Device and method for deacidifying flue gas of hazardous waste incineration system

A flue gas and deacidification technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of increased carbon emissions, unfavorable control costs, and high prices of baking soda, and achieve good control, improve utilization, Achieving zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

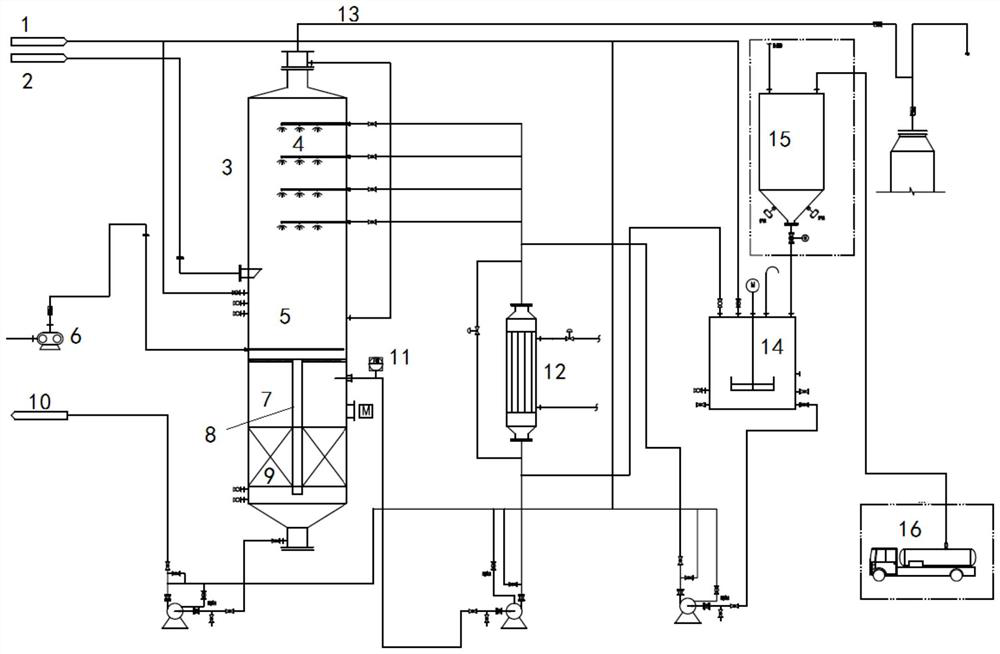

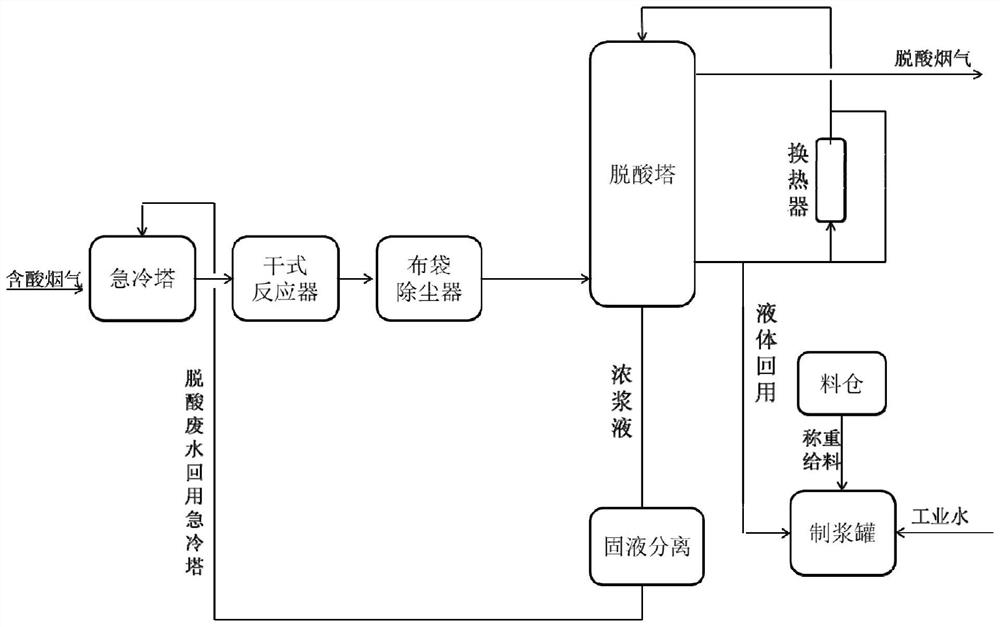

[0062] A hazardous waste incineration production line, the flue gas volume under working conditions is 66832-68661Nm 3 / h, the flue gas outlet temperature of the quench tower is 490-510°C, the inlet flue gas temperature of the deacidification tower is 150-180°C, and the sulfur dioxide concentration is 4500-6600 mg / Nm 3 , hydrogen chloride concentration 2000-3500mg / Nm 3 , the concentration of hydrogen fluoride is less than 100mg / Nm 3 , use the method in the present invention to carry out flue gas deacidification, with figure 1 For the deacidification device, a two-stage deacidification tower is used for absorption.

[0063] like figure 2 As shown, pulping was carried out according to the ratio of magnesium oxide to water as 1:5, and the dosage of magnesium oxide was 200kg / h. The obtained slurry is sent to the primary and secondary deacidification towers by the slurry pump, and the liquid-gas ratio is controlled at about 9. After aeration and solid-liquid separation, the l...

Embodiment 2

[0066] A medical waste incineration production line, the working condition flue gas volume is 8000-12000Nm 3 / h, the flue gas outlet temperature of the quench tower is 500-520°C, the inlet flue gas temperature of the acid absorption tower is 150-180°C, and the hydrogen chloride concentration is 3900-4700 mg / Nm 3 , the sulfur dioxide concentration is less than 50mg / Nm 3 , the concentration of hydrogen fluoride is less than 100mg / Nm 3 , use the method in the present invention to carry out flue gas deacidification, with figure 1 For the deacidification device, a single-stage deacidification tower is used for absorption.

[0067] like figure 2 As shown, pulping was carried out according to the ratio of magnesia to water as 1:6, and the dosage of magnesia was 50kg / h. The obtained slurry is sent to the single-stage deacidification tower respectively by the slurry centrifugal pump, and the liquid-gas ratio is controlled at about 10. After the liquid after absorbing acid gas is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com