Modified resin for removing arsenic from low-concentration arsenic-containing water and preparation method thereof

A modified resin and low-concentration technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as complex multi-stage treatment processes, limited popularization and application, high operating costs, etc., and achieve high efficiency , a wide range of applications, flexible use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

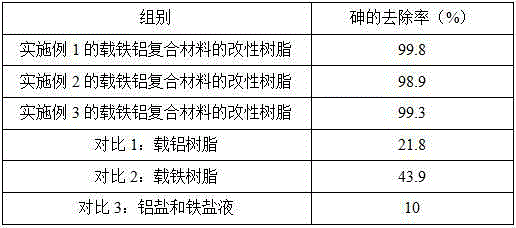

Examples

Embodiment 1

[0028] The preparation of embodiment 1 modified resin

[0029] 1. The preparation method comprises the following steps:

[0030] S1. Dry the resin at 60°C for 10 hours;

[0031] S2. According to the mass ratio of aluminum salt to 13% of the resin, add the dried resin of S1 to the freshly prepared 0.5M AlCl 3 ·6H 2 O solution, stirred at room temperature under vacuum at 600r / min for 1h;

[0032] S3. After vacuum stirring in step S2, stir in the air at 600r / min for 1h, so that aluminum trichloride is fully adsorbed and wrapped on the surface and pores of the resin, and completely hydrolyzed to form nano-aluminum hydroxide, filtered, washed 3 times with water, and placed at 60°C Dried to obtain aluminum-loaded resin;

[0033] S4. According to the mass ratio of iron salt to 13% of the resin, under the protection of nitrogen, add the aluminum-loaded resin of S3 to the freshly prepared 0.5M FeCl 3 ·6H 2 O solution, stirred at 600r / min for 2h at room temperature;

[0034] S5....

Embodiment 2

[0035] The preparation of embodiment 2 modified resins

[0036] 1. The preparation method comprises the following steps:

[0037] S1. Dry the resin at 60°C for 10 hours;

[0038] S2. According to the mass ratio of aluminum salt to 15% of the resin, add the dried resin of S1 to the freshly prepared 0.5M AlCl 3 ·6H 2 O solution, stirred at room temperature under vacuum at 600r / min for 1h;

[0039] S3. After vacuum stirring in step S2, stir in the air at 600r / min for 1h, so that aluminum trichloride is fully adsorbed and wrapped on the surface and pores of the resin, and completely hydrolyzed to form nano-aluminum hydroxide, filtered, washed 3 times with water, and placed at 60°C Dried to obtain aluminum-loaded resin;

[0040] S4. According to the mass ratio of iron salt to 10% of the resin, under the protection of nitrogen, add the aluminum-loaded resin of S3 to the freshly prepared 0.5M FeCl 3 ·6H 2 O solution, stirred at 600r / min for 2h at room temperature;

[0041] S...

Embodiment 3

[0042] The preparation of embodiment 3 modified resins

[0043] 1. The preparation method comprises the following steps:

[0044] S1. Dry the resin at 60°C for 10 hours;

[0045] S2. According to the mass ratio of aluminum salt to 10% of the resin, add the dried resin of S1 to the freshly prepared 0.5M AlCl 3 ·6H 2 O solution, stirred at room temperature under vacuum at 600r / min for 1h;

[0046] S3. After vacuum stirring in step S2, stir in the air at 600r / min for 1h, so that aluminum trichloride is fully adsorbed and wrapped on the surface and pores of the resin, and completely hydrolyzed to form nano-aluminum hydroxide, filtered, washed 3 times with water, and placed at 60°C Dried to obtain aluminum-loaded resin;

[0047] S4. According to the mass ratio of iron salt to 15% of the resin, under the protection of nitrogen, add the aluminum-loaded resin of S3 to the freshly prepared 0.5M FeCl 3 ·6H 2 O solution, stirred at 600r / min for 2h at room temperature;

[0048] S5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com