A method of using microorganisms to treat wastewater containing trivalent arsenic

A technology for microbial treatment and wastewater treatment, applied in biological water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing operation difficulty, increasing treatment cost, long reaction time, etc. Less pollution, lower treatment costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

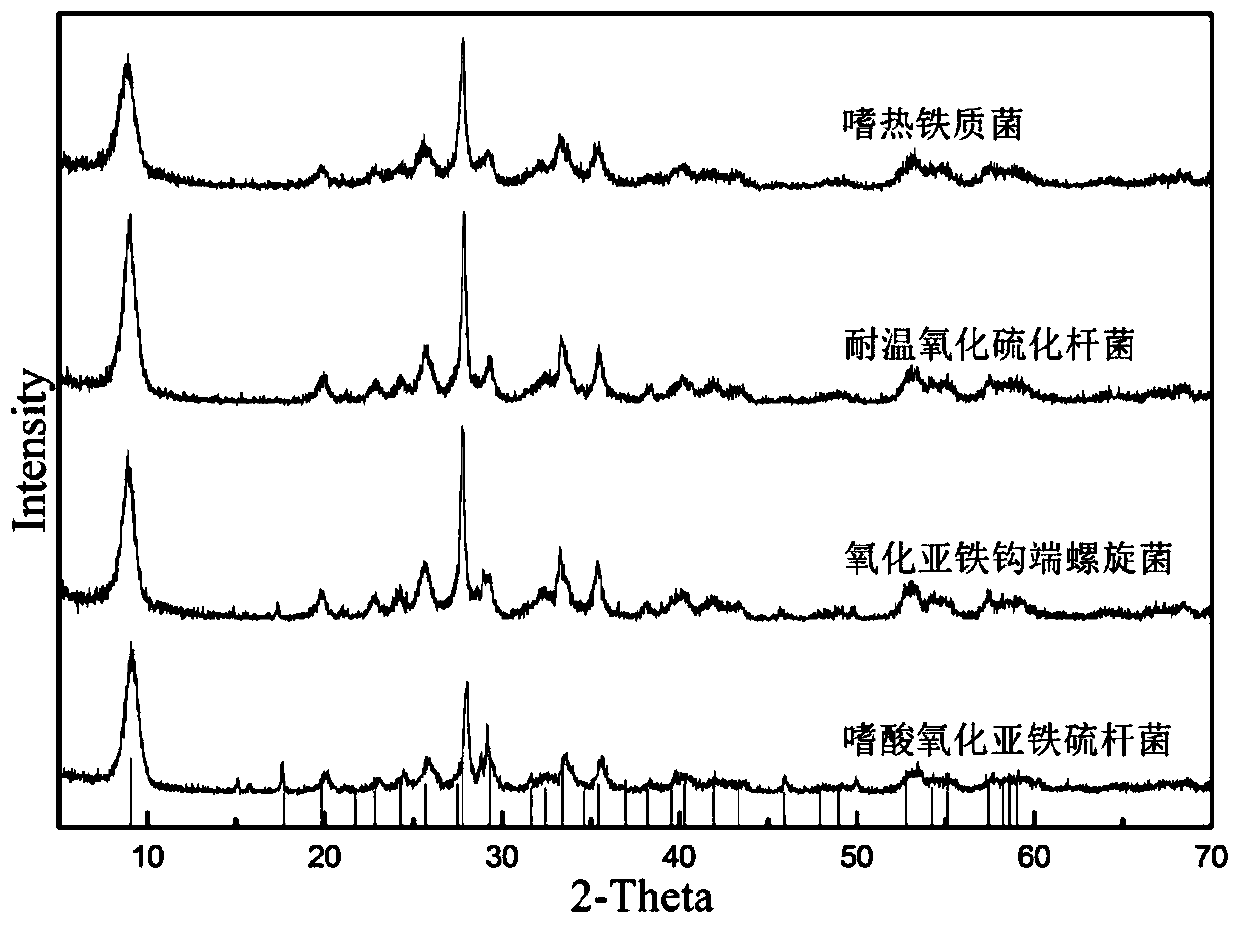

[0033] This embodiment compares different bacteria to process containing As 3+ The impact of wastewater, the specific process is as follows: 3+ Add 44.7g / L FeSO to the wastewater to be treated with a concentration of 2.88g / L (calculated as arsenic) 4 ·7H 2 After O, inoculate acidophilic Thiobacillus ferrooxidans, Leptospira ferrousoxidans, thermostable Sulfobacillus oxidans and thermophilic ferrooxidans in logarithmic phase of growth respectively, the inoculum volume is V 菌 :V 废水 =1:10, the concentration is 2.4-5.2×10 7 Units / mL is calculated, under the conditions of temperature 30°C, pH=2.0, stirring speed 160-180r / min, after normal pressure reaction for 5 days, the solution is left to stand, the precipitate is filtered, and the filtrate is recovered to complete the treatment of arsenic-containing wastewater.

