Adsorbing material for removing arsenic from water and preparation method of material

A technology for adsorbing materials and water bodies, applied in the field of arsenic-containing water purification treatment materials and processes, can solve problems such as not being widely used, and achieve the effects of large specific surface area, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

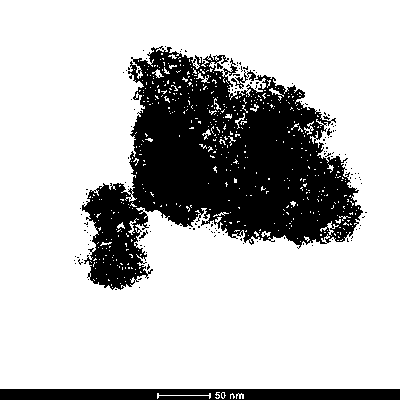

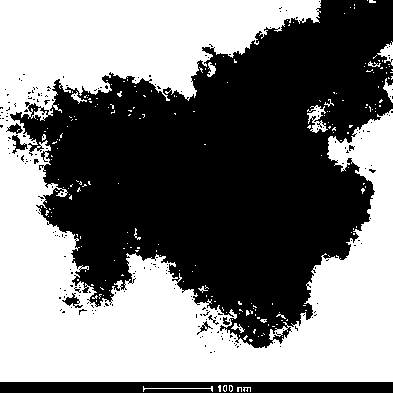

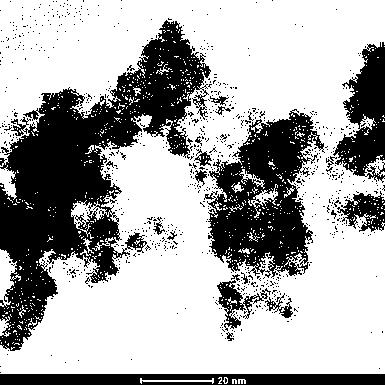

Image

Examples

Embodiment 1

[0031] (1) Weigh 4.040g Fe(NO 3 ) 3 ?9H 2 O, dissolved in 200ml deionized water to obtain Fe 3+ Molar concentration is the iron nitrate solution of 0.05mol / L;

[0032] (2) Weigh 0.02g of surfactant sodium dodecyl sulfonate, add it to the above solution, and stir to make it uniform;

[0033] (3) Add potassium hydroxide to the solution in step (2), and keep stirring until the pH of the solution=10, forming a large amount of insoluble matter;

[0034] (4) Collect a large amount of insoluble matter described in step (3) by suction filtration, wash with deionized water, and suction filtration until the pH of the solution is neutral;

[0035] (5) Collect the solid insolubles in step (4), and dry them in the air at 60°C to obtain amorphous ferric hydroxide powder.

Embodiment 2

[0037] (1) Weigh 40.40g Fe(NO 3 ) 3 ?9H 2 O, dissolved in 200ml deionized water to obtain Fe 3+ Molar concentration is the iron nitrate solution of 0.5mol / L;

[0038] (2) Weigh 0.02g of surfactant sodium dodecyl sulfonate, add it to the above solution, and stir to make it uniform;

[0039] (3) Add ammonia water to the solution in step (2), and keep stirring until the pH of the solution=10, forming a large amount of insoluble matter;

[0040] (4) Collect a large amount of insoluble matter described in step (3) by suction filtration, wash with deionized water, and suction filtration until the pH of the solution is neutral;

[0041] (5) Collect the solid insolubles in step (4), and dry them in the air at 60°C to obtain amorphous ferric hydroxide powder.

[0042] (6) At room temperature, weigh 0.2 g of the above-mentioned adsorption materials in a series of 250 mL Erlenmeyer flasks with stoppers, and add 100 mL of a certain concentration of As ( ) (AsO 2 - ) solution, pla...

Embodiment 3

[0047] (1) Weigh 40.40g Fe(NO 3 ) 3 ?9H 2 O, dissolved in 200ml deionized water to obtain Fe 3+ Molar concentration is the iron nitrate solution of 0.5mol / L;

[0048] (2) Weigh 0.87g Ce(NO 3 ) 3 ?6H 2 O, dissolved in the solution of step (1), yields Ce 3+ Molar concentration is the cerous nitrate solution of 0.01mol / L;

[0049] (3) Weigh 0.02g of surfactant sodium dodecylsulfonate, add it to the above solution, and stir to make it uniform;

[0050] (4) Weigh 0.68 g of hydrogen peroxide with a mass fraction of 30% and pour it into the solution in step (3) (Ce 3+ The molar ratio of hydrogen peroxide to hydrogen peroxide is 1:3), and keep stirring to oxidize trivalent cerous ions into tetravalent ceric ions;

[0051] (5) Add potassium hydroxide to the solution in step (4), and keep stirring until the pH of the solution=10, forming a large amount of insoluble matter;

[0052] (6) Collect a large amount of insoluble matter described in step (5) by suction filtration, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com