Patents

Literature

51results about How to "High arsenic removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

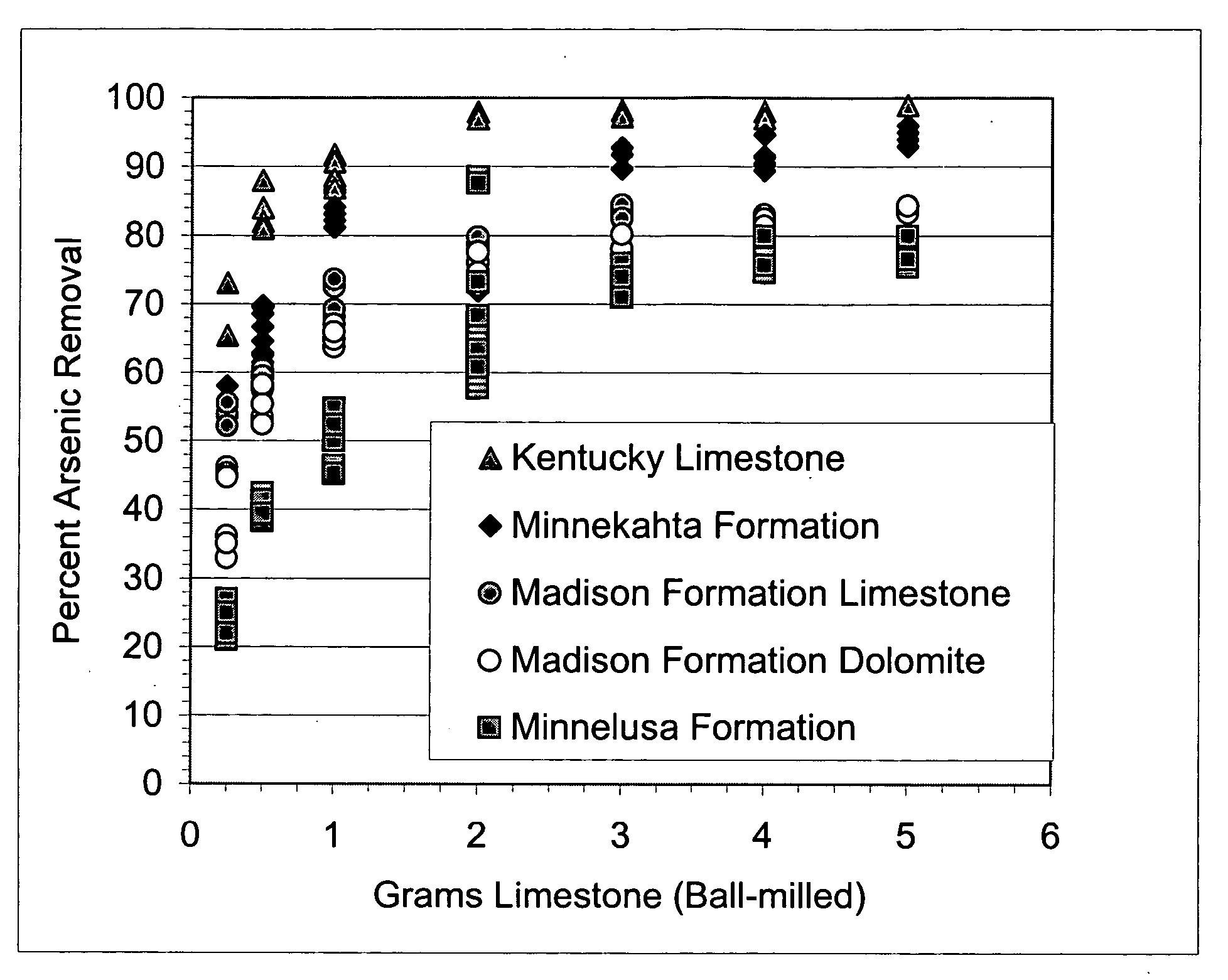

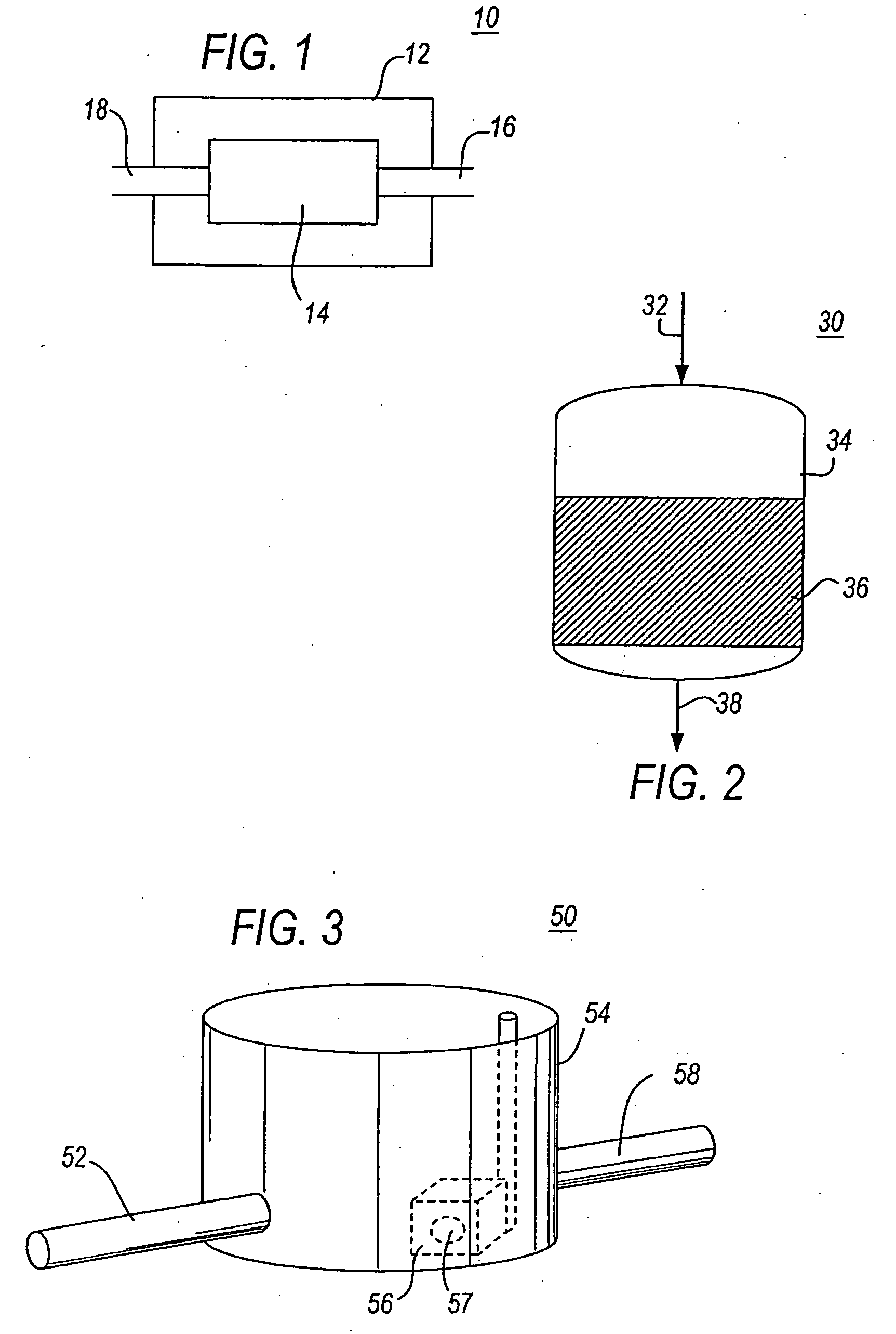

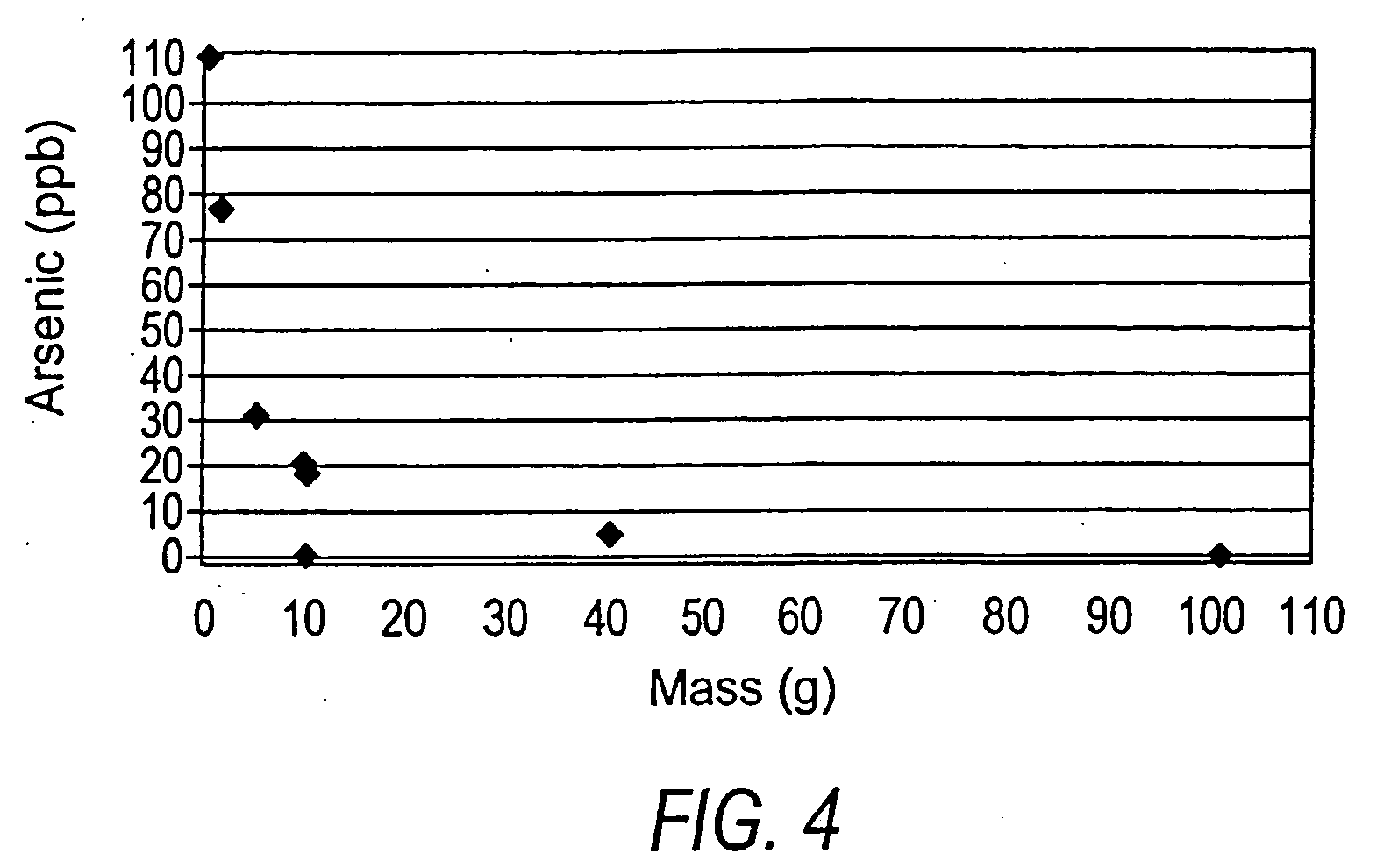

Method and composition to reduce the amounts of arsenic in water

InactiveUS20060186054A1High arsenic removal efficiencyIncrease the areaOther chemical processesWater contaminantsMaceralCarbonate

