Process method for removing arsenic from feed-grade calcium hydrogen phosphate prepared from wet-process phosphoric acid

A technology of wet-process phosphoric acid and calcium hydrogen phosphate, applied in separation methods, chemical instruments and methods, phosphorus compounds, etc., can solve problems such as enterprise losses, inconvenient production operations, poor hydrogen sulfide removal effect, etc., to eliminate hazards and reduce consumption , Excellent effect of washing and desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

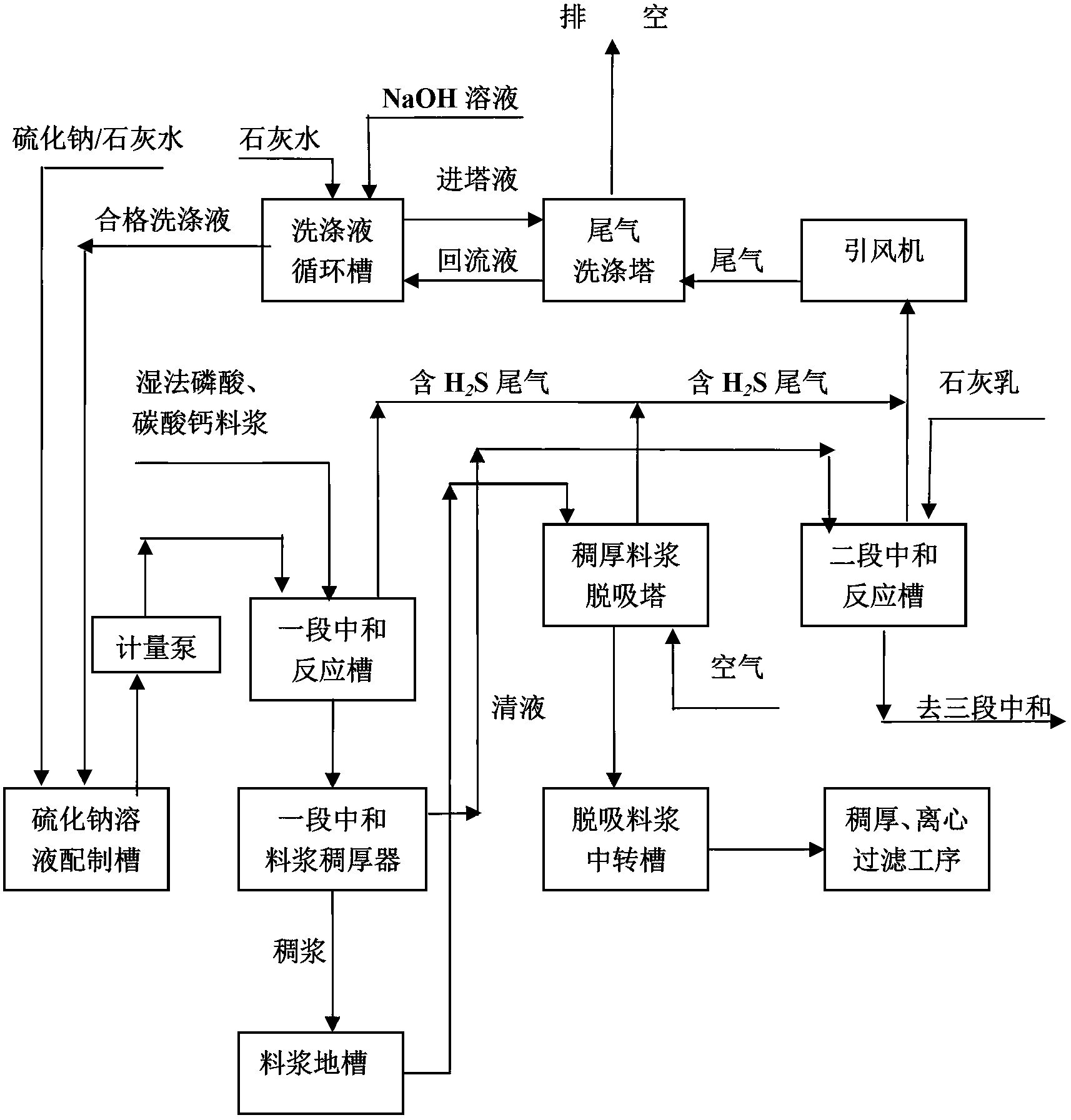

[0022] A kind of processing method of wet process phosphoric acid production feed grade calcium hydrogen phosphate dearsenic, the present invention comprises the following contents:

[0023] 1) Use an adjustable, pressurized metering pump to add sodium sulfide or calcium sulfide solution below the liquid surface to increase the solubility and residence time of hydrogen sulfide gas in the solution;

[0024] 2) Desulfurization by air stripping, that is, using a desorption tower to remove the H in the slurry at the bottom of the thickener 2 S removal;

[0025] 3) The molecular ratio of lime water and liquid caustic soda is Ca(OH) 2 : NaOH=1:1 as the washing water of the tail gas scrubber to recover the H in the tail gas 2 S generates a mixed solution of calcium sulfide and sodium sulfide, and after the concentration of the washing water in the tail washing tower is qualified, it is reused as the raw material of the arsenic removal agent for neutralizing the slurry in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com