Deep purification method of tungsten smelting wastewater

A technology for deep purification and wastewater treatment, applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problems of large wastewater discharge and complex components, achieve no secondary pollution and simple steps , the effect of improving the efficiency of arsenic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

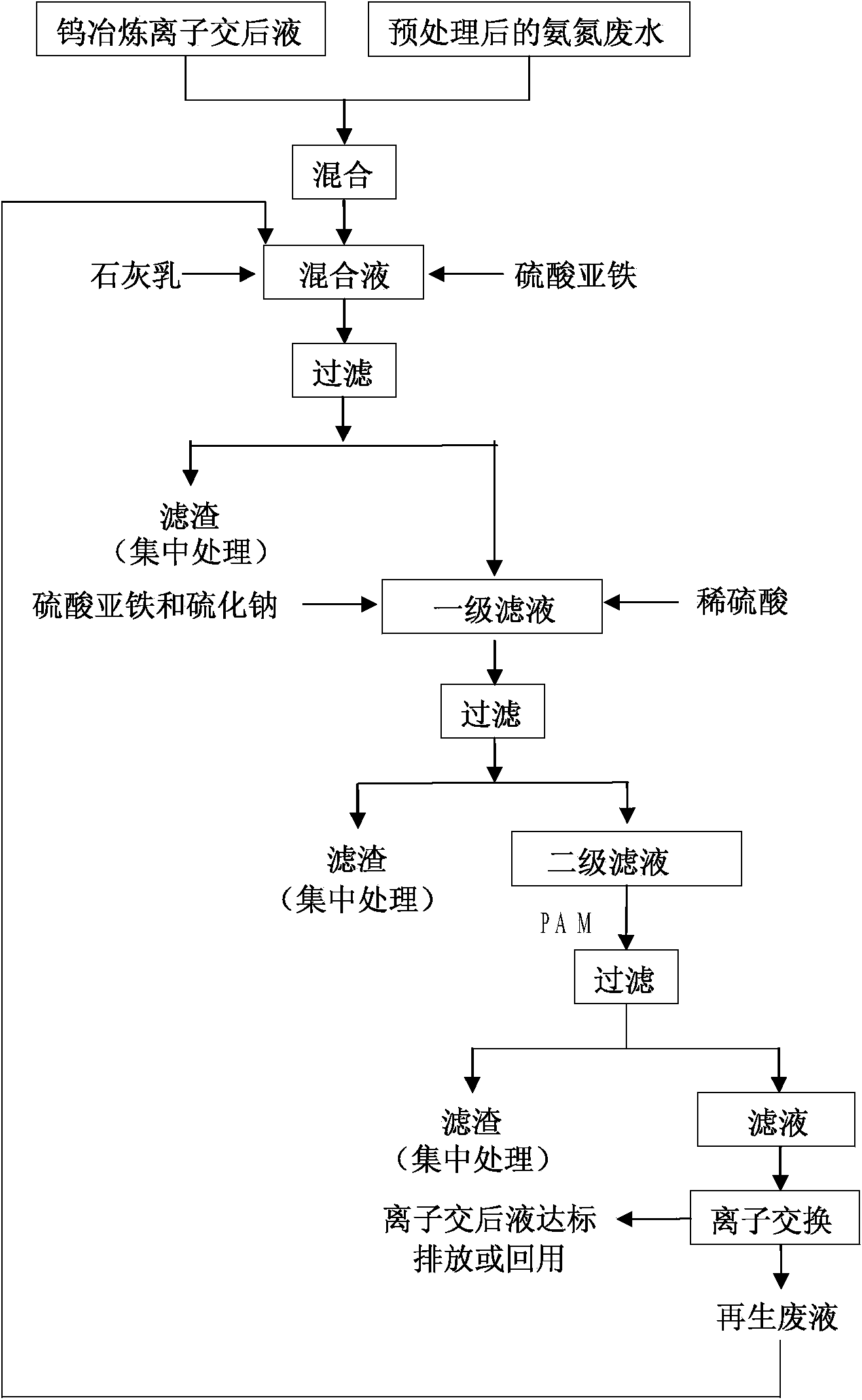

[0034] Such as figure 1 As shown, the deep purification method of tungsten smelting wastewater is:

[0035] Step 1, at normal temperature, pretreat the ammonia nitrogen waste liquid produced during the tungsten smelting process, and then mix the ion exchange liquid produced by the tungsten smelting with the pretreated ammonia nitrogen waste liquid at a volume ratio of 1:5, The total volume of the mixture is 10m 3 , slowly add milk of lime with a mass percentage concentration of 220-250 g / L to the mixed solution to adjust the pH value to 11, detect the content of arsenic in the mixed solution with silver diethylaminodithioformate spectrophotometry, and then add the Add ferrous sulfate to the mixed solution of milk of lime, and the amount of added ferrous sulfate is to make the ratio of ferrous sulfate and arsenic in the mixed solution to be 2:1, and then to the Add 1 kg of ferrous sulfate to the mixed solution and feed air into the mixed solution, then carry out conventional ...

Embodiment 2

[0039] Such as figure 1 As shown, the deep purification method of tungsten smelting wastewater is:

[0040] Step 1, at normal temperature, pretreat the ammonia-nitrogen waste liquid produced in the tungsten smelting process, and then mix the ion exchange liquid produced in the tungsten smelting process with the pretreated ammonia-nitrogen waste liquid at a volume ratio of 1:6, The total volume of the mixture is 10m 3 , slowly add milk of lime with a concentration of 220-250 g / L in mass percentage to the mixed solution to adjust the pH value to 11.5, detect the content of arsenic in the mixed solution by silver diethylaminodithioformate spectrophotometry, and then add the Add ferrous sulfate to the mixed solution of milk of lime, and the amount of added ferrous sulfate is to make the ratio of ferrous sulfate and arsenic in the mixed solution to be 3:1, and then to the Add 1.2kg of ferrous sulfate to the mixed solution while introducing air into the mixed solution, then carry ...

Embodiment 3

[0044] Such as figure 1 As shown, the deep purification method of tungsten smelting wastewater is:

[0045] Step 1, at normal temperature, pretreat the ammonia nitrogen waste liquid produced during the tungsten smelting process, and then mix the ion exchange liquid produced by the tungsten smelting with the pretreated ammonia nitrogen waste liquid at a volume ratio of 1:8, The total volume of the mixture is 10m 3 , slowly add milk of lime with a mass percentage concentration of 220-250 g / L to the mixed solution to adjust the pH value to 12, use silver diethylaminodithioformate to detect the content of arsenic in the mixed solution, and then add the Add ferrous sulfate to the mixed solution of milk of lime, and the amount of added ferrous sulfate is to make the ratio of ferrous sulfate and arsenic in the mixed solution to be 4:1, and then to the Add 1.5kg of ferrous sulfate to the mixed solution while introducing air into the mixed solution, then carry out conventional stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com