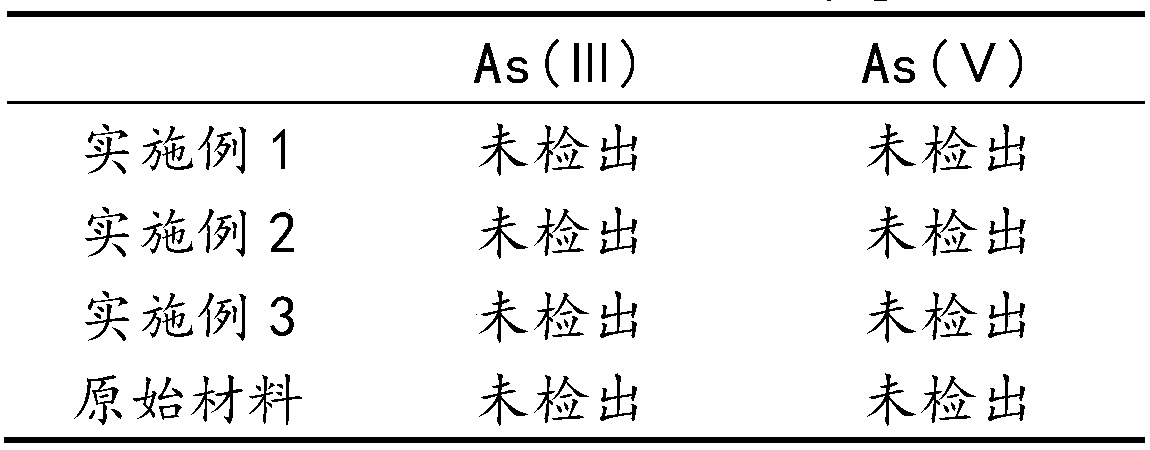

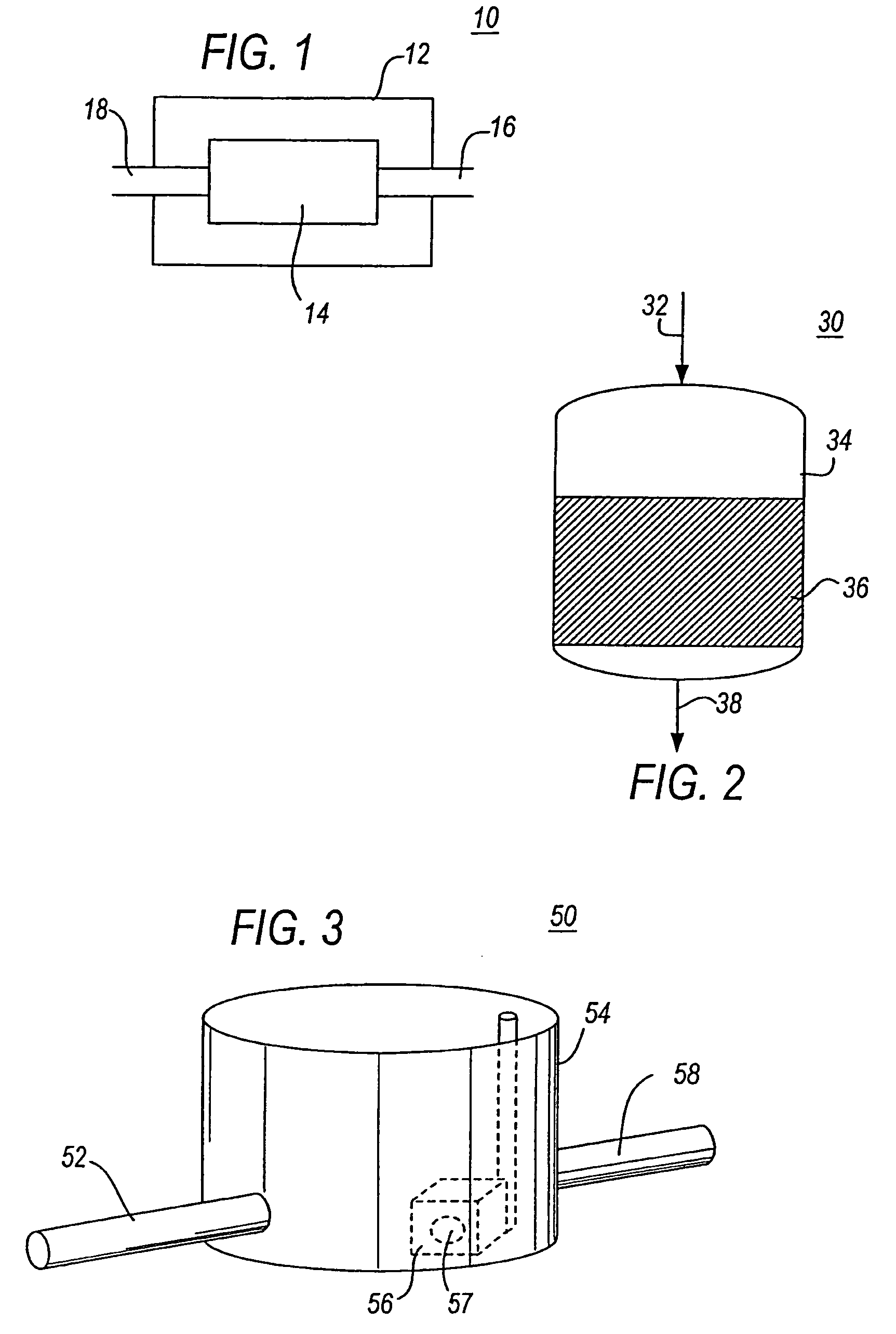

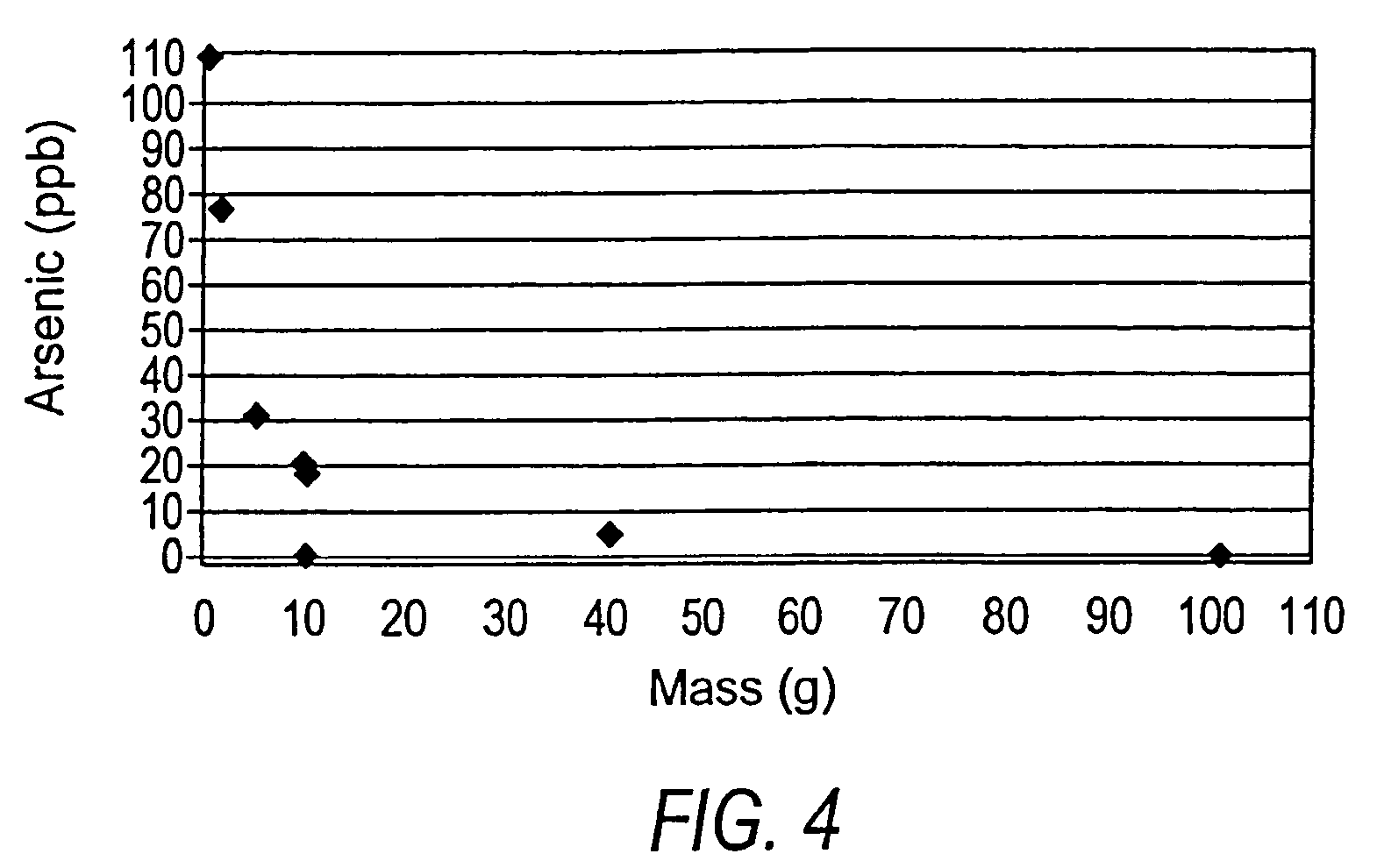

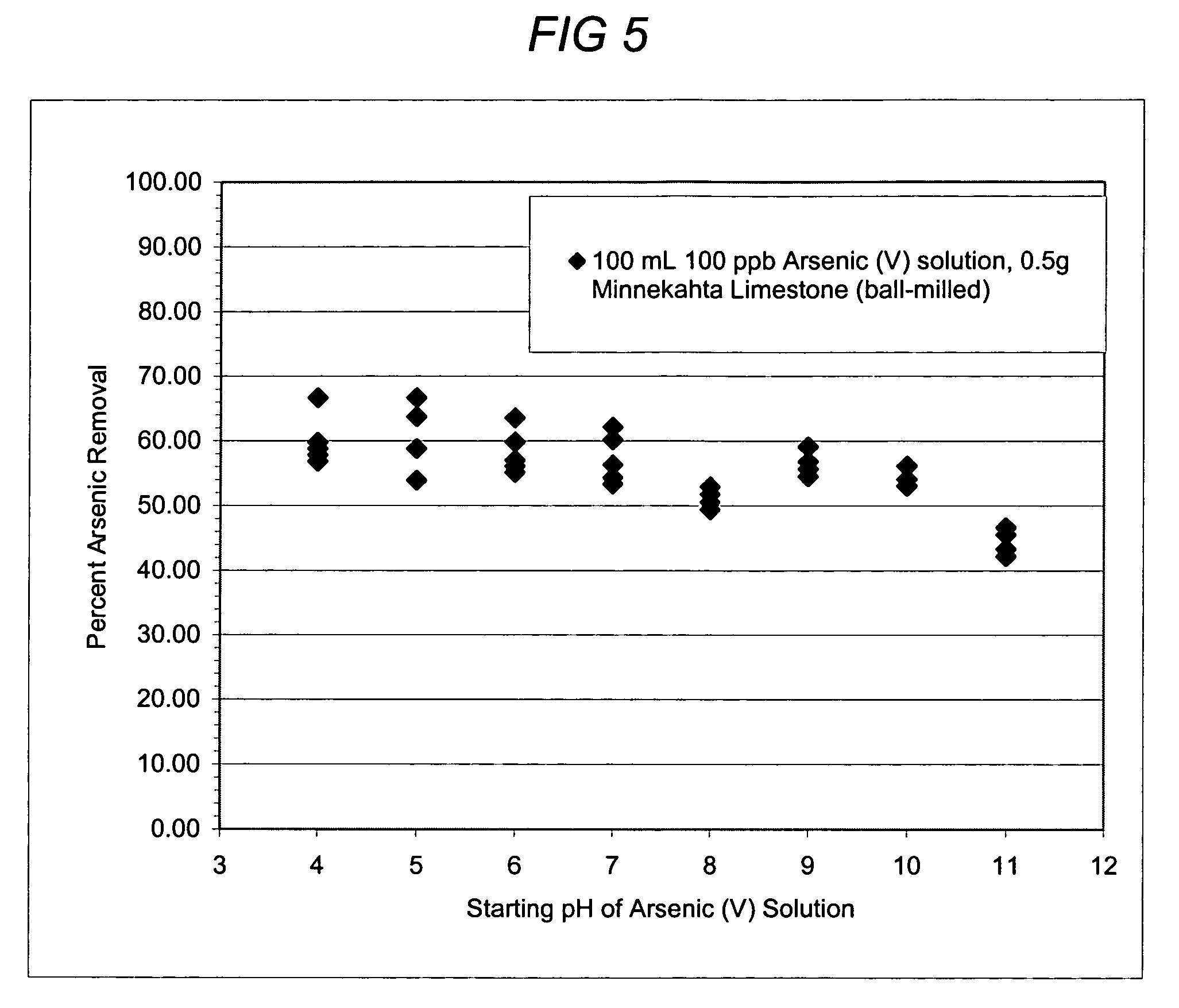

The present invention relates to a method for removing arsenic in arsenic contaminated water, especially for small drinking water systems such as those used in individual homes, rural areas, and small communities, by simply contacting arsenic-contaminated water with an arsenic removal medium. The present invention also relates to the composition of the arsenic removal medium, which comprises particles of calcium carbonate minerals and magnesium carbonate aggregates.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

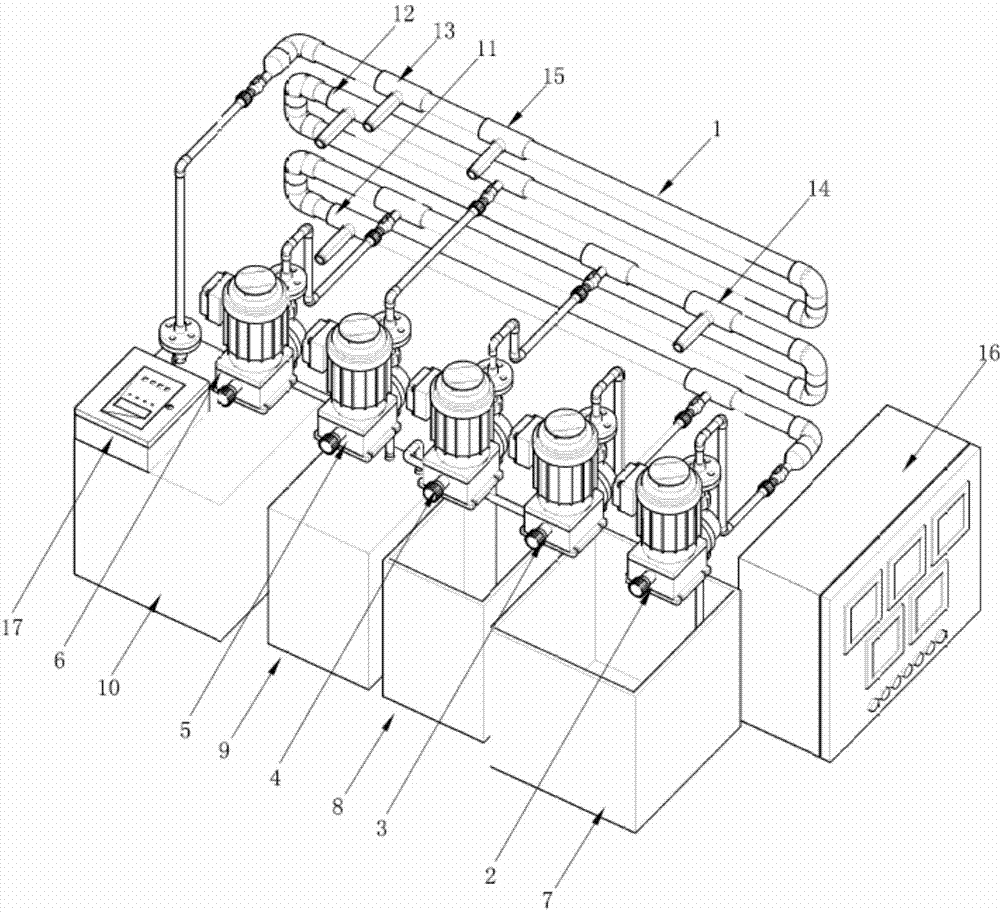

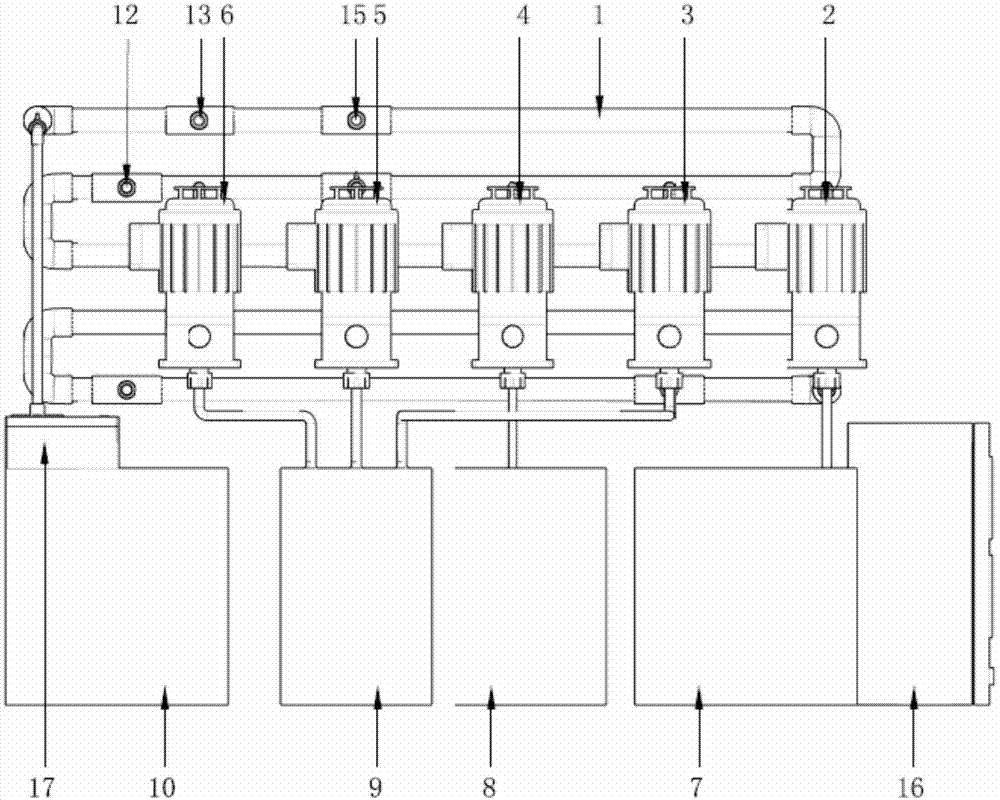

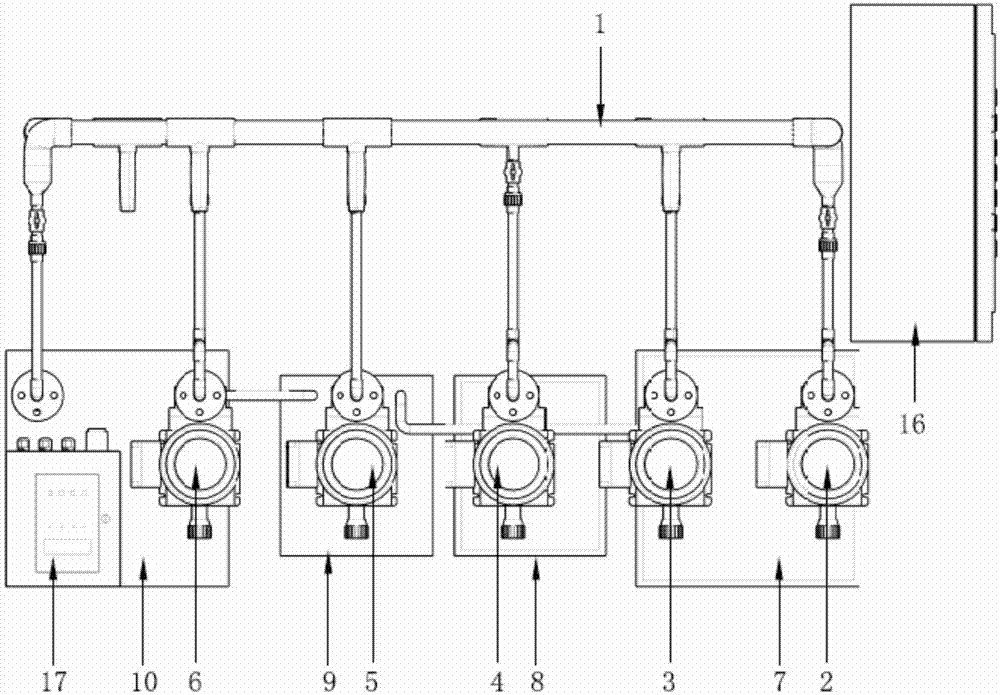

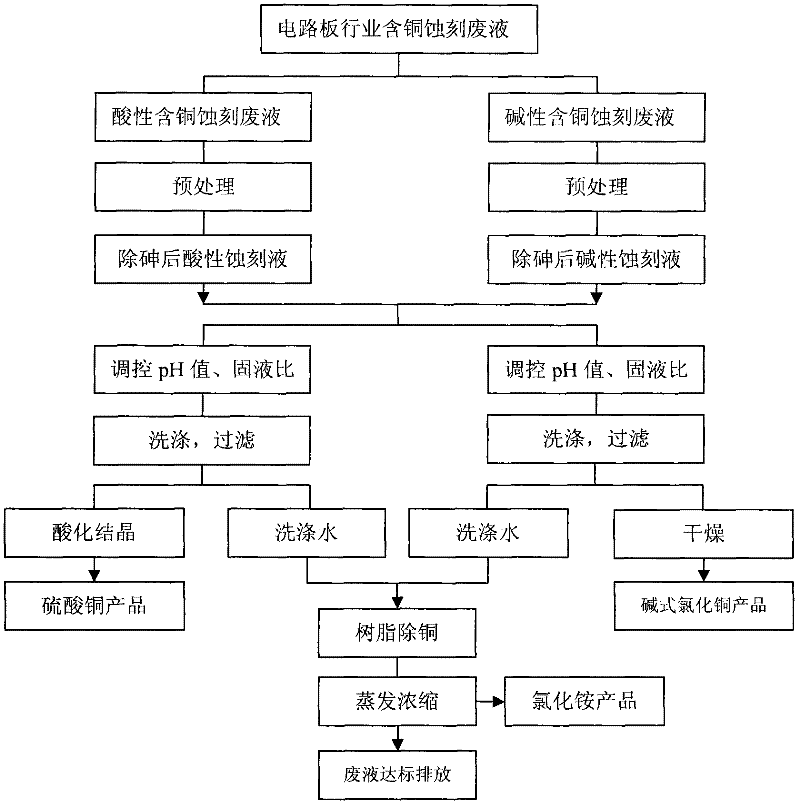

Technique for extracting copper ions from industrial wastewater

ActiveCN104355474AHigh extraction rateGood removal effectWater contaminantsWater/sewage treatment by ion-exchangeIon exchangeIon-exchange resin

The invention discloses a technique for extracting copper ions from industrial wastewater, which comprises the following steps: 1) respectively pretreating an acidic coppery etching waste liquid and an alkaline coppery etching waste liquid; 2) neutralization and precipitation: carrying out neutralization reaction on the acidic coppery etching waste liquid and alkaline coppery etching waste liquid in a neutralizing tank, and precipitating to obtain a basic copper chloride precipitate and a filtrate; 3) adding the basic copper chloride precipitate into a reaction tank, and adding sulfuric acid to obtain a copper sulfate crystal; 4) sending the filtrate into an ion exchange resin tower to adsorb the rest unrecovered copper ions, thereby obtaining ammonia nitrogen wastewater; and 5) carrying out evaporative concentration on the ammonia nitrogen wastewater by a vapor recompression technique, crystallizing the concentrate to produce an ammonium chloride product, treating the condensation water by an ion-exchange process, and discharging after reaching the standard. The technique can greatly enhance the extraction rate of copper ions, solves the problem of environmental pollution caused by heavy metal ions, and can produce other products from the waste liquid to implement cyclic utilization, thereby saving the resources and protecting the environment.

Owner:清远市中宇环保实业有限公司

Treatment method of arsenic wastewater

ActiveCN103112974AShort process routeShort construction periodMultistage water/sewage treatmentFlocculationResource recovery

The invention discloses a treatment method of arsenic wastewater. The treatment method comprises the following steps: optionally adding acid liquor into the arsenic wastewater to adjust the pH value to 0-5; introducing the arsenic wastewater into a reaction unit, continuously removing arsenic by adding sulfide in multistage manner; carrying out solid-liquid separation on the effluent after reaction, recycling the separated arsenic slag; adding alkali into the separated effluent to perform electrochemical advanced treatment, wherein the electrochemical advanced treatment includes an electrolytic coagulation step, an electrolytic flotation step and an electrolytic oxidation reduction step, in the electrolytic coagulation, cations are generated by the electrolyzation of a soluble anodic iron plate for flocculation; carrying out aerated oxidation on the effluent after flocculation to generate floc and micelle sediment including ferric ions, and then carrying out solid-liquid separation, wherein the liquid supernatant after separation can be recycled or reach the standard and drain outwards. The treatment method of arsenic wastewater has the advantages of simple technology, low investment, low cost and high resource recovery and recycling rate, and being green and environment-friendly, and being capable of treating continuously and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Normal temperature de-arsenic agent

ActiveCN101485971AGood dispersionIncrease contactOther chemical processesActive componentRoom temperature

The invention relates to a normal temperature dearsenifying agent, which consists of active components and a carrier, wherein the carrier is clay; and the active components comprise manganese dioxide and ferric oxide. Particularly, the dearsenifying agent consists of the following components in percentage by weight: 20 to 55 weight percent of manganese dioxide, 10 to 45 weight percent of ferric oxide, and 10 to 35 weight percent of the carrier. Based on the dearsenifying agent, the invention further discloses a method for preparing the dearsenifying agent, and the dearsenifying agent prepared by the method has higher arsenic capacity.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Preparation method for amorphous FeOOH water-purifying agent

InactiveCN105800762AHigh arsenic removal efficiencyEfficient removalWater/sewage treatmentAluminum IonHydrolysis

The invention provides a preparation method for an amorphous FeOOH water-purifying agent. The preparation method comprises the following steps: preparing a ferrous sulfate solution from industrial ferrous sulfate heptahydrate; adding a proper amount of sulfuric acid into the ferrous sulfate solution so as to provide an acidic environment; adding hydrogen peroxide into the solution and allowing ferrous sulfate to be oxidized into ferric sulfate under the condition of hydrolysis promotion by sulfuric acid; subjecting an industrial alkali source and the ferric sulfate solution to a precipitation reaction so as to produce iron hydroxide colloid; and dehydrating the iron hydroxide colloid under proper conditions so as to prepare the amorphous FeOOH water-purifying agent. The amorphous FeOOH water-purifying agent can effectively arsenic in water, has arsenic removal efficiency of 98% or above, does not contain aluminum ions or pose secondary pollution to a water body; after arsenic removal with the water-purifying agent, scorodite stably existing in the nature is produced, so pollution is not posed to the environment; moreover, raw materials used in the invention are of an industrial grade, and the preparation method is low in production cost and simple to operate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

