Patents

Literature

35results about How to "Avoid subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of U-shaped through channels

InactiveCN103710733AAvoid subsequent processingIncrease productivityElectroforming processesElectricityEngineering

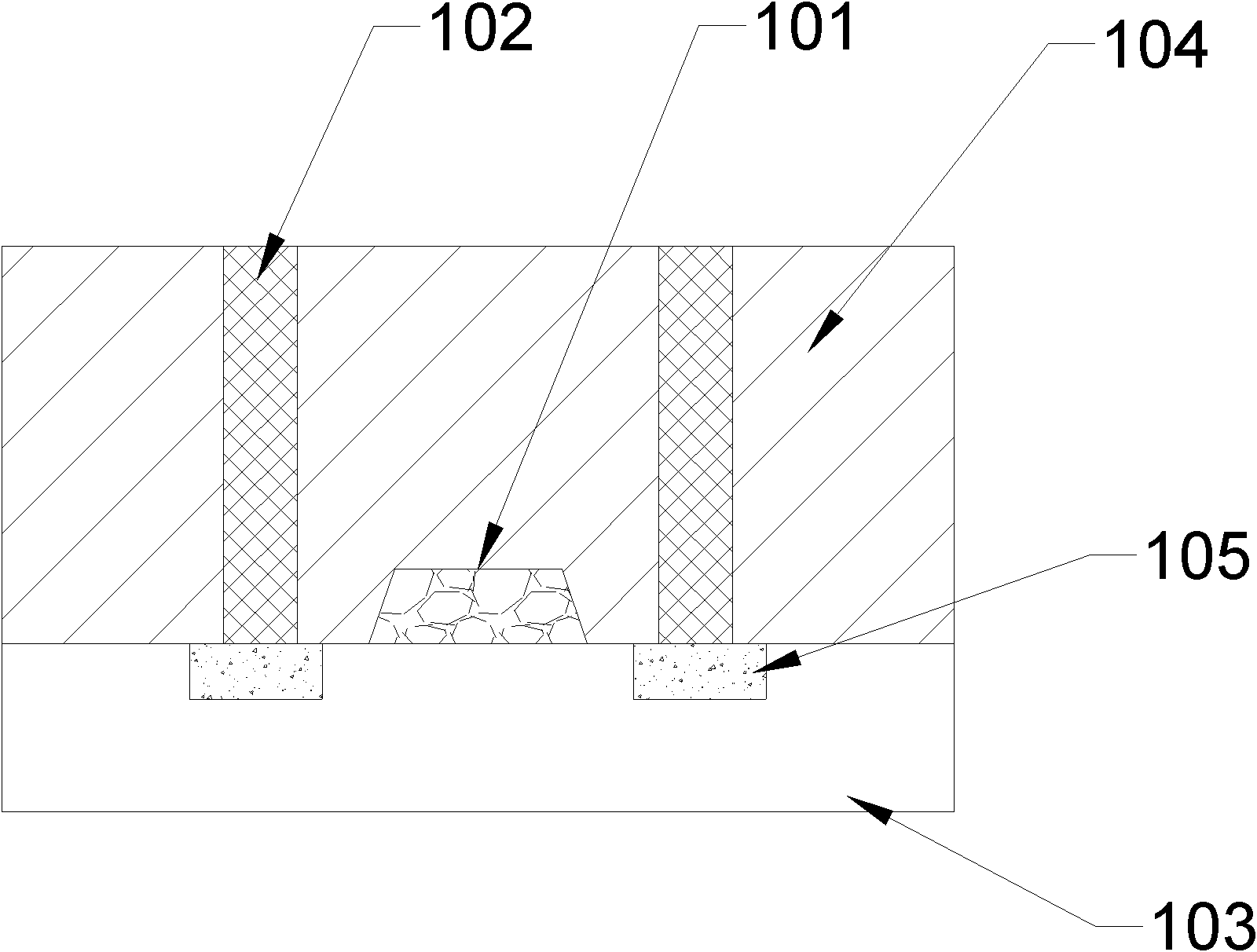

The invention discloses a processing method of U-shaped through channels, which is applied to the through channels which are difficult to process by conventional processing or extremely high in processing cost, belonging to the special processing field. U-shaped through channels with different sections and dimensions are constructed by a mechanically processed base body and a covering layer manufactured by electro-casting. The processing method comprises the following steps: firstly, processing out grooves with sections the same as those of the channels on a corresponding dimension position of the base body, filling filler capable of being removed in the grooves; then, electro-casting a metal covering layer with a certain thickness on the base body by adopting an electro-casting technology; and finally, removing the filler to form through channels. The processing method disclosed by the invention can construct a channel array by one step without being limited by channel section shapes and travelling paths as well as arrangement direction and quantity of channels. The processing method disclosed by the invention further can be used for directly electro-casting and forming holes on an electro-casting structural piece.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

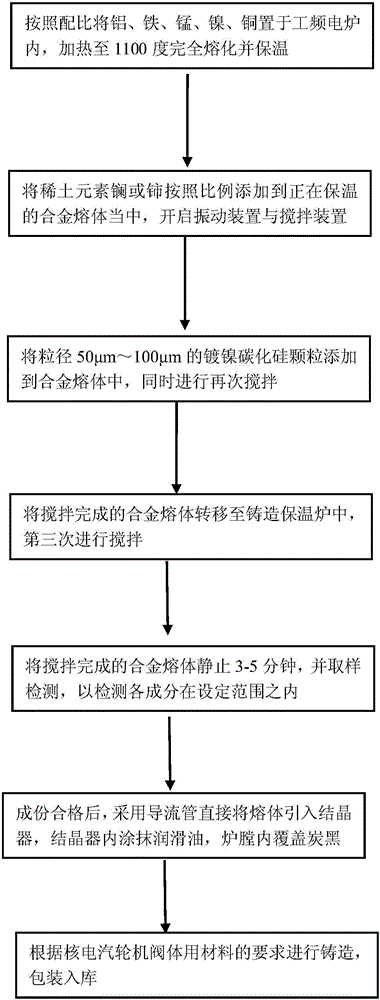

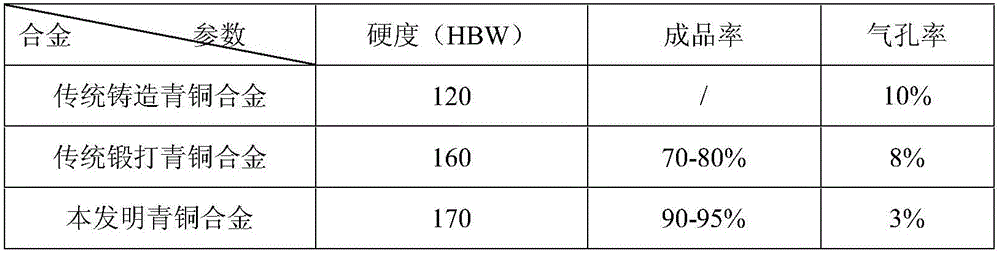

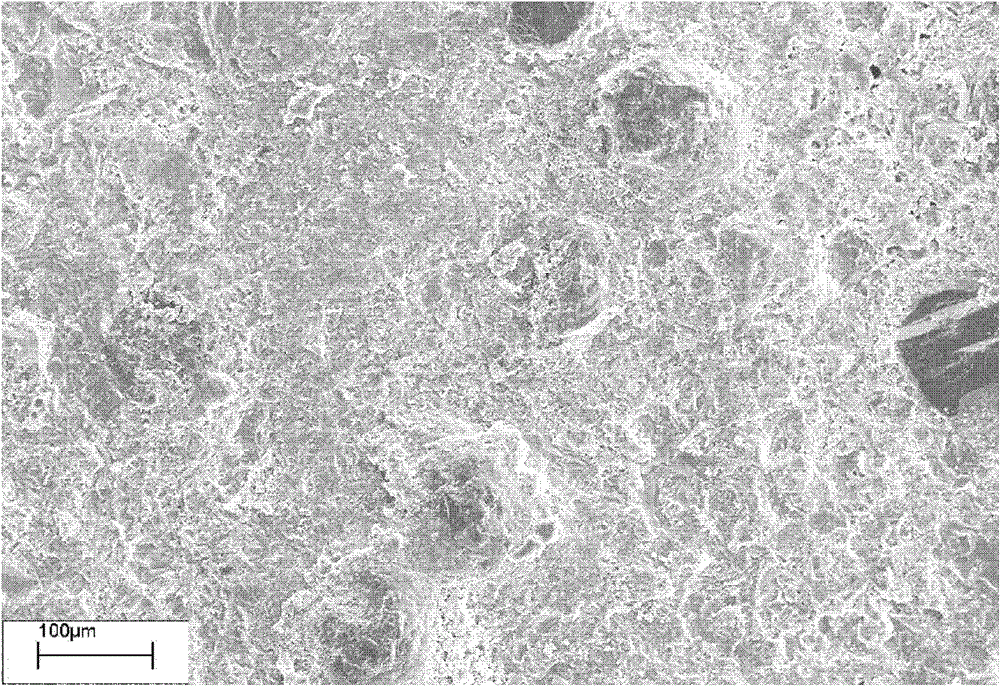

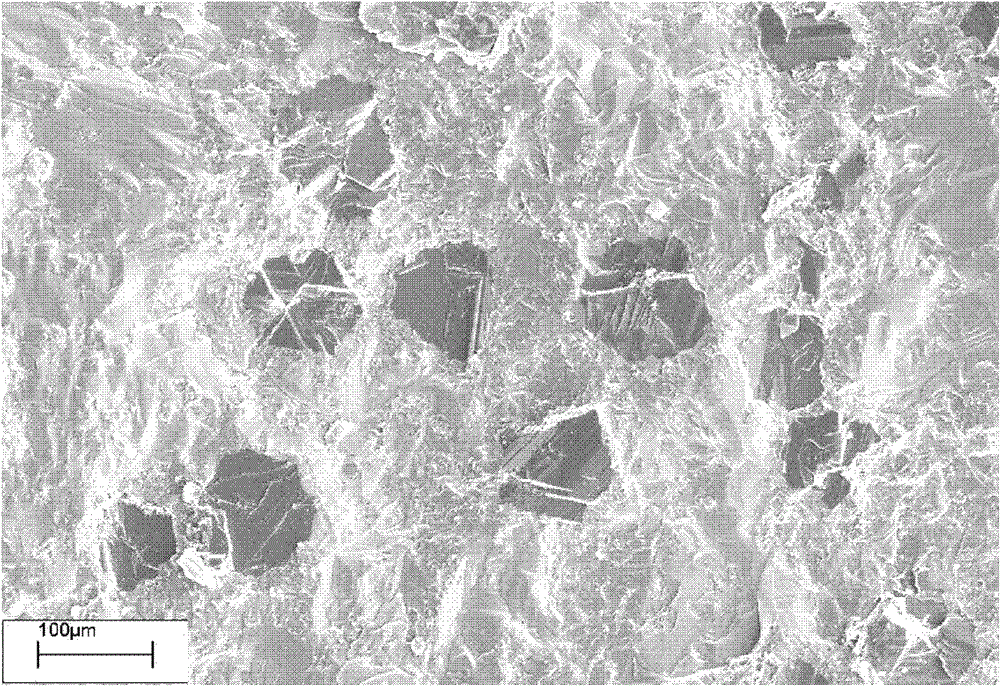

Cast bronze alloy material and preparation method thereof

InactiveCN106636728AHigh hardnessImprove particle size structureLiquid/solution decomposition chemical coatingCeriumManganese

The invention relates to a cast bronze alloy material, in particular to a cast bronze alloy material for a nuclear turbine valve body. The alloy material comprises the following components in percent by weight: 0.5 to 1.5 percent of nickel plating silicon carbide, 15 to 17 percent of aluminum, 4 to 5.5 percent of iron, 0.5 to 1.5 percent of manganese, 0.5 to 1.2 percent of nickel, 0.2 to 0.7 percent of lanthanum or cerium, and the balance copper and inevitable impurities. The strength and the hardness of the alloy material can be realized without the need for further forging or heat treating alloy, the production cost is reduced, the production process is simplified, and the requirement on the material for the nuclear turbine valve body is met. The invention further relates to a preparation method of the cast bronze alloy material.

