A microwave co-processing waste residue to prepare high-efficiency sintering flue gas adsorbent and method

A technology for co-processing and sintering flue gas, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve problems such as soil and water resource hazards, waste of resources, and increased maintenance costs of enterprises, and achieve shortened hydration time, Reduce the cost of raw materials and improve the effect of physical adsorption foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

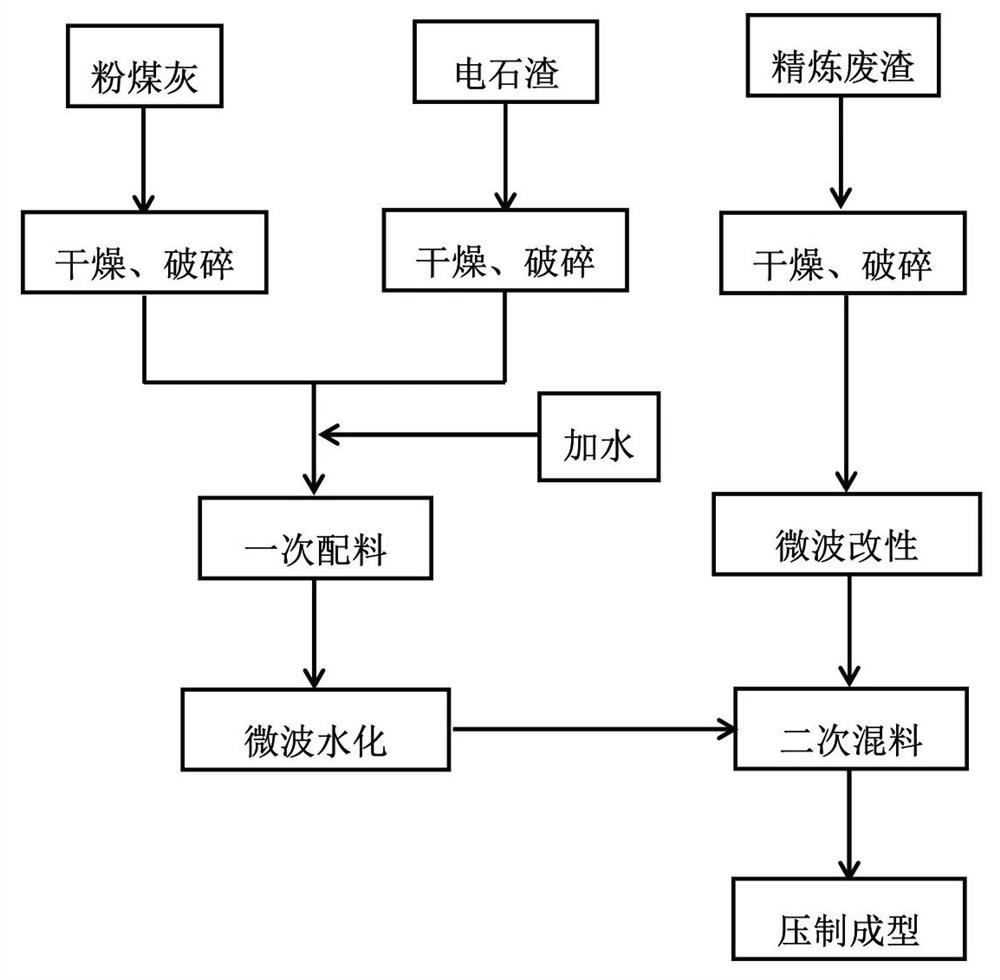

[0028] A method for preparing a high-efficiency sintered flue gas adsorbent by microwave co-processing waste residue of the present invention, the process flow is: crushing-batching-microwave hydration and modification treatment-mixing-briquetting, specifically including the following steps:

[0029] Dry the fly ash produced by burning coal in the selected boiler, the calcium carbide slag produced by hydrolyzing calcium carbide to produce acetylene, and the refining waste produced after molten steel refining to constant weight, then add it to a planetary ball mill for crushing, grinding and screening Particles below 0.074mm are produced; the main chemical components of each raw material are shown in Table 1, Table 2 and Table 3.

[0030] Table 1 The main chemical components of fly ash

[0031] chemical composition SiO 2

al 2 o 3

CaO MgO Loss on ignition other content / % 55.78 15.15 4.87 5.75 15.11 3.34

[0032] Table 2 Main chemic...

Embodiment 2

[0041]This example further illustrates the influence of different adsorbent block sizes on the adsorption effect. The specific operation steps are as follows:

[0042] Dry the fly ash produced by burning coal in the selected boiler, the calcium carbide slag produced by hydrolyzing calcium carbide to produce acetylene, and the refining waste produced after molten steel refining to constant weight, then add it to a planetary ball mill for crushing, grinding and screening Particles below 0.074mm are produced; the main chemical components of each raw material are shown in Table 1, Table 2 and Table 3.

[0043] Prepare qualified fly ash, carbide slag and water at a mass ratio of 1:0.8:2.5 to make a mixed slurry, and then place the mixed slurry in a microwave generator for hydration treatment at an output power of 500W for 50 minutes .

[0044] Weigh the refined waste slag powder with 50% of the total mass of the adsorbent, place it in a microwave generator and modify it with a mi...

Embodiment 3

[0048] This example further illustrates the influence of different adsorbent block sizes on the adsorption effect. The specific operation steps are as follows:

[0049] Dry the fly ash produced by burning coal in the selected boiler, the calcium carbide slag produced by hydrolyzing calcium carbide to produce acetylene, and the refining waste produced after molten steel refining to constant weight, then add it to a planetary ball mill for crushing, grinding and screening Particles below 0.074mm are produced; the main chemical components of each raw material are shown in Table 1, Table 2 and Table 3.

[0050] Prepare qualified fly ash, carbide slag and water at a mass ratio of 1:1.2:3 to make a mixed slurry, and then place the mixed slurry in a microwave generator for hydration treatment at an output power of 700W for 30 minutes .

[0051] Weigh the refined waste slag powder with 50% of the total mass of the adsorbent, place it in a microwave generator and modify it with a mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com