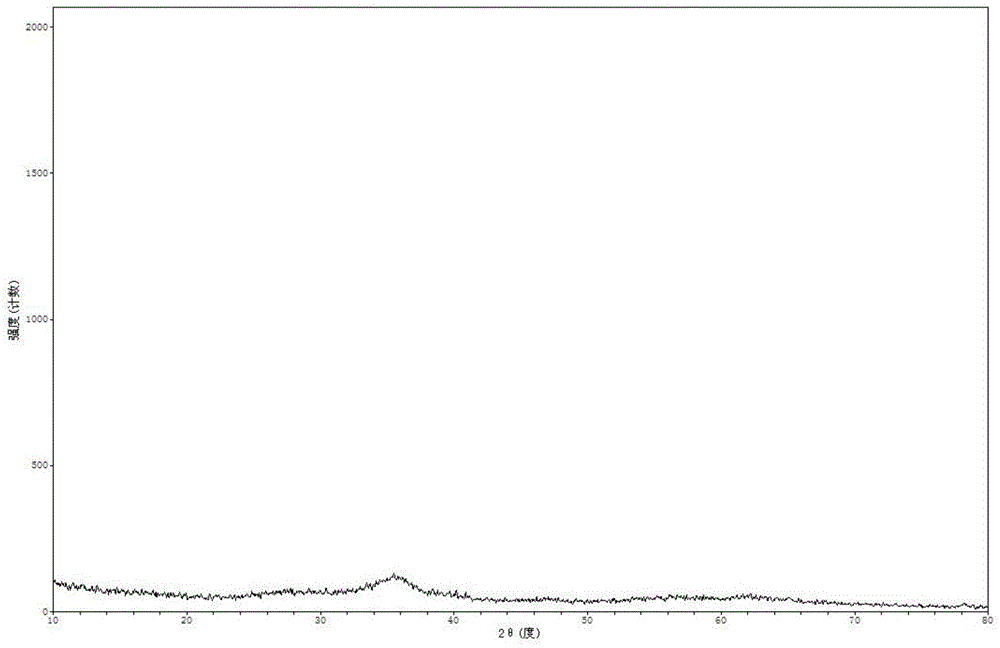

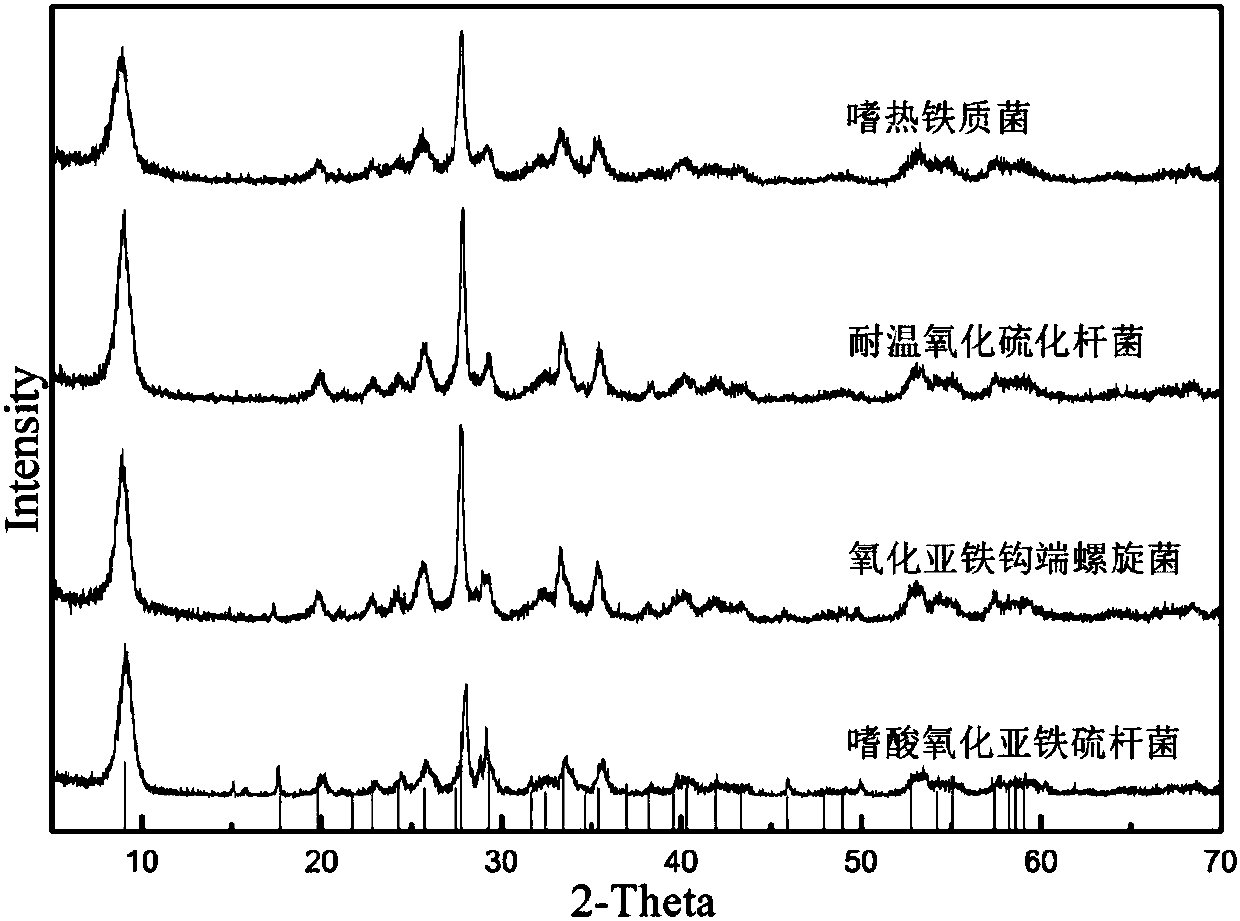

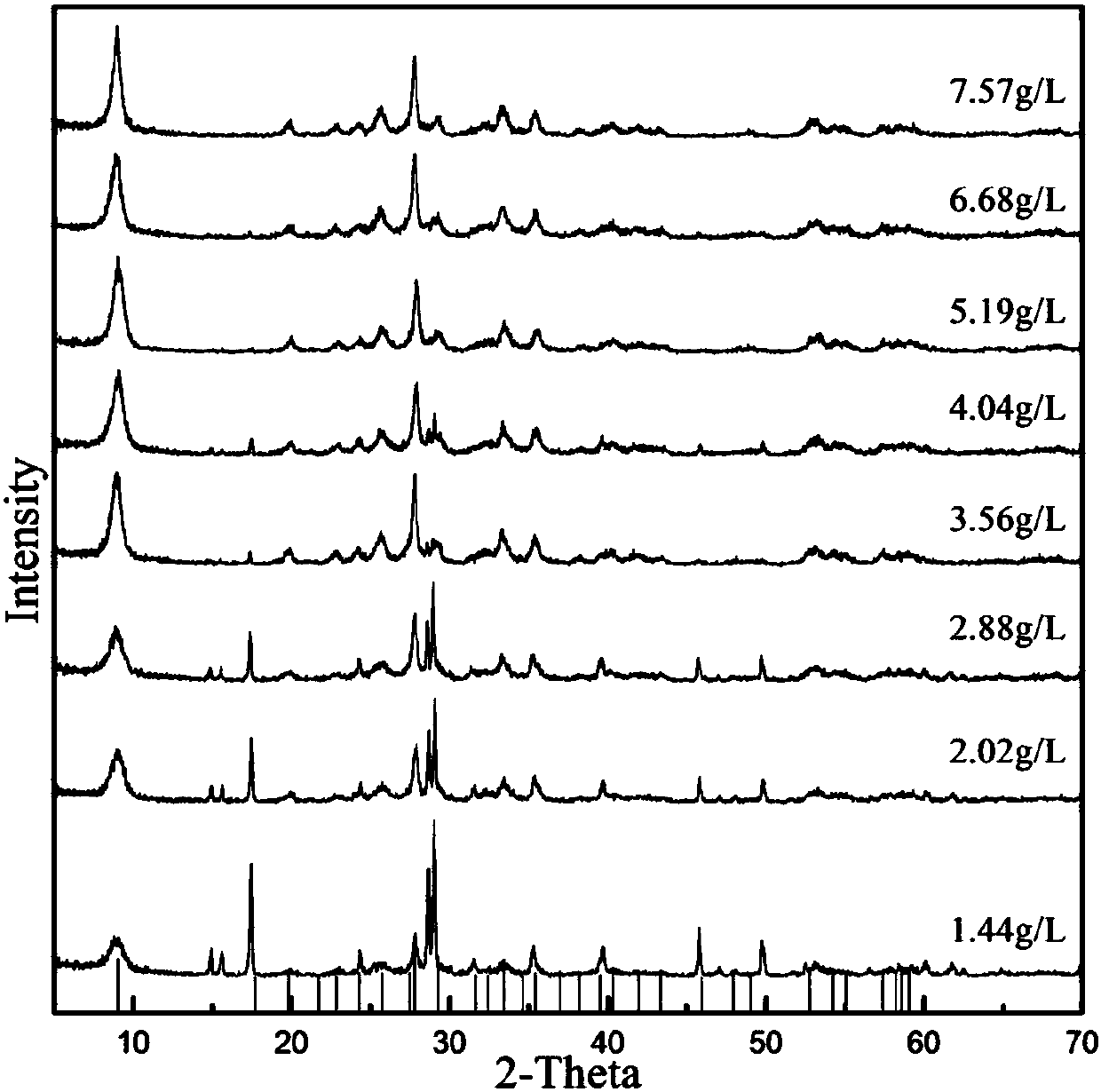

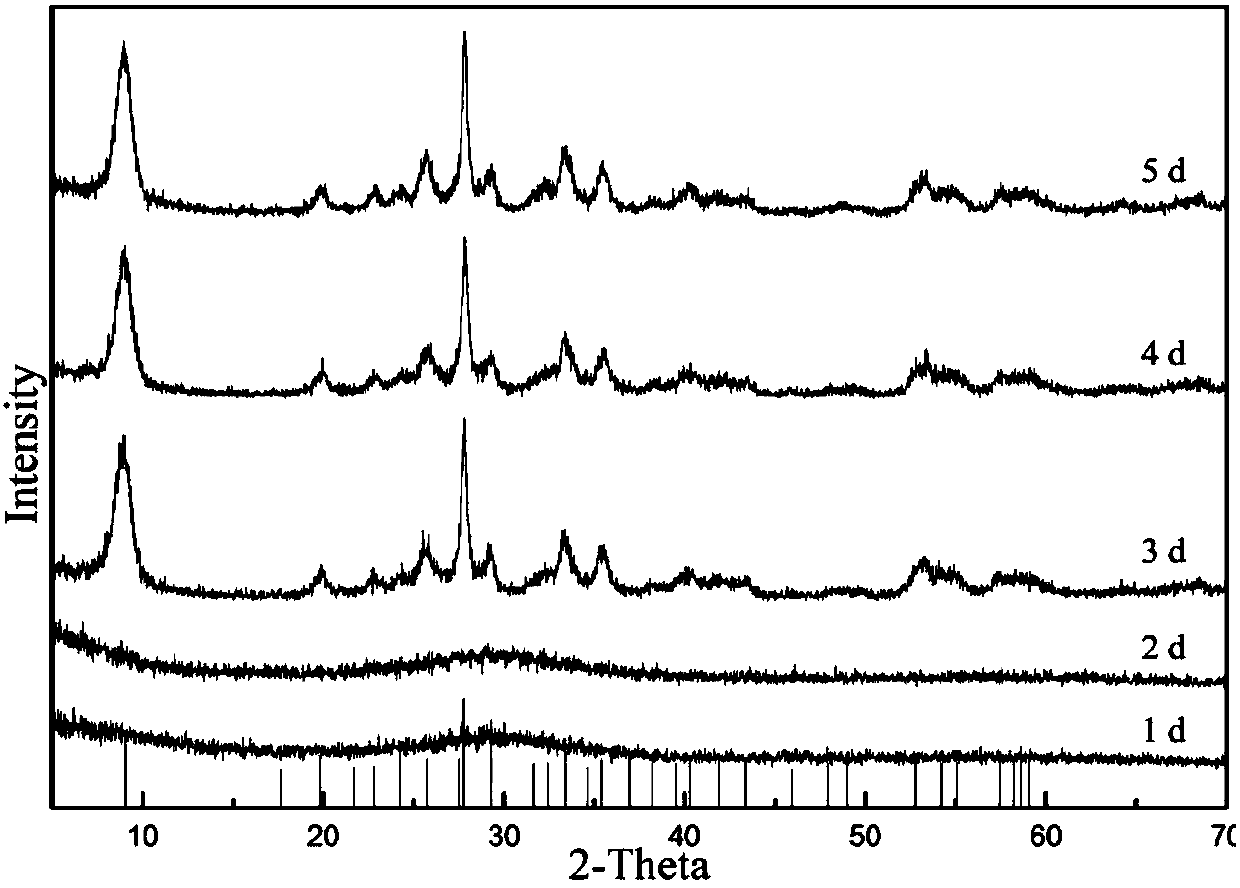

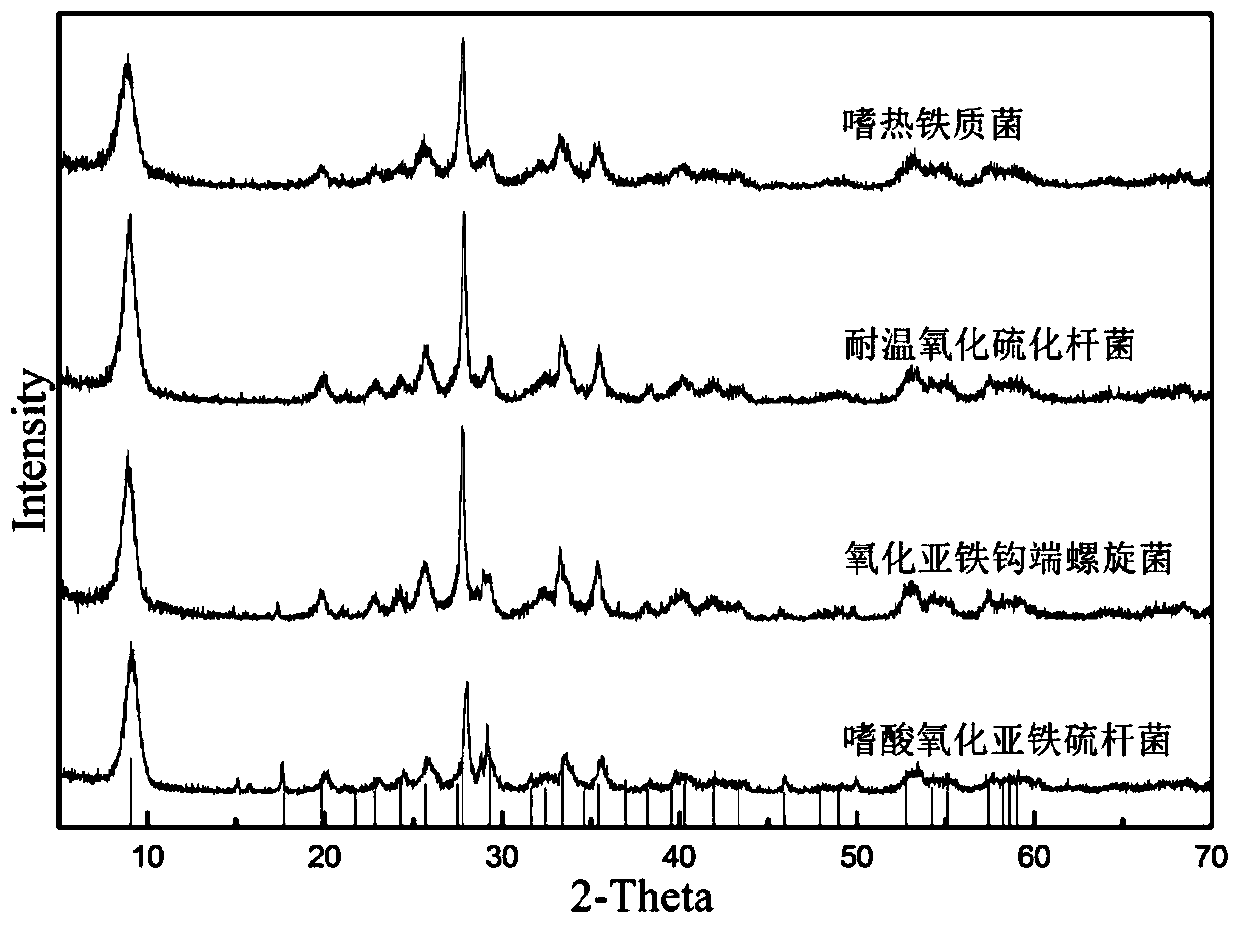

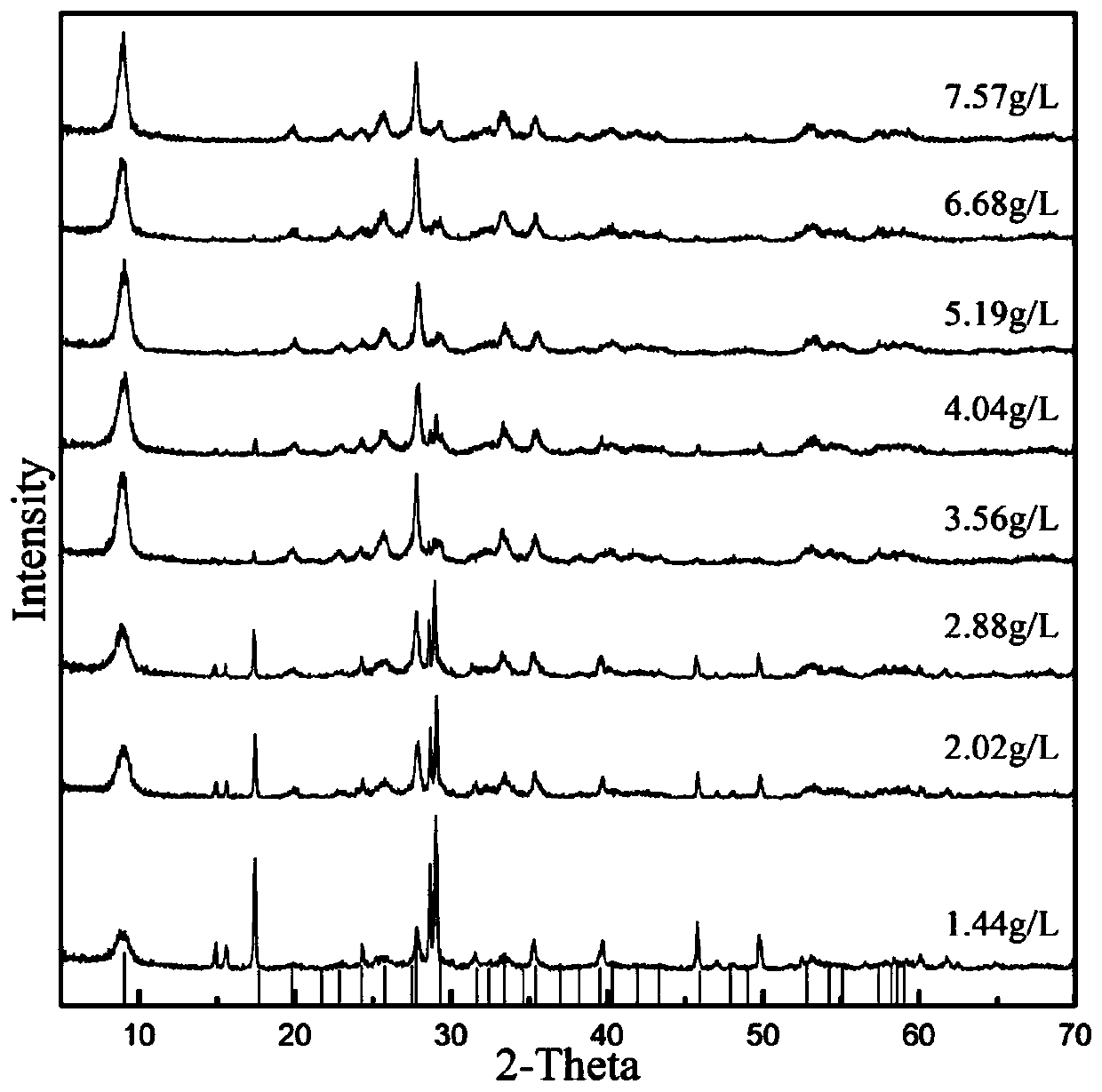

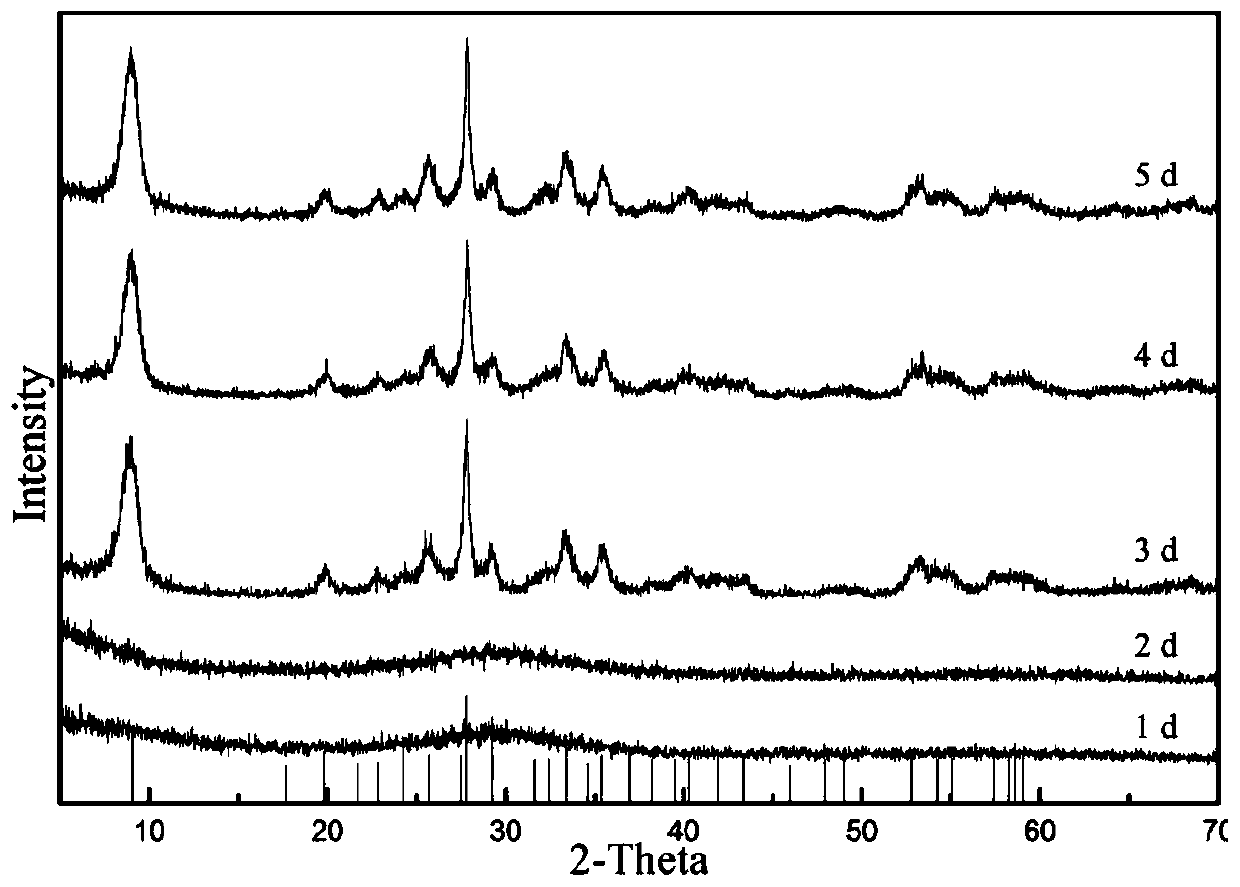

Method for treating wastewater containing trivalent arsenic by utilizing microorganisms

ActiveCN106698821AReduce the first oxidation of As

<sup>3+</sup>

A step ofEasy to handleWater contaminantsMultistage water/sewage treatmentMicroorganismHydrogen

The invention discloses a method for treating wastewater containing trivalent arsenic by utilizing microorganisms. The method comprises the following steps: adding ferrous salt into wastewater to be treated which contains the trivalent arsenic; meanwhile, adding iron-oxidizing bacteria which stays at a growth logarithmic period; adjusting the pH (Potential of Hydrogen) to be 1.6 to 2.8; controlling the temperature to be 25 DEG C to 30 DEG C; uniformly stirring and reacting for 3d to 5d; standing and precipitating the trivalent arsenic in a form of tooeleite; filtering and finishing treatment. A microorganism oxidization method disclosed by the invention can be used for treating the arsenic-containing wastewater with the arsenic content of 3.56g / L to 7.57g / L and adjusting the pH to be 1.6 to 2.8; at room temprature of 25 DEG C to 30 DEG C, the removal rate of the trivalent arsenic within 3d to 4d can reach about 98 percent; the method has the advantages that the raw materials are easy to obtain, the operation is simple and the treatment cost is low; obtained sediment is easy to separate and the arsenic content is high; the stability is good and no secondary pollution is caused.

