A method for treating wastewater containing trivalent arsenic

A technology for treating wastewater and trivalent arsenic, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of high cost and unsatisfactory long-term stability of ion exchange method and reverse osmosis method Practical application, difficult control of arsenic removal operation, etc., to achieve the effect of controllable arsenic removal process, less addition, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

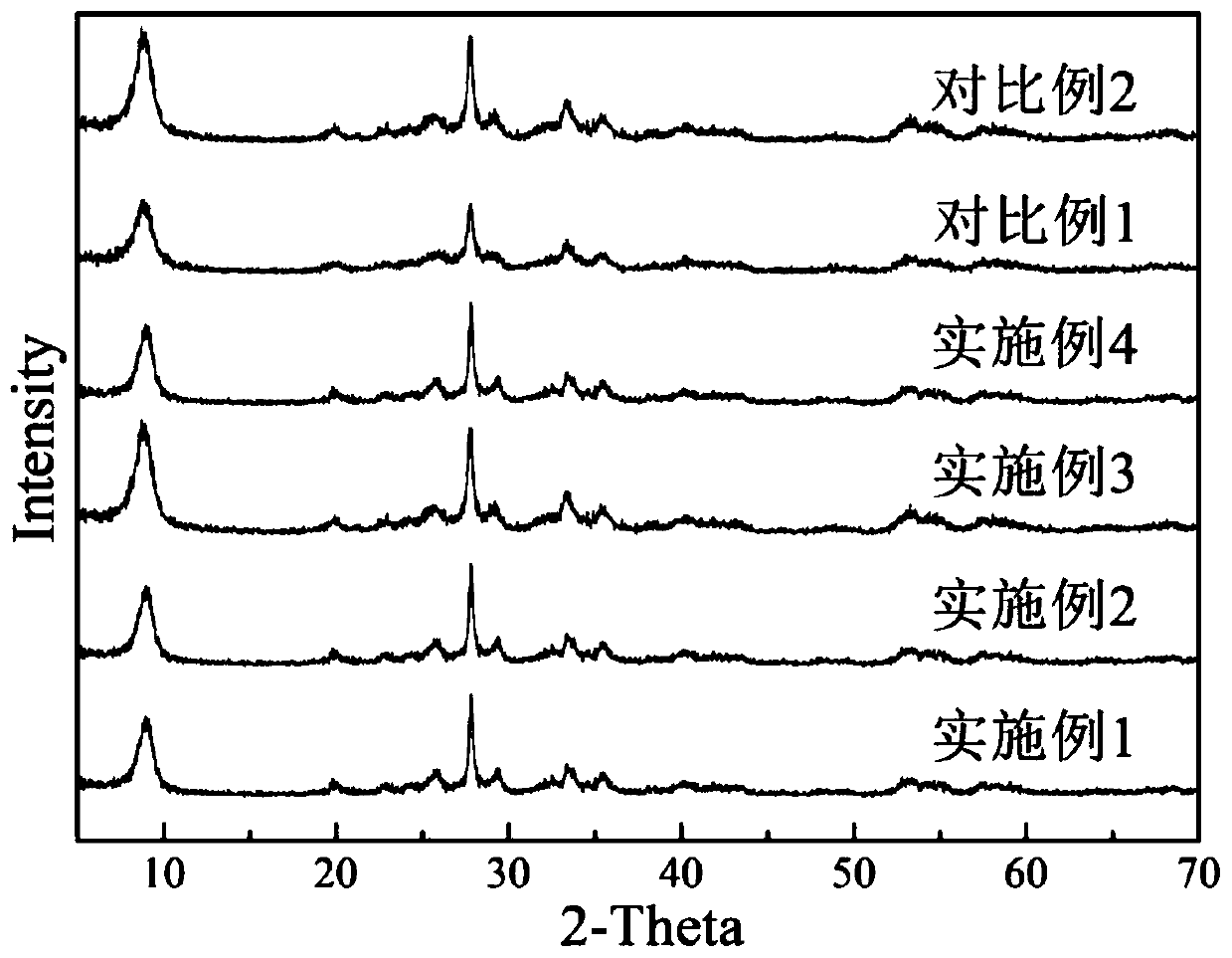

Embodiment 1

[0036] This example provides a method for treating wastewater containing trivalent arsenic. The specific process is as follows: using arsenous acid, ferric nitrate and sodium sulfate as raw materials respectively, preparing As 3+ Arsenic-containing solution with a concentration of 9g / L (calculated as arsenic), Fe 3+ Concentration of 11.2g / L iron salt solution and SO 4 2-The sulfate solution with a concentration of 3.2g / L was used for standby; the three solutions were slowly added into a 250mL three-necked flat-bottomed flask filled with 30mL deionized water bottom liquid at the same time through a peristaltic pump at a rate of 1.5mL / min, and the materials were fully collided and contacted at the same time. The control temperature is 25±1°C, the stirring speed is 600±20r / min, the pH=2.4, the feeding time is 20min, the timing is started at the same time as feeding, and the reaction is 25min. Take a sample of 2.5ml and detect its As 3+ Concentration of As 3+ The removal rate ...

