Wet Process Phosphoric Acid Removal Process

A technology for wet-process phosphoric acid and arsenic removal, which is applied in the fields of phosphorus compounds, chemical instruments and methods, and inorganic chemistry. The consumption of arsenic removal agent and the effect of improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

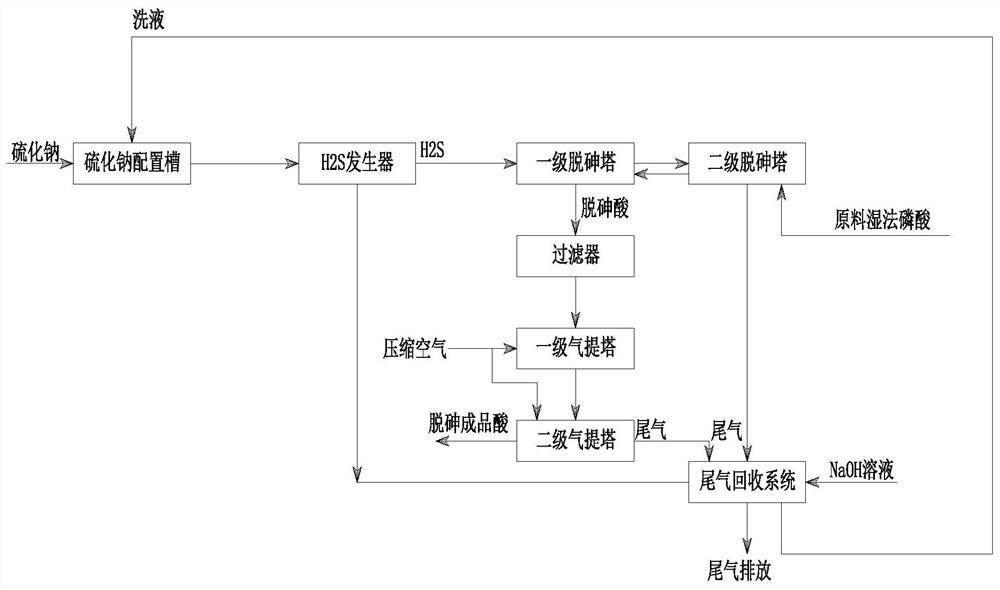

[0022] Combine below figure 1 Technical process of the present invention is described in detail:

[0023] 1) Na in the sodium sulfide configuration tank 2 S solution sent to H 2 S Generator with H 3 PO 4 The reaction produces H 2 S and sodium dihydrogen phosphate, the resulting sodium dihydrogen phosphate is recycled, H 2 S is sent to the first-stage arsenic removal tower and the second-stage arsenic removal tower sequentially as a de-arsenic agent; the H 2 The pressure of the S generator is 0.1-0.2MPa(G), and the temperature is 60-70°C;

[0024] Two) the wet-process phosphoric acid (P) from the wet-process phosphoric acid plant in the phosphoric acid storage tank 2 o 5 Concentration is 35-45%, mass percentage) solution is sent into secondary arsenic removal tower and primary arsenic removal tower successively, and the H in the tower 2 S reverse mixed contact reaction, in the arsenic removal tower, H 2S dissolves in wet-process phosphoric acid and ionizes to S 2- , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com