Owner:CENT SOUTH UNIV

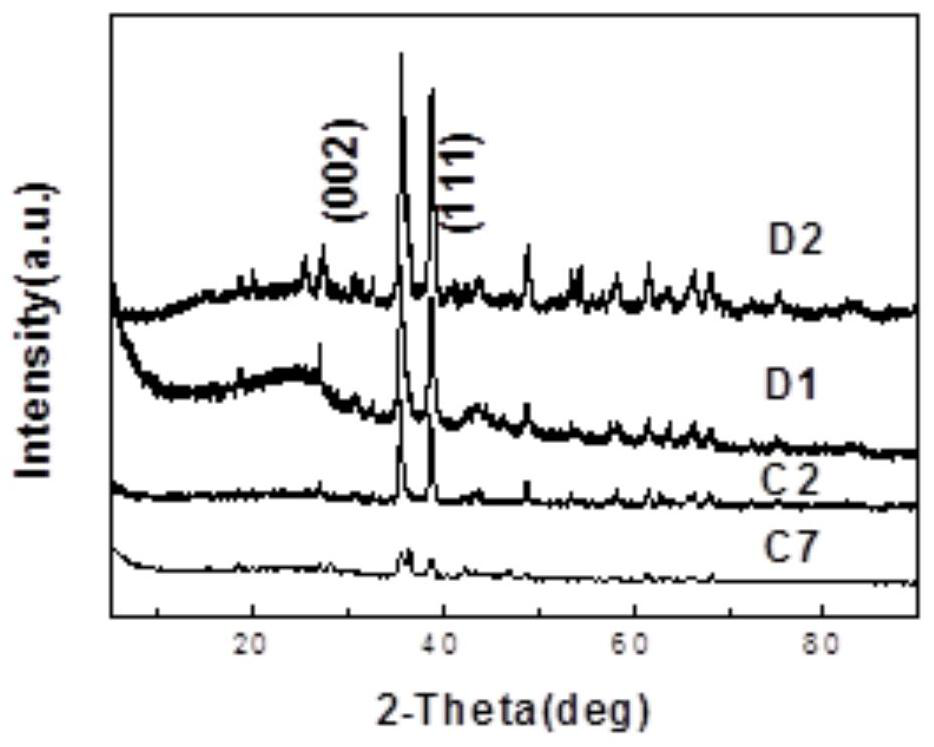

Method for treating wastewater with trivalent arsenic

ActiveCN107010704AHigh arsenic removal efficiencyHigh Precipitated Arsenic ContentWater contaminantsWater/sewage treatment by flocculation/precipitationIron saltsHydrogen

The invention discloses a method for treating wastewater with trivalent arsenic. The method includes simultaneously feeding the to-be-treated wastewater with the trivalent arsenic, iron salt solution and sulfate solution and simultaneously sufficiently colliding the to-be-treated wastewater, the iron salt solution and the sulfate solution with one another to obtain first mixtures; regulating the pH (potential of hydrogen) of the first mixtures until the pH of the first mixtures reaches 1.8-3.0; uniformly mixing the first mixtures with one another at the normal temperature; carrying out reaction; separating precipitates. The method has the advantages that feeding reaction is carried out under the conditions of the temperatures of 25+ / -1 DEG C, the speeds of 600+ / -20 r / min and the pH of 2.4 for 18 min when the arsenic solution with the As <3+> content of 20.5 g / L, the iron salt solution with the Fe <3+> content of 23.0 g / L and the sulfate solution with the SO<4><2-> content of 6.56 g / L are added into 30 mL of deionized water at the speeds of 1.8 mL / min, water hydroxyl sarmientite minerals are good in crystallization, and the As <3+> removal rate is 87.6%; the method for treating the wastewater with the trivalent arsenic is high in arsenic removal efficiency, good effects can be realized, raw materials are low in cost and are easily available, conditions are mild, procedures can be controlled, the precipitates are high in arsenic content, are stable and are easy to separate, secondary pollution can be prevented, and accordingly the method has a broad practical application prospect.

Owner:CENT SOUTH UNIV

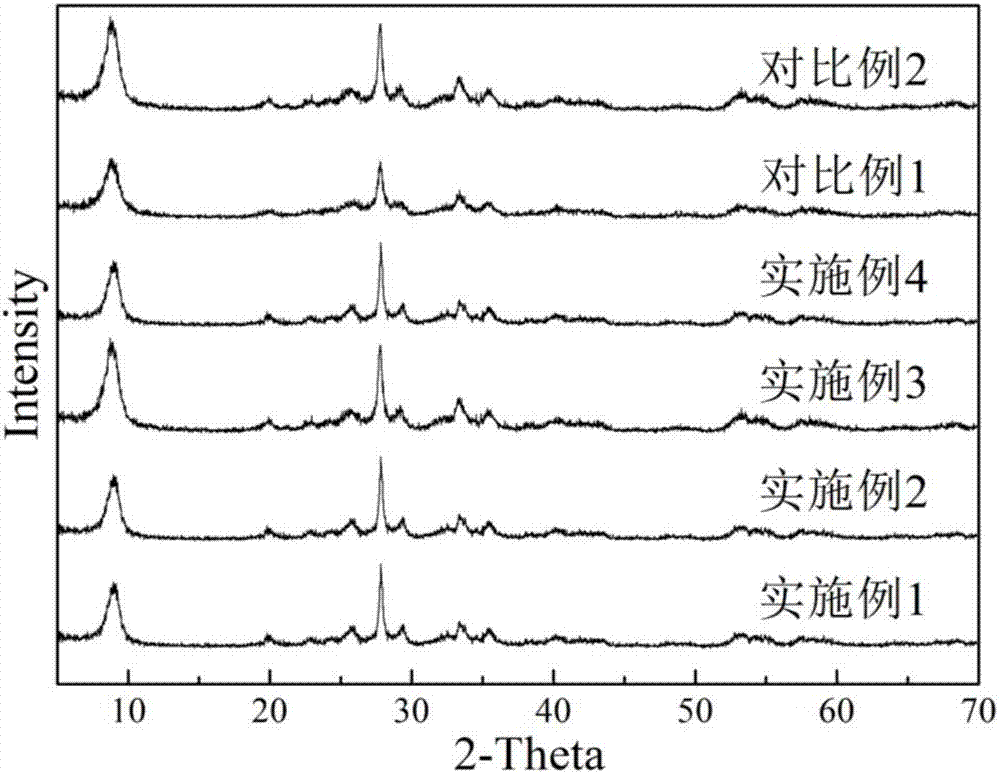

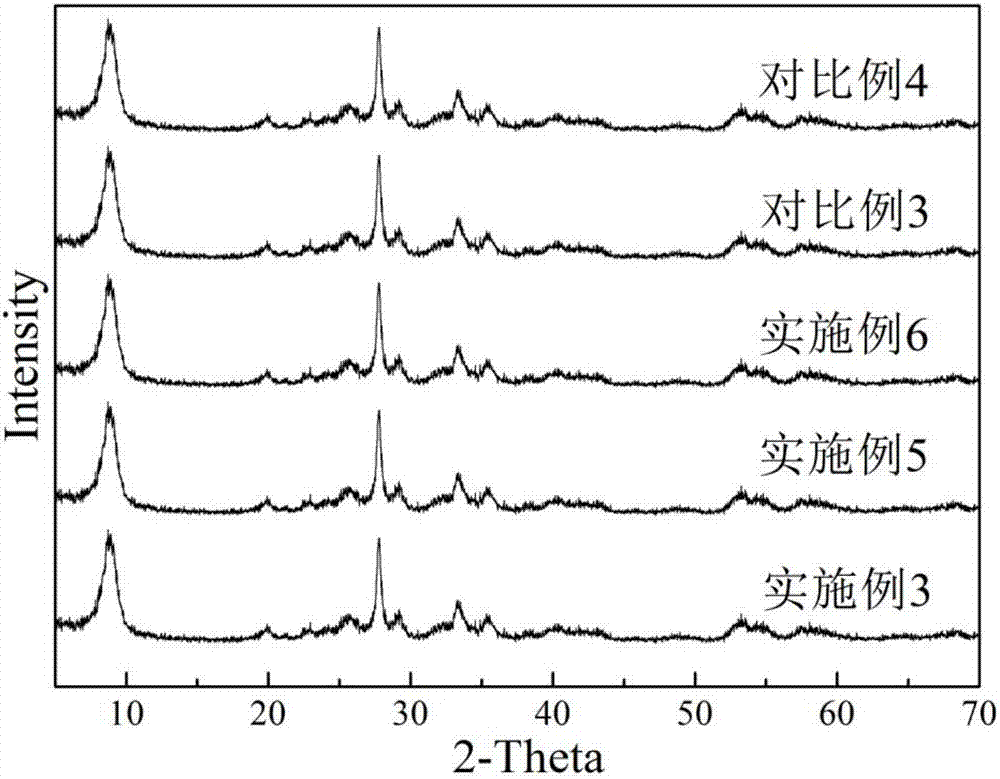

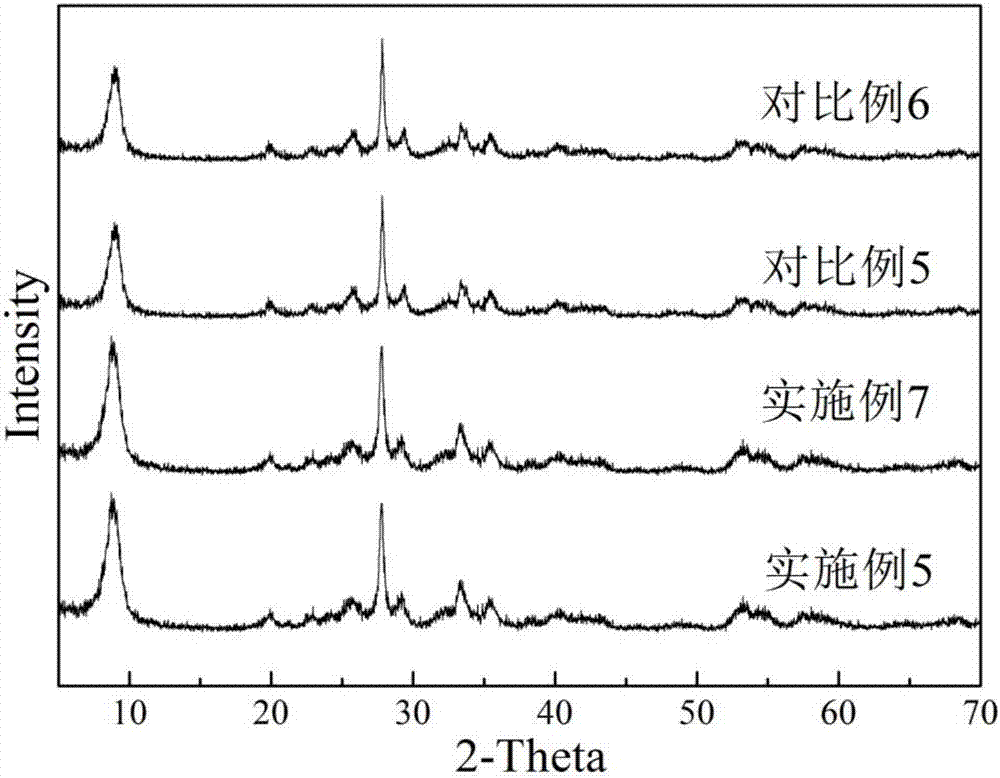

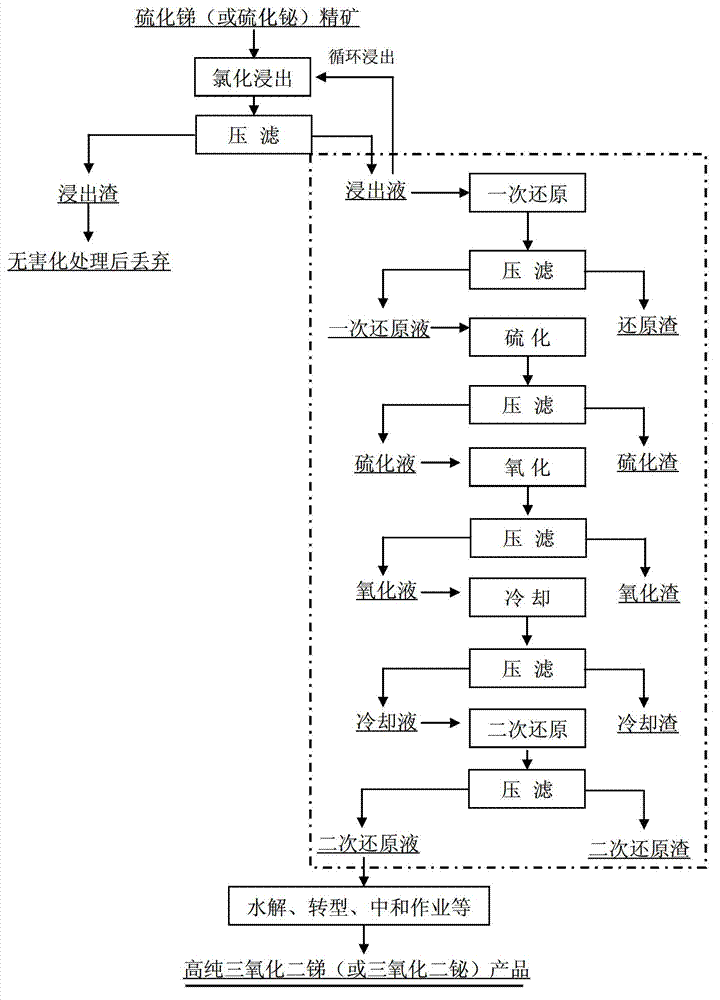

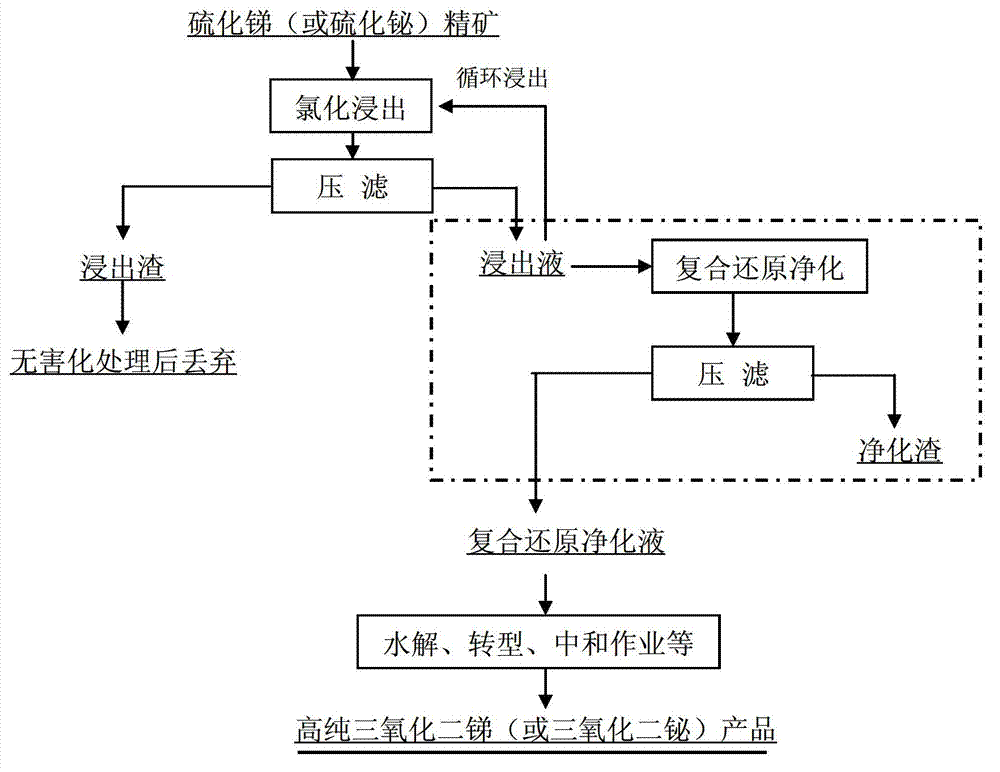

Short-flow method for preparing antimony or bismuth hydrolysis mother solution and composite cleaning agent for short-flow method

InactiveCN102816929AAdaptableShort processProcess efficiency improvementCleansing AgentsAntimony trioxide

The invention discloses a short-flow method for preparing antimony or bismuth hydrolysis mother solution and a composite cleaning agent for the short-flow method. The short-flow method comprises a chlorinated acid leaching step and a composite restoring purification step; and the obtained qualified hydrolysis mother solution can be hydrolyzed, converted and washed to obtain high-purity diantimony trioxide (or bismuth trioxide). The short-flow method comprises the following specific steps of: firstly, carrying out chlorinated acid leaching on antimony sulfide ore concentrate (or bismuth sulfide ore concentrate); secondly, carrying out composite restoring purification on leachate; and filtering the composite restoring purification liquid to obtain antimony (or bismuth) hydrolysis mother solution, wherein main impurity metals of the mother solution comprise Pb<2+> of which the concentration can be smaller than 50mg / L, As<3+> of which the concentration is smaller than 30mg / L and the S<2-> of which the concentration can be smaller than 50mg / L. The quality of the obtained hydrolysis mother solution can completely meet the requirement of preparing special high-grade and high-purity diantimony trioxide (or bismuth trioxide) by hydrolysis. Compared with a traditional method, the short-flow method has the advantages that the flow is greatly shorten and the production period is shorten by over one third; the whiteness of a high-purity diantimony trioxide (or bismuth trioxide) product obtained by the hydrolysis mother solution can stably reach over 92 percent. The contents of iron, arsenic and aluminum impurities in the product are below 10ppm. A novel process has the remarkable advantages of strong adaptability of raw materials, short process flow, fewer process control points, stable quality of products and the like.

Owner:CENT SOUTH UNIV

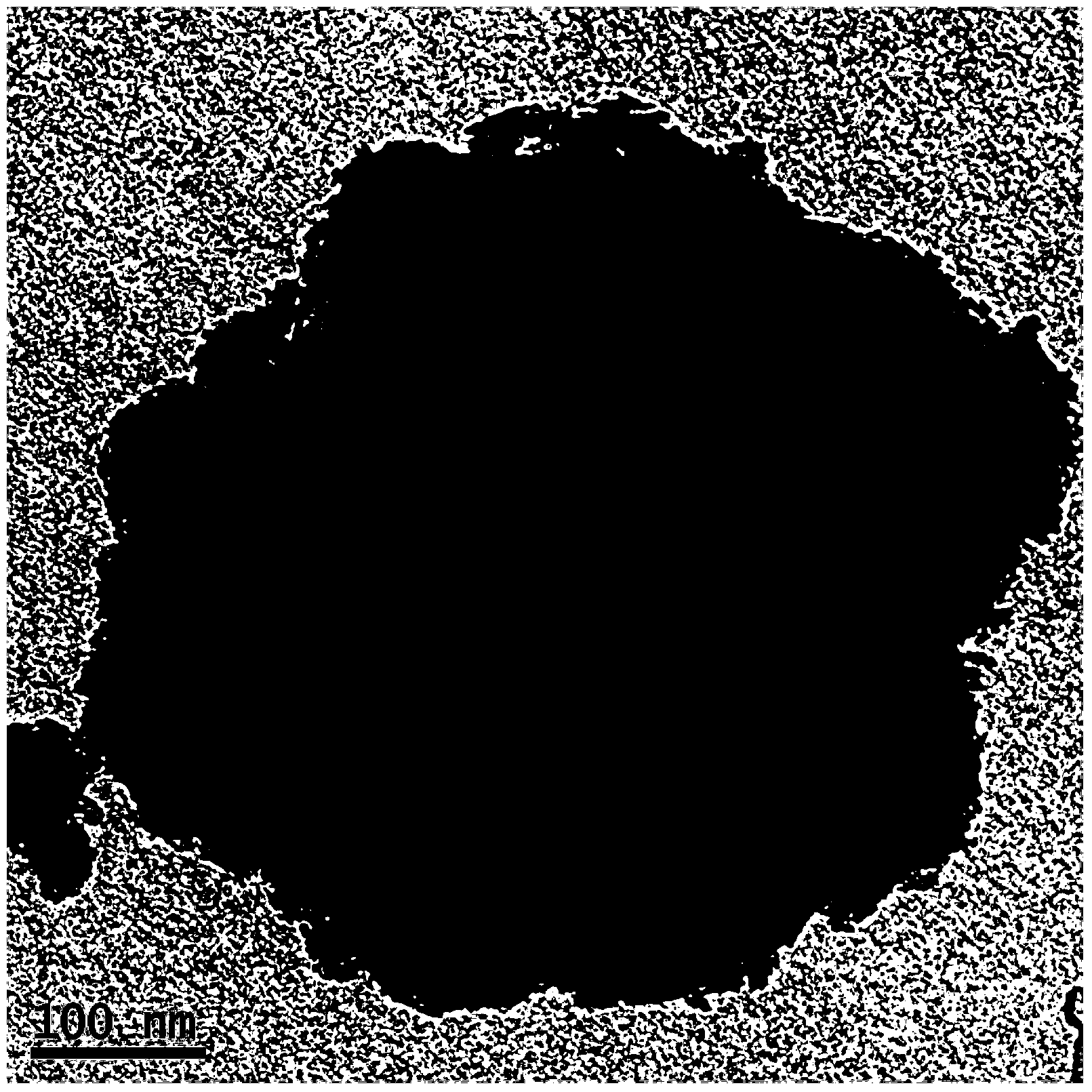

Nano magnetic iron oxide/kaolin particle as well as preparation method and use thereof