Owner:SUZHOU TIANJIAN METAL NEW MATERIAL

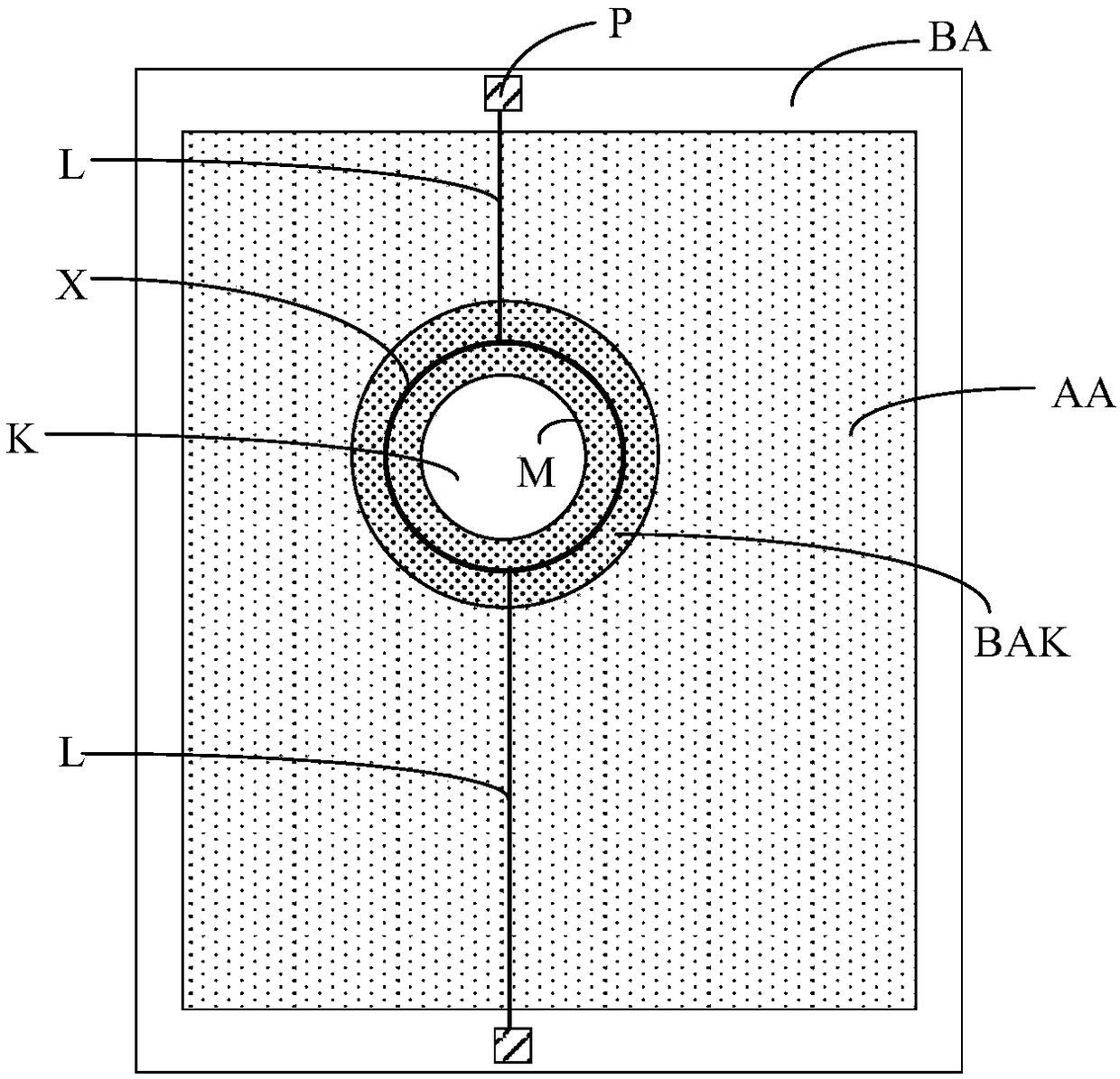

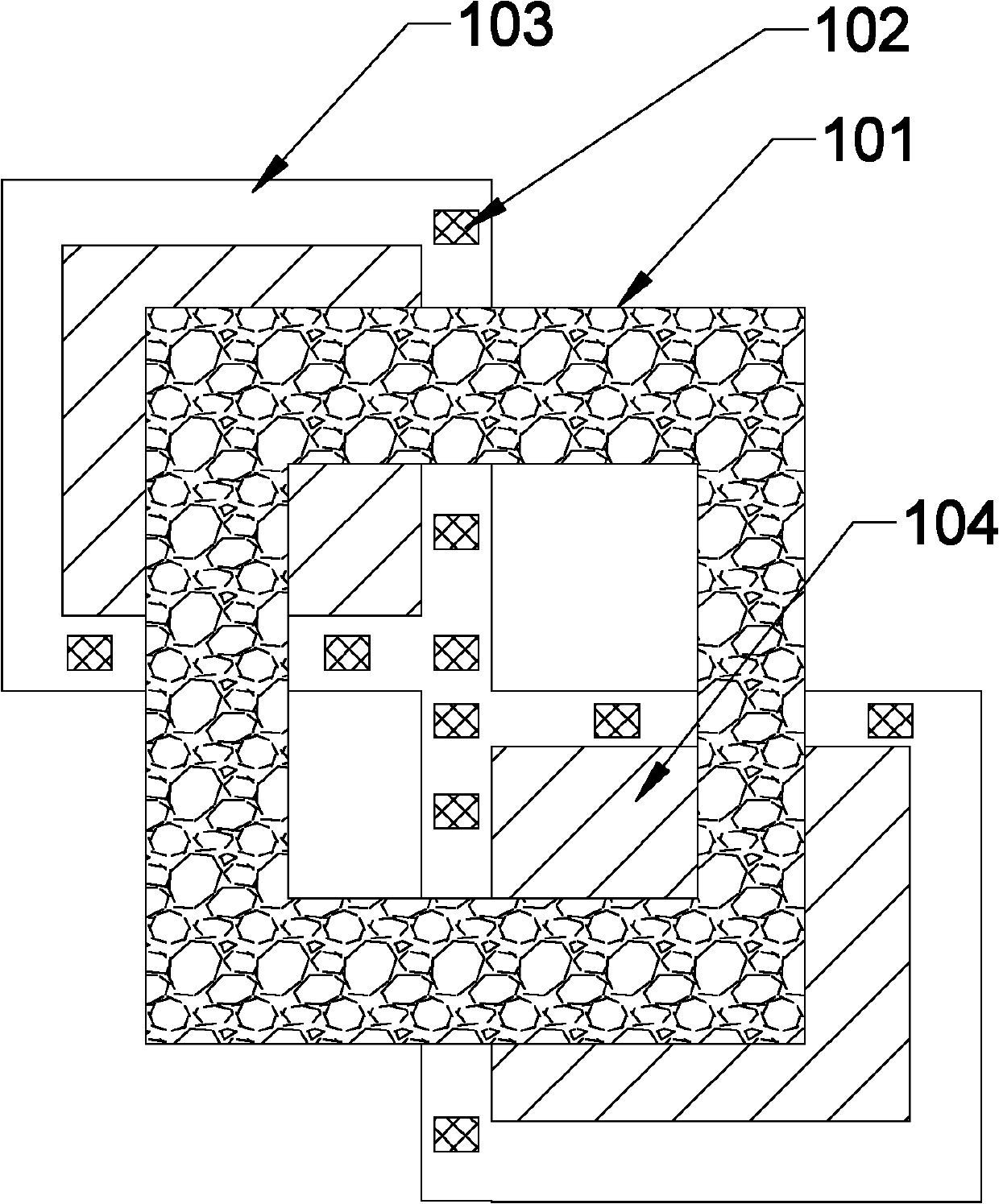

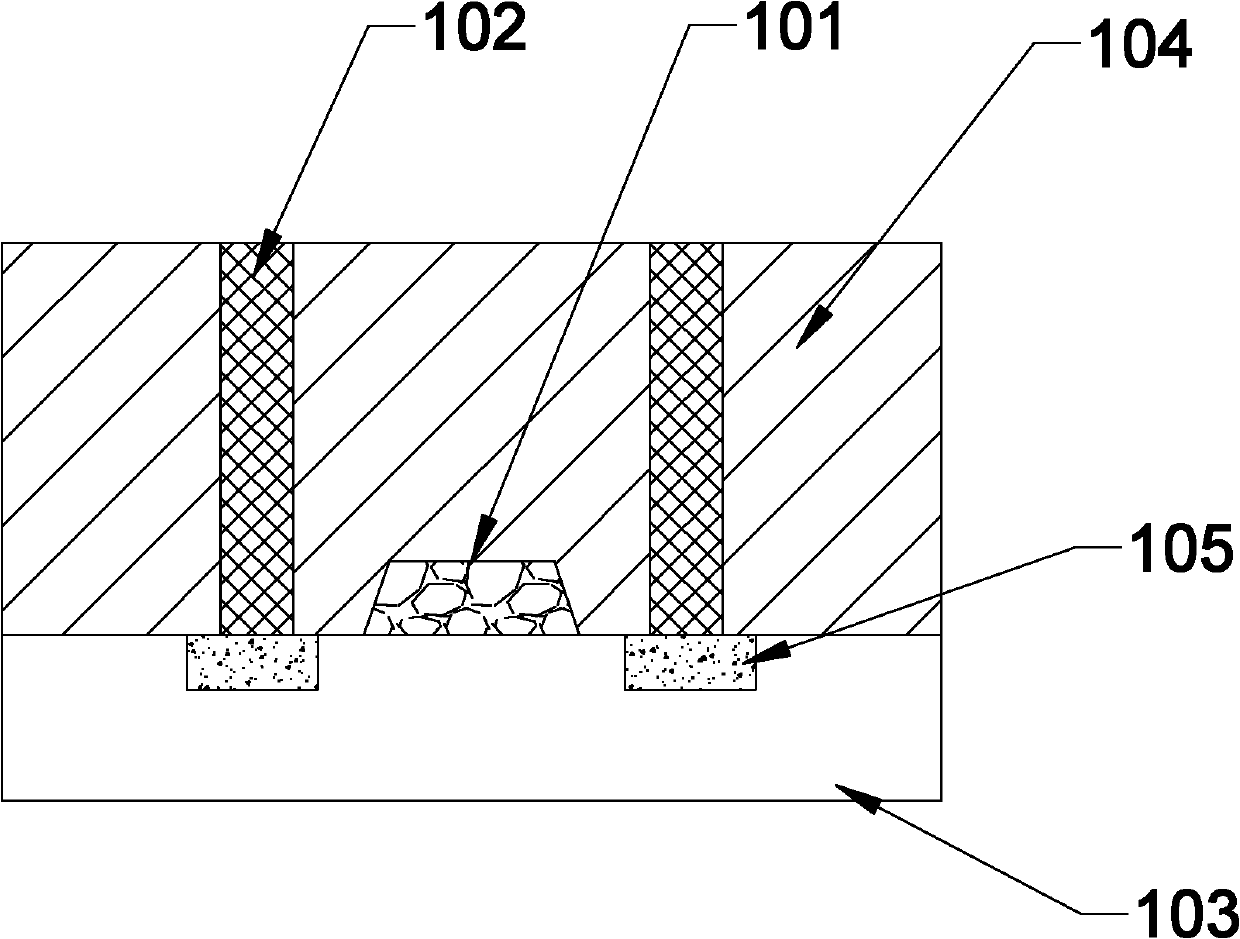

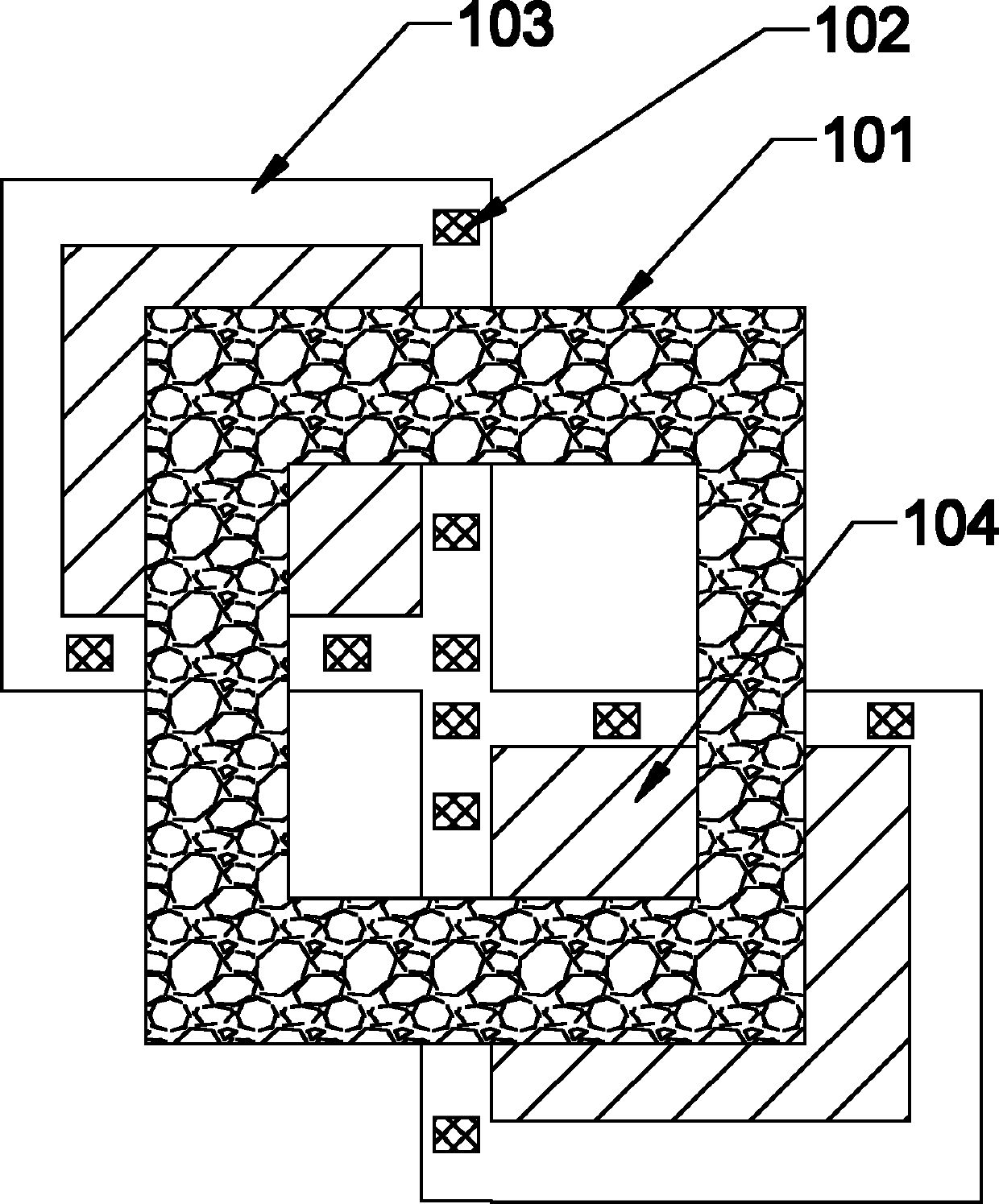

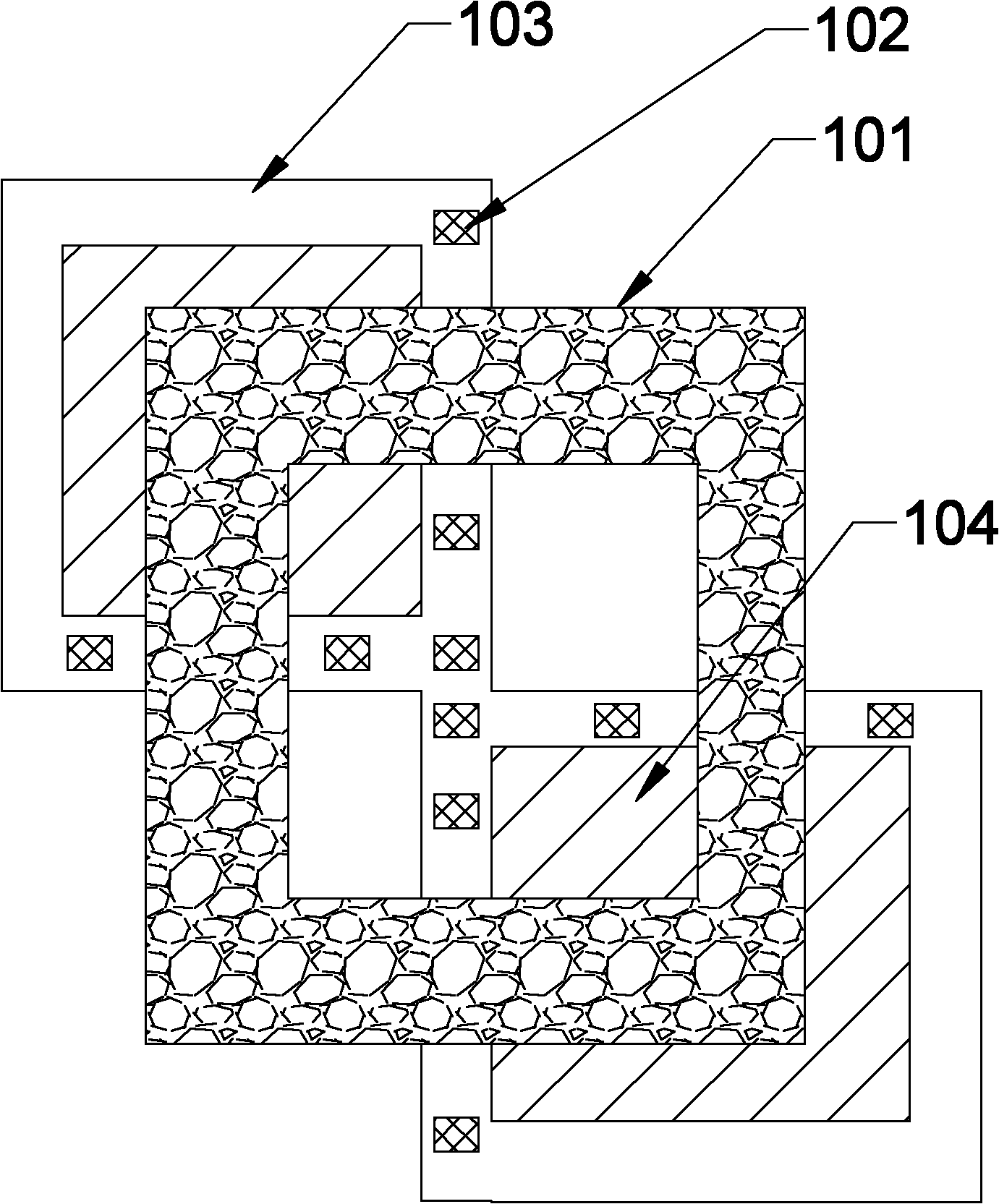

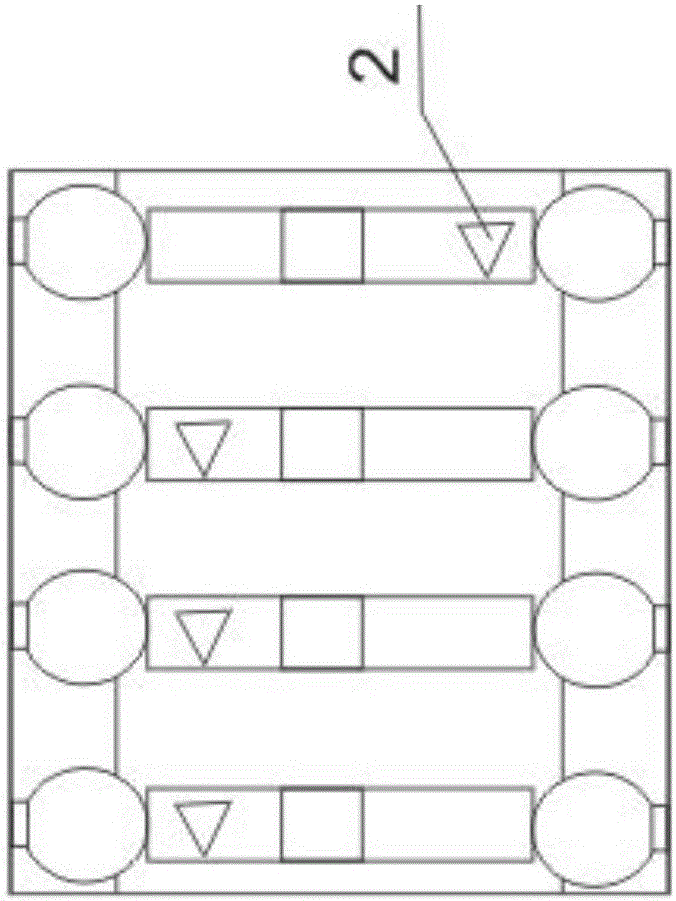

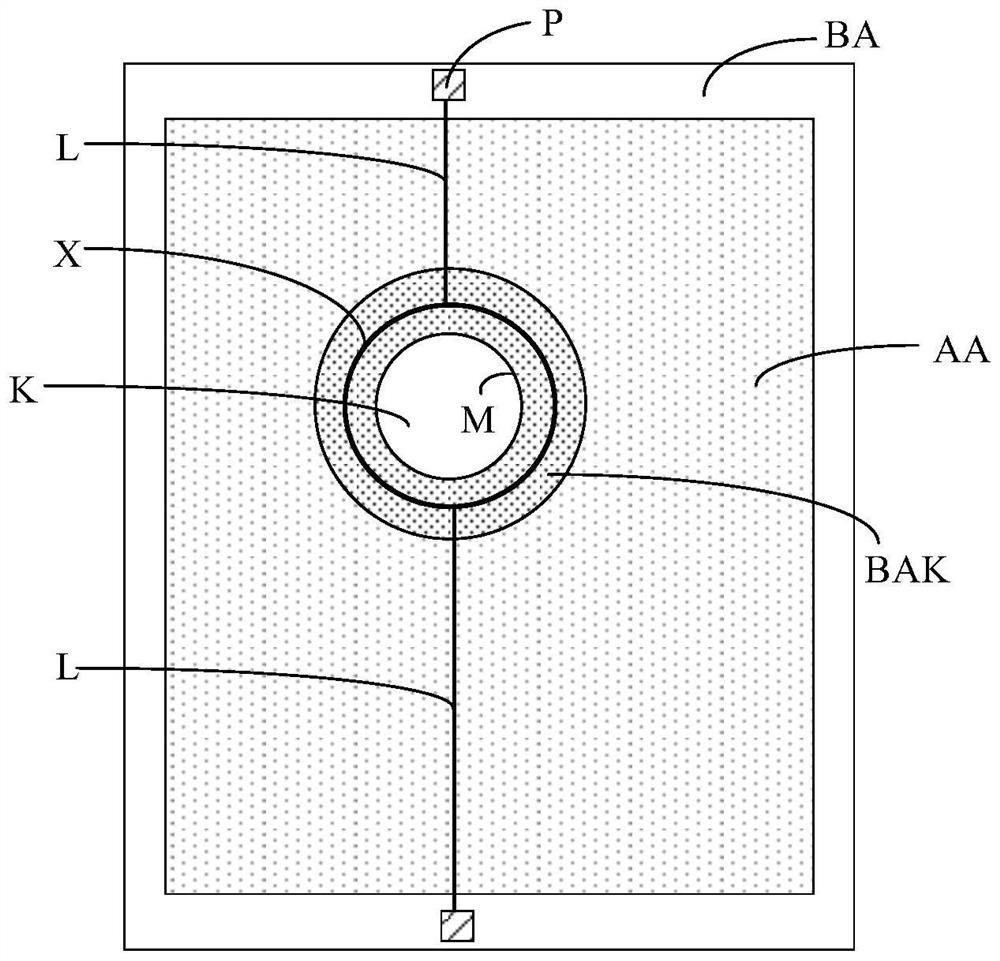

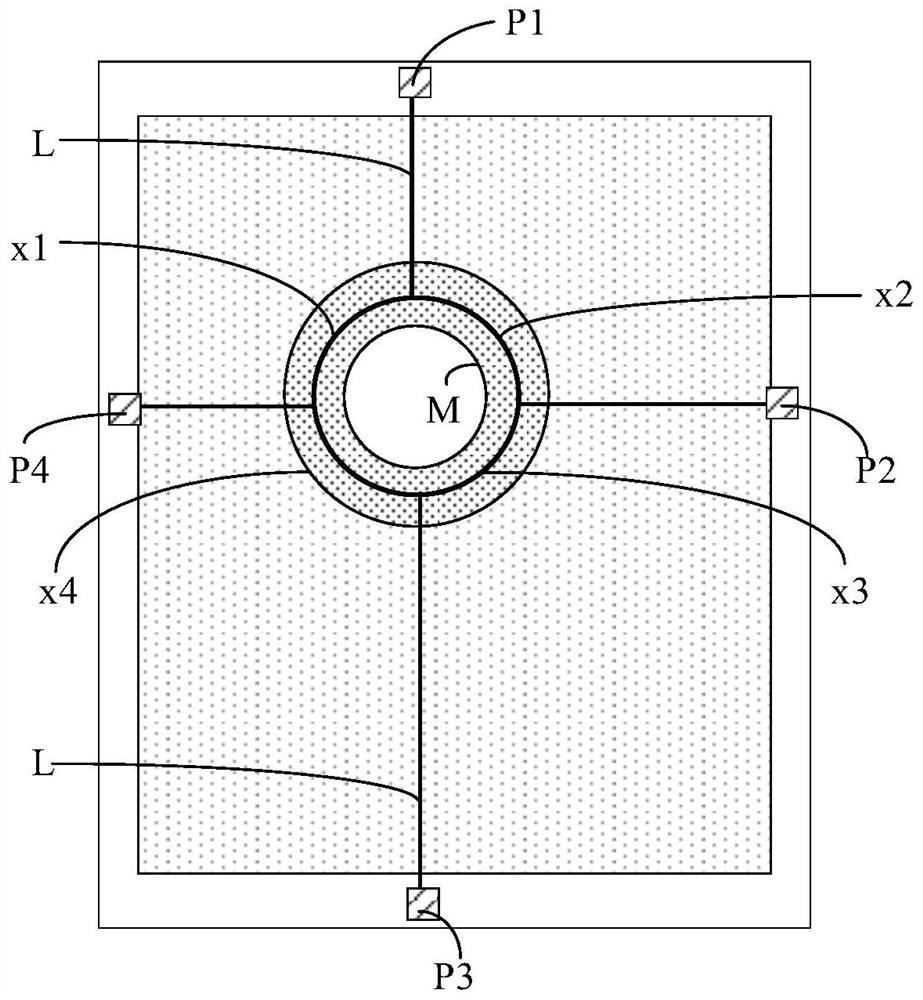

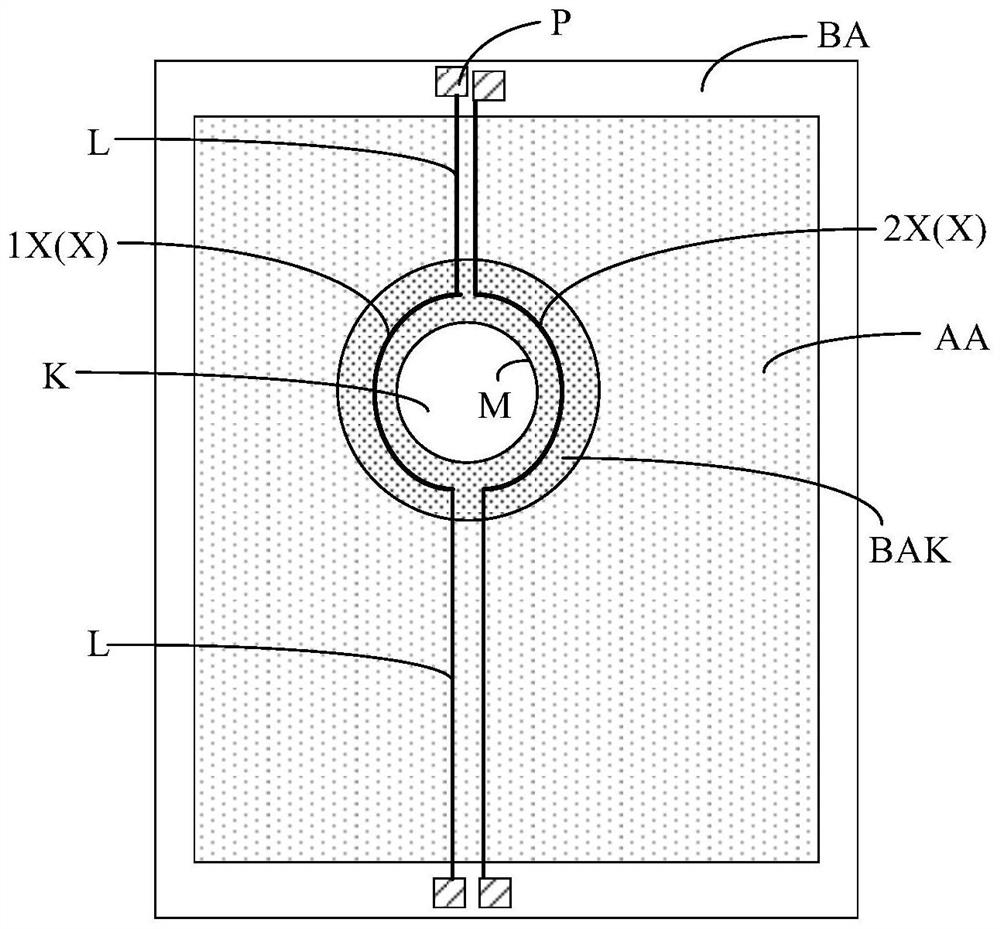

Array base plate, display panel and cutting control method of array base plate

ActiveCN109270758AAvoid subsequent processingSolid-state devicesNon-linear opticsElectricityEngineering

The invention discloses an array base plate, a display panel and a cutting control method of the array base plate. The array base plate comprises a notch, a display area and a notch non-display area,wherein the notch non-display area surrounds the notch, and the display area surrounds the notch non-display area; the array base plate further comprises conductive wires and test plates, wherein theconductive wires are positioned in the notch non-display area, and are arranged along the edge of the notch; the test plates are electrically connected with the conductive wires through connecting lines; and at least two test plates are electrically connected with the same conductive wire. The control of the cutting accuracy of the array base plate can be realized.

