Method for treating wastewater with trivalent arsenic

A technology for treating wastewater and trivalent arsenic, which is used in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. High cost, difficulty in secondary pollution operation, etc., to achieve the effect of controllable arsenic removal process, good effect, and low addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

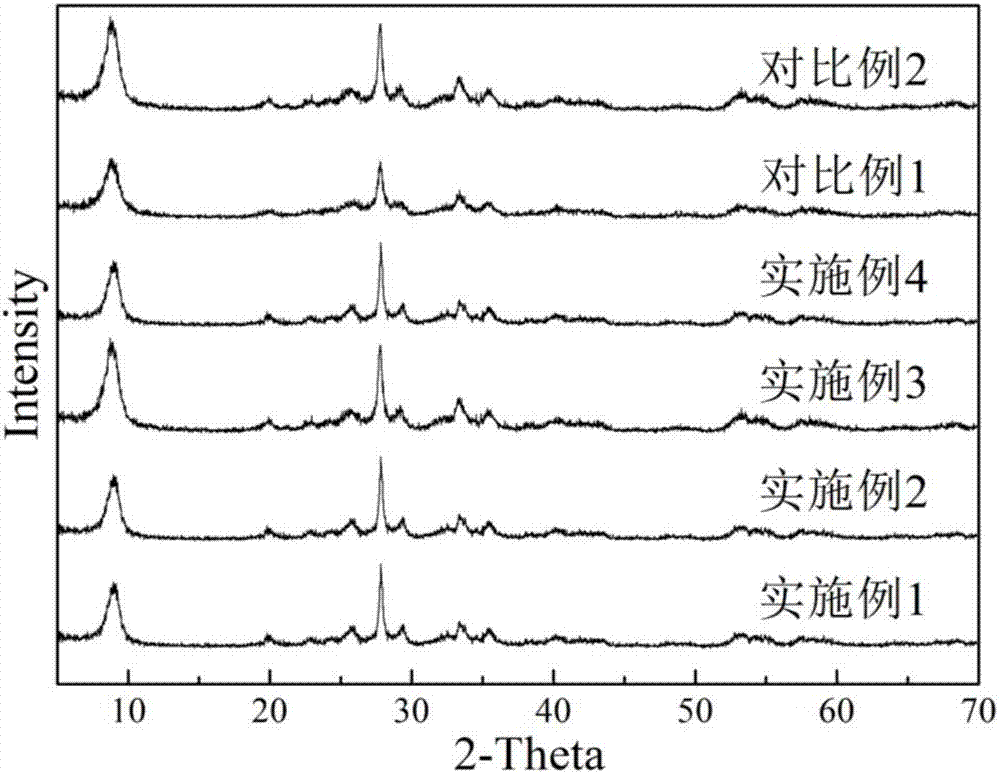

Embodiment 1

[0036] This example provides a method for treating wastewater containing trivalent arsenic. The specific process is as follows: using arsenous acid, ferric nitrate and sodium sulfate as raw materials respectively, preparing As 3+ Arsenic-containing solution with a concentration of 9g / L (calculated as arsenic), Fe 3+ Concentration of 11.2g / L iron salt solution and SO 4 2-The sulfate solution with a concentration of 3.2g / L was used for standby; the three solutions were slowly added into a 250mL three-necked flat-bottomed flask filled with 30mL deionized water bottom liquid at the same time through a peristaltic pump at a rate of 1.5mL / min, and the materials were fully collided and contacted at the same time. The control temperature is 25±1°C, the stirring speed is 600±20r / min, the pH=2.4, the feeding time is 20min, the timing is started at the same time as feeding, and the reaction is 25min. Take a sample of 2.5ml and detect its As 3+ Concentration of As 3+ The removal rate ...

Embodiment 2

[0038] This example provides a method for treating wastewater containing trivalent arsenic. The specific process is as follows: using arsenous acid, ferric nitrate and sodium sulfate as raw materials respectively, preparing As 3+ Arsenic-containing solution with a concentration of 15g / L (calculated as arsenic), Fe 3+ Concentration of 16.8g / L iron salt solution and SO 4 2- The sulfate solution with a concentration of 4.8g / L was used for standby; the three solutions were slowly added into a 250mL three-necked flat-bottomed flask filled with 30mL of deionized water bottom liquid through a peristaltic pump at the same time at a rate of 1.5mL / min, and the materials were fully collided and contacted at the same time. The control temperature is 25±1°C, the stirring speed is 600±20r / min, the pH=2.4, the feeding time is 20min, the timing is started at the same time as feeding, and the reaction is 25min. Take a sample of 2.5ml and detect its As 3+ Concentration of As 3+ The removal ...