InactiveCN103721671ALarge specific surface areaLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesIn situ remediationFerrous salts

The invention relates to a nano magnetic iron oxide / kaolin particle as well as a preparation method and use thereof. The particle is of a core-shell structure with an inner core and a shell, wherein the inner core is kaolin mineral; the shell is nano magnetic iron oxide; the ingredient of the nano magnetic iron oxide is Fe3O4; the nano magnetic iron oxide particle is 10-80nm in particle size. The nano magnetic iron oxide / kaolin particle is prepared by virtue of the following steps: bathing the fully dissolved polyvinylpyrrolidone solution; adding kaolin, adding an alkali liquor to adjust the pH value of the system after fully mixing, and then adding a ferrous salt solution; dropwise dripping a ferric salt solution under strong agitation, so that a dark brown sediment is generated; simultaneously, continuously adding the alkali liquor to keep the pH value of the system at 8-10; fully washing and filtering after bathing and ageing; drying and baking the sediment in vacuum; cooling and then grinding, so as to obtain the particles. The particles can be used for in-situ remediation of arsenic in high-arsenic groundwater. The particles are strong in adsorption capacity, simple in preparation, cheap and available in raw material, and easy to popularize and use, and the pollutants such as arsenic in the water can be efficiently removed.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

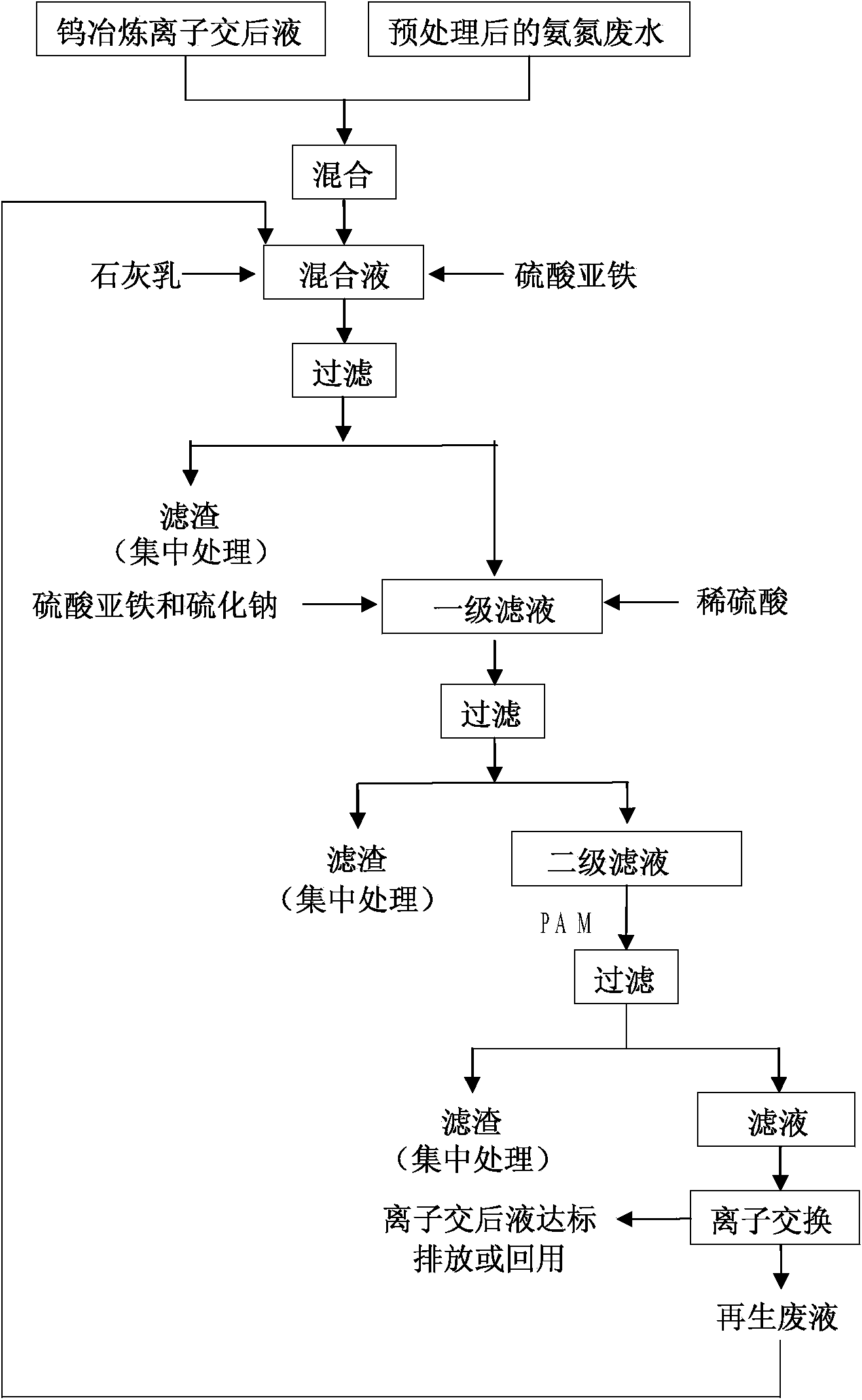

Deep purification method of tungsten smelting wastewater

ActiveCN103523950ALess investmentReduce processing costsWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wastePurification methods

The invention discloses a deep purification method of tungsten smelting wastewater. The deep purification method is characterized by comprising the steps of mixing an ammonia nitrogen waste solution after pretreatment and an ion after-exchange solution produced by tungsten smelting according to the volume ratio of (1: 8)-(1: 5) at normal temperature, then adding lime milk to regulate the pH value of a mixed solution to 11-12, and then adding ferrous sulfate into the mixed solution to perform first-stage treatment to obtain first-stage filtrate; adding dilute sulfuric acid into the first-stage filtrate to regulate the pH value to 5-6, and then respectively adding sodium sulfide and ferrous sulfate into the first-stage filtrate to perform second-stage treatment to obtain second-stage filtrate; adding a flocculant into the second-stage filtrate, naturally settling, then performing precision filtration, and pumping obtained third-stage filtrate into a styrene quaternary amine type strong base anion exchange column. According to the method disclosed by the invention, two-stage chemical precipitation and ion exchange processes are taken as main processes of wastewater treatment, and the method has the advantages of simple steps, low equipment investment, easiness in monitoring, easiness in operation, low treatment cost, no secondary pollution, energy conservation and environmental friendliness.

Owner:CNMC GUANGXI PGMA

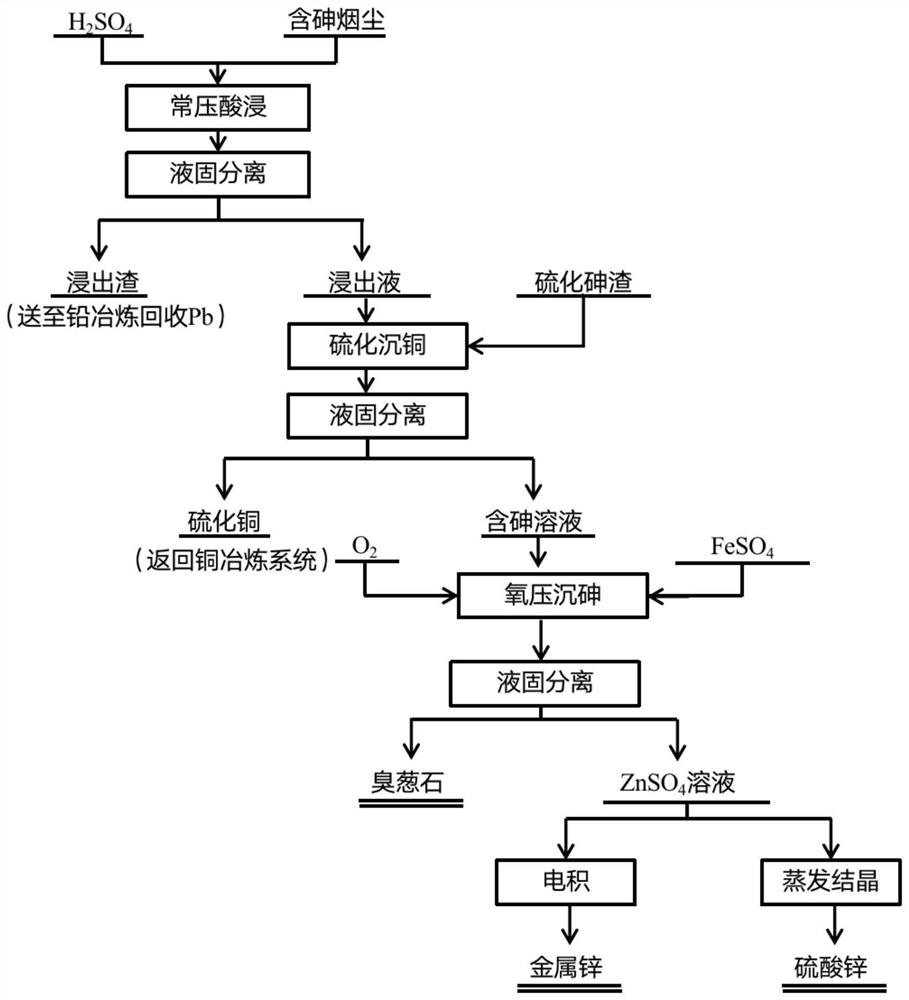

Method for co-processing arsenic sulfide slag and arsenic-containing smoke in copper smelting

InactiveCN113684368AImprove leaching rateEasy to operateZinc sulatesPhotography auxillary processesSulfate zincLead smelting

The invention relates to a method for co-processing arsenic sulfide slag and arsenic-containing smoke in copper smelting. The method comprises the following steps that copper, zinc, iron, arsenic and like enter a solution through normal-pressure acid leaching of arsenic-containing smoke, lead is recovered from leaching slag through a lead smelting system, copper in smoke acid leaching liquid is precipitated through sulfuration of the arsenic sulfide slag, ferrous sulfate is added into the solution after copper precipitation, high-stability scorodite is obtained through reaction under the condition of oxygen pressure, the loss of valuable metal in the arsenic precipitation process is small, and the arsenic-removed solution with few impurities can be directly fed to a zinc electrodeposition process to obtain electrodeposited zinc or evaporated and crystallized to obtain a zinc sulfate product. According to the method, the valuable metal recovery rate is high, operation is easy, the problems that the arsenic sulfide slag is low in value and difficult to treat are effectively solved through arsenic sulfide slag sulfuration copper precipitation, and efficient utilization of dangerous solid waste and harmless treatment of arsenic are achieved.

Owner:CENT SOUTH UNIV

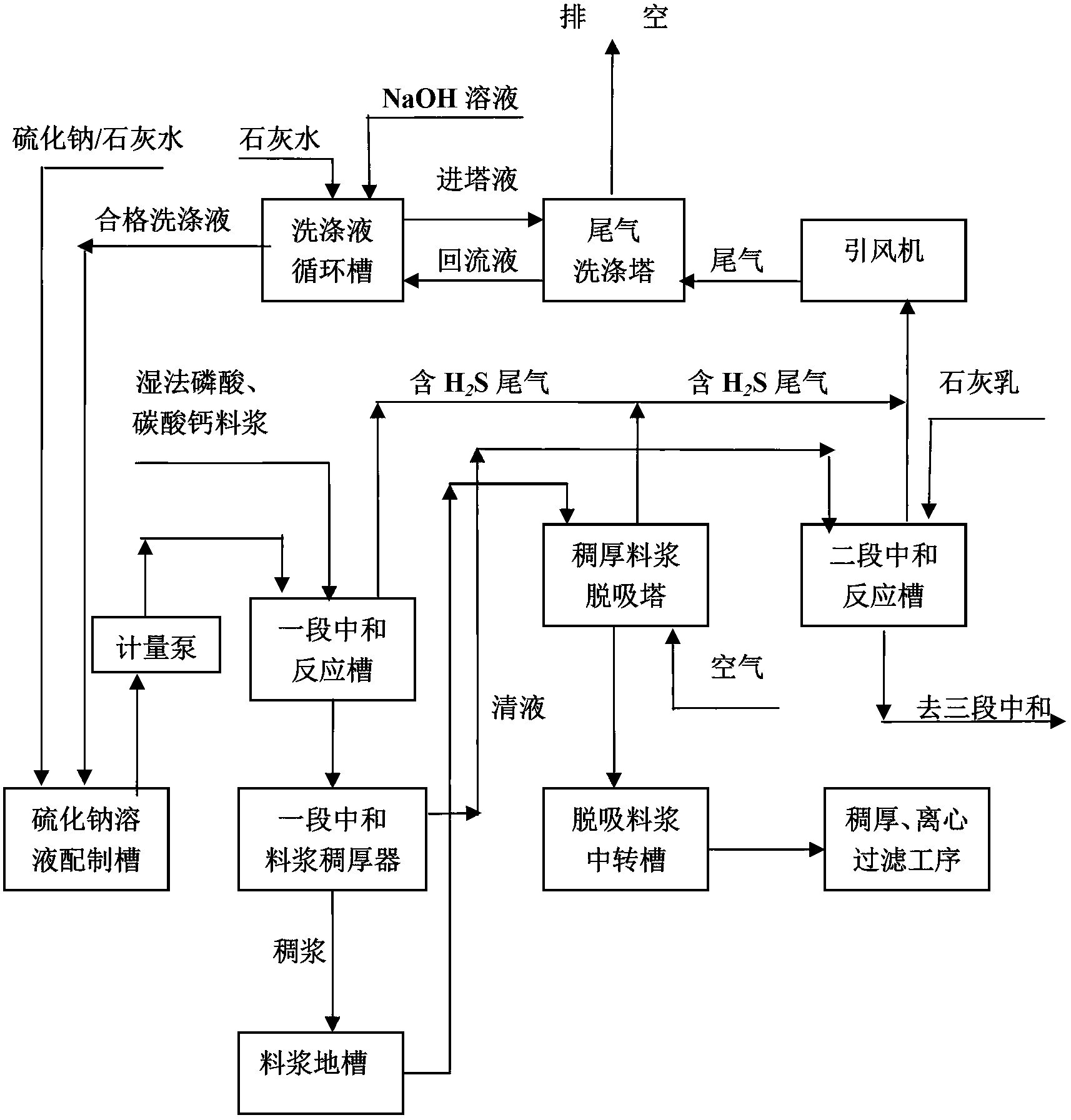

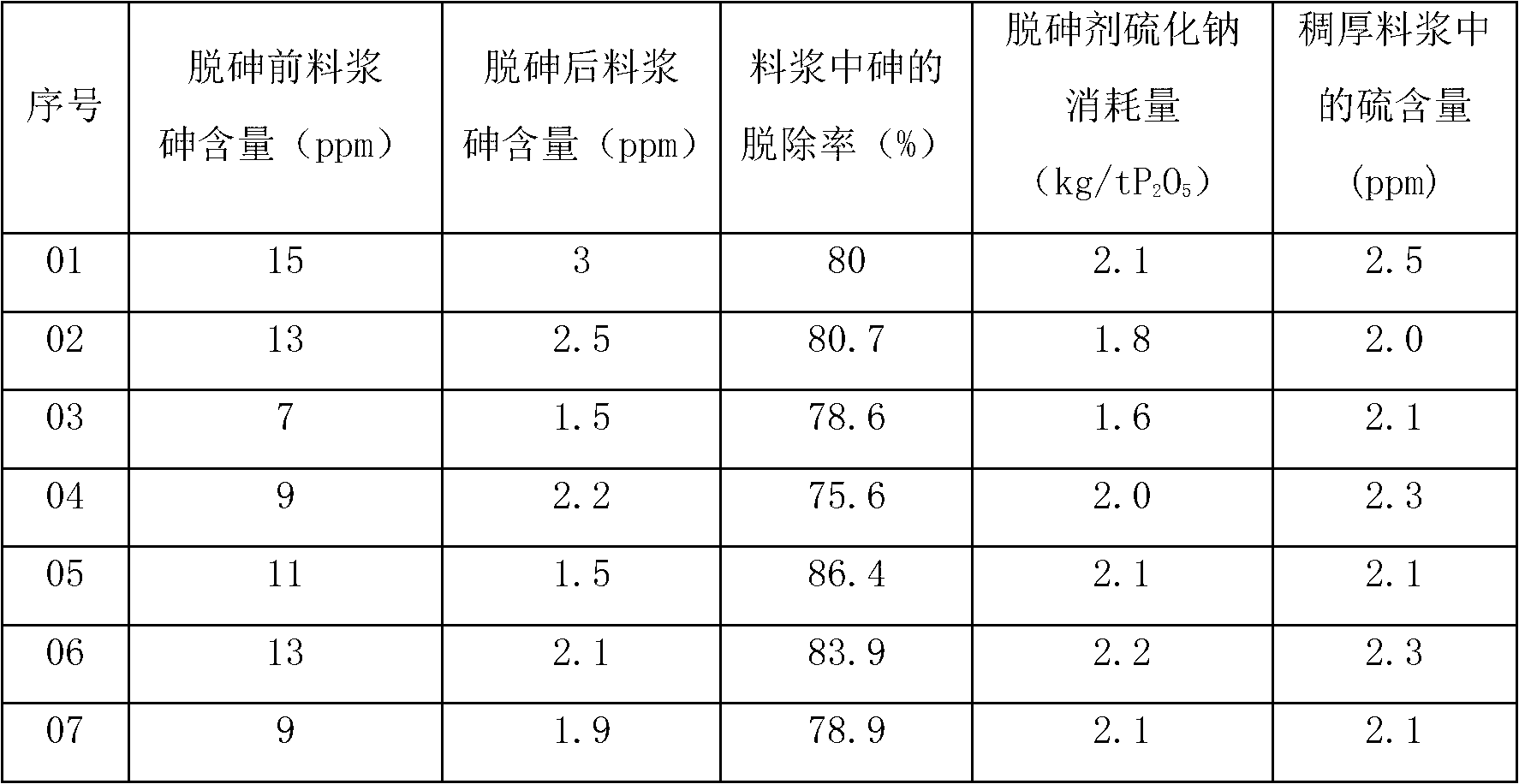

Process method for removing arsenic from feed-grade calcium hydrogen phosphate prepared from wet-process phosphoric acid

ActiveCN102701170AGood arsenic removal effectGuaranteed SolubilityDispersed particle separationPhosphorus compoundsDesorptionPhosphoric acid

The invention relates to a process method for removing arsenic from feed-grade calcium hydrogen phosphate prepared from wet-process phosphoric acid. The process method comprises the following steps of: 1) adding a sodium sulfide or calcium sulfide solution into neutralized slurry by using an adjustable pressure metering pump until the solution reaches a position which is 50cm away from the liquid level of the neutralized slurry; 2) desulfurizing by an air stripping method, namely removing hydrogen sulfide (H2S) from slurry at the bottom of a thickener by using a desorption tower; 3) recovering the H2S in tail gas to generate a mixed solution of calcium sulfide and sodium sulfide by using lime water and liquid caustic soda in a molecular ratio of Ca(OH)2 to NaOH of 1:1 as washing water of a tail gas washing tower, wherein the washing water of the tail gas washing tower is used as a raw material of an arsenic remover for the neutralized slurry in a section I and recycled after the concentration of the washing water is qualified; and 4) adding the sodium sulfide or calcium sulfide solution into the last one or two reaction tanks for one-stage neutralization of the wet-process phosphoric acid. The process method has the advantages that the content of the H2S in the slurry is reduced to about 3ppm, and the slurry does not have the odor of the H2S; and arsenic removal cost is reduced by more than half compared with that of a treatment method in which lime is not used.

