Method for treating arsenic in waste smelting acid by using copper slag

A technology of copper slag and dirty acid, applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of toxic elements polluting the environment, difficult to stockpile, difficult to recycle, etc., to achieve simple operation process, Low economic cost, good arsenic removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the method of this copper slag processing non-ferrous smelting dirty acid is as follows:

[0023] 1. Carry out dry copper slag (see Table 1 for copper slag composition) by ball milling and magnetic separation (the speed of the ball mill is 760r / min, the grinding time is 11min, and the magnetic separation intensity of the magnetic separator is 800mT) to obtain iron-rich copper slag and other Impurities; other impurities are stockpiled and processed, and the iron-rich copper slag is pretreated at 800°C for 6 hours;

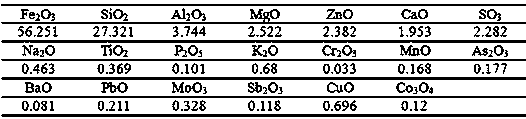

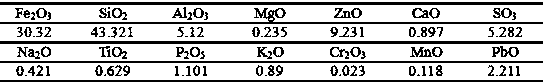

[0024] Table 1

[0025] ;

[0026] 2. Water-quench the high-temperature iron-rich copper slag with high-speed water injection. The flow rate of high-speed water is 14m / s. After water-quenching, the copper slag is dried and ground, and the particle size of the copper slag is controlled below 200 mesh;

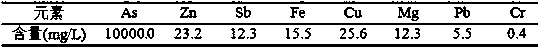

[0027] 3. Press H 2 o 2 With a molar ratio of 1.2:1 to arsenic, the H 2 o 2 Mix it with dirty acid (the dirty acid comes from the sulfuri...

Embodiment 2

[0033] Embodiment 2: the method of this copper slag processing non-ferrous smelting dirty acid is as follows:

[0034] 1. Ball mill and magnetically separate the dried copper slag (composition of the copper slag is shown in Table 1) (the speed of the ball mill is 910r / min, the grinding time is 8min, and the magnetic separation intensity of the magnetic separator is 1000mT) to obtain iron-rich copper slag and other impurities ; Other impurities are stockpiled and treated, and the iron-rich copper slag is pretreated at a temperature of 500 ° C for 8 hours;

[0035] Table 1

[0036]

[0037] 2. Water-quench the high-temperature iron-rich copper slag with high-speed water injection. The flow rate of high-speed water is 12m / s. After water-quenching, the copper slag is dried and ground, and the particle size of the copper slag is controlled below 200 mesh;

[0038] 3. Press H 2 o 2 With a molar ratio of 1:1 to arsenic, the H 2 o 2 Mix it with dirty acid (the dirty acid comes...

Embodiment 3

[0044] Embodiment 3: the method of this copper slag processing non-ferrous smelting dirty acid is as follows:

[0045] 1. The dry copper slag (composition of the copper slag is shown in Table 1) is subjected to ball milling and magnetic separation (the speed of the ball mill is 800r / min, the grinding time is 9min, and the magnetic separation intensity of the magnetic separator is 900mT) to obtain iron-rich copper slag and other Impurities; other impurities are stockpiled and processed, and the iron-rich copper slag is pretreated at 650°C for 7 hours;

[0046] Table 1

[0047]

[0048] 2. Water-quench the high-temperature iron-rich copper slag with high-speed water injection. The flow rate of high-speed water is 11m / s. After water-quenching, the copper slag is dried and ground, and the particle size of the copper slag is controlled below 200 mesh;

[0049] 3. Press H 2 o 2 With a molar ratio of 1.1:1 to arsenic, the H 2 o 2 Mix it with dirty acid (the dirty acid comes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com