[0034] figure 1 For different bacterial pairs containing As 3+ The XRD pattern of the precipitate obtained from the wastewater to be treated with a concentration...

Embodiment 2

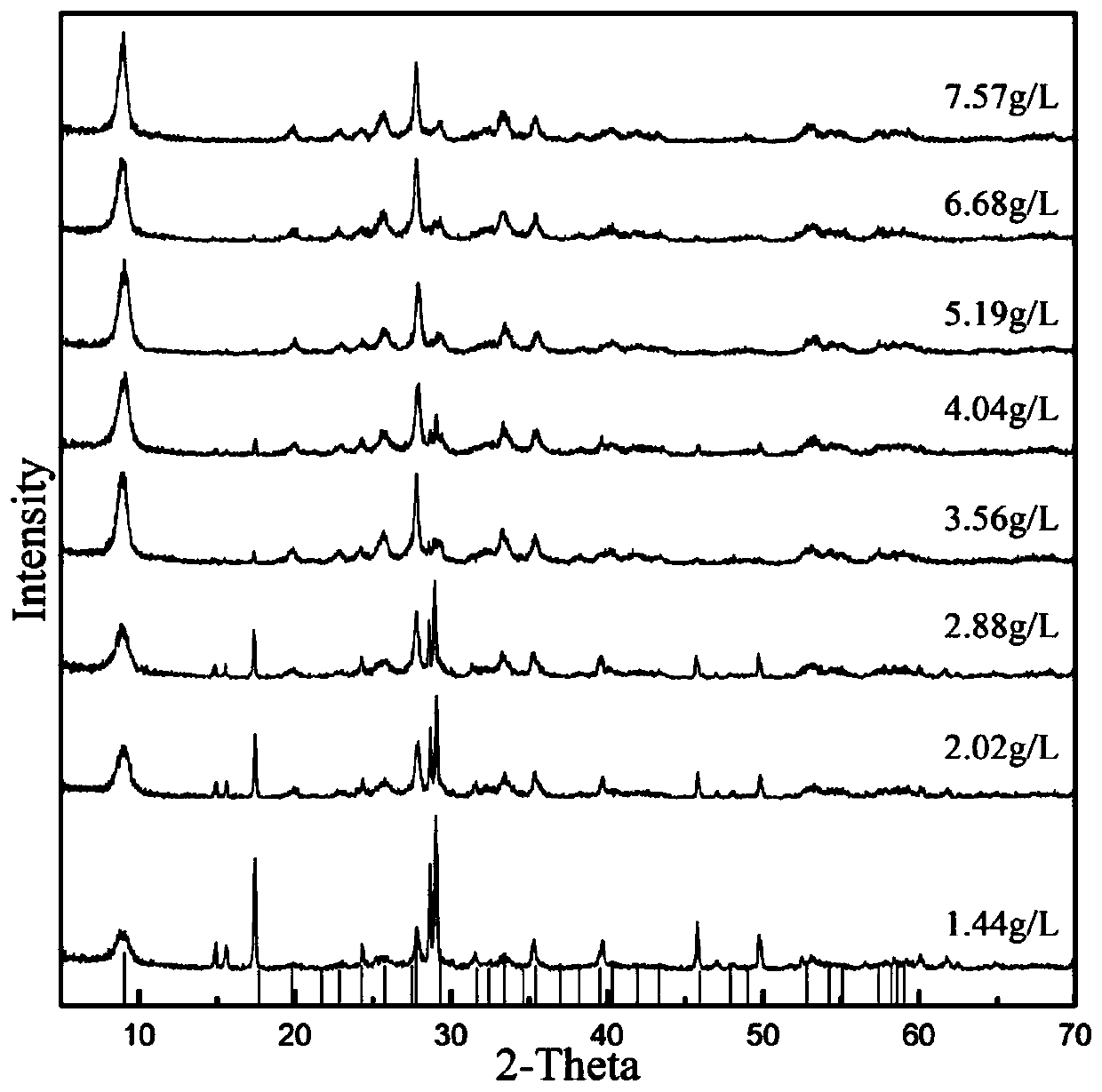

[0037] This example compares the thermotolerant oxidative sulfur bacteria to the treatment containing different As 3+ Concentration of wastewater, the specific process is as follows: in the As-containing 3+ Concentrations of 1.44g / L, 2.02g / L, 2.88g / L, 3.56g / L, 4.04g / L, 5.19g / L, 6.68g / L, 7.57g / L (calculated as arsenic) to be treated Add 44.7g / L FeSO to wastewater 4 ·7H 2 After O, inoculate thermotolerant Sulfur oxidans in the logarithmic phase of growth, and the inoculum volume is V 菌 :V 废水 =1:10, the concentration is 2.4-5.2×10 7 Units / mL calculation, under the conditions of temperature 30°C, pH=2.0, and stirring speed 160-180r / min, after 1-5 days of normal pressure reaction, the solution was left to stand, the precipitate was filtered, and the filtrate was recovered to complete the arsenic-containing wastewater. processing.