Owner:SHANGHAI AVIC OPTOELECTRONICS

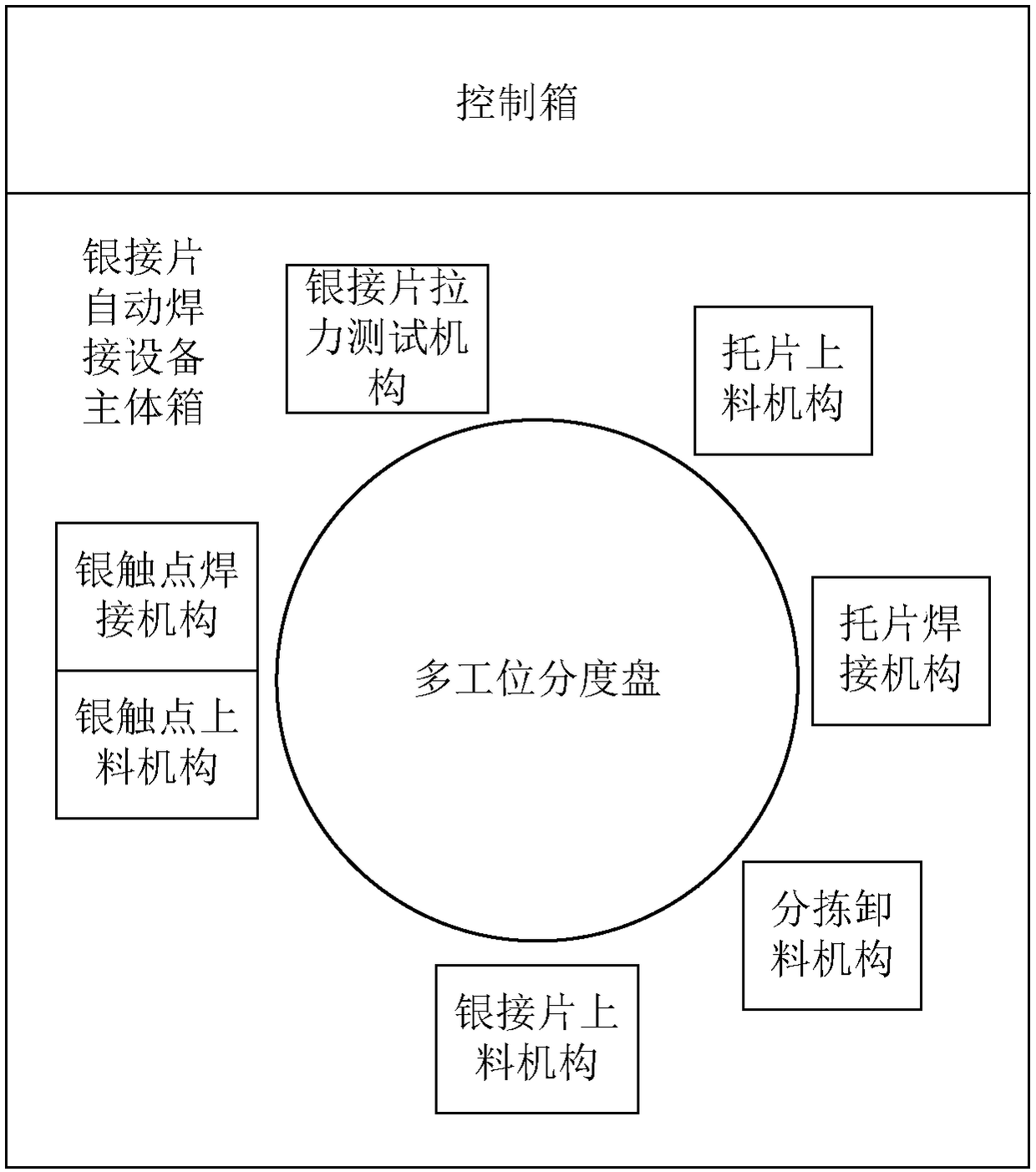

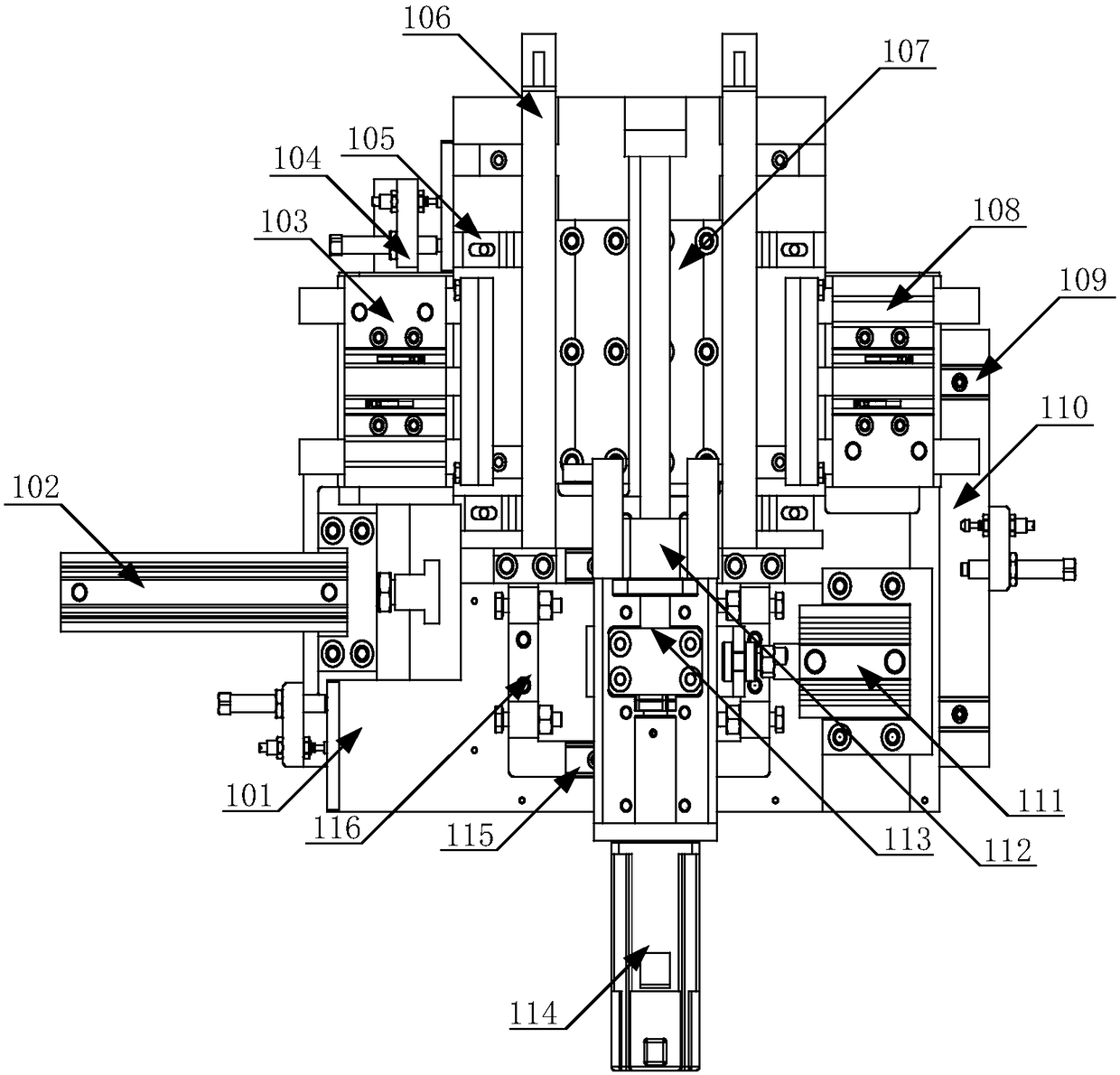

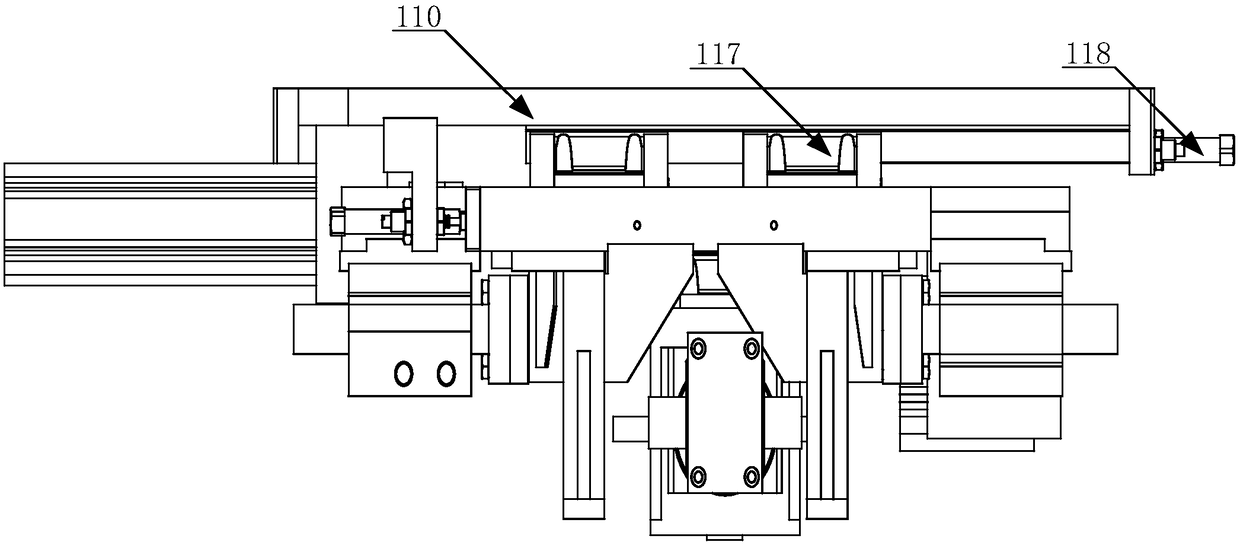

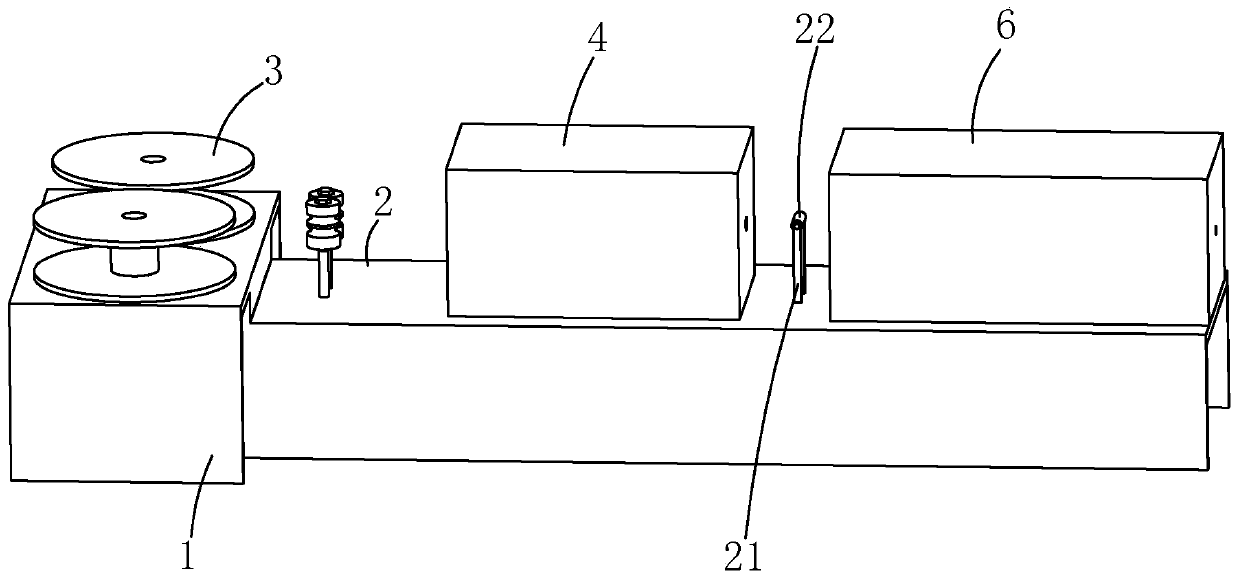

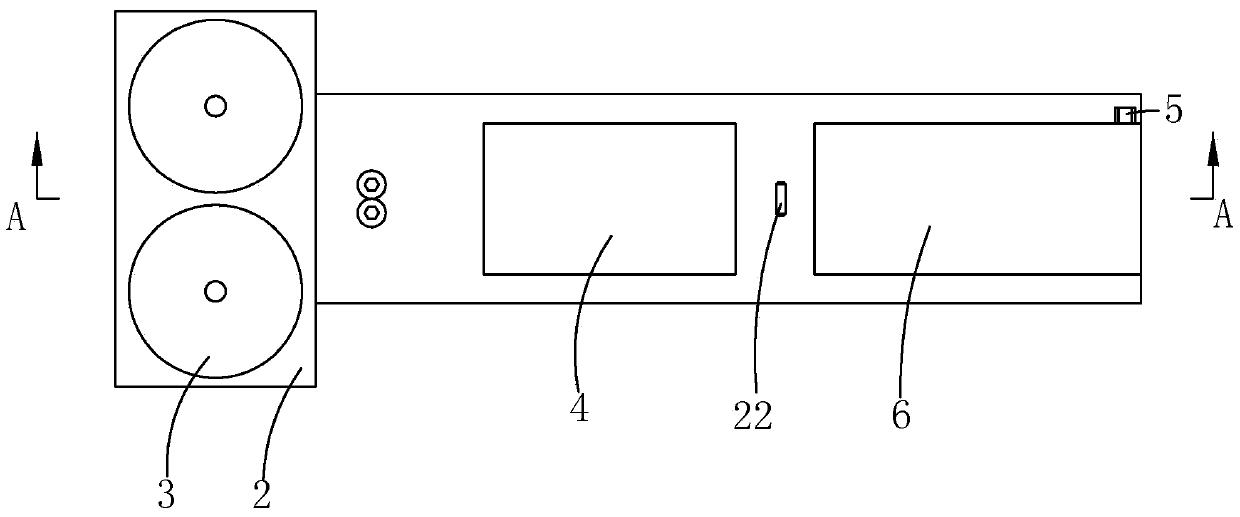

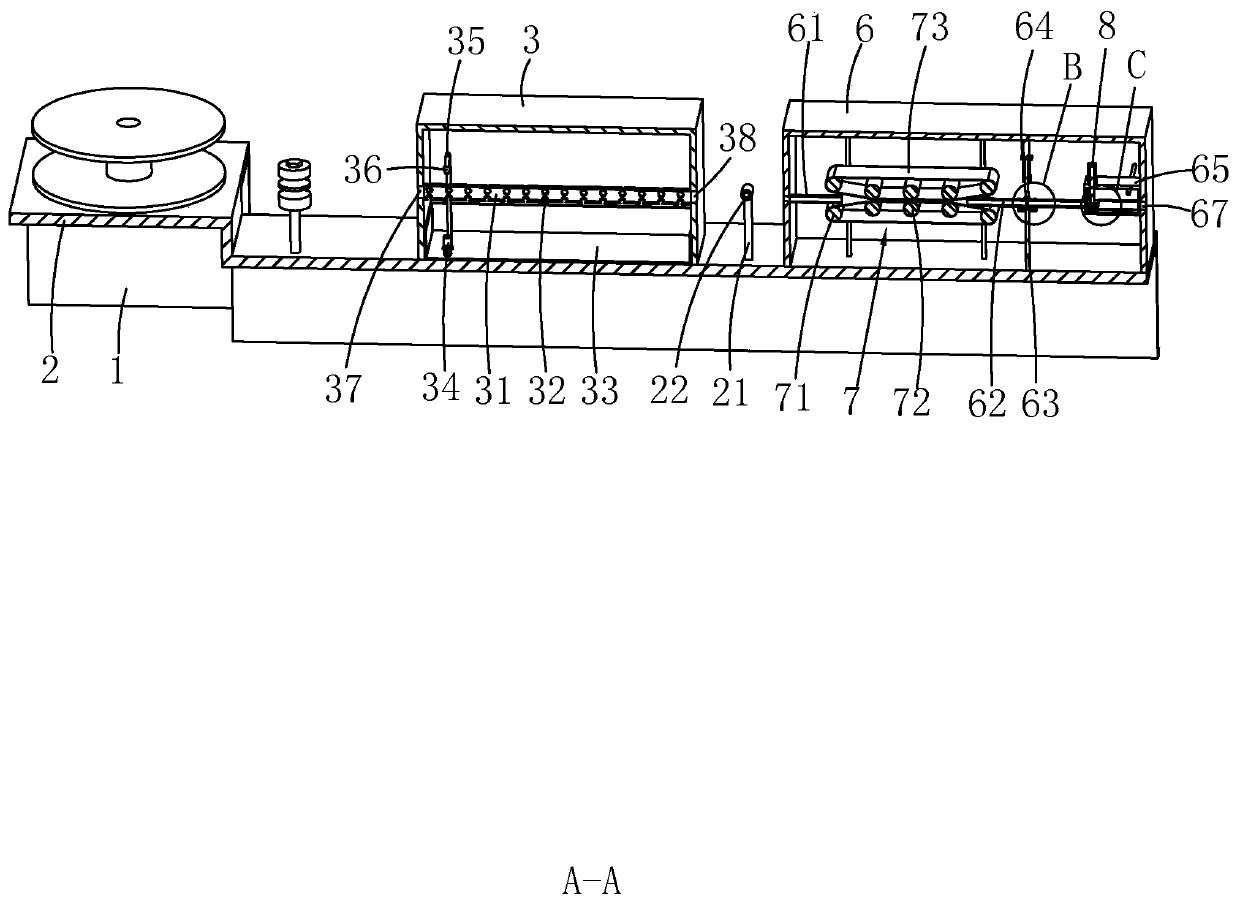

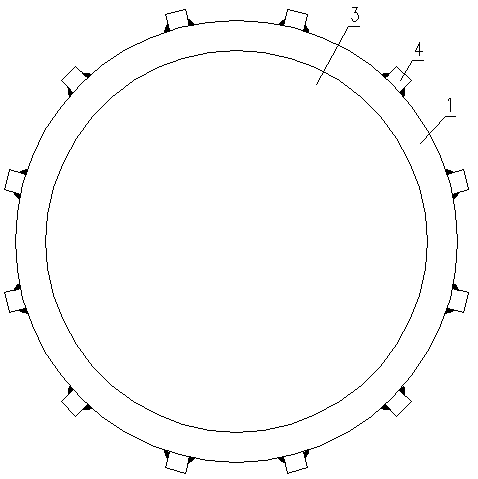

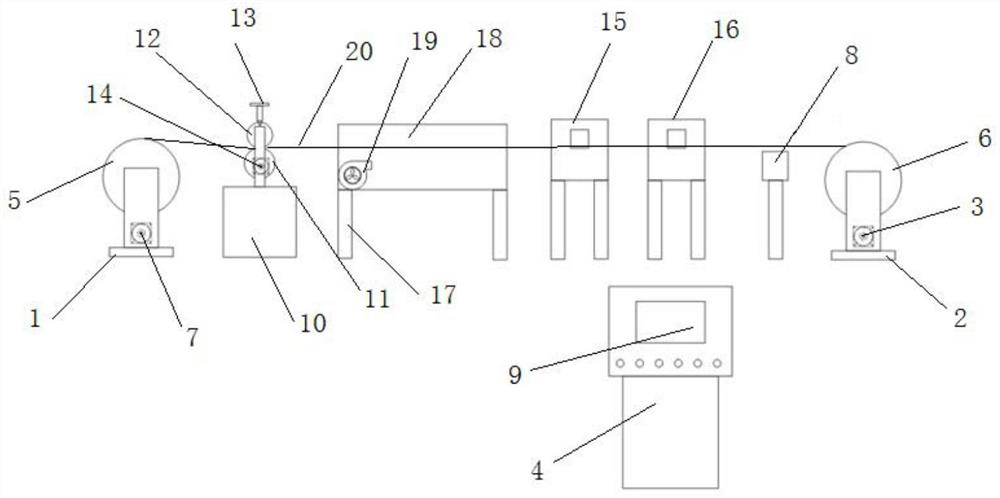

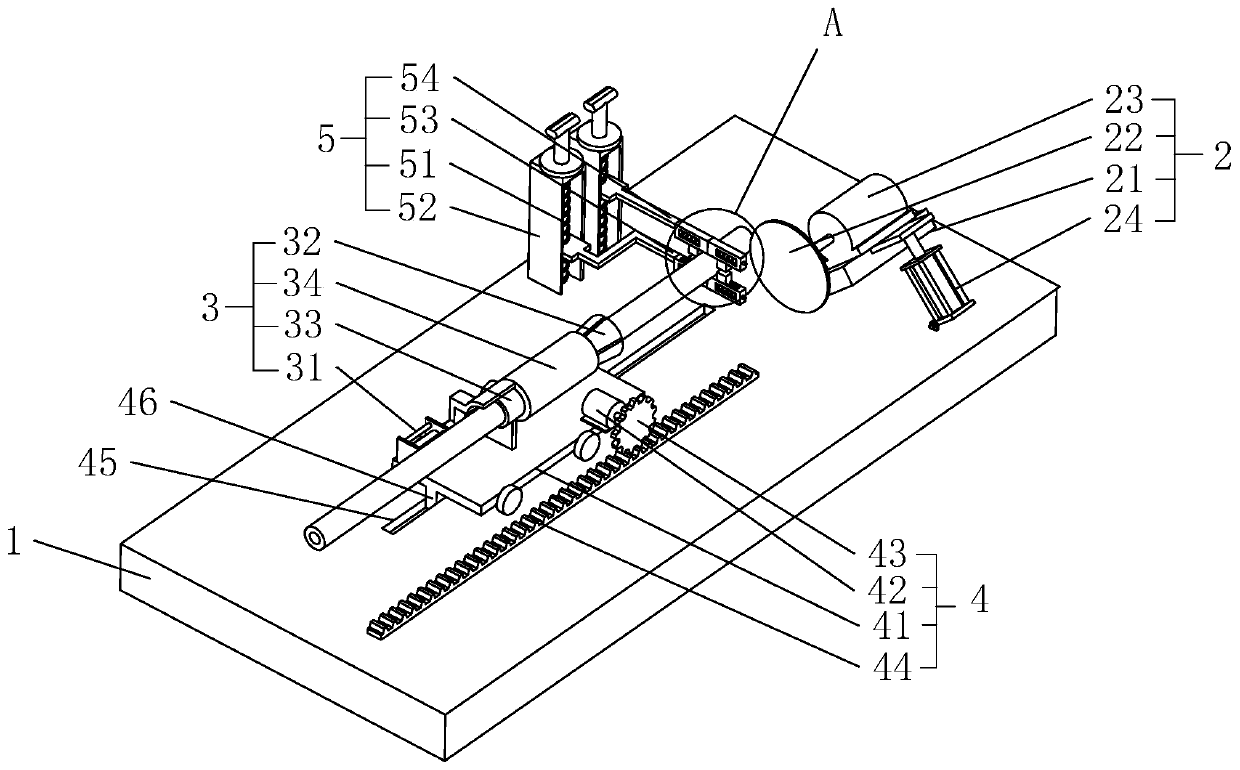

