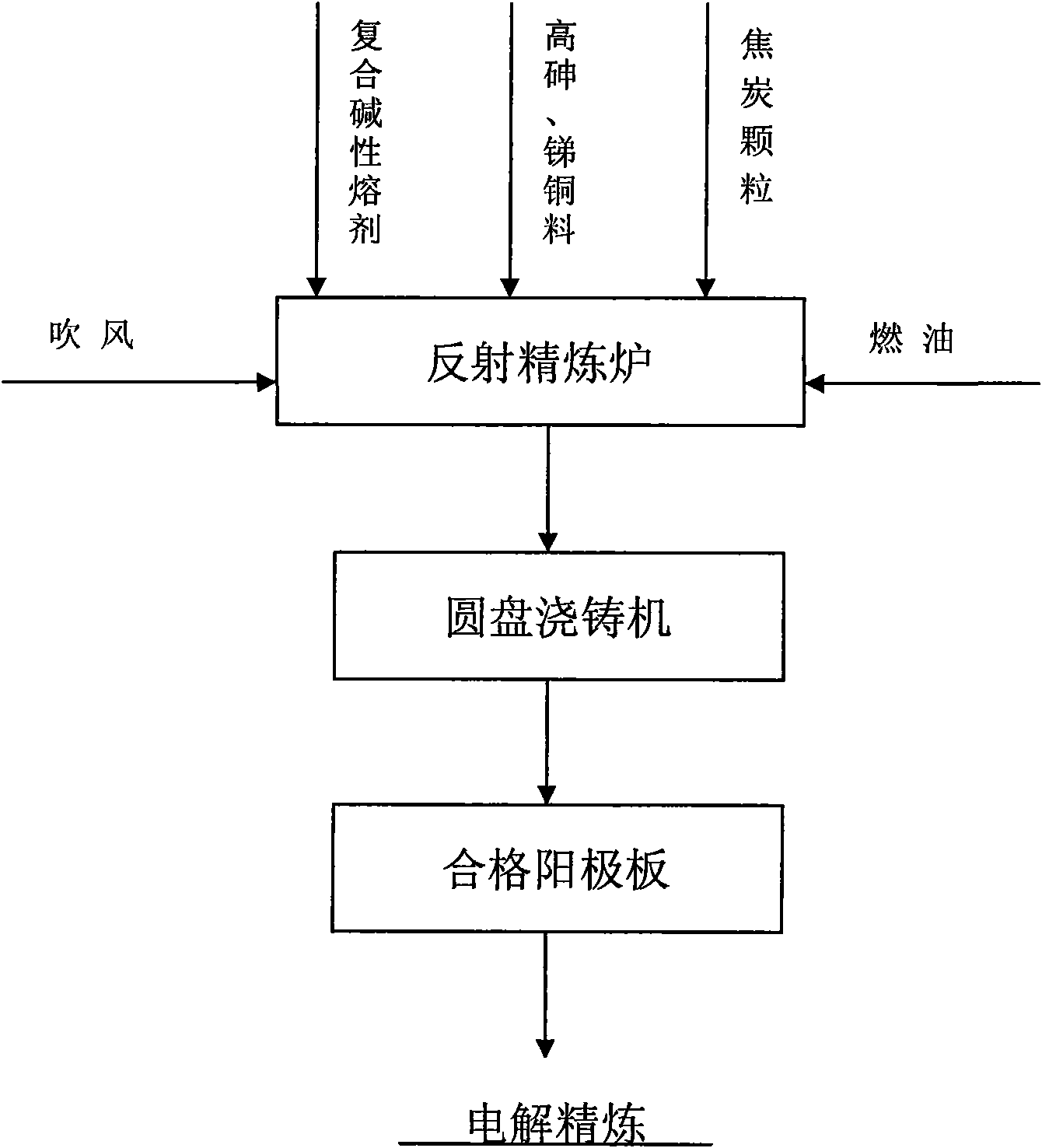

Reverberatory furnace pyrorefining method of crude copper with high arsenic and antimony

A pyro-refining and reverberatory furnace technology, applied in the field of non-ferrous metallurgy, can solve the problems of high energy consumption, low impurities that are difficult to remove, poor adaptability of raw materials, etc., and achieve the effect of expanding raw material source channels, meeting process requirements, and meeting production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] First of all, the present invention is based on the chemical reaction mechanism, the affinity of impurities to oxygen, and the oxidation sequence of arsenic and antimony is ranked after aluminum, silicon, manganese, zinc, tin, iron and nickel, that is, arsenic and antimony are more difficult to oxidize than the above elements. Therefore, in order to remove arsenic and antimony more completely, the copper solution must contain a higher concentration of cuprous oxide. According to the chemical principle, the oxygen content in the copper liquid reaches 1%, which is equivalent to 9% cuprous oxide, and this concentration exceeds the saturation concentration of cuprous oxide in the copper melt at 1150°C, so the process of the present invention During the operation of the technology, the melt temperature must be controlled at a temperature higher than 1150°C.

[0019] Secondly, there is a certain limit to the combination and dissolution of impurities, otherwise, even if the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com