Method for preparing ultra-metallurgical grade silicon from crystalline silicon cutting waste

A technology for cutting waste and metallurgical grade silicon, applied in chemical instruments and methods, silicon compounds, non-metallic elements, etc., can solve the problems of long process, low efficiency, high energy consumption, etc., and achieve the effect of efficient corrosion and dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

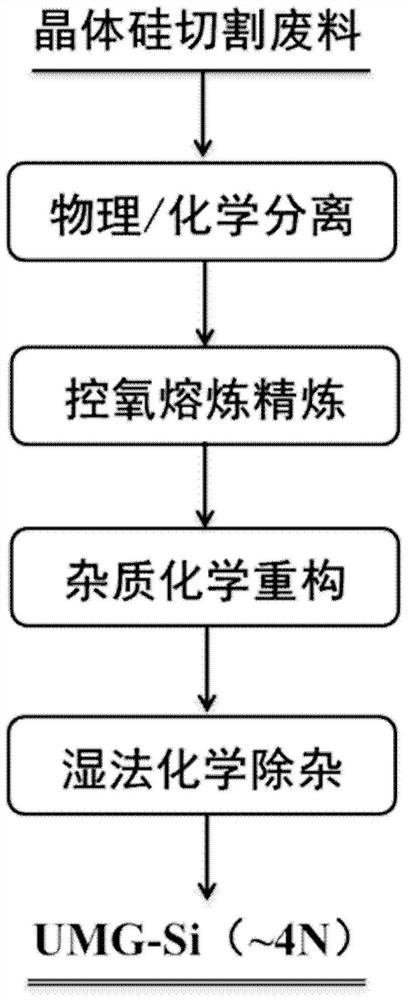

[0123] The method for preparing ultra-metallurgical grade silicon from crystalline silicon cutting waste in this embodiment is as follows: figure 1 As shown, it specifically includes the following steps:

[0124] (1) After crushing and grading the crystalline silicon mortar cutting waste, it is mixed with an aqueous medium to form a slurry, and SiC, Fe, Al and other inclusions are separated and removed by a hydrocyclone to obtain a crystalline silicon roughing slurry and inclusion residue. The rough selection material slurry is separated from solid and liquid by a filter press, and after pickling to remove impurities, water washing and drying, the purified selection material is obtained.

[0125](2) After the purified and selected material obtained in step (1) is combined with binder mixing, pressing and drying, the selected material block is obtained. Add Na to the intermediate frequency furnace 2 O-SiO 2 The slag agent is melted into a slag pool, and a small amount of sel...

Embodiment 2

[0129] The method for preparing ultra-metallurgical grade silicon from crystalline silicon cutting waste in this embodiment comprises the following steps:

[0130] (1) After crushing and grading the crystalline silicon mortar cutting waste, it is mixed with an aqueous medium to form a slurry, and SiC, Fe, Al and other inclusions are separated and removed by a hydrocyclone to obtain a crystalline silicon roughing slurry and inclusion residue. The rough selection material slurry is separated from solid and liquid by a filter press, and after pickling to remove impurities, water washing and drying, the purified selection material is obtained.

[0131] (2) After the purified and selected material obtained in step (1) is combined with binder mixing, pressing and drying, the selected material block is obtained. Add Na to the intermediate frequency furnace 2 O-SiO 2 The slag agent is melted into a slag pool, and a small amount of selected material blocks are put into the slag pool ...

Embodiment 3

[0135] The method for preparing ultra-metallurgical grade silicon from crystalline silicon cutting waste in this embodiment comprises the following steps:

[0136] (1) After the crystalline silicon diamond wire cutting waste is crushed and graded, it is subjected to pickling to remove impurities, water washing, and drying to obtain purified and selected materials.

[0137] (2) After the purified and selected material obtained in step (1) is combined with binder mixing, pressing and drying, the selected material block is obtained. Add Na to the intermediate frequency furnace 2 O-SiO 2 -CaF 2 The slag agent is melted into a slag pool, and a small amount of selected material blocks are put into the slag pool several times under the protection of argon for smelting. After the silicon block is completely melted, carry out the first slag removal, and then add Na 2 O-SiO 2 -CaF 2 The slag agent is refined to remove impurities, and the smelting and refining temperature is 1500°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com