Treatment method of arsenic wastewater

A treatment method and technology for wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can achieve the effects of high chemical utilization rate and reaction efficiency, small chemical dosage, and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

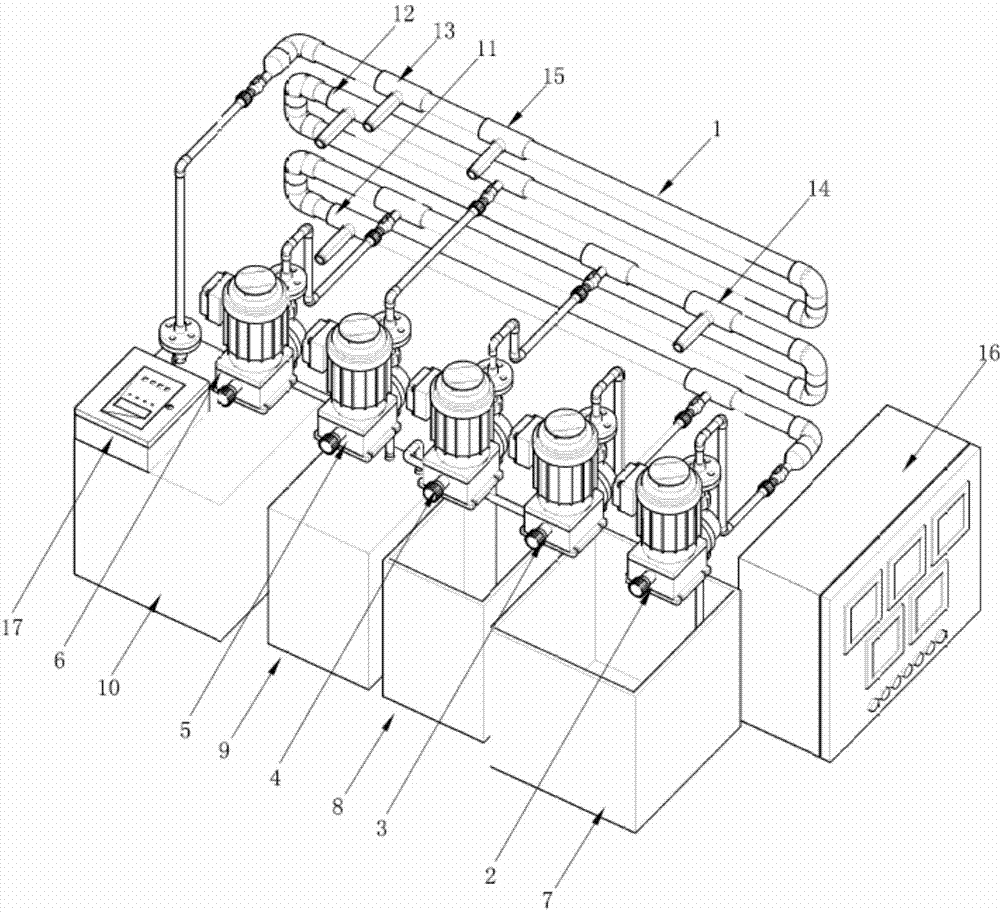

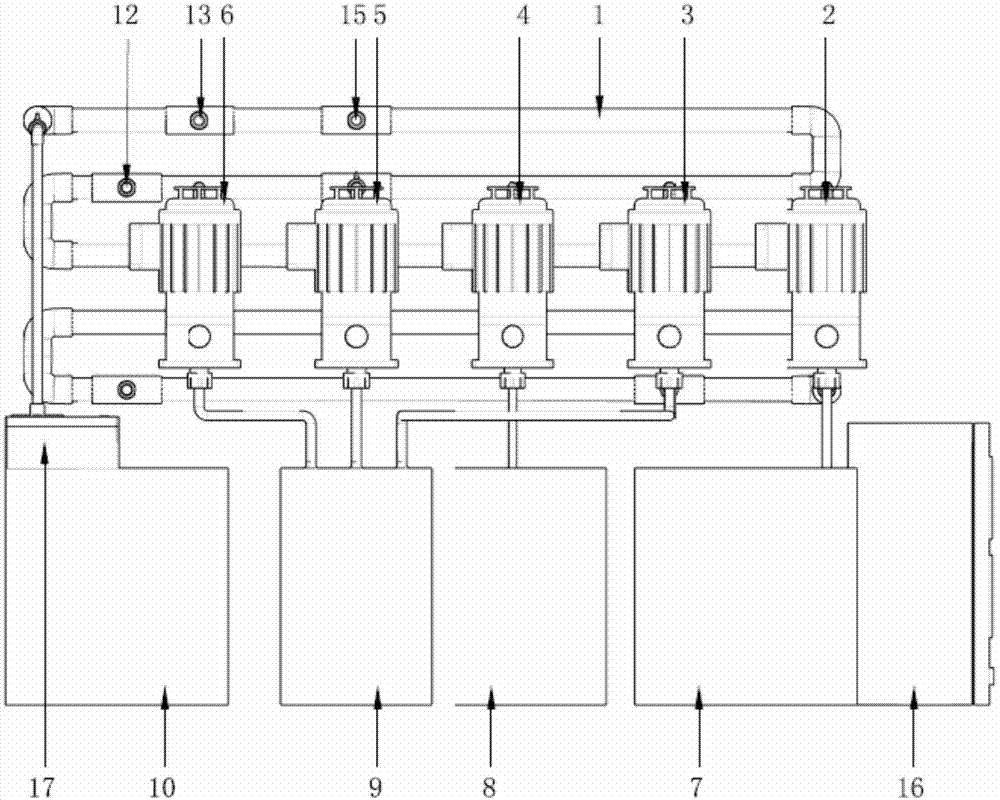

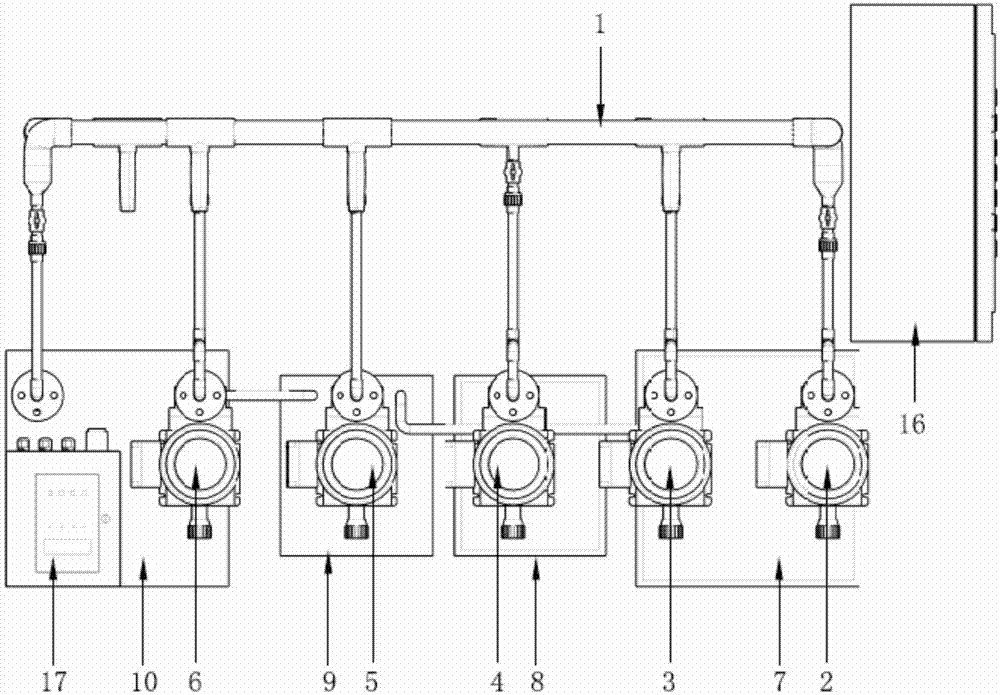

Image

Examples

Embodiment 1

[0037] A kind of wastewater containing high concentration of arsenic and heavy metals to be treated, wherein the content of arsenic is 10000mg / L, the content of cadmium is 100mg / L, the content of copper is 50mg / L, the content of lead is 80mg / L, the pH of the wastewater is 8, and the present invention is adopted as Figure 4 The treatment method shown is to treat the arsenic-containing wastewater by adopting a continuous water inflow method, and the treatment volume is controlled at 500L / h, which specifically includes the following steps:

[0038] (a) pH adjustment: transport the waste water to be treated to the first adjustment tank, add concentrated sulfuric acid to the waste water to be treated, and adjust its pH value to below 5;

[0039] (b) Sulfurization and arsenic removal: Pass the pH-adjusted wastewater into a tubular arsenic removal continuous treatment device (referred to as the tubular arsenic removal device), and control the pH value of the reaction environment in ...

Embodiment 2

[0062] A kind of wastewater containing high concentration of arsenic and heavy metals to be treated, wherein the content of arsenic is 5000mg / L, the content of cadmium is 80mg / L, the content of copper is 30mg / L, the content of lead is 50mg / L, the pH of wastewater=6, adopt the present invention The treatment method for this arsenic-containing wastewater is treated by continuous water inflow, and the treatment volume is controlled at 1000L / h, which specifically includes the following steps:

[0063] (a) pH adjustment: step (a) of this example is the same as Example 1;

[0064] (b) Sulfurization and arsenic removal: Step (b) of this example is the same as that of Example 1;

[0065] (c) Solid-liquid separation: Step (c) of this example is the same as Example 1; the arsenic content in the effluent after centrifugation is 0.3 mg / L, the cadmium content is 0.8 mg / L, and the copper content is 0.4 mg / L. The lead content is 1.2 mg / L (see Table 2 below); it can be seen that the removal ...

Embodiment 3

[0072] A kind of wastewater containing high concentration of arsenic and heavy metals to be treated, wherein the content of arsenic is 1000mg / L, the content of cadmium is 10mg / L, the content of copper is 8mg / L, the content of lead is 20mg / L, the pH of wastewater=5, adopt the present invention The treatment method for this arsenic-containing wastewater is treated by continuous water inflow, and the treatment volume is controlled at 2000L / h, which specifically includes the following steps:

[0073] (a) pH adjustment: step (a) of this example is the same as Example 1;

[0074] (b) Sulfurization and arsenic removal: Step (b) of this example is the same as that of Example 1;

[0075] (c) Solid-liquid separation: Step (c) of this example is the same as Example 1; the arsenic content in the effluent after centrifugation is 0.4 mg / L, the cadmium content is 0.2 mg / L, and the copper content is 0.3 mg / L. The lead content is 0.5mg / L (see Table 3 below); it can be seen that the removal ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com