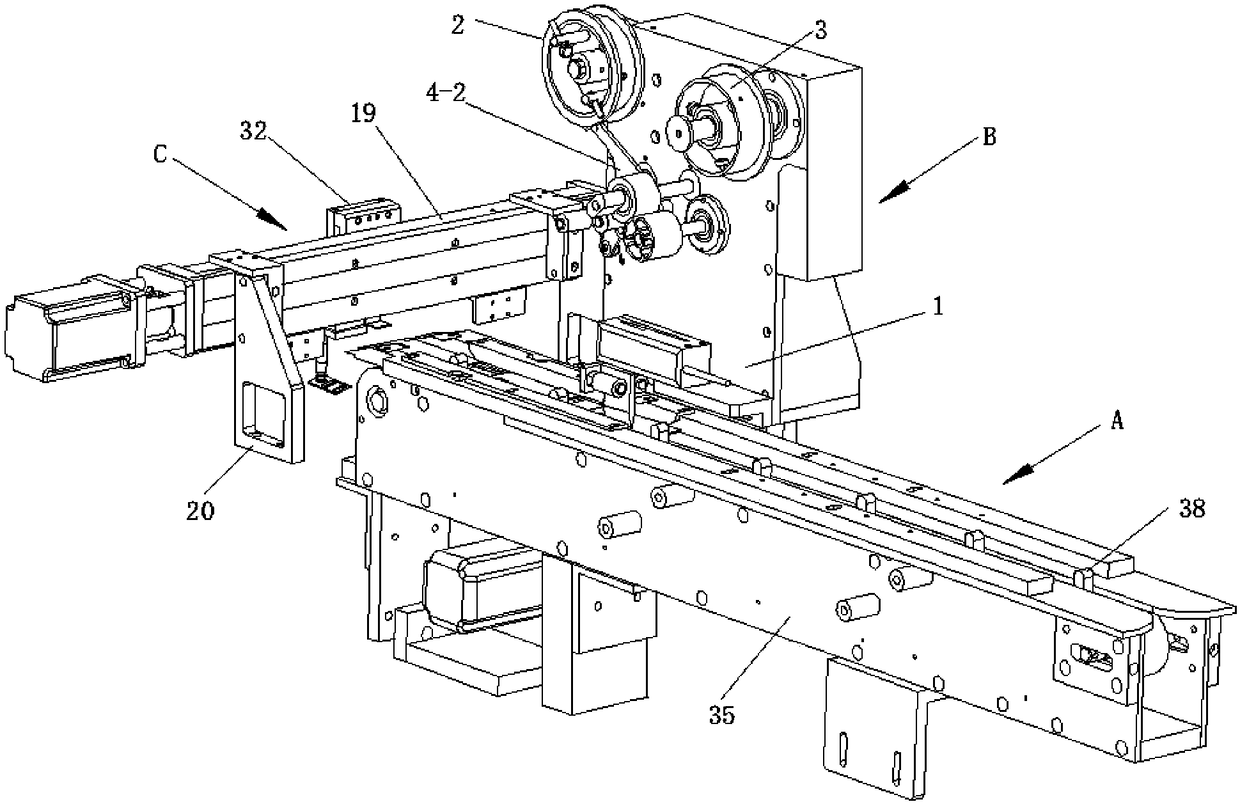

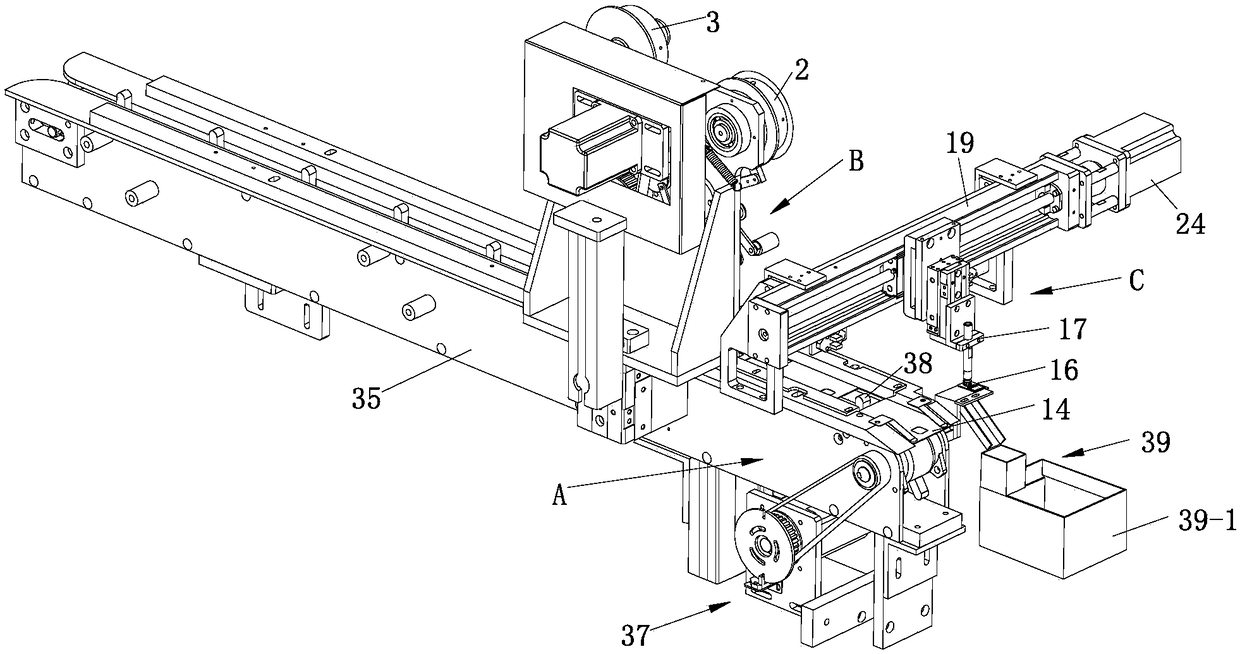

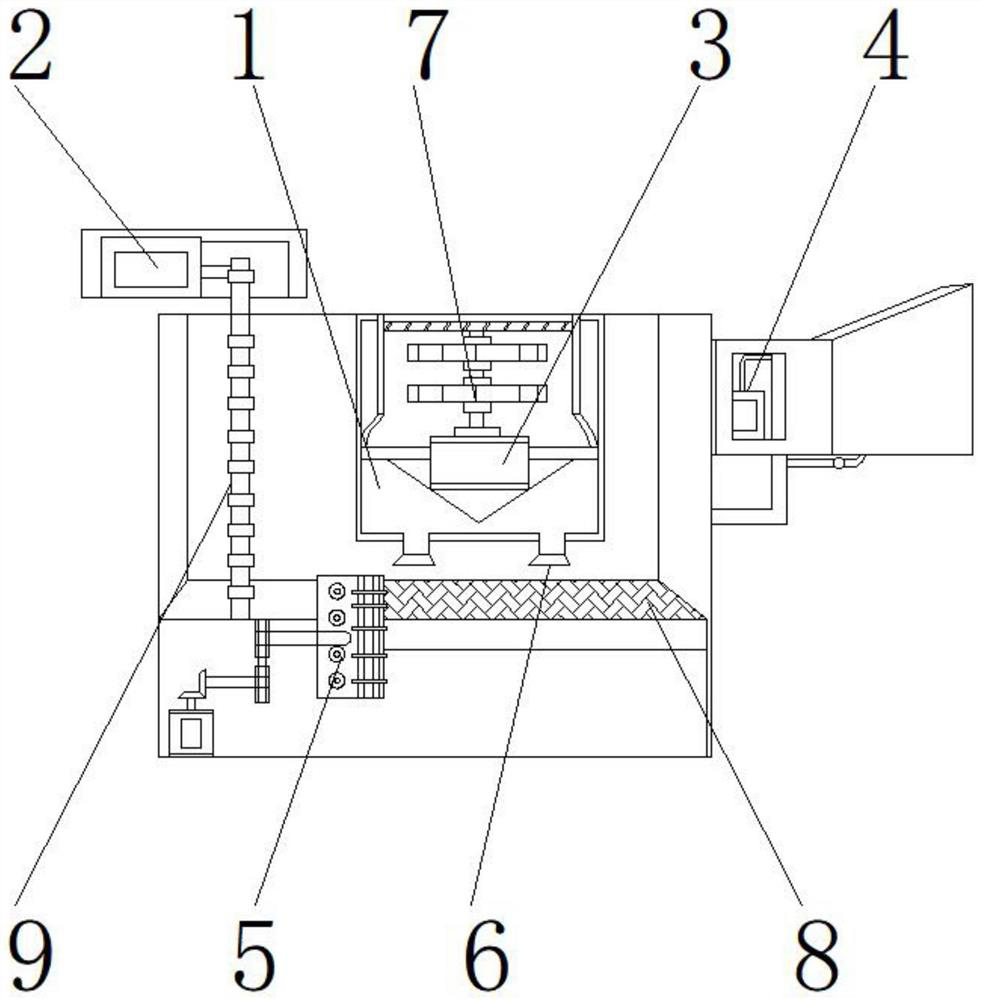

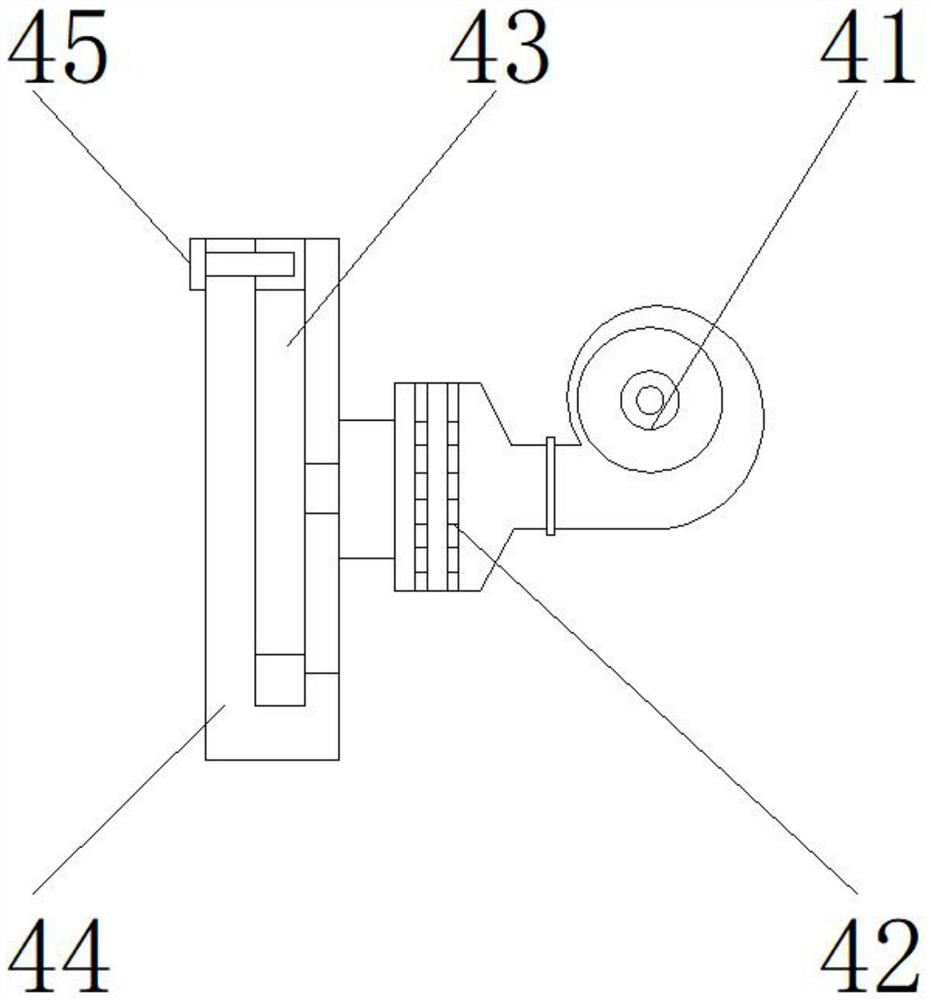

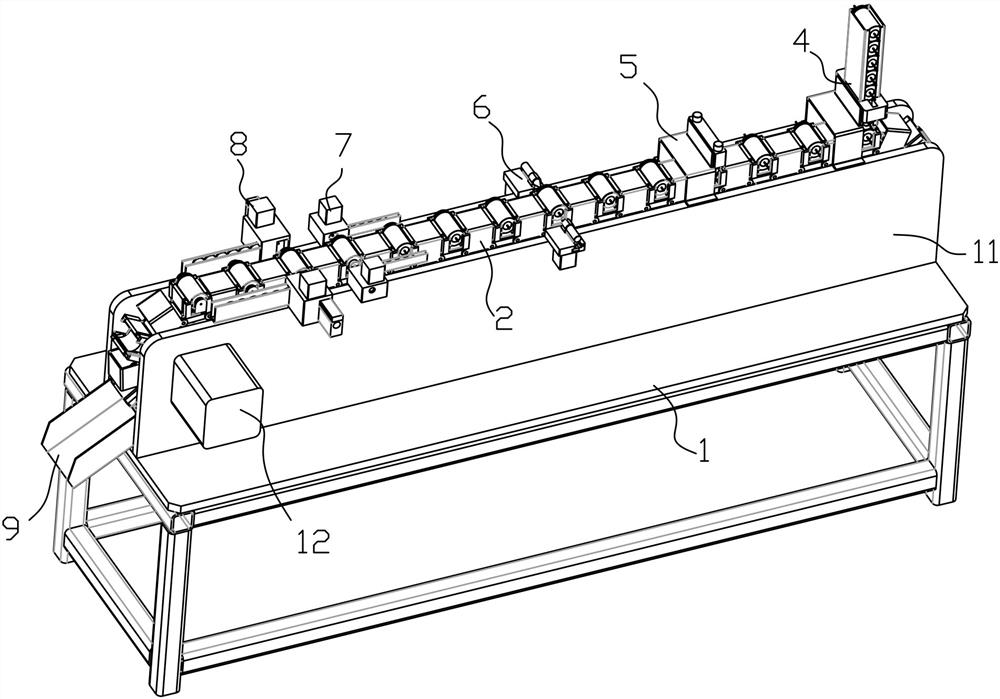

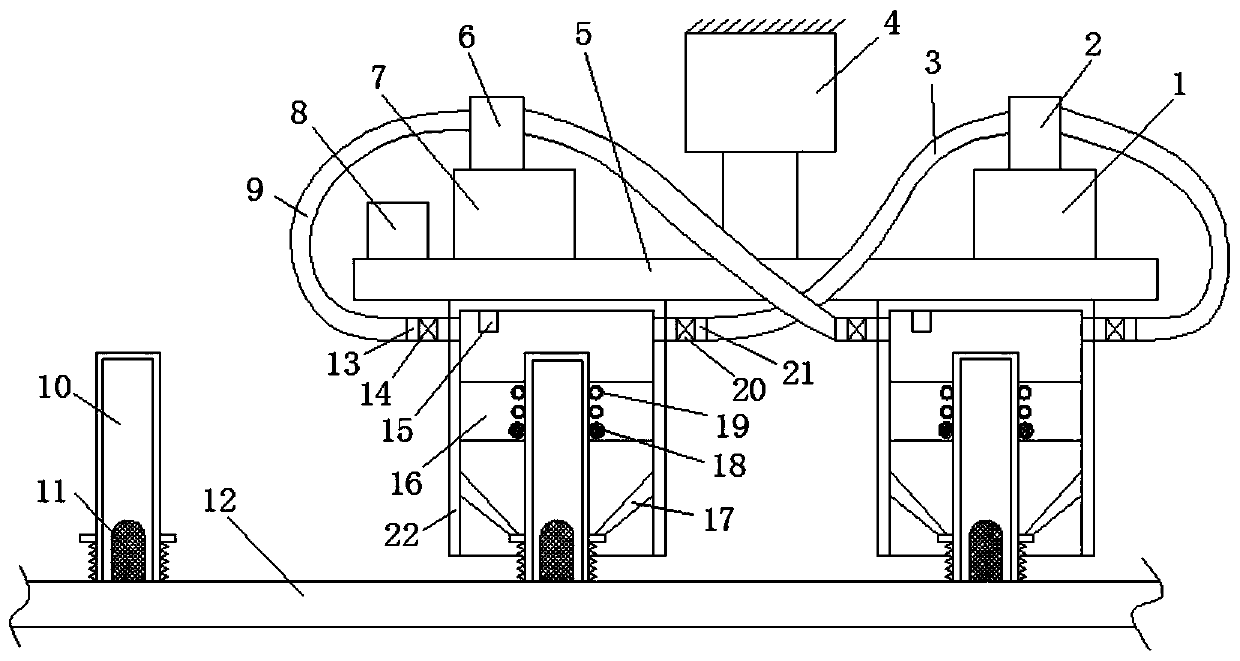

Silver contact chip automatic-welding equipment

ActiveCN108422072AImprove running accuracyWon't wear outWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction risk

