Method for resource utilization and innocent treatment of etching waste liquid containing copper in circuit board industry

A technology of harmless treatment and copper etching, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as temporary treatment but not root cause, environmental pollution, etc., and achieve environmental pollution Less, low operating cost, simple control of water washing volume and temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

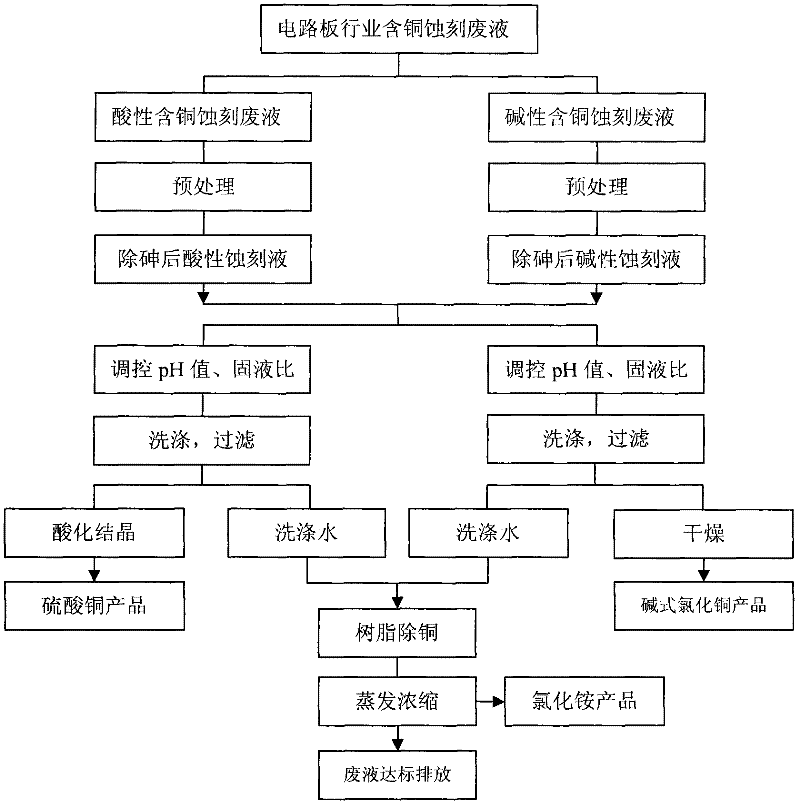

Method used

Image

Examples

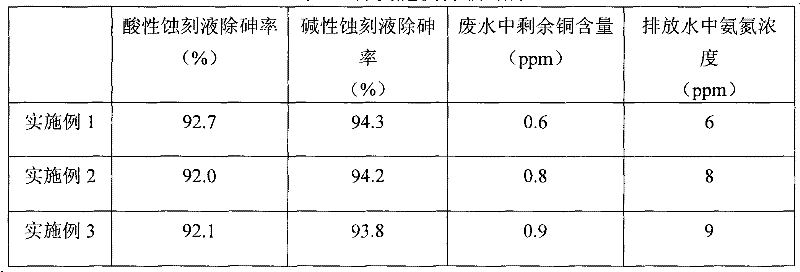

Embodiment 1

[0046] Step A: (1) 1. Get 50 liters of the acidic copper-containing etching waste liquid detected in Table 1, use 100 mesh filter cloth to filter the acidic copper-containing etching waste liquid, and remove the suspended matter in the acidic etching waste liquid, 2. Filter the The acidic copper-containing etching waste liquid is slowly added dropwise to a height of 20 centimeters, and the volume is in the diisooctyl sulfide extraction and leaching resin column of 240 cubic centimeters, and the residence time of the waste liquid at the diisooctyl sulfide extraction and leaching resin column is In 2 minutes, the acidic copper-containing etching waste liquid passed through the diisooctyl sulfide extraction resin column is the etching waste liquid after arsenic removal, and 3. the acidic copper-containing etching waste liquid after removing arsenic is analyzed and detected, and The arsenic content is 1.3ppm, and the removal rate of arsenic is 92.7%; (2) 1. get 50 liters of alkalin...

Embodiment 2

[0051] In addition, the composition of the circuit board acid and alkali copper-containing etching waste solution is shown in Table 2.

[0052] Table 2 Composition of acid and alkali copper-containing etching waste liquid

[0053] Cu 2+ (g / L) Cl - (g / L) pH value As (mg / L) Acidic etching waste 115.90 253.67 -0.94 20 Alkaline etching waste liquid 96.12 148.76 8.85 15.5

[0054] Step A: (1) 1. Get 1 ton of the acidic copper-containing etching waste liquid detected in Table 2, and use a 70-purpose filter cloth to filter the acidic copper-containing etching waste liquid to remove suspended objects in the acidic etching waste liquid. The acidic copper-containing etching waste liquid is slowly added dropwise to a height of 1 meter, and the volume is in the diisooctyl sulfide extraction and leaching resin column of 12 cubic meters. The residence time of the waste liquid in the diisooctyl sulfide extraction and leaching resin c...

Embodiment 3

[0059] In addition, the components of the circuit board acid and alkali copper-containing etching waste liquid are shown in Table 3.

[0060] Table 3 Composition of acid and alkali copper-containing etching waste liquid

[0061] Cu 2+ (g / L) Cl - (g / L) pH value As (mg / L) Acidic etching waste 108.37 245.32 -0.99 21.5 Alkaline etching waste liquid 84.54 145.38 8.84 16

[0062]Step A: (1) ① get 10 tons of acidic copper-containing etching waste liquid detected in table 3, use 50 purpose filter cloth to filter acidic copper-containing etching waste liquid, remove suspended matter in the acidic etching waste liquid, ② filtered The acidic copper-containing etching waste liquid is slowly added dropwise to a height of 1 meter, and the volume is in the diisooctyl sulfide extraction and leaching resin column of 12 cubic meters. The residence time of the waste liquid in the diisooctyl sulfide extraction and leaching resin column is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com