Method for preparing diamond/silicon carbide ceramic matrix composite material

A silicon carbide ceramic matrix and composite material technology, applied in the field of ceramic materials, can solve the problems of low equipment requirements, high equipment requirements and high cost, and achieve the effects of low equipment requirements, simple impregnation process and low-cost preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

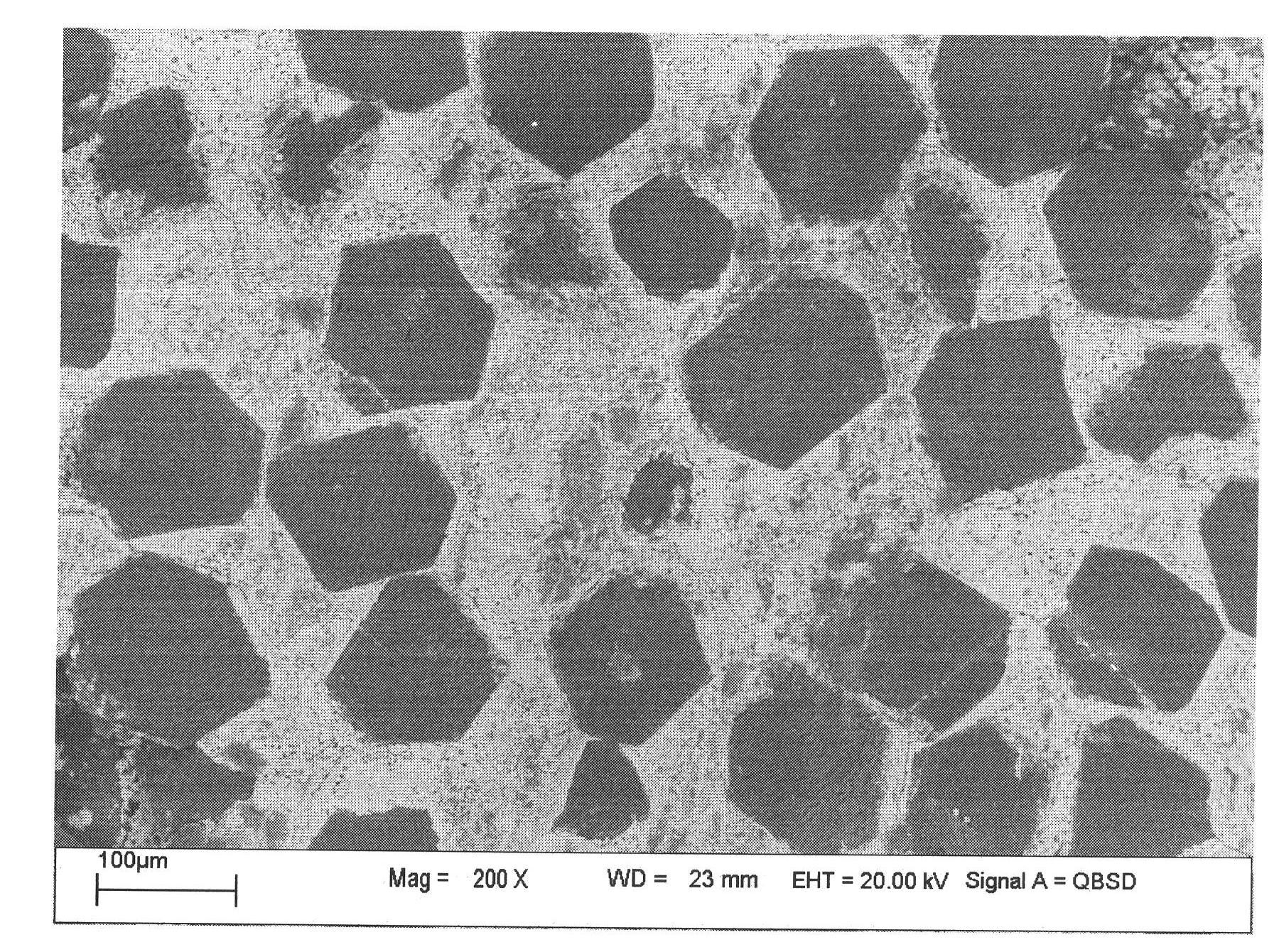

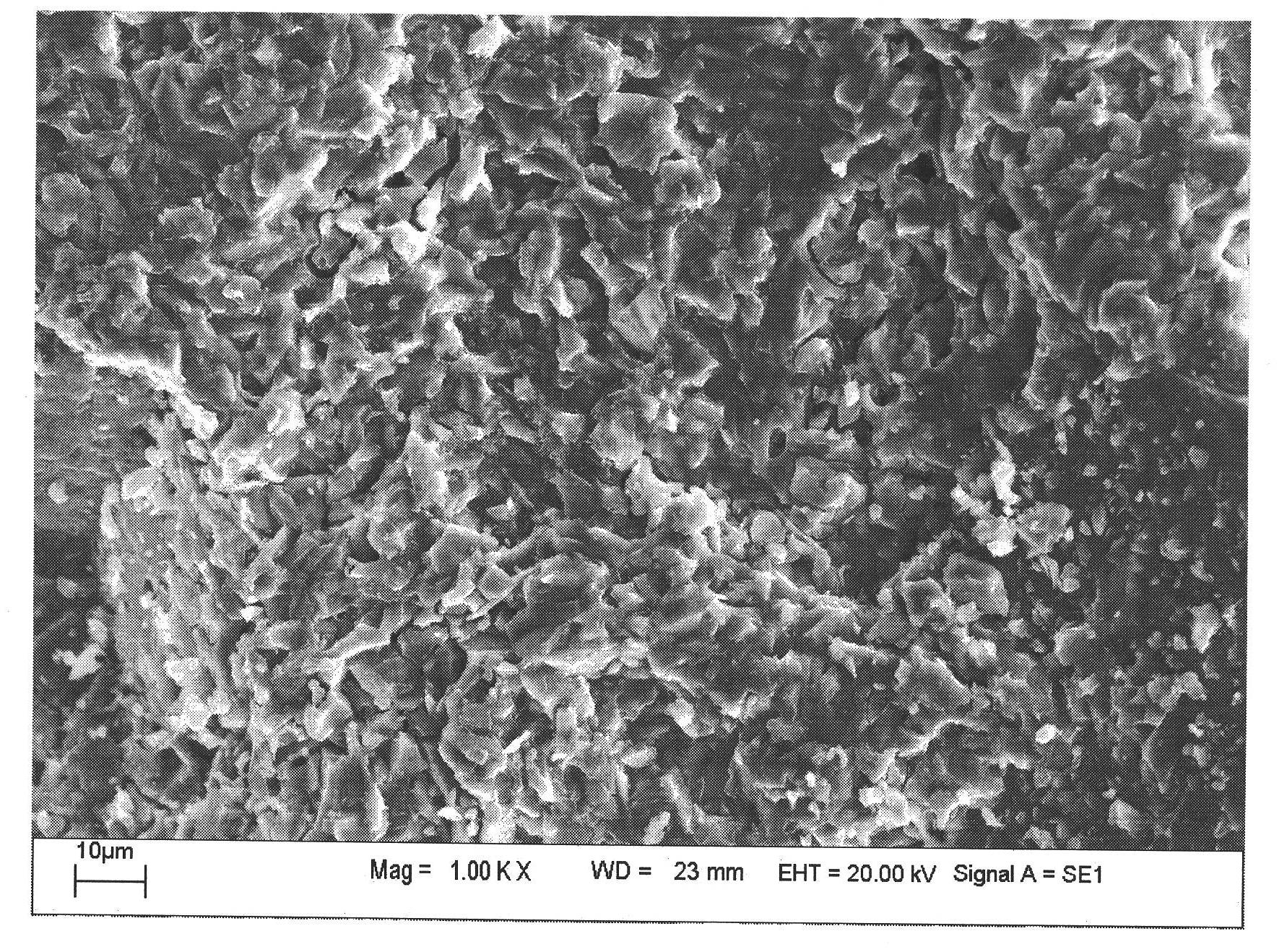

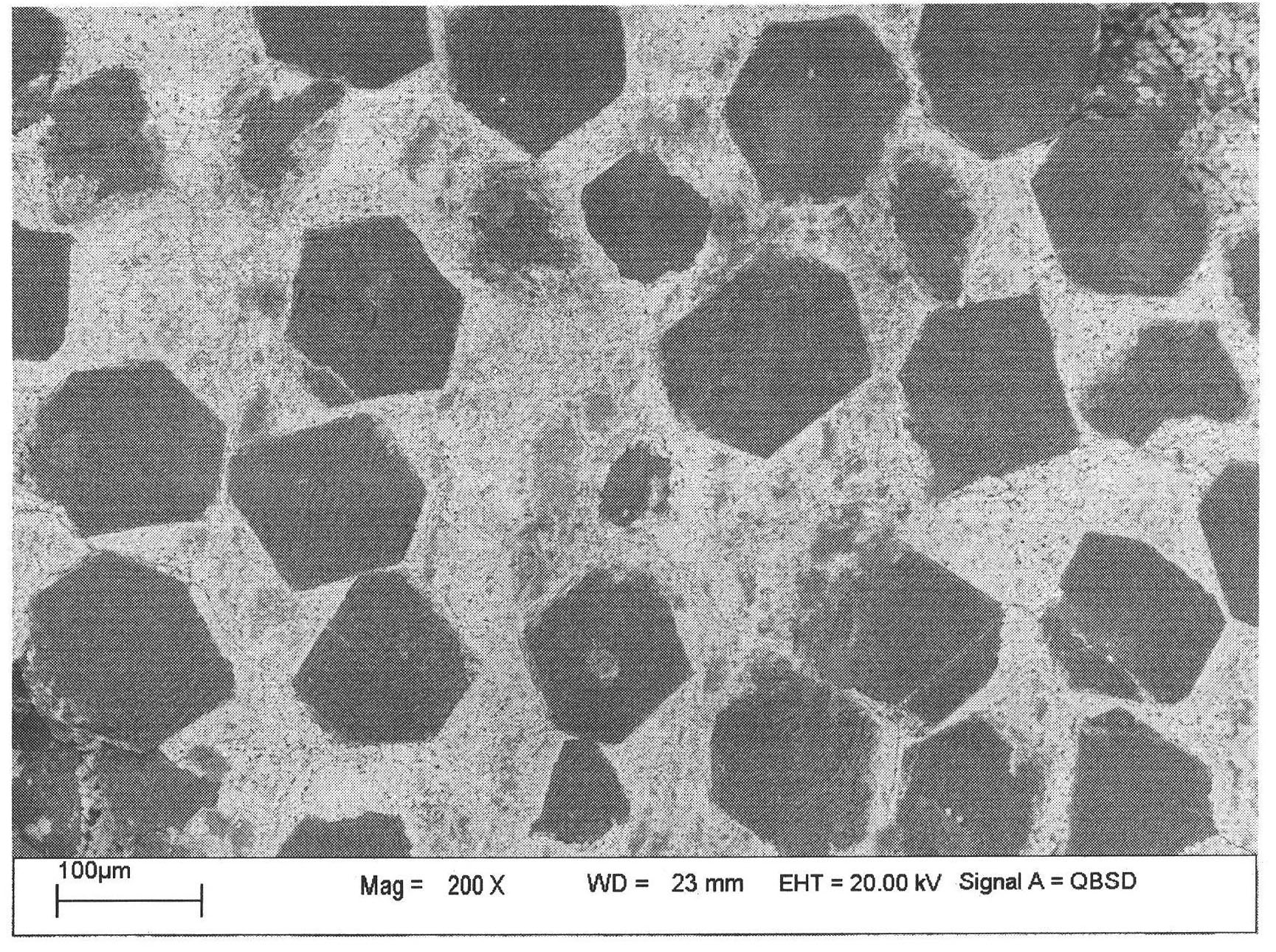

[0017] In terms of weight percentage, 9.7% of adhesive, 28.3% of silicon carbide powder with a particle size of 10 μm, and 62% of diamond particles with a particle size of 120 μm were wet mixed in n-hexane for 8 hours, dried, crushed, sieved and placed in a hydraulic press Upper compression molding, pressing pressure 75MPa, preoxidation in air at 200°C for 9h, sintering at 1000°C in nitrogen protective atmosphere for 12h, to obtain a density of 2.53g / cm 3 porous substrate.