The invention discloses silver contact chip automatic-welding equipment which comprises a main box of the silver contact chip automatic-welding equipment and a control box, wherein the control box isconnected with the main box of the silver contact chip automatic-welding equipment; the main box of the silver contact chip automatic-welding equipment is instituted by a multi-station indexing plateas well as a silver contact chip feeding mechanism, a silver contact point feeding mechanism, a silver contact point welding mechanism, a silver contact chip tension testing mechanism, a support sheetfeeding mechanism, a support sheet welding mechanism and a sorting-discharging mechanism which are positioned around the multi-station indexing plate and sequentially arranged according to the clockwise direction; one and the same feeding mechanism is selected as the silver contact chip feeding mechanism and the support sheet welding mechanism; and one and the same electrode rotation welding mechanism is selected as the silver contact point welding mechanism and the support sheet welding mechanism. By adoption of the silver contact chip automatic-welding equipment provided by the invention, the production of silver contact chips can be automatically completed; the automation degree of the silver contact chip automatic-welding equipment can be greatly improved; the product quality and theproduction efficiency can be improved; and the production risk of an enterprise can be further reduced.

Owner:成都成焊焊接设备有限公司

Wire harness threading device and using method thereof

ActiveCN110947878AImprove practicalityAvoid wastingMetal working apparatusTurning machinesStructural engineeringWorkbench

The invention relates to a wire harness threading device which comprises a frame body and a workbench, wherein a winding post is rotatably connected to the surface of the workbench; a driving component is arranged on one side of the winding post; a housing is disposed on the periphery of the driving component; a first hollow wire pipe and a second hollow wire pipe are arranged on two sides of thedriving component; a mounting hole is formed in the housing; a hollow supporting pipe is arranged at the mounting hole; a shell is disposed on the periphery of the hollow supporting pipe; a through hole is formed in the shell; a second hollow wire pipe, the through hole, the hollow supporting pipe and the mounting hole are arranged concentrically; a cutting gap is formed in the second hollow wirepipe; a supporting seat is arranged below the cutting gap; a cutter is arranged right above the cutting gap; and a cutter handle part of the cutter is connected with a first air cylinder. According tothe wire harness threading device and a using method thereof, the shearing of the wire harness is realized such that the wire harness extends out of the sleeve. The wire harness threading device is convenient to use, avoids a waste of the sleeve caused by the secondary cutting of the sleeve, saves the processing cost, and is improved in practicability.

Owner:西咸新区吉亚汽车部件有限公司

Detection structure suitable for detecting source and drain conduction and detection method for detection structure

ActiveCN102569116AAvoid subsequent processingSemiconductor/solid-state device testing/measurementElectrical testingWaste productVoltage contrast

The invention provides a detection structure suitable for detecting source and drain conduction. The detection structure is arranged on a substrate, and comprises at least one polygonal active area ring of which horizontal section is hollow; at least one polycrystalline silicon grid is arranged on each active area ring; and the polycrystalline silicon grid and the active area rings on two sides of the polycrystalline silicon grid form a metal oxide semiconductor (MOS) structure. The detection structure is suitable for detecting the voltage contrast of epitaxial metals by using an E-beam detection method; and by observing the brightness degree, whether source and drain conduction exists in the detection structure can be clearly displayed, and whether source and drain conduction exists on a wafer can be further judged. Because the problem is early discovered, unnecessary subsequent processing for waste products can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

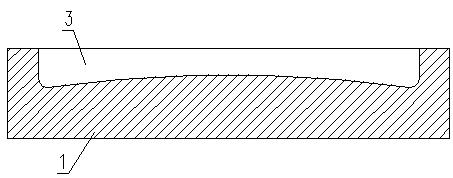

Build-up welding method for large-diameter thin-wall double-tube plate

InactiveCN109551082AGuaranteed thicknessReduce distortionArc welding apparatusDouble tubeEngineering

The invention discloses a build-up welding method for a large-diameter thin-wall double-tube plate. The build-up welding method comprises the following steps: 1) pre-processing, wherein grooves are processed in build-up welding surfaces of two tube plates, and the bottom surfaces of the grooves are tapered; 2) connecting, wherein the two tube plates are fixedly connected into an integer; 3) build-up welding, wherein each tube plate is subjected to build-up welding in layers, build-up welding at each layer is accomplished by two or more local build-up welding processes, and local build-up welding processes of the two tube plates are alternatively performed, first-time local build-up welding process at each layer of each tube plate starts build-up welding from the centre position of the groove, and then performs ring-shaped build-up welding towards the edge in sequence, the rest of local build-up welding processes at each layer of each tube plate perform ring-shaped build-up welding frominside to outside in sequence; and 4) thermal treatment, wherein the integer is fed into a furnace to heat and subject to heat preservation, and each rib plate is dismounted after welding stress is eliminated. The build-up welding method can greatly reduce deformation caused by tube plate build-up welding, avoids follow-up processing, can improve processing efficiency, reduces the cost, and guarantees the thickness of a build-up welding layer very well.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Intelligent wire printer

PendingCN112895737AAvoid enteringGuarantee the safety of useMaterial analysis by electric/magnetic meansTypewritersControl systemEngineering

The invention discloses an intelligent wire printer. The intelligent wire printer comprises a pay-off rack, a take-up rack, printing equipment, drying equipment, wire defect detection equipment, a take-up driving device and a control system. A pay-off reel and a take-up reel are rotatably arranged on the pay-off rack and the take-up rack respectively. After a wire is led out of the pay-off reel, the wire passes through the printing equipment, the drying equipment and the wire defect detection equipment in sequence, finally, the wire is wound and taken up by the take-up reel, the take-up driving device drives the take-up reel to rotate, the printing equipment can print characters on the surface of the wire passing through the printing equipment, the drying equipment can dry printing ink on the surface of the wire, the wire defect detection equipment can detect defects on the surface of the wire and transmit information to the control system, the control system controls the take-up driving device, the printing equipment and the drying equipment to start or stop, printed wires with the defects can be prevented from entering a cabling procedure, defective wires are prevented from being subjected to subsequent processing, material waste is avoided, and wire use safety is ensured.

Owner:新光机电(昆山)有限公司

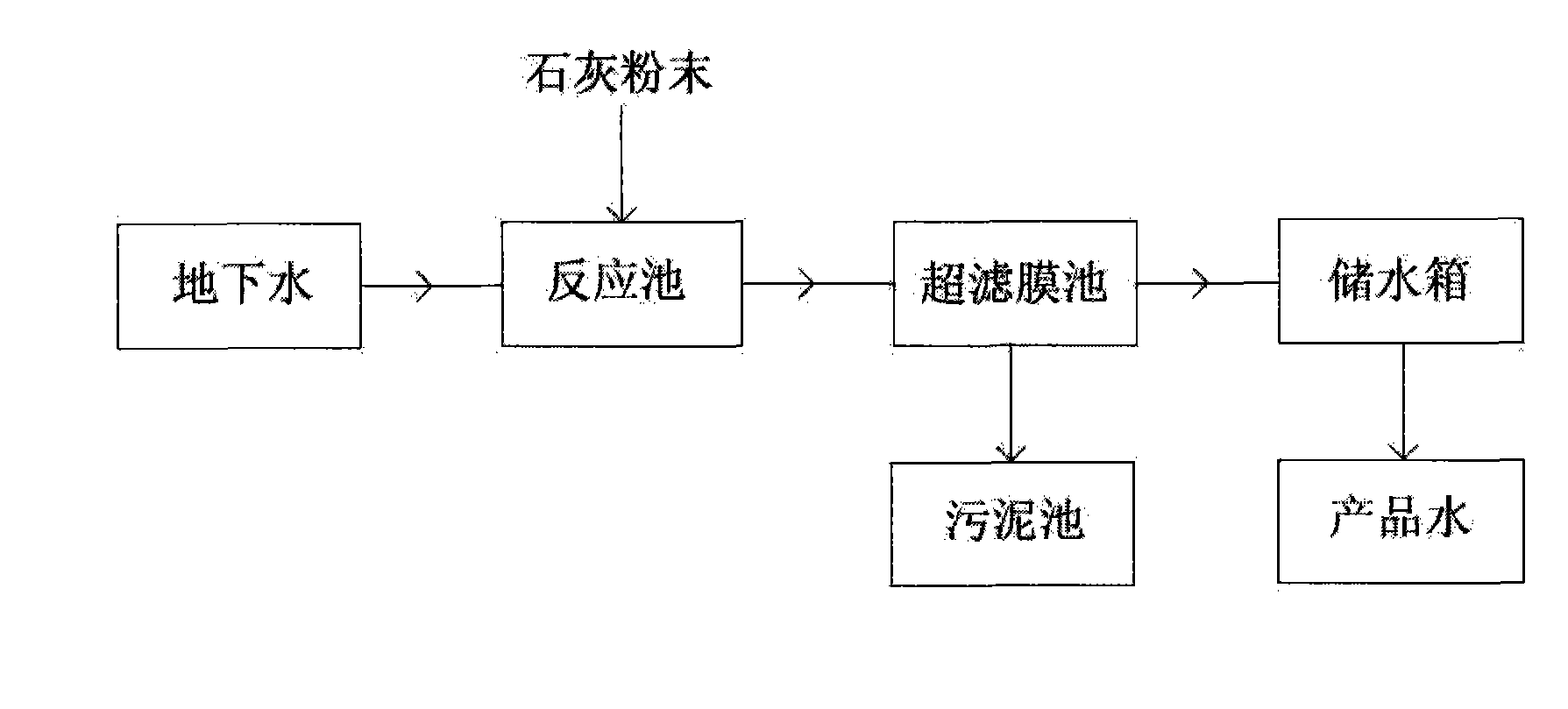

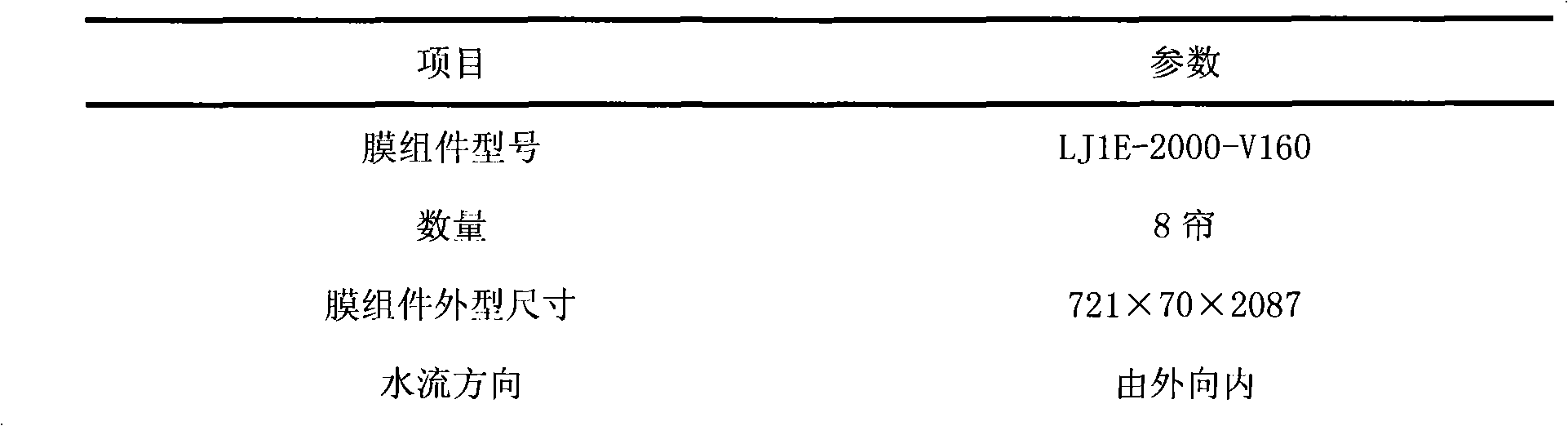

Method for removing underground water hardness by combination of lime and ultrafiltration

InactiveCN102838235ARemove temporary hardnessGood effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical reactionUltrafiltration

The invention relates to a method for removing underground water hardness by combination of lime and ultrafiltration. The method comprises the following steps: pumping high-hardness underground water into a reaction pond through a pump, adding lime powder into the reaction pond through a chemical liquid adding device while the underground water is pumped into the reaction pond, fully mixing to guarantee full chemical reaction of the lime powder and the underground water, and generating a CaCO3 floc turbid solution difficultly soluble in the water; and enabling the floc turbid solution to flow to an ultrafiltration membrane for filtering, quickly depositing CaCO3 intercepted on a liquid inlet side of the ultrafiltration membrane and difficultly soluble compounds of Fe, Si in an original high-hardness water body so as to greatly reduce turbidity of the water, and obtaining safe and good-quality drinking water through a permeating solution of the ultrafiltration membrane. The method has the advantages as follows: an effect of quickly and efficiently removing hardness and turbidity of the underground water is obtained by organic combination of a lime method and an ultrafiltration membrane process, and good-quality qualified domestic drinking water is produced; and the method is high in water production efficiency, stable to implement and small in occupied area, and can greatly reduce investment and operation costs.