[0038] figure 2 As 3+ Concentrations of 1.44g / L, 2.02g / L, 2.88g / L, 3.56g / L, 4.04g / L, 5.19g / L, 6.68g / L, 7.57g / L (calculated as arsenic) to be tr...

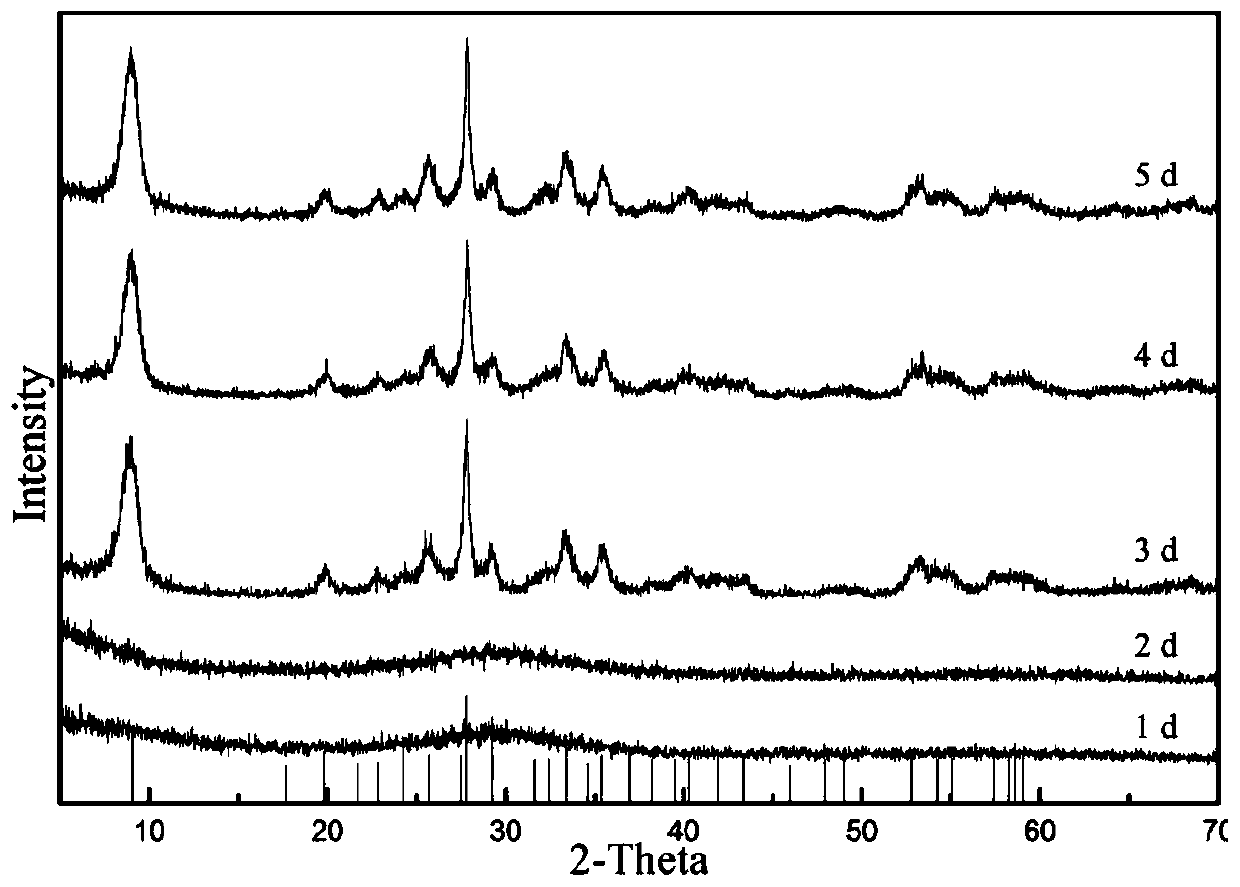

Embodiment 3

[0048] This embodiment compares different pH values to the temperature-resistant sulfur oxidative bacteria treatment concentration is 4.04g / L (calculated as arsenic) containing As 3+ The impact of wastewater, the specific process is as follows: 3+ Add 44.7g / L FeSO to the wastewater to be treated with a concentration of 4.04g / L (calculated as arsenic) 4 ·7H 2 After O, inoculate a volume in logarithmic phase of growth of 10% V 废水 , the concentration is 2.4-5.2×10 7 Each / mL of thermostable Sulfobacillus oxidans, when the temperature is 30°C and the stirring speed is 160-180r / min, the pH is adjusted to 1.6, 1.8, 2.0, 2.2, 2.5 and 2.8 respectively, and after 1-5 days of normal pressure reaction, The solution is left to stand, the precipitate is filtered, and the filtrate is recovered to complete the treatment of the arsenic-containing wastewater.

[0049] Figure 4 As 3+ The XRD patterns of the precipitates obtained from the treated wastewater with a concentration of 4.04g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com