Arsenic-containing wastewater treatment method

A treatment method and technology for wastewater, applied in water/sewage treatment, heating water/sewage treatment, illumination water/sewage treatment, etc., can solve the problem of high residual arsenic content increasing the amount of arsenic-containing hazardous waste, low production efficiency, and low leaching toxicity and other problems, to achieve the effect of reducing the consumption of iron salts, reducing the cost, and reducing the amount of arsenic-containing slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

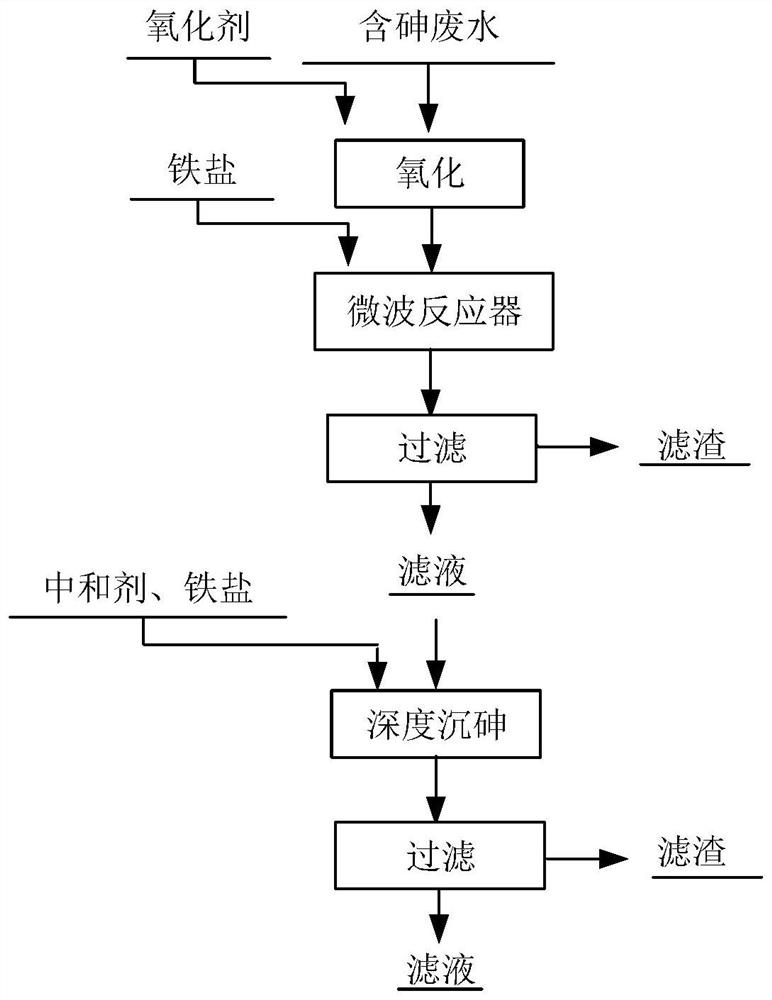

[0028] A method for treating arsenic-containing wastewater of the present invention, the schematic diagram of its technological process is as follows figure 1 As shown, the treated arsenic-containing wastewater is the mixed wastewater (arsenic content is 8.9g / L) of an antimony smelter's arsenic-alkali slag leaching solution and acid sewage, which specifically includes the following steps:

[0029] (1) Add 2 mL of hydrogen peroxide to 220 mL of arsenic-containing wastewater, stir and react for 60 minutes, filter after the reaction, remove the filter residue, and enter the filtrate for subsequent treatment;

[0030] (2) Add the filtrate after step (1) into the microwave reactor, start the microwave, the microwave frequency is 2450MHz, heat up to 85°C, and slowly mix the iron and arsenic molar ratio of 1.25:1 under the stirring speed of 200r / min. Add 30mL of ferric sulfate solution dropwise at a rate of 0.5mL / min, and carry out the arsenic precipitation reaction under the conditi...

Embodiment 2

[0034] A method for treating arsenic-containing wastewater of the present invention, the processed arsenic-containing wastewater is the acid sewage of a certain lead-zinc smelter (its main chemical composition is as shown in Table 1), specifically comprising the following steps:

[0035] Main constituent elements and content of arsenic-containing wastewater in Table 1 Example 2

[0036] element As Cd Pb Cu Zn content 2.17g / L 145mg / L 18mg / L 0.16mg / L 0.56mg / L

[0037] (1) Add 1 mL of hydrogen peroxide to 100 mL of arsenic-containing wastewater, stir and react for 60 minutes, filter after the reaction, remove the filter residue, and enter the filtrate for subsequent processing;

[0038] (2) Put the filtrate after step (1) into the microwave reactor, start the microwave, the microwave power is 2450MHz, heat up to 85°C, at the stirring speed of 200r / min, the molar ratio of iron to arsenic is 1.2:1 and slowly Add 30mL of ferric sulfate solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com