Owner:PIPE NETWORK MANAGEMENT BRANCH OF BEIJING WATERWORKS GRP CO LTD +2

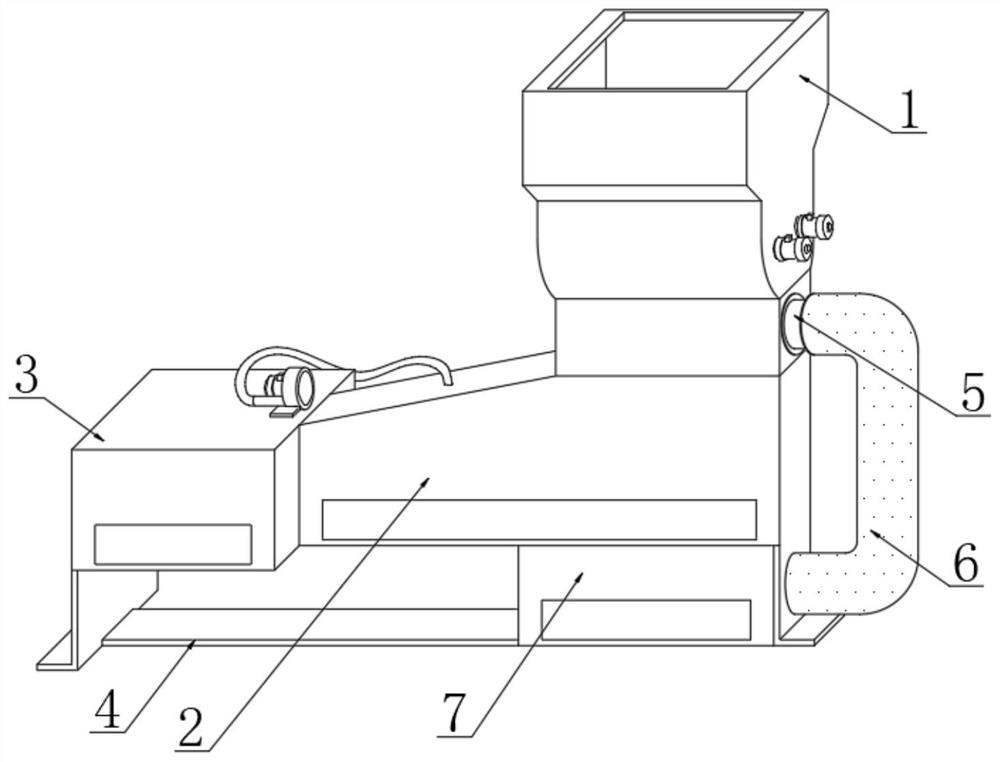

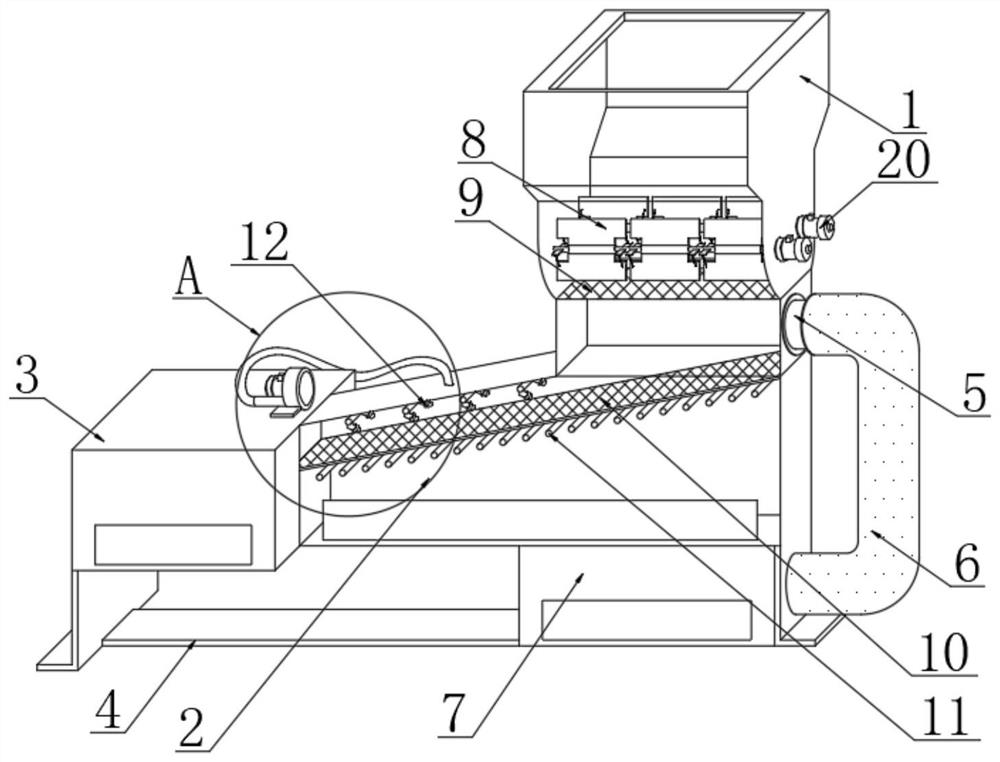

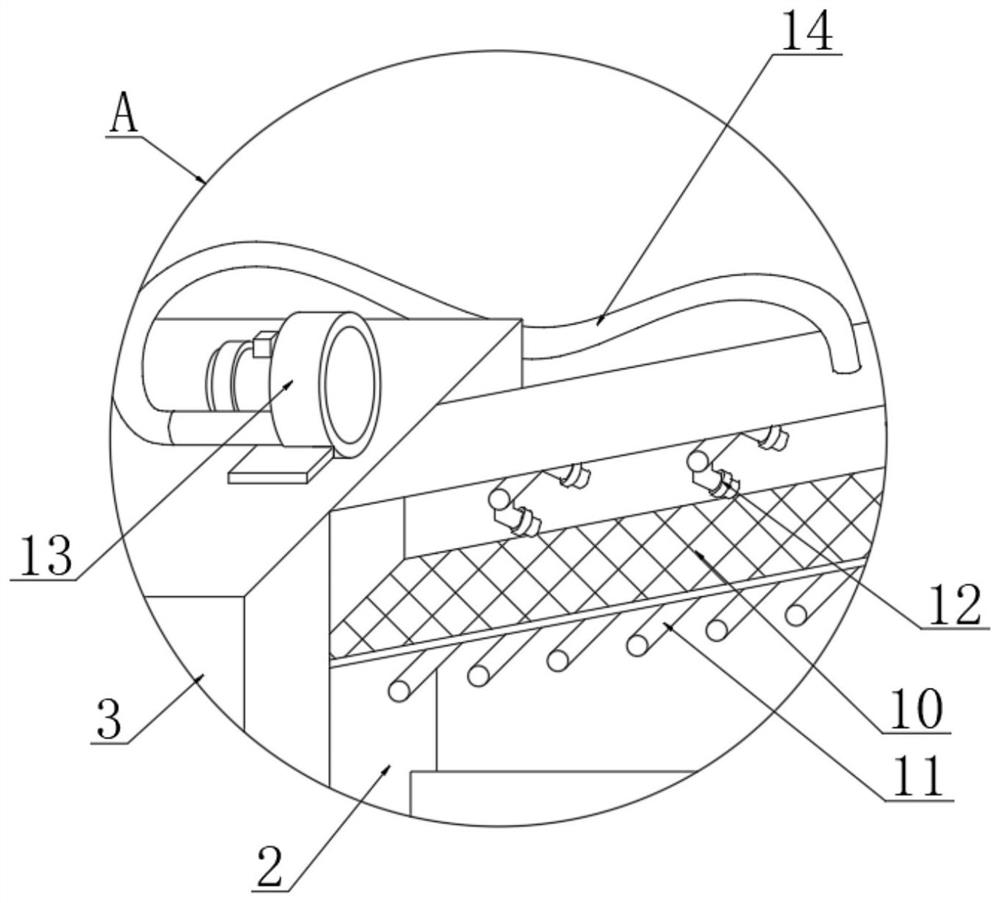

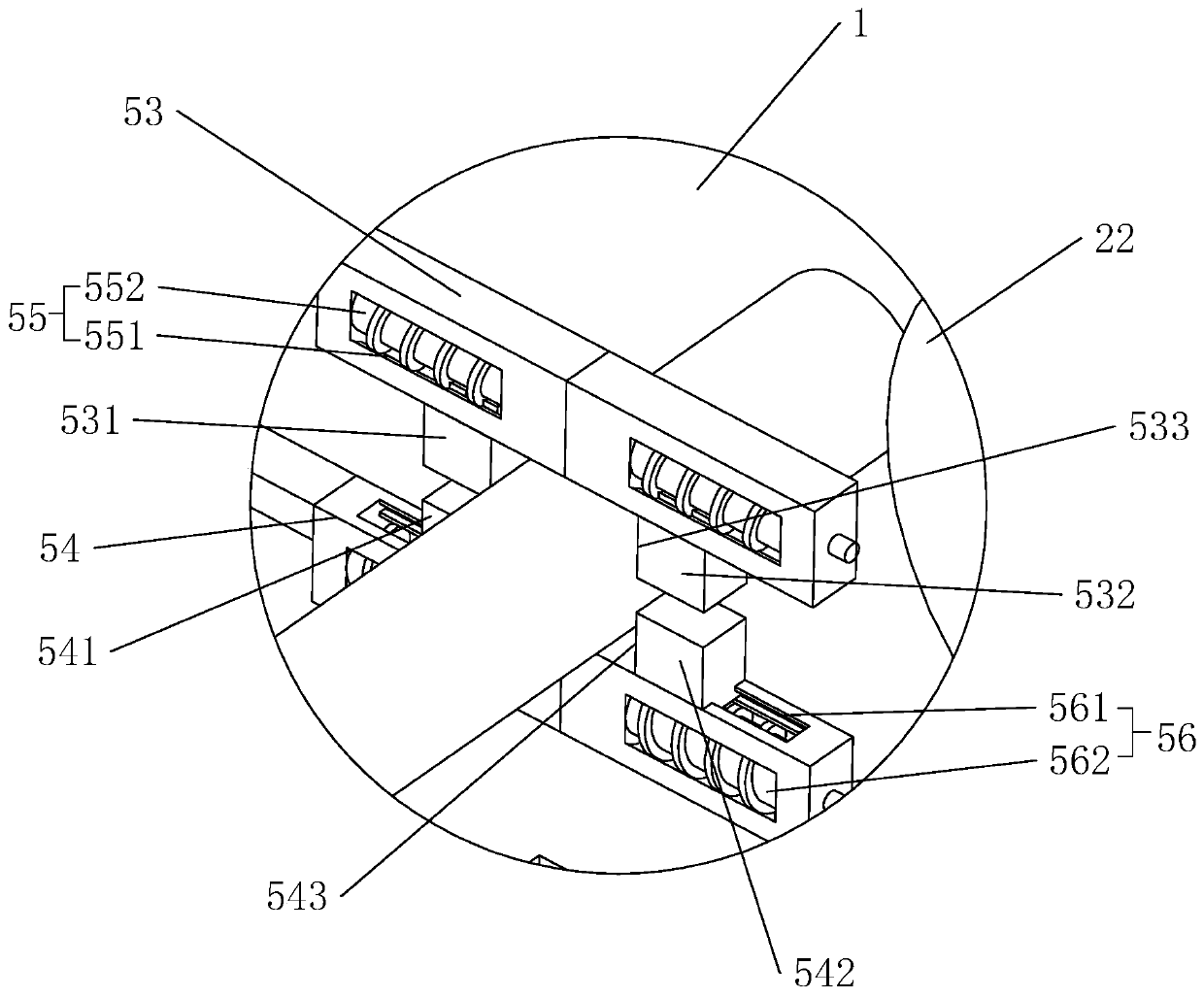

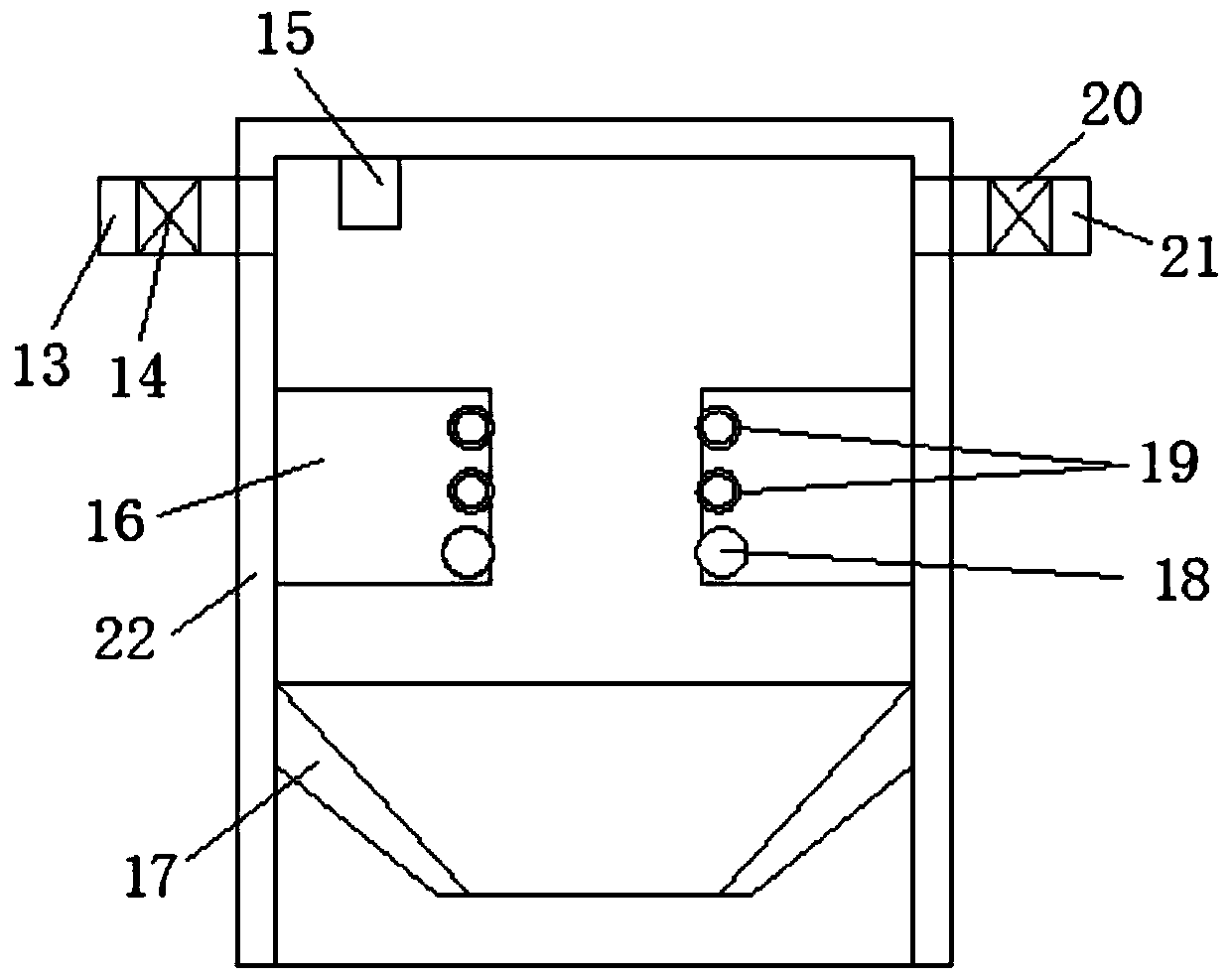

Screening device for rice processing

InactiveCN113842975AHigh size separation efficiencyAvoid subsequent processingGrain huskingGrain polishingAgricultural engineeringRice grain

The invention relates to the technical field of rice processing, in particular to a screening device for rice processing. The screening device comprises a storage hopper, wherein sieved small-particle materials are mounted on the lower side of the storage hopper, sieved large-particle materials are mounted on one side of the sieved small-particle materials, a support frame is arranged on the lower side of the sieved large-particle materials, a filter residue collecting box is arranged on the lower side of the sieved small-particle material, an exhaust fan is installed at the upper end of the other side of the sieved small-particle material, a cloth cylinder filter bag is installed at the outer end of the exhaust fan, a hulling component is installed at the lower end of the interior of the storage hopper, a feeding net is installed at the joint of the storage hopper and the sieved small-particle material, and a screen is mounted at the upper end of the interior of the sieved small-particle material. The screening device is of a closed structure, dust floating in the screening process is avoided, circulating dust filtration is achieved, the dust filtration efficiency is high, rice before screening is hulled, the hulling structure is elastic mixing and stirring blades, and the integrity of the rice is guaranteed.