Owner:KUNMING CHUAN JINNUO CHEM IND

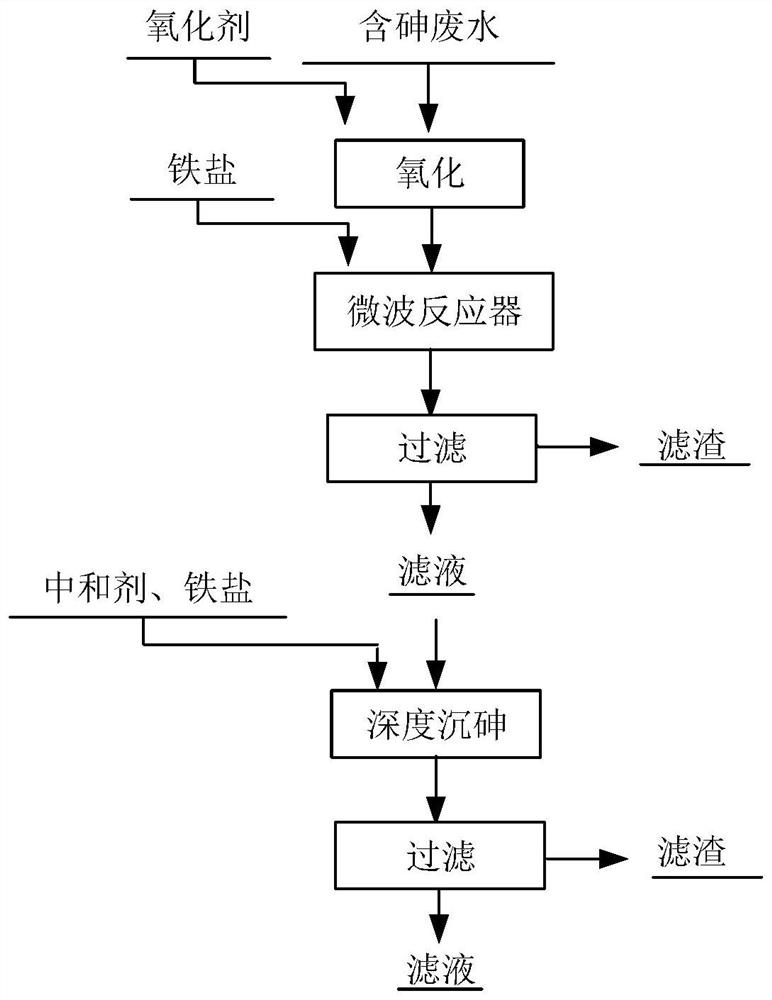

Arsenic-containing wastewater treatment method

ActiveCN113023987AImprove processing efficiencyReduce consumption of iron saltsWater/sewage treatment by irradiationWater contaminantsEnvironmental chemistryAqueous solution

The invention provides an arsenic-containing wastewater treatment method which comprises the following steps: adding an oxidizing agent into arsenic-containing wastewater, stirring for reaction, filtering after the reaction is completed, removing filter residues, and carrying out subsequent treatment on filtrate, pouring the filtrate into a microwave reactor, starting microwaves, heating, then slowly dropwise adding ferric salt, carrying out an arsenic precipitation reaction under the condition that the pH value is 2-3, carrying out heat preservation and aging after the reaction is completed, and then filtering to obtain a low-arsenic wastewater solution and filter residues which are scorodite; and firstly adding a neutralizer into a low-arsenic wastewater solution to adjust the pH value, then adding ferric salt to deeply remove residual arsenic in the low-arsenic wastewater, and filtering to obtain filtrate, namely arsenic-removed wastewater. According to the treatment method disclosed by the invention, the arsenic-containing wastewater is treated by microwave assistance, so that the wastewater treatment efficiency is effectively improved, the consumption of ferric salt in the subsequent deep arsenic removal process is effectively reduced, and the hazardous waste amount is reduced and the cost is further reduced.

Owner:HUNAN RES INST FOR NONFERROUS METALS

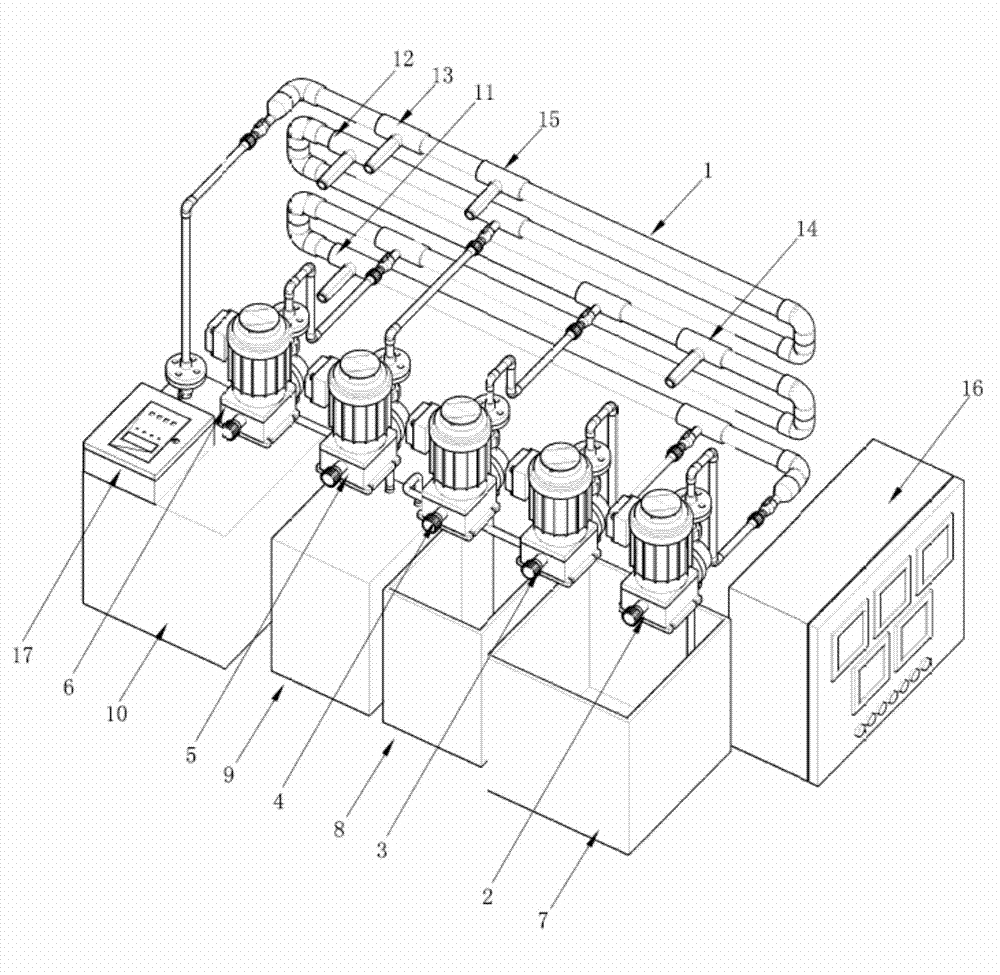

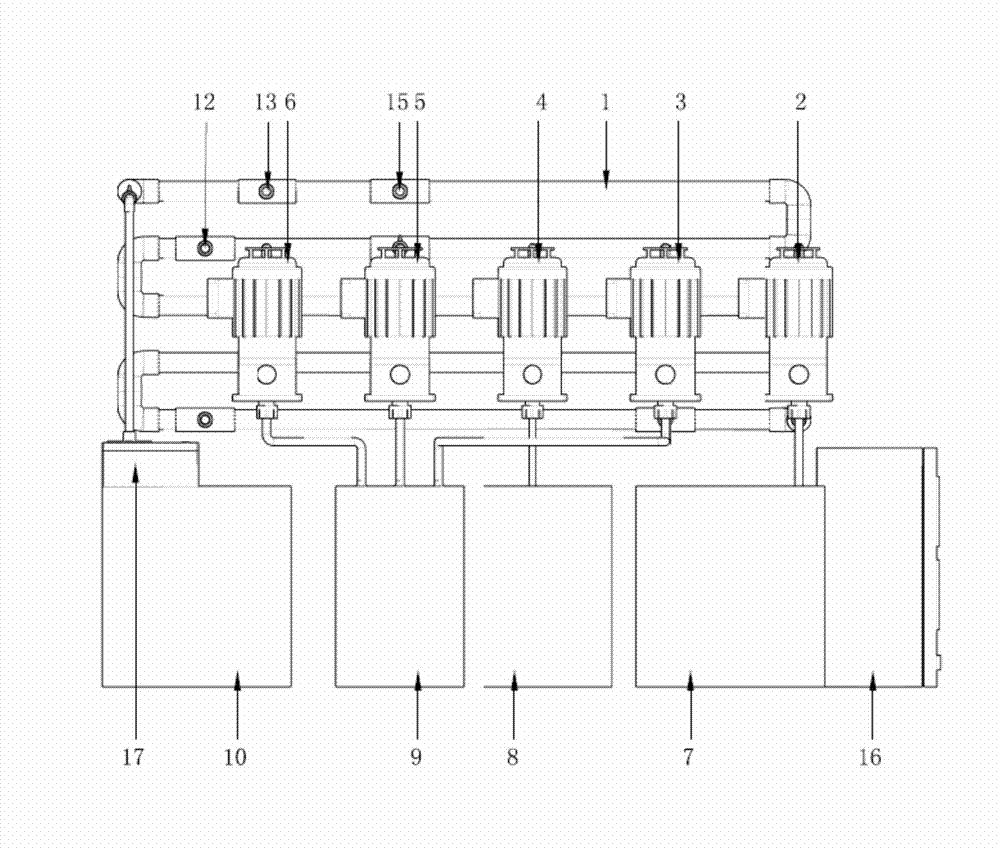

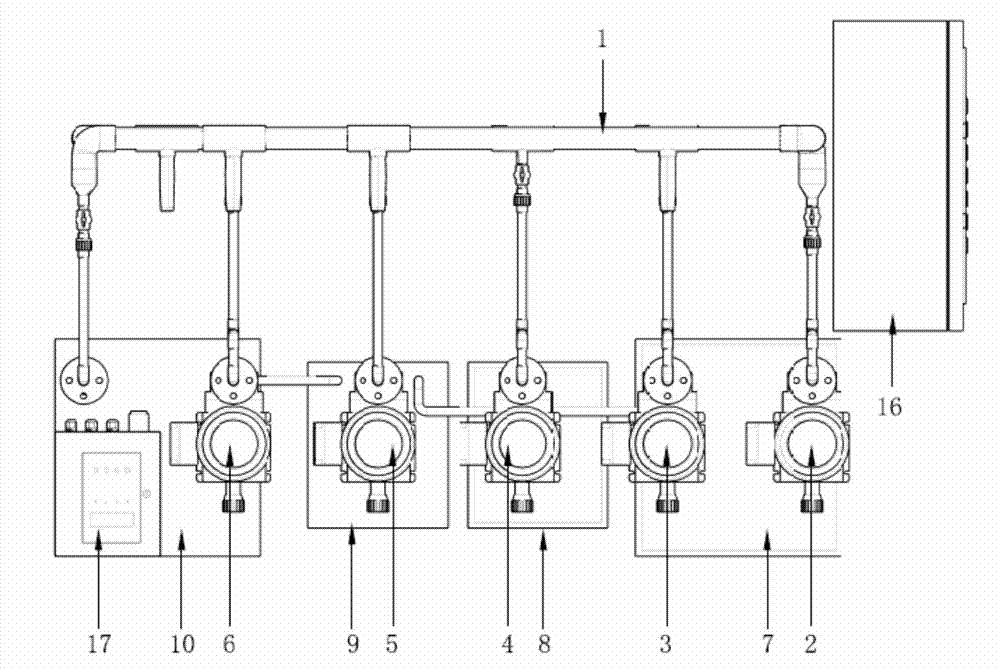

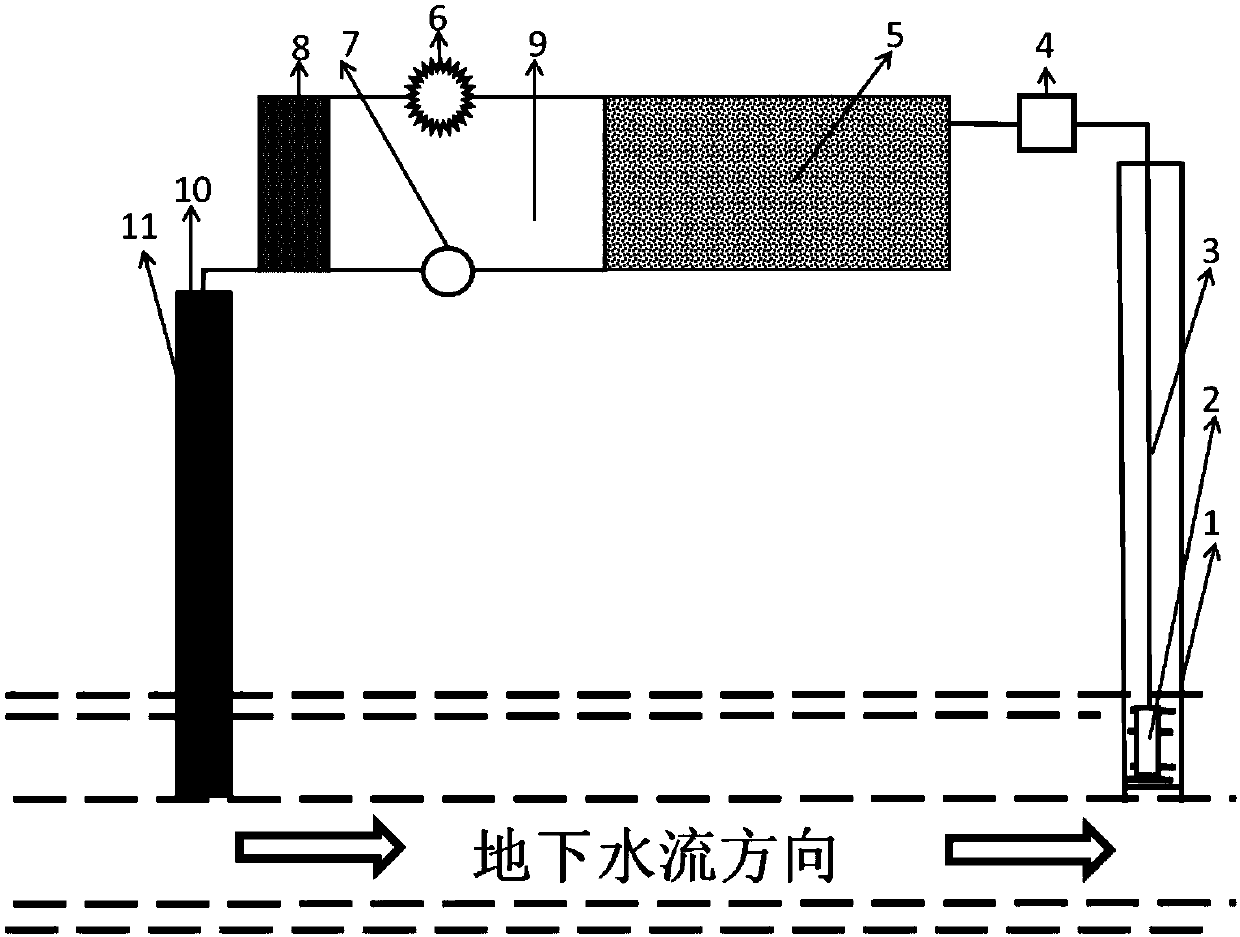

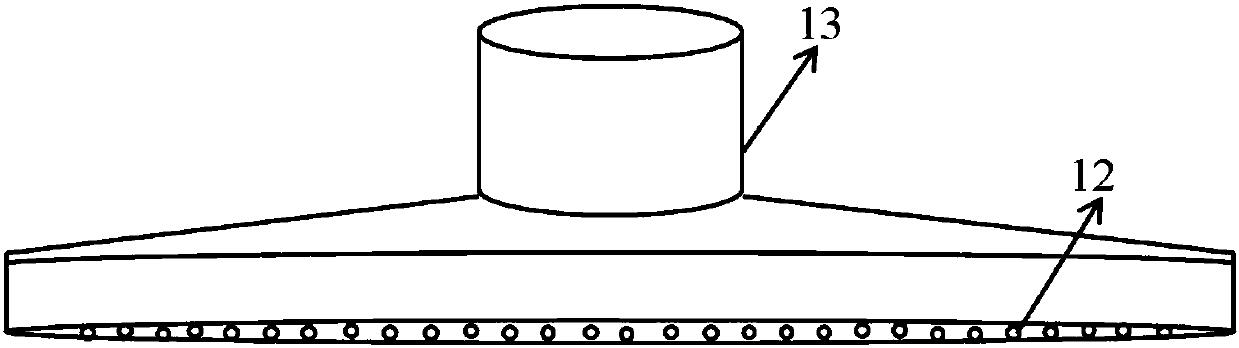

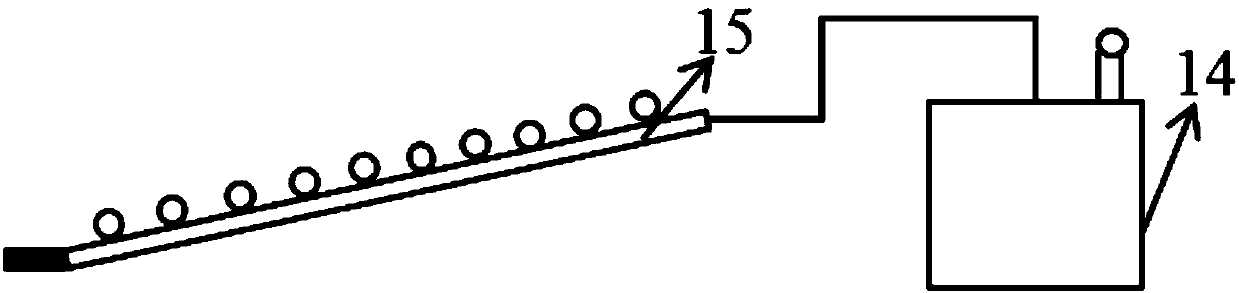

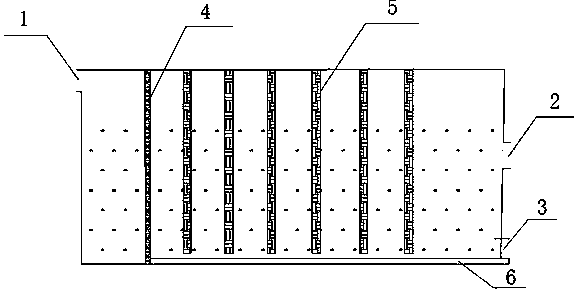

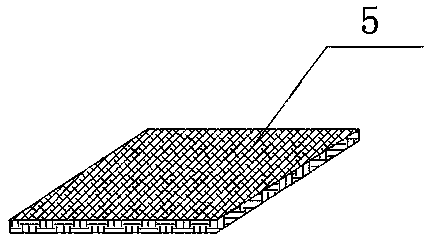

A device and method for eliminating underground water arsenic pollution

InactiveCN107555679AHigh arsenic removal efficiencyPrevent compactionMultistage water/sewage treatmentContaminated groundwater/leachate treatmentActivated carbonArsenic pollution

A device for eliminating underground water arsenic pollution is provided. The device includes a water suction system, a reinjection system and a treatment system between the water suction system and the reinjection system. According to the water suction system, a water suction pump is disposed in a water suction well, and is connected to a pretreatment zone in the treatment system through a watersuction pipe, and the water suction pump is connected to a flow rate controller. The treatment system includes the pretreatment zone and a treatment zone, wherein the pretreatment zone is a layer filled with activated carbon and fine sand, a water inlet of the pretreatment zone is connected to the water suction pump through the water suction pipe, the upper end of the treatment zone is provided with a zero-valent iron feeding device, the lower end of the treatment zone is provided with a nanometer aeration device, one end of the treatment zone is provided with an osmotic membrane, and a wateroutlet of the treatment zone is connected to a reinjection well of the reinjection system. The reinjection well of the reinjection system is filled with a reinjection filler. A method for eliminatingunderground water arsenic pollution by utilizing the device is also disclosed.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

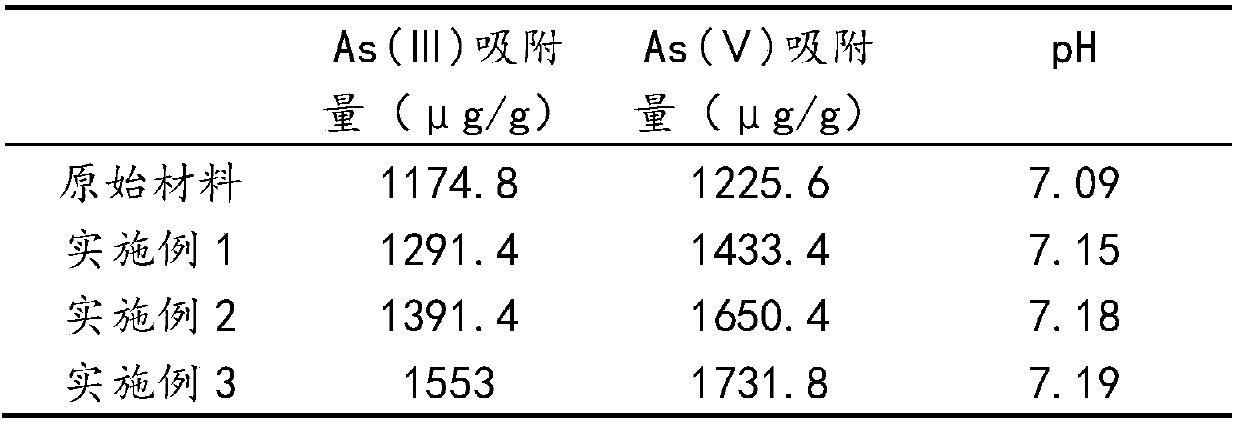

Preparation method of modified steel slag for removing arsenic from water body

InactiveCN108031429AImprove adsorption capacityWill not desorbOther chemical processesWater contaminantsSlagAdsorption effect

The invention relates to a preparation method of modified steel slag for removing arsenic from water body. The preparation method comprises the following steps: cleaning the steel slag, and drying thesteel slag until the weight of the steel slag is constant for standby use; adding the steel slag which is dried to the constant weight into a culture solution comprising iron oxidizing bacteria, performing erosion soaking, and obtaining modified steel slag. The preparation method has the beneficial effects that the modified steel slag prepared by the invention has the characteristics that the modification method is simple, the cost is low, raw materials are easy to obtain, and the effect for removing arsenic from water is apparent; compared with the original steel slag, the adsorption capacity of the modified material for the arsenic is increased by 32.2 to 41.3 percent; in addition, the adsorption effect is little influenced by the temperature, the adsorbed arsenic cannot be desorbed inneutral water after the saturated adsorption, the modified steel slag is high in arsenic removal efficiency and high in saturated adsorption capacity, the material is stable after the adsorption, thesecondary pollution is avoided, and the recycling of solid waste is realized.

