Preparation method of modified steel slag for removing arsenic from water body

A steel slag and modification technology, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of expensive preparation and complicated preparation process, and achieve easy-to-obtain raw materials, simple and convenient modification methods, and unique The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

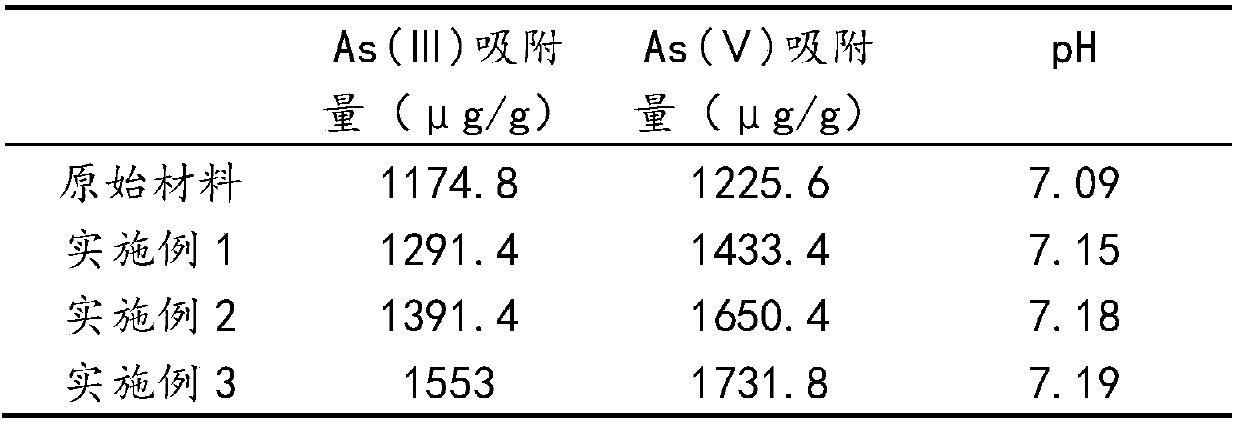

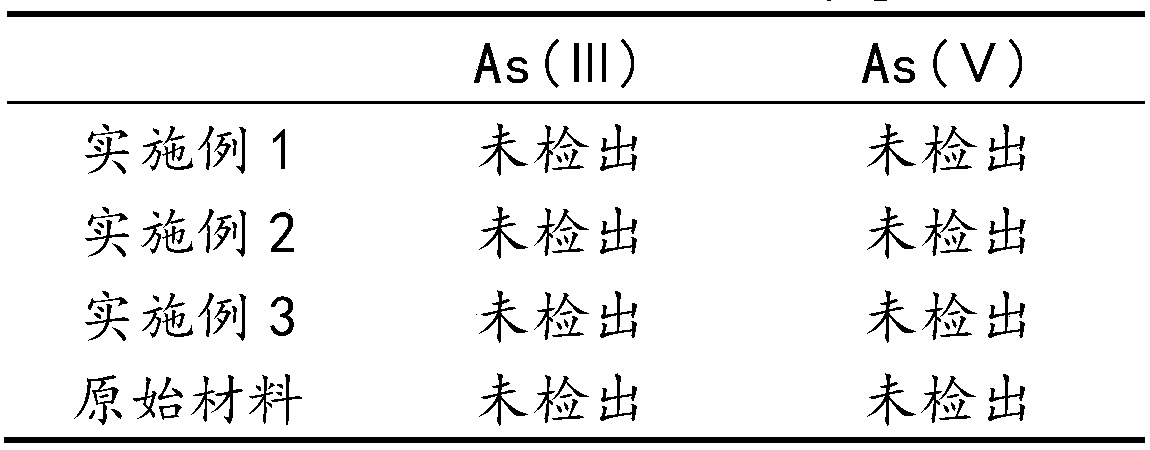

Embodiment 1

[0038] S100, taking 200g of steel slag and washing it with deionized water to near neutral pH, and drying it in a constant temperature drying oven at 105°C to a constant weight, the steel slag is 100-200 mesh, for use;

[0039] S200, first obtain a piece of rusted iron, soak it in tap water for about 7 days, filter the obtained water sample, and use this as the source water sample of microorganisms; prepare a selective medium, the composition of which is as follows: 0.5g / L NaNO 3 , 0.2g / LCaCl 2 ·2H 2 O, 0.5g / L KH 2 PO 4 ·3H 2 O, 0.5g / L (NH 4 ) 2 SO 4 , 0.5g / L MgSO 4 ·7H 2 O, 10g / LFeC 6 H 5 O 7 ·NH 4 OH (ferric ammonium citrate), 20g / L agar powder, and the corresponding enrichment medium; spread the source water sample on the selective medium, and invert the culture in a constant temperature incubator at 25°C until the surface of the medium grows White filamentous colonies; pick a single white filamentous colony and inoculate it on a new selective medium to contin...

Embodiment 2

[0042] S100, taking 200g of steel slag and washing it with deionized water to near neutral pH, and drying it in a constant temperature drying oven at 105°C to a constant weight, the steel slag is 100-200 mesh, for use;

[0043] S200, first obtain a piece of rusted iron, soak it in tap water for about 7 days, filter the obtained water sample, and use this as the source water sample of microorganisms; prepare a selective medium, the composition of which is as follows: 0.5g / L NaNO 3 , 0.2g / LCaCl 2 ·2H 2 O, 0.5g / L KH 2 PO 4 ·3H 2 O, 0.5g / L (NH 4 ) 2 SO 4 , 0.5g / L MgSO 4 ·7H 2 O, 10g / LFeC 6 H 5 O 7 ·NH 4 OH (ferric ammonium citrate), 20g / L agar powder, and the corresponding enrichment medium; spread the source water sample on the selective medium, and invert the culture in a constant temperature incubator at 25°C until the surface of the medium grows White filamentous colonies; pick a single white filamentous colony and inoculate it on a new selective medium to contin...

Embodiment 3

[0046] S100, taking 200g of steel slag and washing it with deionized water to near neutral pH, and drying it in a constant temperature drying oven at 105°C to a constant weight, the steel slag is 100-200 mesh, for use;

[0047] S200, first obtain a piece of rusted iron, soak it in tap water for about 7 days, filter the obtained water sample, and use this as the source water sample of microorganisms; prepare a selective medium, the composition of which is as follows: 0.5g / L NaNO 3 , 0.2g / LCaCl 2 ·2H 2 O, 0.5g / L KH 2 PO 4 ·3H 2 O, 0.5g / L (NH 4 ) 2 SO 4 , 0.5g / L MgSO 4 ·7H 2 O, 10g / LFeC 6 H 5 O 7 ·NH 4 OH (ferric ammonium citrate), 20g / L agar powder, and the corresponding enrichment medium; spread the source water sample on the selective medium, and invert the culture in a constant temperature incubator at 25°C until the surface of the medium grows White filamentous colonies; pick a single white filamentous colony and inoculate it on a new selective medium to contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com