Embodiment 2

[0038] This example provides a method for treating wastewater containing trivalent arsenic. The specific process is as follows: using arsenous acid, ferric nitrate and sodium sulfate as raw materials respectively, preparing As 3+ Arsenic-containing solution with a concentration of 15g / L (calculated as arsenic), Fe 3+ Concentration of 16.8g / L iron salt solution and SO 4 2- The sulfate solution with a concentration of 4.8g / L was used for standby; the three solutions were slowly added into a 250mL three-necked flat-bottomed flask filled with 30mL of deionized water bottom liquid through a peristaltic pump at the same time at a rate of 1.5mL / min, and the materials were fully collided and contacted at the same time. The control temperature is 25±1°C, the stirring speed is 600±20r / min, the pH=2.4, the feeding time is 20min, the timing is started at the same time as feeding, and the reaction is 25min. Take a sample of 2.5ml and detect its As 3+ Concentration of As 3+ The removal ...

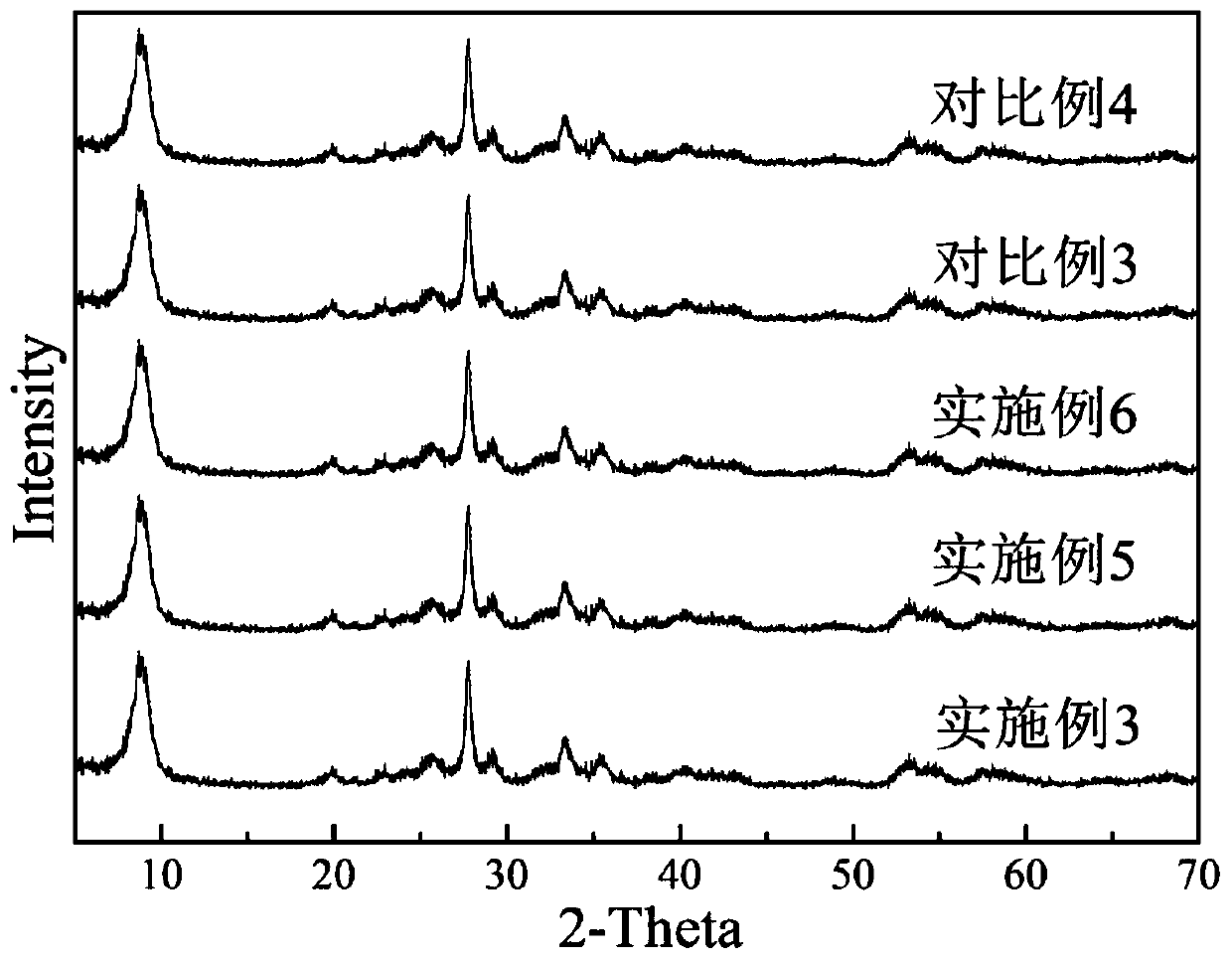

Embodiment 3

[0040] This example provides a method for treating wastewater containing trivalent arsenic. The specific process is as follows: using arsenous acid, ferric nitrate and sodium sulfate as raw materials respectively, preparing As 3+ Arsenic-containing solution with a concentration of 20.5g / L (calculated as arsenic), Fe 3+ Concentration of 23.0g / L iron salt solution and SO 4 2- The sulfate solution with a concentration of 6.56g / L was used for standby; the three solutions were slowly added into a 250mL three-necked flat-bottomed flask filled with 30mL of deionized water bottom liquid at the same time through a peristaltic pump at a rate of 1.5mL / min, and the materials were fully collided and contacted at the same time. The control temperature is 25±1°C, the stirring speed is 600±20r / min, the pH=2.4, the feeding time is 20min, the timing is started at the same time as feeding, and the reaction is 25min. Take a sample of 2.5ml and detect its As 3+ Concentration of As 3+ The remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com