Adsorption arsenic removal catalyst and preparation method thereof

A catalyst and arsenic removal technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of low arsenic removal efficiency of the catalyst, complex process operation, small adsorption capacity, etc., and achieve excellent arsenic removal performance , Improve reaction efficiency, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

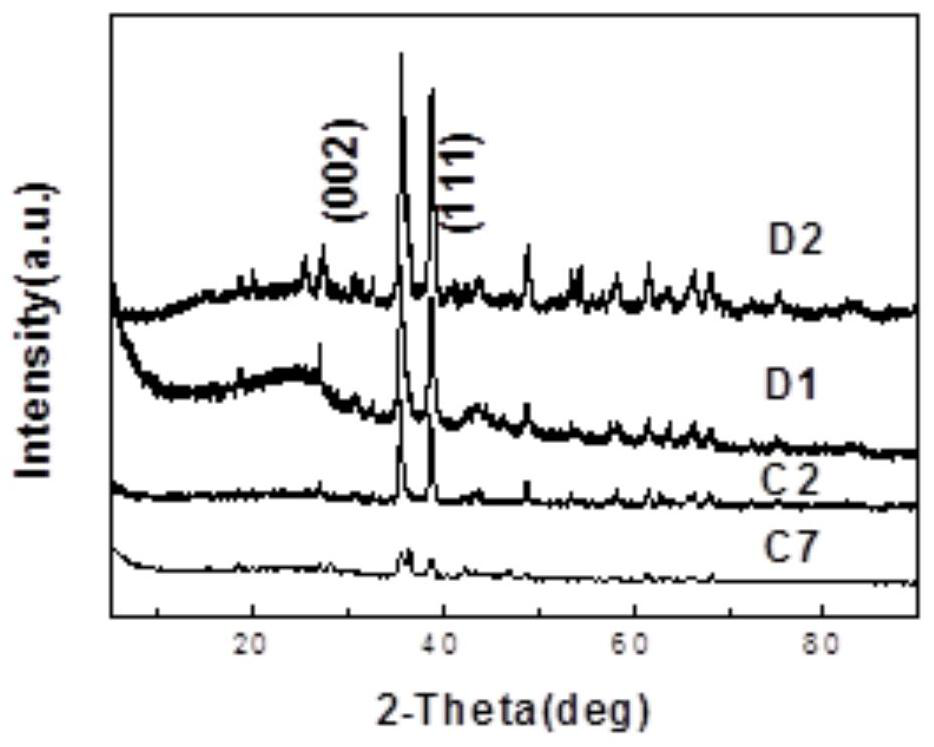

Embodiment 1

[0048] Mix 500g of activated carbon, 1000g of pseudo-boehmite, 30g of turnip powder and 20g of methyl cellulose for 5 minutes, add 1600g of aqueous solution containing 5% nitric acid, roll for 30 minutes and then knead for 30 minutes, extrude with a Φ3.0 orifice plate, Drying at 120°C for 2 hours, and calcining at 450°C for 4 hours in an oxygen-free atmosphere to obtain carrier Z-1. Dissolve the metal salt containing copper nitrate in deionized water, and use the equal volume saturated impregnation method to load the above impregnation solution on the carrier Z-1, let it stand and dry for 12 hours, then dry it at 120°C for 2 hours, and bake it at 300°C for 4 hours. Catalyst C1 is obtained.

Embodiment 2

[0050] Mix 500g of activated carbon, 500g of pseudo-boehmite, 50g of turnip powder and 50g of methyl cellulose for 5 minutes, add 1000g of aqueous solution containing 5% nitric acid, roll for 30 minutes and then knead for 30 minutes, extrude with a Φ3.0 orifice plate, Drying at 120°C for 2 hours, and calcining at 450°C for 4 hours in an oxygen-free atmosphere to obtain carrier Z-2. Dissolve the metal salt containing copper nitrate in deionized water, and use the equal volume saturated impregnation method to load the above impregnation solution on the carrier Z-2, let it stand and dry for 12 hours, then dry at 120°C for 2 hours, and bake at 300°C for 4 hours, finally Catalyst C2 is obtained.

Embodiment 3

[0052] Mix 1000g of activated carbon, 500g of pseudo-boehmite, 80g of turnip powder and 80g of ethyl cellulose for 5 minutes, add 1600g of aqueous solution containing 5% nitric acid, roll for 30 minutes and then knead for 30 minutes, extrude with a Φ3.0 orifice plate, Dry at 120°C for 2h, and calcined at 450°C for 4h in an oxygen-free atmosphere to obtain carrier Z-3. Dissolve the metal salt containing copper nitrate in deionized water, and use the equal volume saturated impregnation method to load the above impregnation solution on the carrier Z-3, let it stand and dry for 12 hours, then dry at 120°C for 2 hours, and bake at 300°C for 4 hours, finally Catalyst C3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com