[0018] The porous matrix is vacuum impregnated in the precursor impregnation solution, the impregnation vacuum degree is -0.1MPa, the impregnation time is 1h, the mass concentration of the impregnation solution is 40%, pre-oxidized in air at 200°C for 9h, and sintered at 1000°C in a nitrogen protective atmosphere After 12 hours, after cooling with the furnace, vacuum impregnation, oxidation, sintering, and cooling were carried out under the same conditions. After 7 cycles, a dense diamond / silicon carbide...

Embodiment 2

[0020] In terms of weight percentage, 7.5% of adhesive, 21.5% of silicon carbide powder with a particle size of 20 μm, and 71% of diamond particles with a particle size of 140 μm were wet-mixed in n-hexane for 10 hours, dried, crushed, sieved and placed in a hydraulic press Upper compression molding, pressing pressure 225MPa, pre-oxidation in air at 200°C for 9h, sintering at 1200°C in a nitrogen protective atmosphere for 14h, to obtain a density of 2.61g / cm 3 porous substrate.

[0021] The porous matrix is vacuum impregnated in the precursor impregnation solution, the impregnation vacuum degree is -0.1MPa, the impregnation time is 1h, the mass concentration of the impregnation solution is 30%, pre-oxidized in air at 200°C for 9h, and sintered at 1200°C in a nitrogen protective atmosphere After 14 hours, after cooling with the furnace, vacuum impregnation, oxidation, sintering, and cooling were carried out under the same conditions. After 7 cycles, a dense diamond / silicon ca...

Embodiment 3

[0023] In terms of weight percentage, 7.5% of adhesive, 44% of silicon carbide powder with a particle size of 10 μm, and 48.5% of diamond particles with a particle size of 120 μm were mixed in n-hexane for 8 hours, dried, crushed, sieved and placed in a hydraulic press Upper compression molding, pressing pressure 225MPa, pre-oxidation in air at 200°C for 9h, sintering at 1000°C in a nitrogen protective atmosphere for 8h, to obtain a density of 2.46g / cm 3 porous substrate.

[0024] The porous matrix is vacuum impregnated in the precursor impregnation solution, the impregnation vacuum degree is -0.1MPa, the impregnation time is 1h, the mass concentration of the impregnation solution is 40%, pre-oxidized in air at 200°C for 9h, and sintered at 1000°C in a nitrogen protective atmosphere 8h, after cooling with the furnace, vacuum impregnation, oxidation, sintering, and cooling were carried out under the same conditions, and a dense diamond / silicon carbide ceramic matrix composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com