Owner:WUHAN UNIV OF TECH

Method and composition to reduce the amounts of arsenic in water

InactiveUS7790653B2High arsenic removal efficiencyIncrease the areaOther chemical processesWater contaminantsRural areaMaceral

The present invention relates to a method for removing arsenic in arsenic contaminated water, especially for small drinking water systems such as those used in individual homes, rural areas, and small communities, by simply contacting arsenic-contaminated water with an arsenic removal medium. The present invention also relates to the composition of the arsenic removal medium, which comprises particles of calcium carbonate minerals and magnesium carbonate aggregates.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

A method of using microorganisms to treat wastewater containing trivalent arsenic

ActiveCN106698821BEasy to handleReduce processing costsWater contaminantsMultistage water/sewage treatmentMicroorganismHydrogen

The invention discloses a method for treating wastewater containing trivalent arsenic by utilizing microorganisms. The method comprises the following steps: adding ferrous salt into wastewater to be treated which contains the trivalent arsenic; meanwhile, adding iron-oxidizing bacteria which stays at a growth logarithmic period; adjusting the pH (Potential of Hydrogen) to be 1.6 to 2.8; controlling the temperature to be 25 DEG C to 30 DEG C; uniformly stirring and reacting for 3d to 5d; standing and precipitating the trivalent arsenic in a form of tooeleite; filtering and finishing treatment. A microorganism oxidization method disclosed by the invention can be used for treating the arsenic-containing wastewater with the arsenic content of 3.56g / L to 7.57g / L and adjusting the pH to be 1.6 to 2.8; at room temprature of 25 DEG C to 30 DEG C, the removal rate of the trivalent arsenic within 3d to 4d can reach about 98 percent; the method has the advantages that the raw materials are easy to obtain, the operation is simple and the treatment cost is low; obtained sediment is easy to separate and the arsenic content is high; the stability is good and no secondary pollution is caused.

Owner:CENT SOUTH UNIV

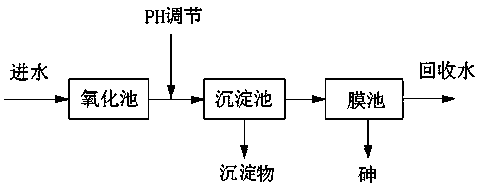

Arsenic removal film for treating arsenic-containing wastewater in mine

InactiveCN108970420AImproves Strength and ToughnessGuaranteed porosityWaste water treatment from quariesMembranesFiberGlass fiber

The invention discloses an arsenic removal film for treating arsenic-containing wastewater in a mine. The arsenic removal film is prepared from the following raw materials: bamboo pulp fiber, glass fiber and eggshell powder, and the bamboo pulp fiber is mixed with the glass fiber and then wet process paper technology is used for papermaking the arsenic removal film, and the bamboo pulp fiber and the glass fiber are evenly spread out in a crisscross pattern. The bamboo pulp fiber, the glass fiber and the egg shell powder of the arsenic removal film has multiple functions, and the film made by the three has a very good separation and purification effect on arsenic in the arsenic-containing wastewater in the mine, and greatly improves the efficiency of arsenic removal. .

Owner:黄林海

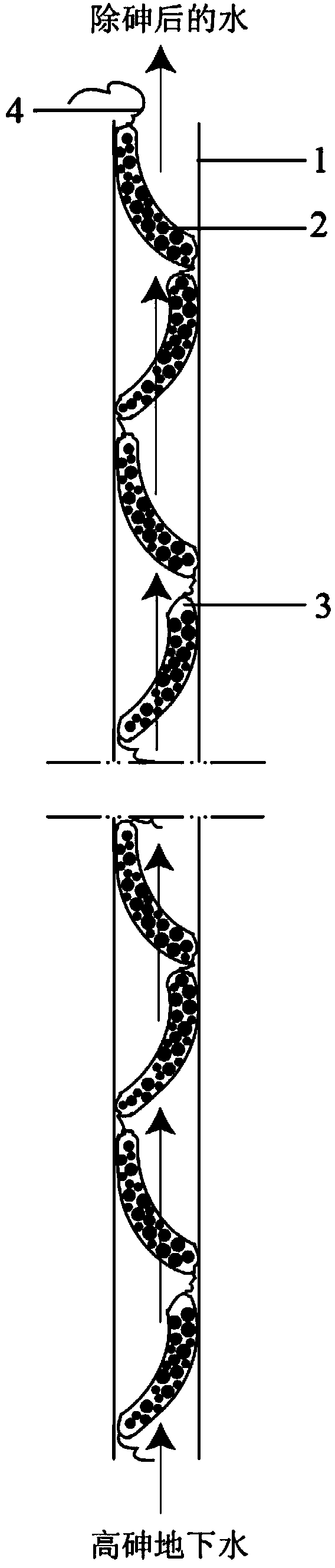

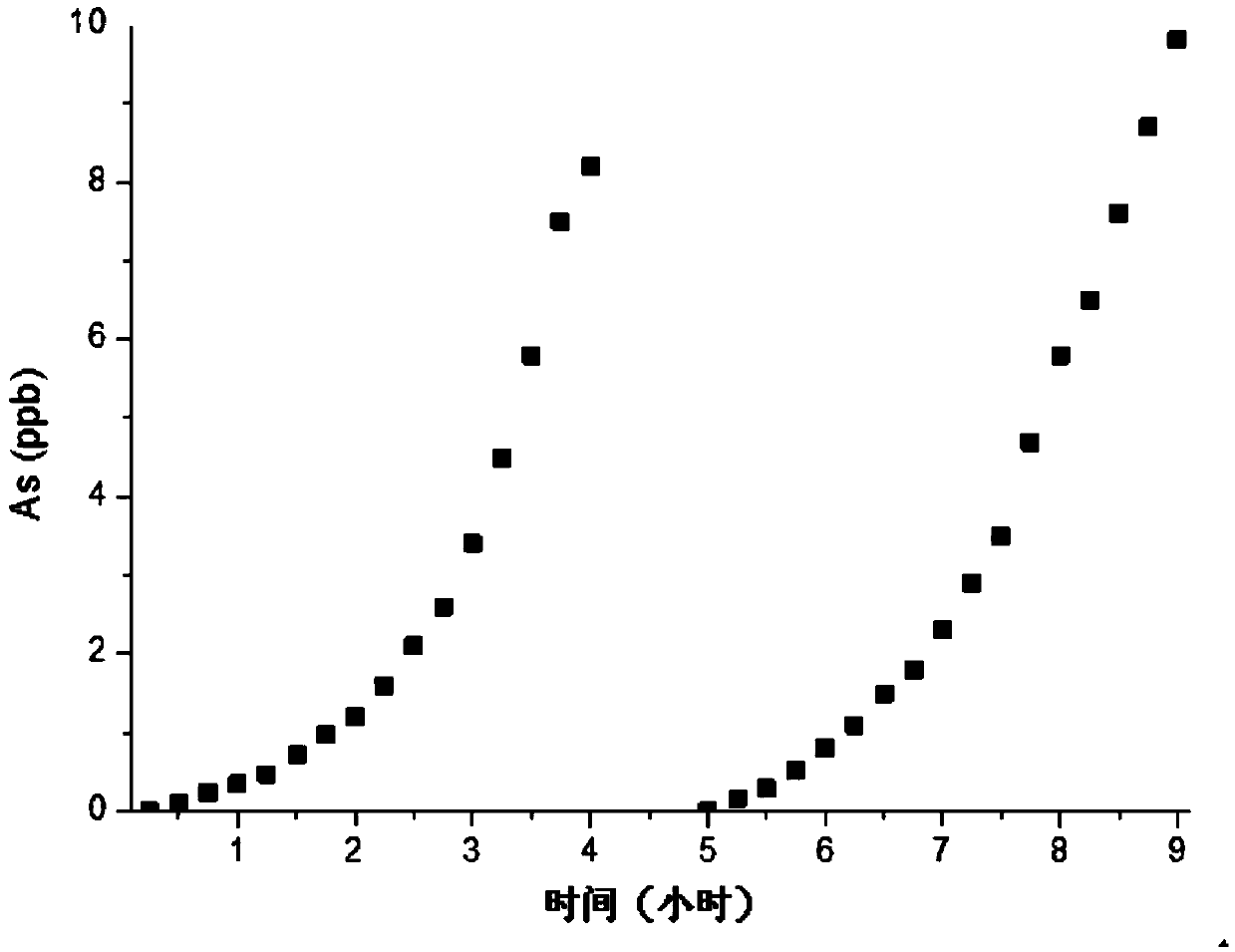

Arsenic removal method for rural well in high-arsenic underground water region

ActiveCN103739057AEasy to operateEasy to manage and maintainWater/sewage treatment by sorptionWater/sewage treatment by oxidationIonSupply energy

The invention provides an arsenic removal method for a rural well in a high-arsenic underground water region. The arsenic removal method comprises the following steps: filling a plurality of filter screen bags with cement balls loaded with nano-scale ion and manganese oxides on the surface taken as a particle filter material, and connecting the filter screen bags in a head-to-tail end so as to form a wave-shaped long strip arsenic removal belt, and arranging the long strip arsenic removal belt in water of the well in a suspended manner so as to remove arsenic in water. The method is designed according to the characteristics of a water supply method for the rural well in the high-arsenic underground water region, and the arsenic removal effect of high-arsenic underground water is good; moreover, raw materials are low in cost and are easily available, the technical requirements are simple, the checking and the maintenance are convenient, the administrative and management costs are low, external electric power or other energy supply facility is not needed, and the method is extremely suitable for being popularized and used in the rural well in the high-arsenic underground water region.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Arsenic removing method of iron ore

InactiveCN108913878AGood arsenic removal effectHigh arsenic removal efficiencyProcess efficiency improvementArsenicSolid matter

The invention discloses an arsenic removing method of iron ore. The method comprises the following steps that 1) ore pulp is prepared; 2) biological arsenic removing is performed; 3) grinding is performed; 4) oxidizing roasting is performed, specifically, a mixture C obtained in the step 3) is subjected to oxidizing roasting under the weak oxidization atmosphere, the mixture C is constantly stirred in the oxidizing roasting process, flowing carrier gas is introduced and used for expelling a produced gas D, and a solid matter obtained after oxidizing roasting is completed is arsenic-removed iron ore; and 5) recovery is cycled. The method has a remarkable arsenic removing effect on the arsenic-contained iron ore, through mutual cooperation of biological arsenic removing and gasification arsenic removing, and the arsenic removing efficiency is effectively improved; and meanwhile, the produced gasification arsenic removing products are subjected to recovery and recycling treatment, environmental pollution to the environment is reduced, environment pollution is small, and comprehensive utilization of arsenic-contained ore resources can be achieved easily.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Normal temperature de-arsenic agent

ActiveCN101485971BGood dispersionIncrease contactOther chemical processesActive componentRoom temperature

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Treatment method of arsenic wastewater

ActiveCN103112974BShort process routeShort construction periodMultistage water/sewage treatmentFlocculationElectrolysis

The invention discloses a method for treating arsenic-containing wastewater, which comprises the following steps: selectively adding acid solution to the arsenic-containing wastewater to adjust its pH value from 0 to 5; then passing the arsenic-containing wastewater into a reaction device, Continuous treatment and removal of arsenic by adding sulfide in multiple stages; solid-liquid separation of the effluent after reaction, and recycling of the separated arsenic slag; addition of alkali to the separated effluent, electrochemical advanced treatment of the effluent, electrochemical advanced treatment includes electrolysis Coagulation, electrolytic air flotation and electrolytic redox steps; in electrolytic coagulation, cations are generated by electrolysis of soluble anode iron plates for flocculation; the subsequent effluent is aerated and oxidized to generate flocs containing ferric ions in the effluent, The micelle-like precipitate is then separated from the solid and liquid, and the separated supernatant can be recycled or discharged up to the standard. The invention has the advantages of short process, small investment, low cost, high resource recycling rate, environmental protection, continuous processing and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

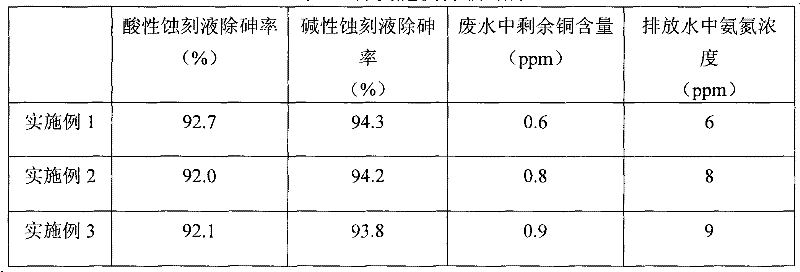

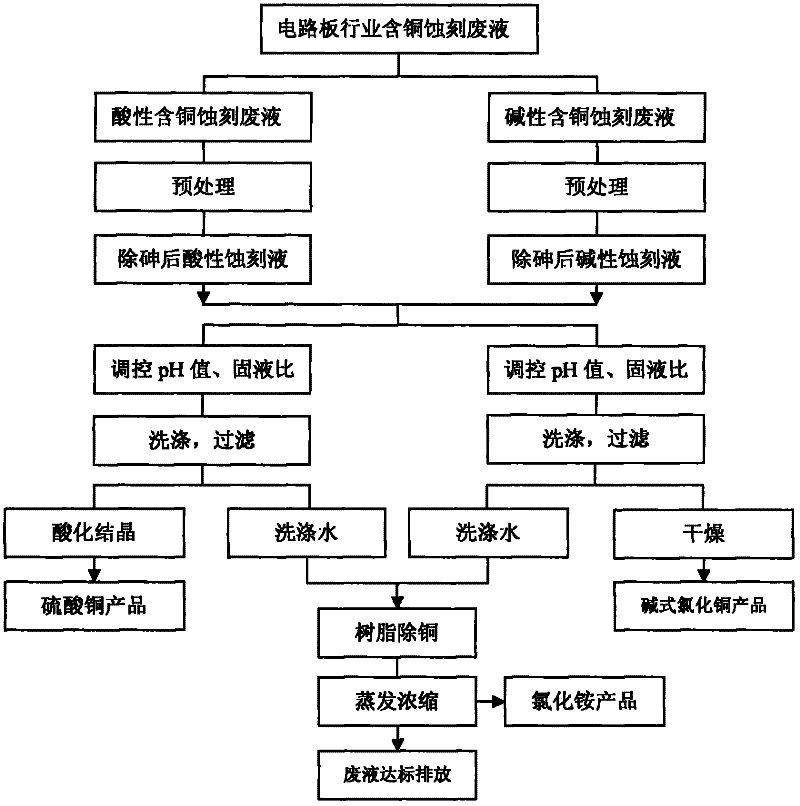

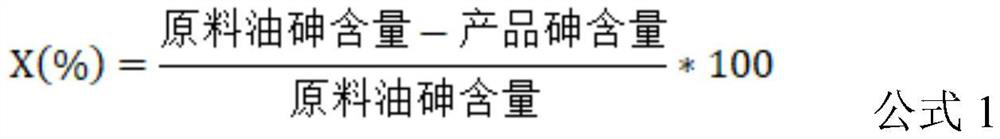

Method for resource utilization and innocent treatment of etching waste liquid containing copper in circuit board industry

ActiveCN102107978BHigh arsenic removal efficiencySimple arsenic removal processAnimal feeding stuffAccessory food factorsAcid etchingDesorption

The invention discloses a method for resource utilization and innocent treatment of etching waste liquid containing copper in the circuit board industry. The method comprises the following steps of: pre-treating acid etching waste liquid containing the copper and alkali etching waste liquid containing the copper; performing a neutralization reaction of the pre-treated etching waste liquid to generate copper sulphate and basic copper chloride, recovering the copper from remaining wastewater containing low-concentration copper through absorption by adopting an ion exchange technology after mostcopper is recovered, and obtaining a regenerated copper chloride raw material after resin desorption; and evaporating remaining copper-free wastewater, i.e. ammonia nitrogen wastewater, by using a multi-effect evaporator to recover an ammonium chloride product which can be used as a regenerated etching liquid, and discharging the remaining wastewater up to the standard. By the method, the pollution problem of heavy metal ions to the environment is solved, and cyclic utilization of the waste liquid for production of other products can be realized, so the resources are saved and the environmentis protected.

Owner:惠州TCL环境科技有限公司

Arsenic removal method for preparing bio-adsorbent from traditional Chinese medicine waste residues

PendingCN112473632AEasy accessLow costOther chemical processesWater contaminantsSorbentProcess engineering

The invention discloses an arsenic removal method for preparing a biological adsorbent from traditional Chinese medicine waste residues, which comprises the following steps: washing the traditional Chinese medicine waste residues, performing drying in an oven, taking the traditional Chinese medicine waste residues out, performing pulverizing and screening to obtain waste residue powder; adding theobtained waste residue powder into a FeCl3 solution, performing stirring to react, and performing filtering, cleaning and drying to obtain a biological adsorbent; and adding the obtained biological adsorbent into arsenic-containing waste liquid to be treated, and stirring for reaction to remove arsenic. According to the method, traditional Chinese medicine waste residues obtained after a pharmaceutical process in the traditional Chinese medicine industry is finished are subjected to physicochemical treatment and then modified to obtain the biomass adsorption material, the biomass adsorption material reacts with low-concentration arsenic-containing wastewater, the final arsenic removal efficiency can reach 98%, and compared with other methods, the method is low in cost, raw materials are easy to obtain, the process is simple, and the removal efficiency is high.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Adsorption arsenic removal catalyst and preparation method thereof

PendingCN114377668AIncrease profitFacilitated DiffusionCatalyst carriersCatalyst activation/preparationActivated carbonPtru catalyst

The invention discloses a catalytic cracking gasoline adsorption dearsenification catalyst with large specific surface area, hierarchical pore distribution and high dearsenification performance and a preparation method thereof, and the method comprises the following steps: 1) mixing active carbon and pseudo-boehmite in proportion, grinding, stirring, adding a pore-enlarging agent and an acid solution, extruding into strips, drying, and roasting under an anaerobic condition to prepare a carbon-alumina composite carrier; (2) adjusting the pH value of the metal precursor solution, and impregnating the solution containing the active metal precursor into the carrier by adopting an isovolumetric saturated impregnation method; and 3) drying the catalyst, and roasting in an oxygen-free environment to obtain the finished product catalyst. The carrier with a composite pore channel structure can improve diffusion, reaction and escape of reactant molecules in pore channels, and the reaction efficiency is improved; metal with partially filled d tracks is selected as active metal, so that the acting force between the arsenide and the metal can be improved, and the arsenide is deeply removed; the pH value of the metal precursor solution is adjusted to be higher than the isoelectric point of the metal oxide or hydroxide, the acting force between the metal and the carrier can be weakened, the dispersity of the metal is improved, and finally the arsenic removal efficiency of the catalyst is improved.