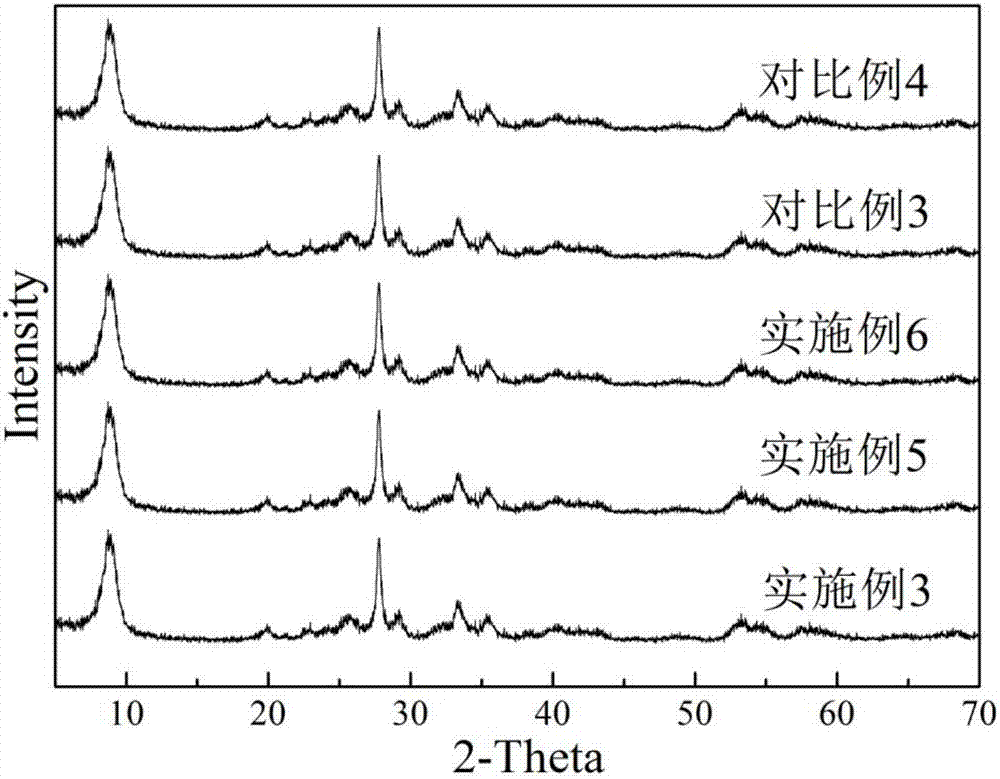

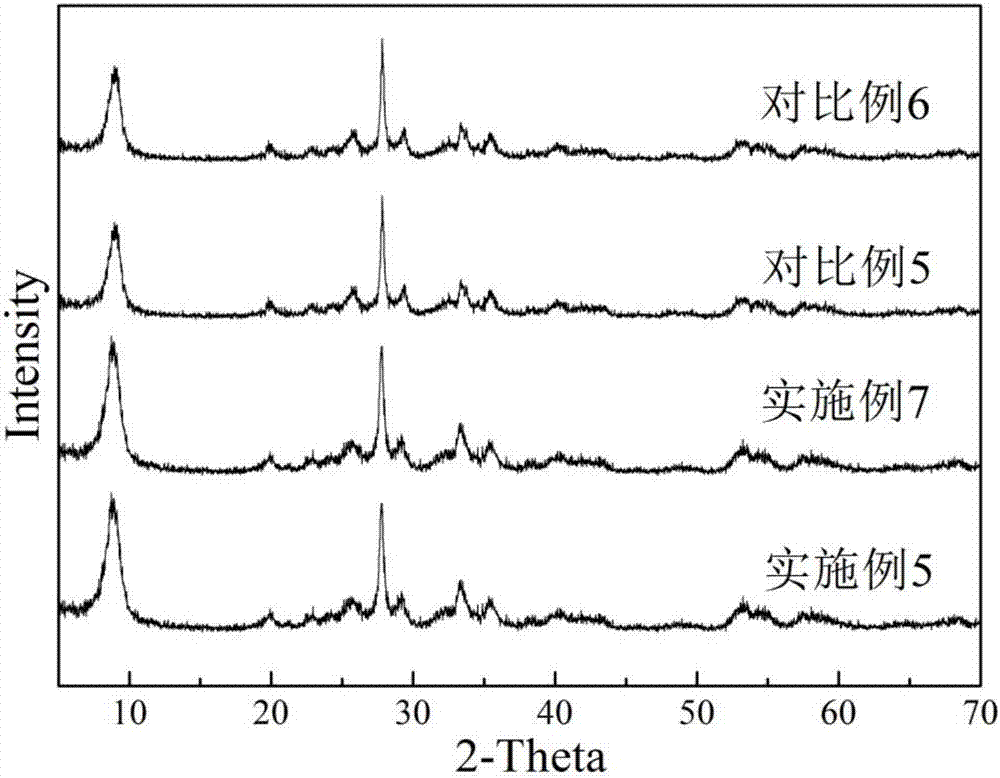

Embodiment 3

[0040] This example provides a method for treating wastewater containing trivalent arsenic. The specific process is as follows: using arsenous acid, ferric nitrate and sodium sulfate as raw materials respectively, preparing As 3+ Arsenic-containing solution with a concentration of 20.5g / L (calculated as arsenic), Fe 3+ Concentration of 23.0g / L iron salt solution and SO 4 2- The sulfate solution with a concentration of 6.56g / L was used for standby; the three solutions were slowly added into a 250mL three-necked flat-bottomed flask filled with 30mL of deionized water bottom liquid at the same time through a peristaltic pump at a rate of 1.5mL / min, and the materials were fully collided and contacted at the same time. The control temperature is 25±1°C, the stirring speed is 600±20r / min, the pH=2.4, the feeding time is 20min, the timing is started at the same time as feeding, and the reaction is 25min. Take a sample of 2.5ml and detect its As 3+ Concentration of As 3+ The remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com