Large double-cycle fluidized bed semi-dry process flue gas desulphurization tower

A dual-circulation, fluidized bed technology, applied to chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of increasing the resistance and energy consumption of the desulfurization system, and the small capacity of the boiler unit, so as to reduce investment and operation and maintenance The effect of cost, simplification of tower structure and process flow, and reduction of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

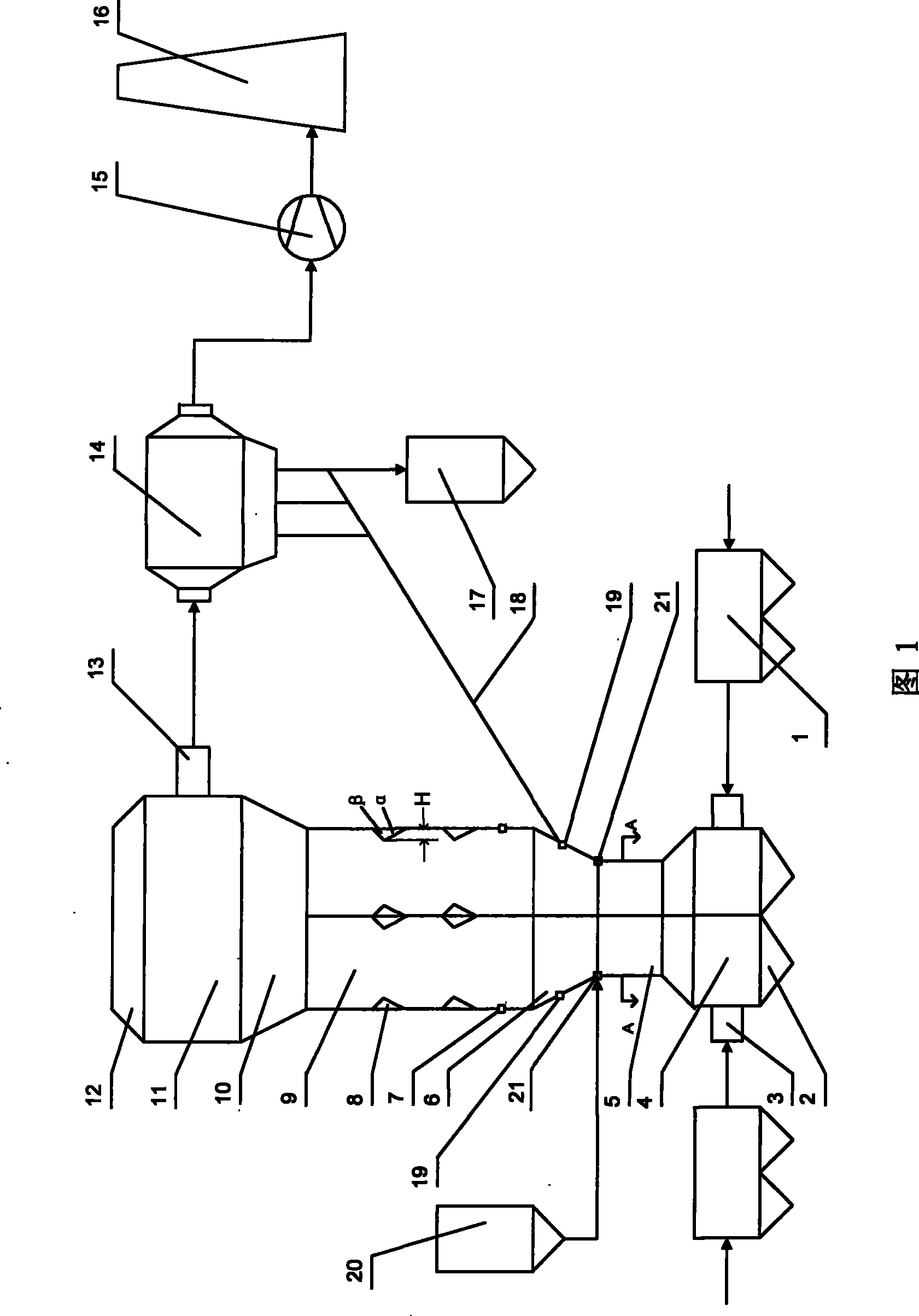

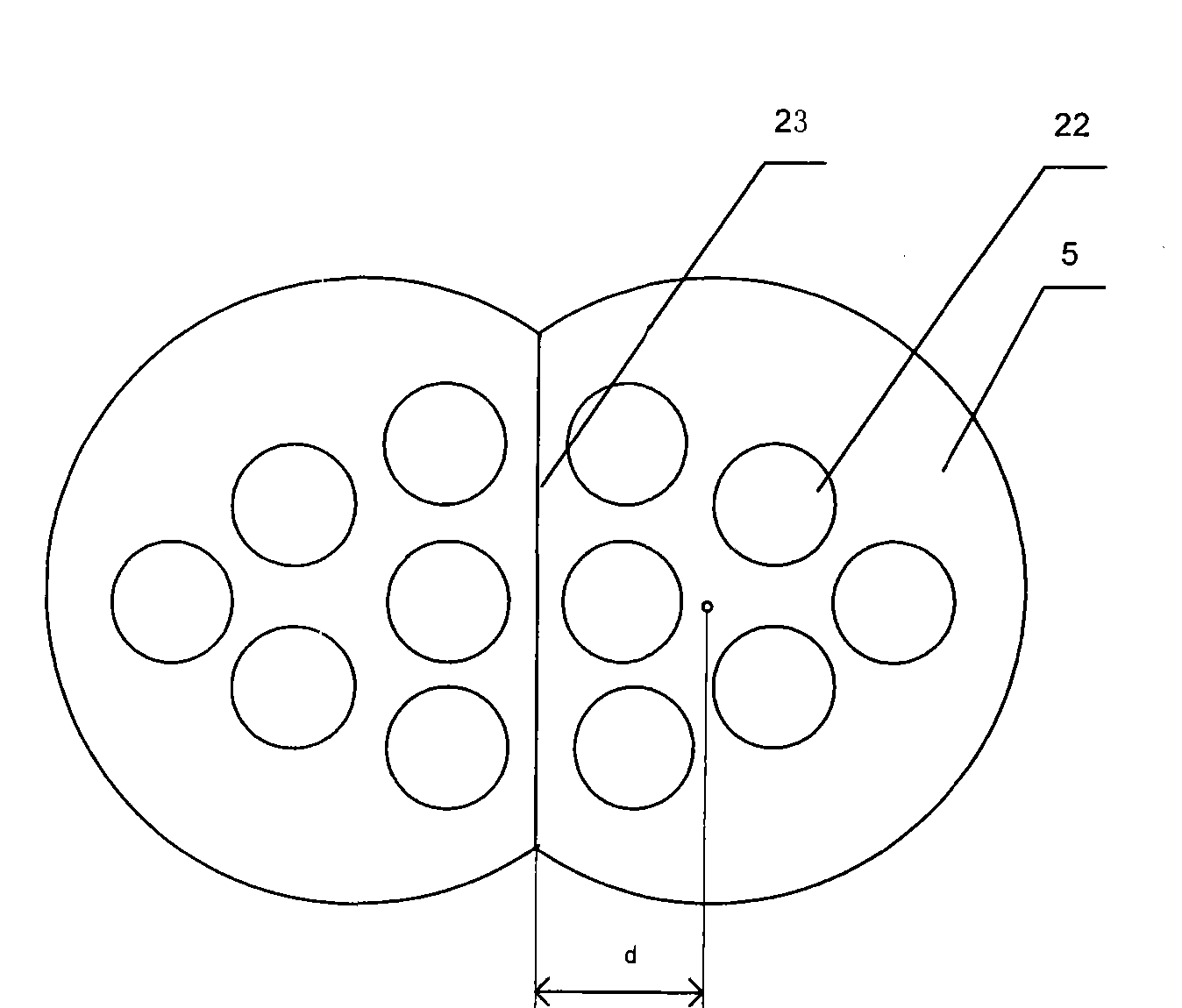

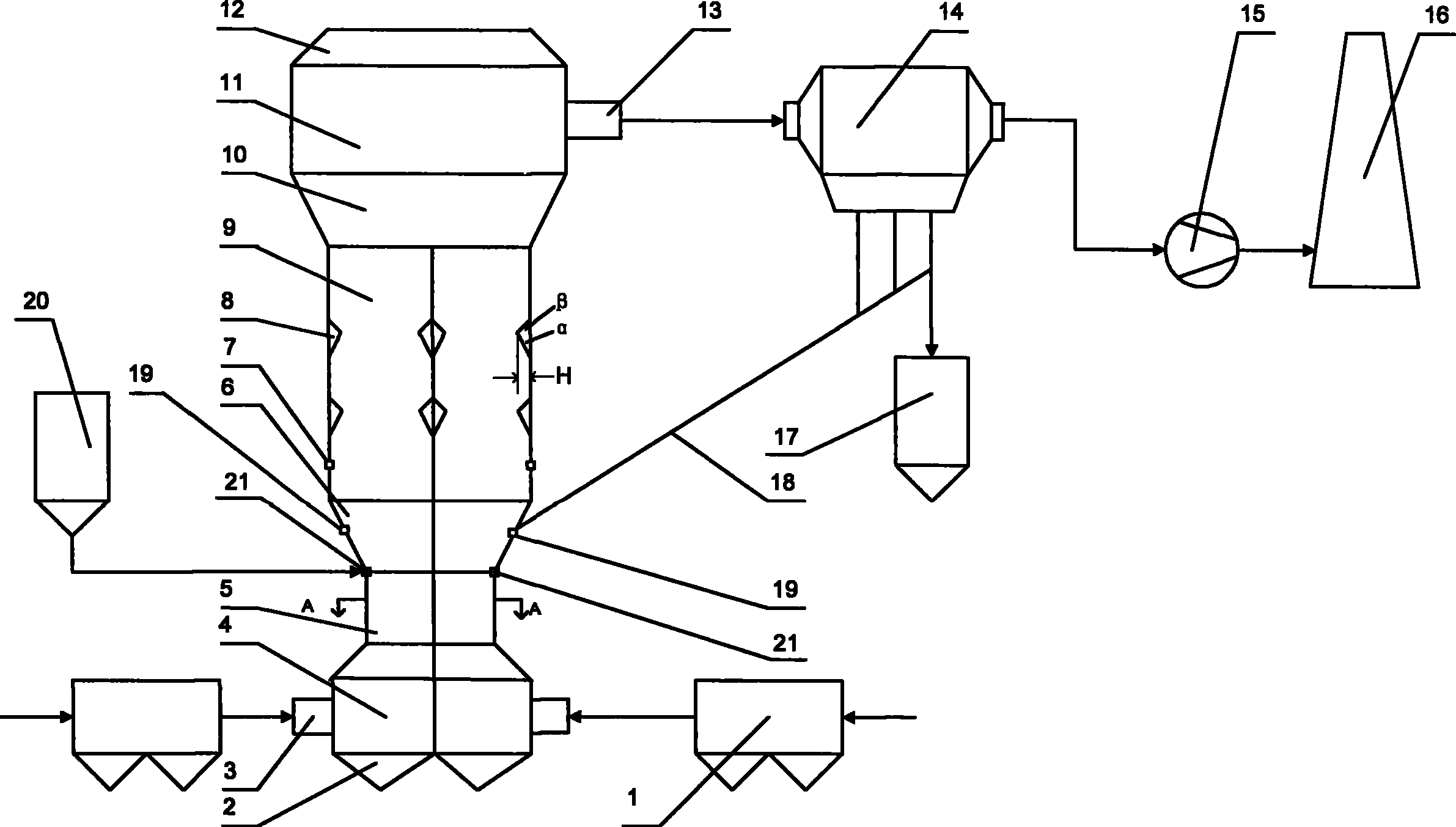

[0014] The large-scale double-circulating fluidized bed semi-dry flue gas desulfurization tower shown in the figure has an integral reaction tower body 12, and the reaction tower body 12 is provided with ash storage bin 2 at the bottom of the tower and a flue gas mixing chamber from bottom to top. Chamber 4, Venturi tube fluidization section 5, gradual expansion section 6, intermediate reaction section 9, tower top transition section 10 and tower top section 11. Among them: the ash storage bin 2 at the bottom of the tower, the flue gas mixing chamber 4, the fluidized section 5 of the Venturi tube, the expanding section 6 and the intermediate reaction section 9 are all divided into two independent chambers by a middle partition 23 . On the sides of the two independent chambers of the flue gas mixing chamber 4, flue gas inlets 3 are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com