Owner:PETROCHINA CO LTD

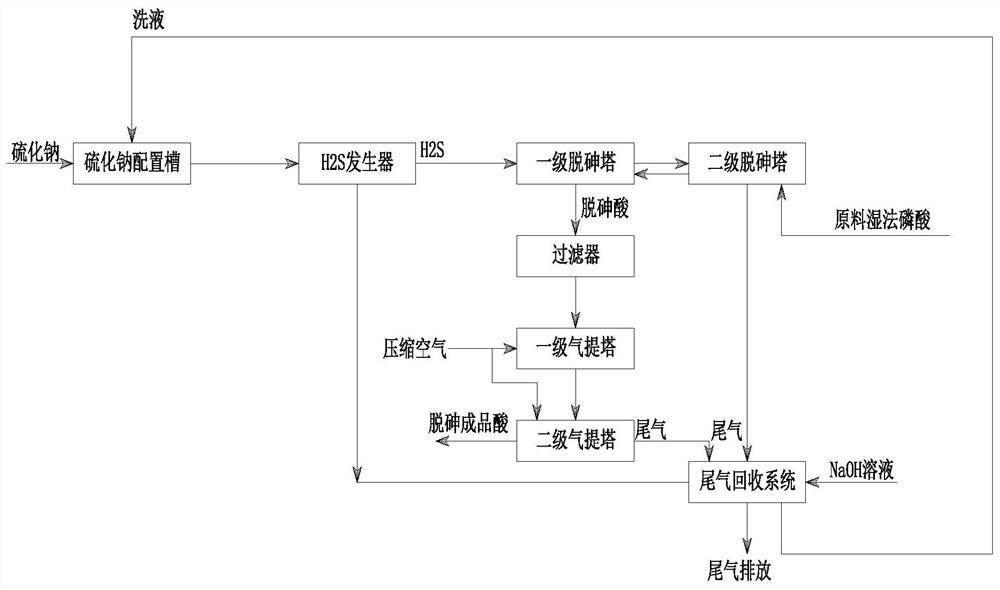

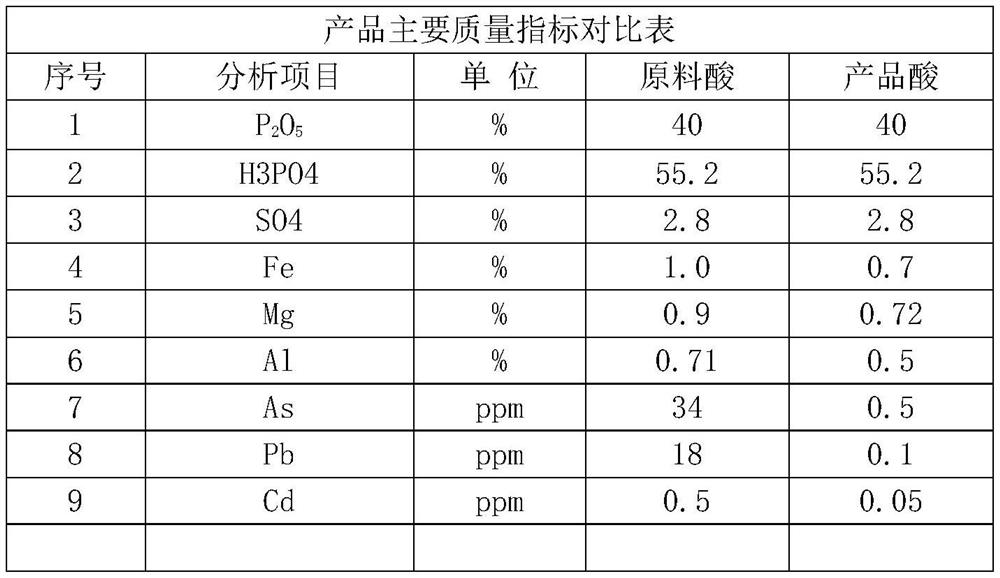

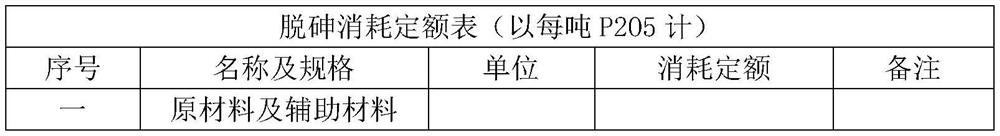

Wet Process Phosphoric Acid Removal Process

ActiveCN112225188BSynchronous removalImprove solubilityHydrogen sulfidesPhosphorus compoundsO-Phosphoric AcidPhosphate

The invention discloses a process for removing arsenic by wet-process phosphoric acid. 2 S gas with a concentration of 35‑45% P 2 o 5 The wet-process phosphoric acid is countercurrently contacted in a two-stage arsenic removal tower. In the arsenic removal tower, H 2 S dissolves in wet-process phosphoric acid and ionizes to S 2+ , ionized S 2+ As in phosphoric acid 3+ Generate As 2 S 3 Arsenic slag, As 2 S 3 The arsenic slag crystallizes and grows into a crystal. After the reaction, the wet-process phosphoric acid containing arsenic slag is filtered to remove the arsenic slag, and then sent to the stripping tower to strip the H dissolved in the acid. 2 S gas, the dearsenic acid after stripping is sent to the follow-up device as a finished product; compressed air is introduced into the stripping tower as stripping gas to contact with the phosphoric acid after deslagging in countercurrent. The invention has the advantages of simple process, high arsenic removal efficiency, small consumption of arsenic removal agent, good air stripping effect, and residual H in the product phosphoric acid 2 S is low, the process is environmentally friendly, and the production and operation costs are low.

Owner:WUHUAN ENG

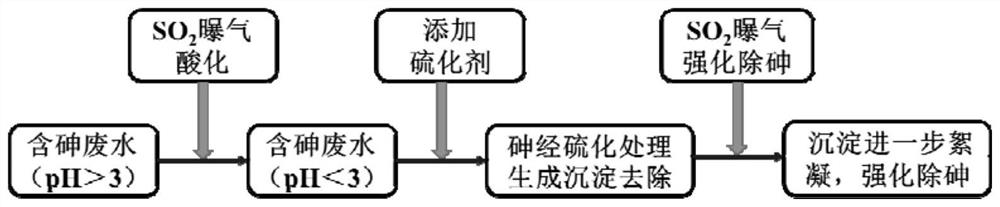

Method for strengthening sulfidizing treatment of arsenic-containing wastewater by utilizing sulfur dioxide

PendingCN113443690AImprove stabilitySolve secondary pollutionWater contaminantsWater/sewage treatment by flocculation/precipitationSulfidationWastewater

The invention relates to a method for strengthening sulfidizing treatment of arsenic-containing wastewater by utilizing sulfur dioxide. The method comprises the following steps of: 1, introducing sulfur dioxide gas with a proper concentration into the arsenic-containing wastewater with a pH value of more than 3, and rapidly reducing the pH value of the wastewater; 2, when the pH value of the wastewater is lower than 3, stopping aeration with the sulfur dioxide gas, and then adding a sulfidizing agent to enable sulfide precipitates to gradually aggregate and grow; 3, introducing sulfur dioxide gas into the sulfurized wastewater in a stirring state again; and 4, filtering the treated wastewater to obtain arsenic sulfide slag, recycling the arsenic sulfide slag, and subjecting low-concentration arsenic waste liquid formed by a supernatant to deep removal of arsenic. Compared with the prior art, the arsenic removal efficiency of the wastewater can be remarkably improved, and meanwhile, the problems of acid consumption and additional waste salt generation caused by pH value adjustment of the wastewater can be solved; and the method has the good effects of recycling resources and treating the waste with the waste.

Owner:SHANGHAI JIAO TONG UNIV

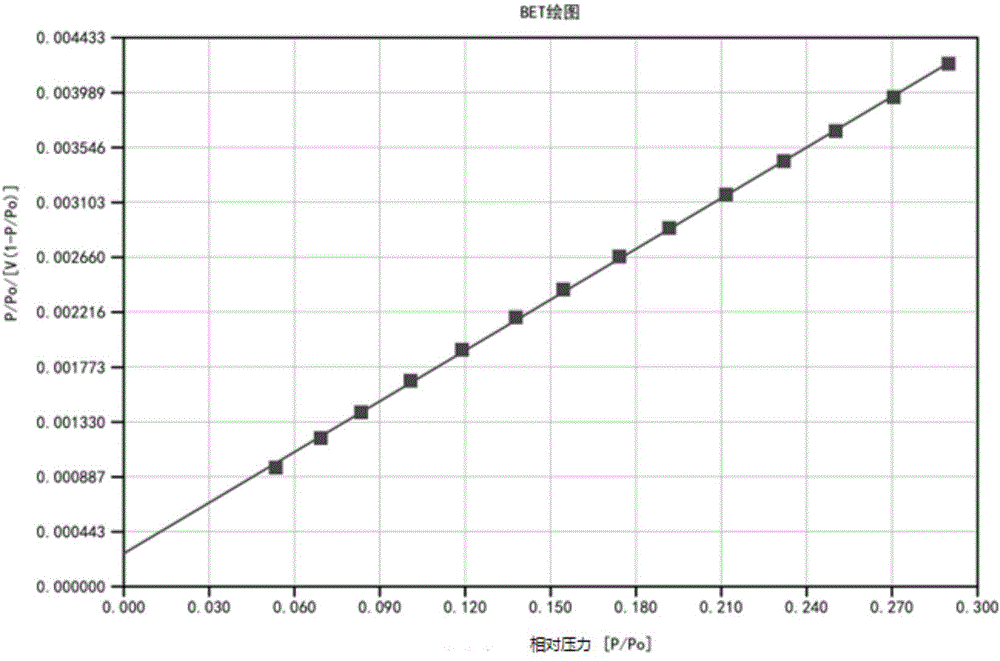

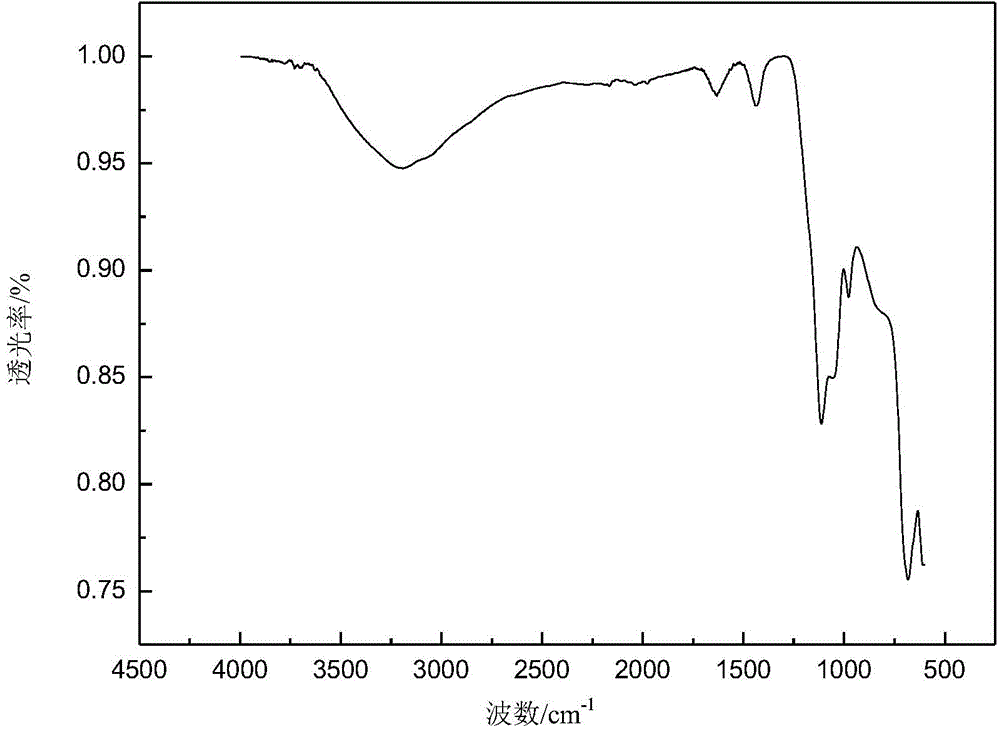

Method for adsorbing and removing arsenic by using iron-manganese oxide/mesoporous silica adsorbent

InactiveCN111569823AHigh arsenic removal efficiencyHigh porosityOther chemical processesWater contaminantsManganese oxideArsenic

The invention relates to a method for adsorbing and removing arsenic by using an iron-manganese oxide / mesoporous silica adsorbent, and belongs to the technical field of heavy metal pollution treatment. The iron-manganese oxide / mesoporous silica adsorbent is prepared by taking mesoporous silica as a carrier and loading the iron-manganese oxide, the agglomeration effect of the iron-manganese oxide is reduced by adding the mesoporous silica, and the porosity and the corresponding arsenic removal efficiency of the adsorbent can be improved by taking the silica as the carrier and loading the iron-manganese oxide. The preparation method of the adsorbent is simple, the adsorption amount for an arsenic solution is large, the adsorption rate is high, and the adsorbent has a wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

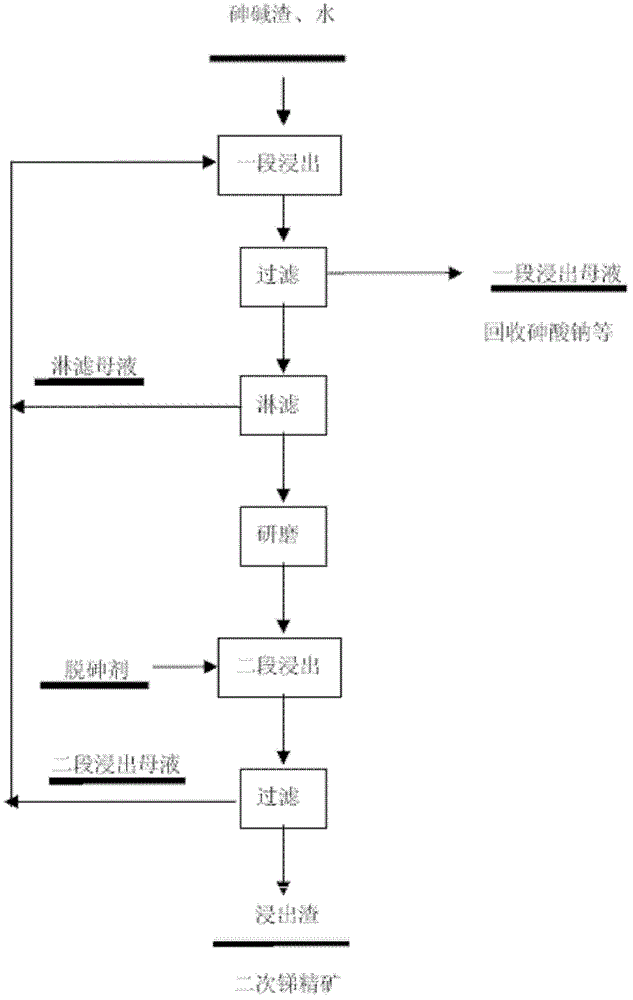

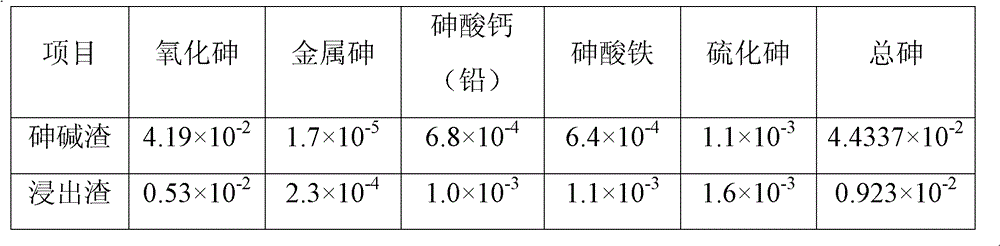

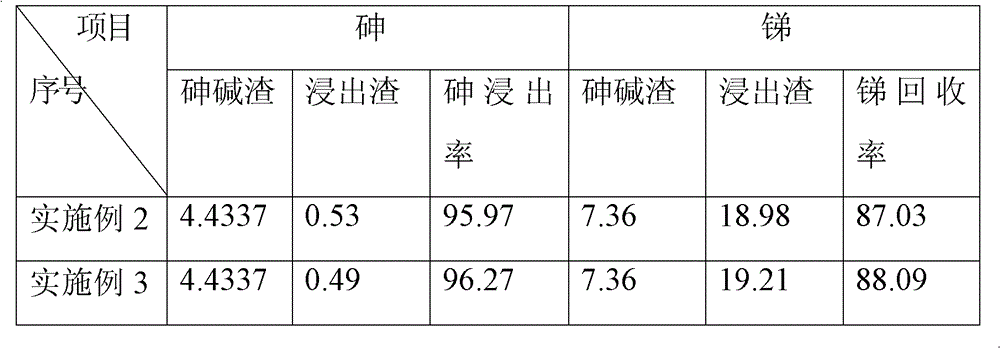

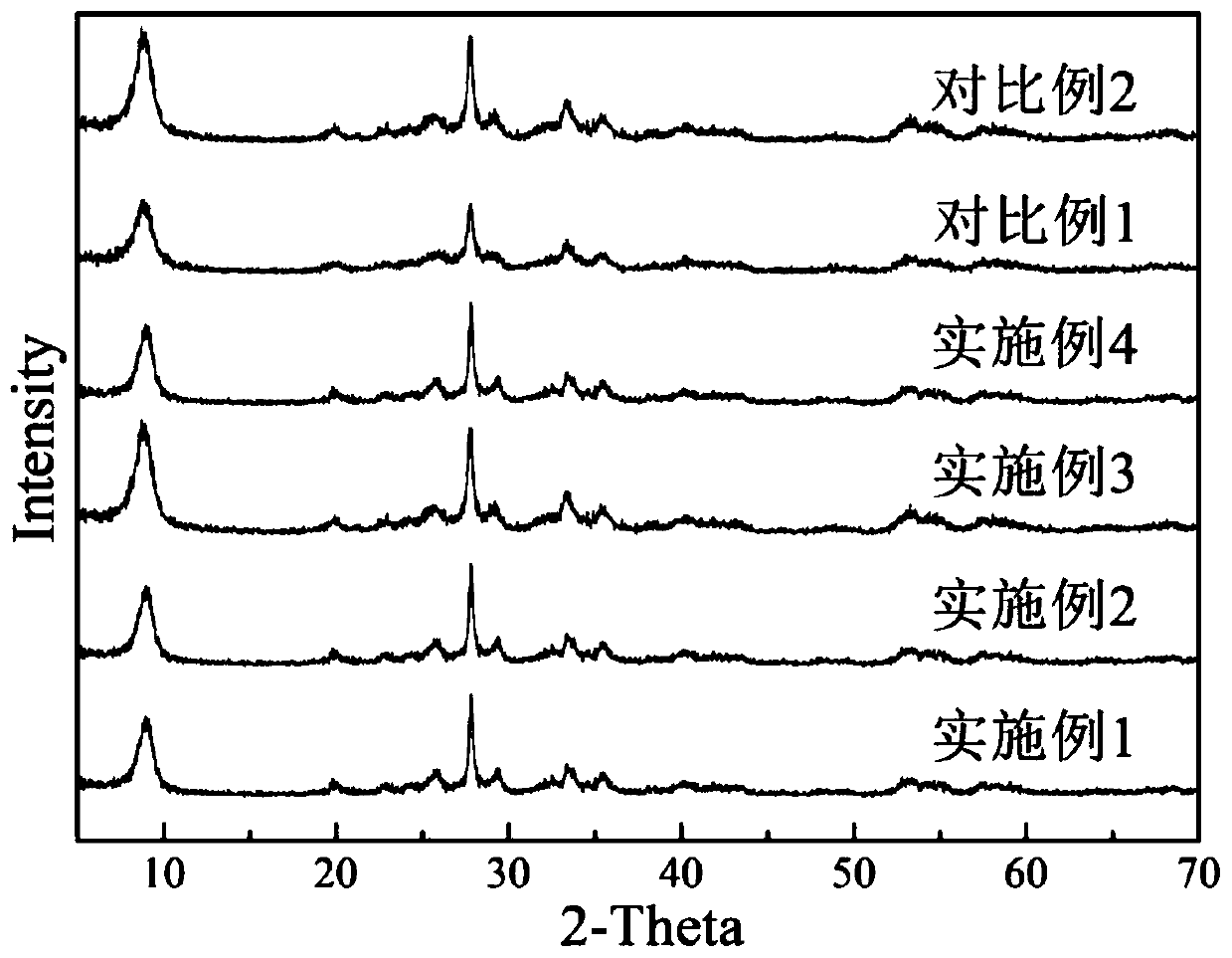

Method for dearsenization through hot leaching of arsenic alkali residue water

ActiveCN102382989BSimple process routeHigh arsenic removal efficiencyProcess efficiency improvementSmelting processSodium sulfate

The invention provides a method for dearsenization through hot leaching of arsenic alkali residue water, which comprises the following specific steps: crushing arsenic alkali residue into particle being smaller than 5mm, and then performing first hot leaching with water; filtering and separating the firstly leached mother liquid and residue, and collecting the firstly leached mother liquid to be used for recovering sodium carbonate, sodium arsenate or sodium sulfate and the like; leaching the filter residue, water ratio of the filter residue being reduced to 30%-50%, and leaching the mother solution to be reused as first leaching water; grinding and crushing leached filter residue to particle being less than 0.35mm of particle size (42 mesh), then adding hydrodearsenic catalyst for secondwater hot leaching, after being filtered, the obtained second leached mother solution being reused as first leaching water; and water ratio of the filtered residue being reduced to 30%-50%. With the invention, the leaching rate of arsenic reaches more than 95%, arsenic content of the leached residue is less than 0.5%, the leaching rate of arsenic is improved, arsenic content of the leached residue is reduced, the harmful effect of over-high arsenic content of the leached residue on antimony smelting process is solved, and comprehensive utilization of arsenic alkali residue can be effectively realized.

Owner:HUNAN RES INST FOR NONFERROUS METALS +2

A method for treating wastewater containing trivalent arsenic

ActiveCN107010704BHigh arsenic removal efficiencyHigh Precipitated Arsenic ContentWater contaminantsWater/sewage treatment by flocculation/precipitationIron saltsHydrogen

The invention discloses a method for treating wastewater with trivalent arsenic. The method includes simultaneously feeding the to-be-treated wastewater with the trivalent arsenic, iron salt solution and sulfate solution and simultaneously sufficiently colliding the to-be-treated wastewater, the iron salt solution and the sulfate solution with one another to obtain first mixtures; regulating the pH (potential of hydrogen) of the first mixtures until the pH of the first mixtures reaches 1.8-3.0; uniformly mixing the first mixtures with one another at the normal temperature; carrying out reaction; separating precipitates. The method has the advantages that feeding reaction is carried out under the conditions of the temperatures of 25+ / -1 DEG C, the speeds of 600+ / -20 r / min and the pH of 2.4 for 18 min when the arsenic solution with the As <3+> content of 20.5 g / L, the iron salt solution with the Fe <3+> content of 23.0 g / L and the sulfate solution with the SO<4><2-> content of 6.56 g / L are added into 30 mL of deionized water at the speeds of 1.8 mL / min, water hydroxyl sarmientite minerals are good in crystallization, and the As <3+> removal rate is 87.6%; the method for treating the wastewater with the trivalent arsenic is high in arsenic removal efficiency, good effects can be realized, raw materials are low in cost and are easily available, conditions are mild, procedures can be controlled, the precipitates are high in arsenic content, are stable and are easy to separate, secondary pollution can be prevented, and accordingly the method has a broad practical application prospect.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com