Owner:安徽慈弘农业发展有限公司

Detection structure suitable for detecting source and drain conduction and detection method for detection structure

ActiveCN102569116BAvoid subsequent processingSemiconductor/solid-state device testing/measurementElectrical testingWaste productVoltage contrast

The invention provides a detection structure suitable for detecting source and drain conduction. The detection structure is arranged on a substrate, and comprises at least one polygonal active area ring of which horizontal section is hollow; at least one polycrystalline silicon grid is arranged on each active area ring; and the polycrystalline silicon grid and the active area rings on two sides of the polycrystalline silicon grid form a metal oxide semiconductor (MOS) structure. The detection structure is suitable for detecting the voltage contrast of epitaxial metals by using an E-beam detection method; and by observing the brightness degree, whether source and drain conduction exists in the detection structure can be clearly displayed, and whether source and drain conduction exists on a wafer can be further judged. Because the problem is early discovered, unnecessary subsequent processing for waste products can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

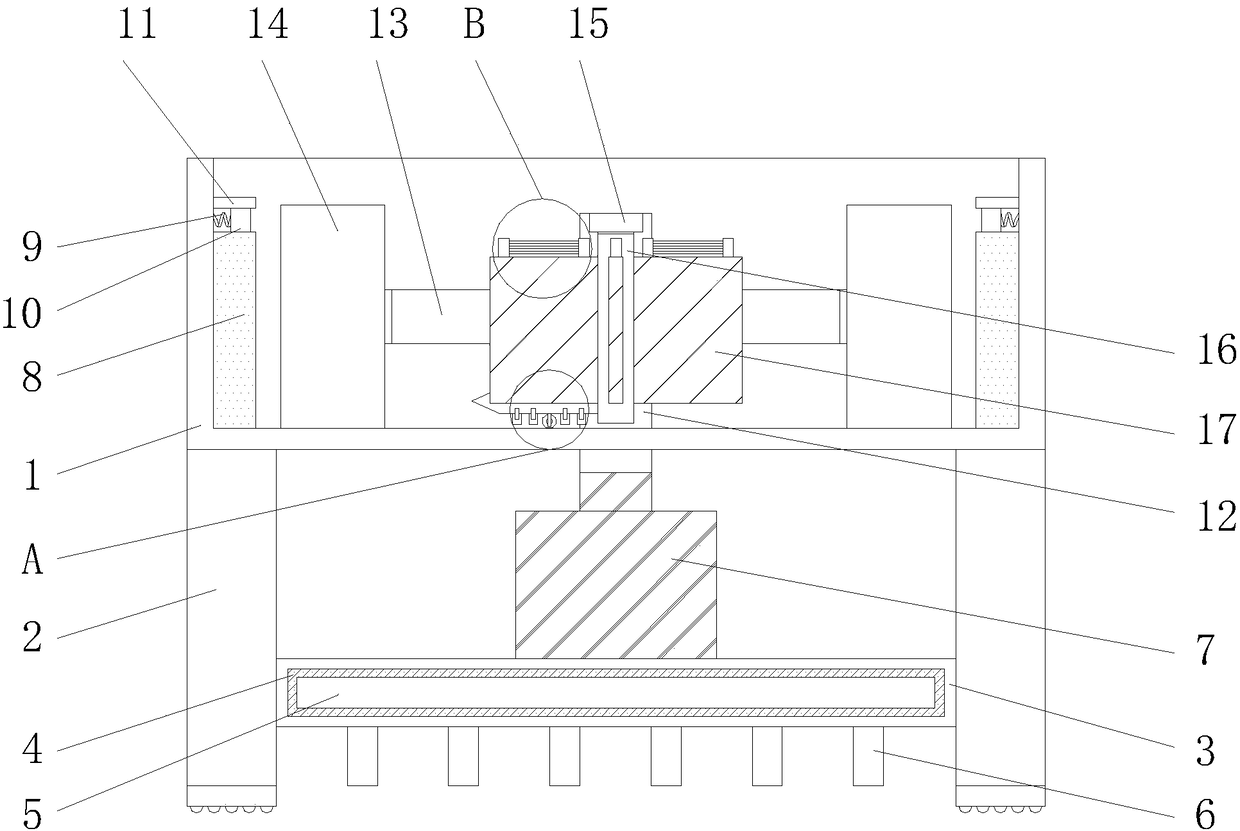

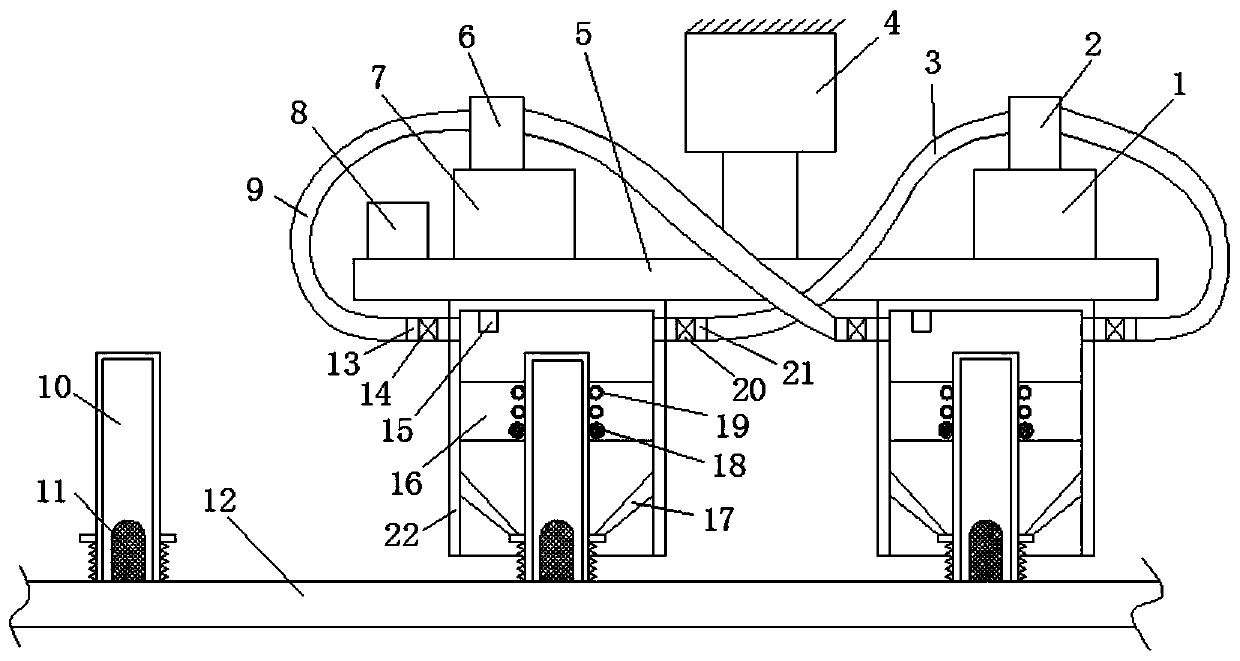

Centralized optical fiber end grinding and cleaning device

ActiveCN104816236AFacilitate subsequent processingAvoid subsequent processingLapping machinesWork carriersChinese charactersWater wheel

The invention relates to a centralized optical fiber end grinding and cleaning device which comprises a circulating water tank and a grinding chamber. The circulating water tank is communicated with the grinding chamber through a circulating pump, the grinding chamber comprises a grinding groove, an optical fiber positioning frame, a driving water wheel, at least one grinding roller and a driving device, wherein the cross section of the grinding groove is in a shape of a Chinese character 'ao', the driving water wheel is located at the bottom of the grinding groove, the grinding roller is located in the grinding groove and located under the circulating water level, the optical fiber positioning frame is embedded into the upper end face of the grinding groove, at least four optical fiber positioning holes are distributed in the optical fiber positioning frame in a rectangular array mode, optical fiber positioning clamps are additionally arranged at the positions of the optical fiber positioning holes, and the driving device is located outside the grinding grooves and is connected with the driving water wheel and the grinding rollers respectively. In addition, the centralized optical fiber end grinding and cleaning device has grinding and cleaning functions, the surface cleanness and finish degree of optical fiber ends can be greatly improved, noise and dust pollution easily caused in the optical fiber end grinding process is effectively avoided, and optical fiber machining operation environment is greatly improved.

Owner:南通鸿图健康科技有限公司

Crushing and drying system for mechanical product paint

InactiveCN106607158AEasy to put inImprove crushing effectDrying machines with progressive movementsGrain treatmentsSupporting systemCollection system

The invention relates to a crushing and drying system for mechanical product paint. The crushing and drying system for the mechanical product paint comprises a conveying system. Conveying rotating mechanism supporting mechanisms are mounted on the left side and the right side of the interior of the conveying system correspondingly. The conveying rotating mechanisms are mounted on the upper portions of the conveying rotating mechanism supporting mechanisms. A conveying belt is mounted between the conveying rotating mechanisms. A drying treatment system bearing mechanism is mounted at the bottom of the conveying system and located between the conveying rotating mechanism supporting mechanisms. A drying treatment system is mounted at the top of the drying treatment system bearing mechanism. A mechanical product paint collection system is mounted on the right side of the conveying system, and a bearing cylinder mechanism is arranged on the upper portion of the mechanical product paint collection system. A supporting system is arranged on the upper portion of the bearing cylinder mechanism. By adoption of the crushing and drying system, the mechanical product paint can be placed in the crushing system conveniently so as to be crushed through the rotating mechanisms, the crushed mechanical product paint can be conveyed through the conveying belt and dried conveniently, and the mechanical product paint crushing effect is improved.

Owner:CHONGQING XIONGCHUANG ARCHITECTURAL ENG TECH

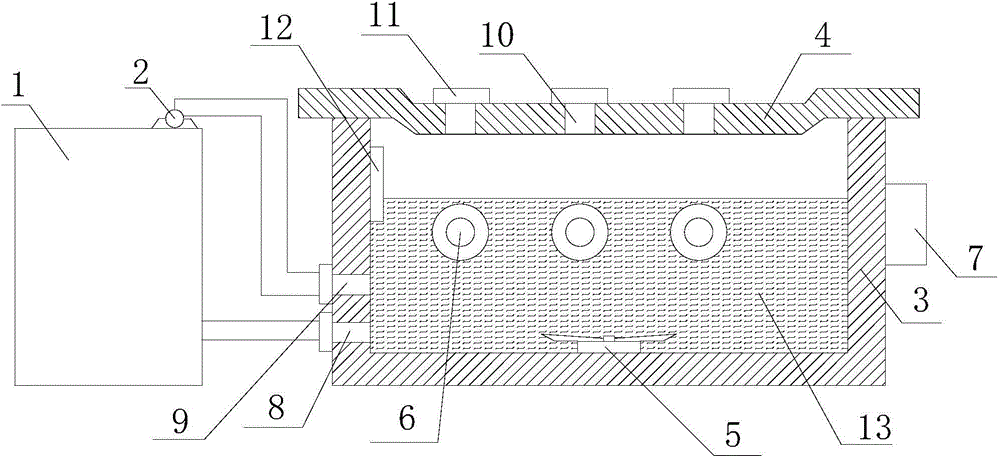

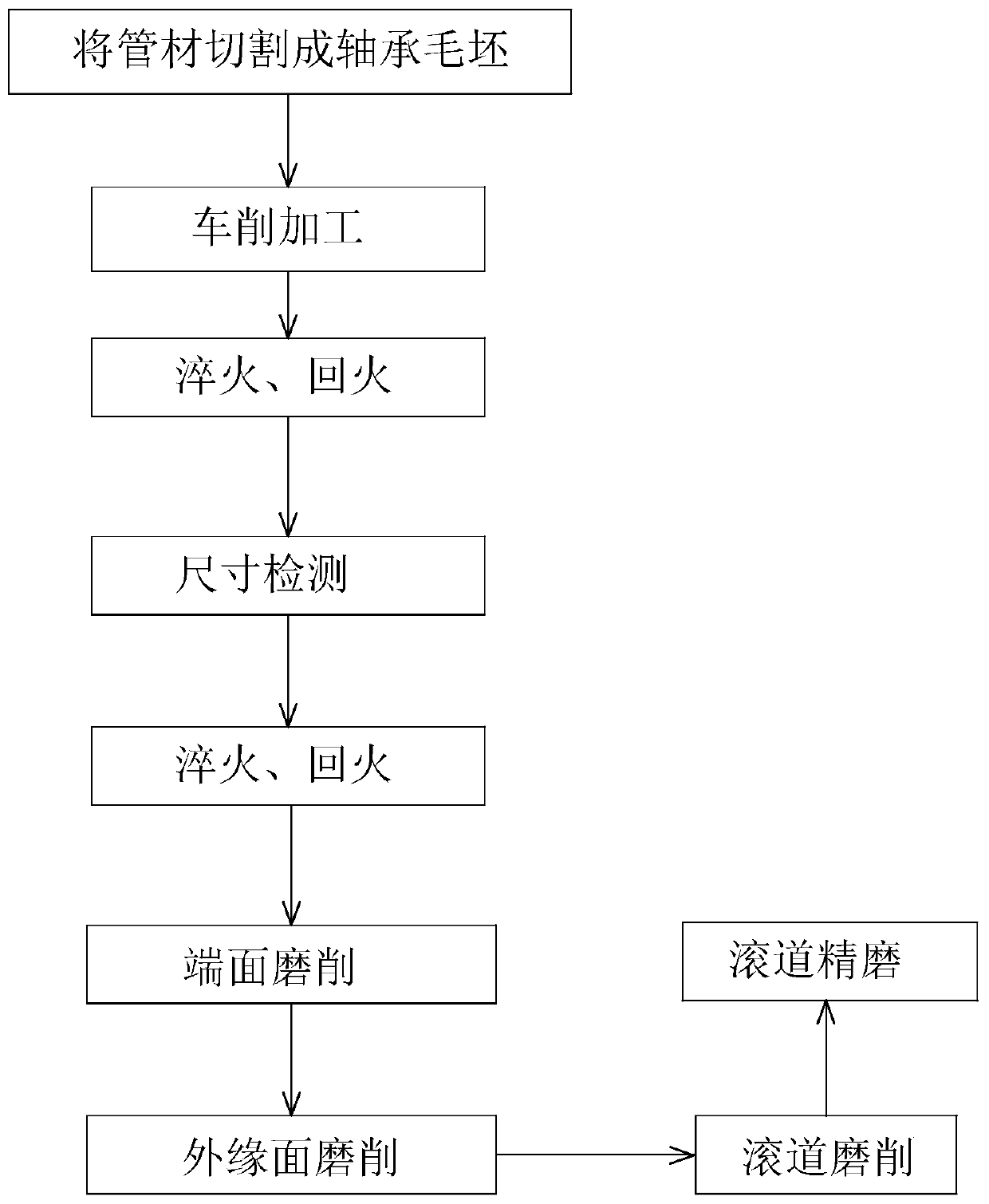

A kind of bearing processing technology

The invention relates to the technical field of bearing machining, and discloses a bearing machining technology. The bearing machining technology comprises the steps that 1, a pipe is cut into a disc-shaped blank through bearing cutting equipment; 2, the blank is subjected to turning machining through a lathe; 3, quenching heat treatment and tempering heat treatment are conducted on the blank subjected to turning; 4, the diameters of the inner circle and the outer circle of a bearing are detected through a bearing automatic detector; 5, the end surface of the blank is ground through a circulartruncated cone surface grinder; 6, the peripheral surface of the blank is ground through a centerless grinder; 7, a roller bed of the bearing is machined through a roller bed grinder; and 8, the roller bed is subjected to finish machining through a precise channel superfinishing grinding machine. According to the bearing machining technology, size detection is conducted before the bearing blank is subjected to grinding machining, so that rejected parts are removed in advance, the situation that the rejected parts are polished in the later period is avoided, energy resources are saved, and themachining efficiency of finished products is improved.

Owner:XINCHANG COUNTY XINXIANGYU BEARING

Card and instruction leaflet overlaying and sticking device in smart card packaging machine

The invention discloses a card and instruction leaflet overlaying and sticking device in a smart card packaging machine. The card and instruction leaflet overlaying and sticking device comprises an instruction leaflet conveying mechanism, a sticking mechanism and a card conveying mechanism. The card conveying mechanism comprises a supporting frame, a card catching mechanism and a driving mechanism; the card catching mechanism comprises a card catching assembly and a card catching power mechanism which drives the card catching assembly to move in the vertical direction, and the card catching assembly comprises an adhesive disk which is used for catching cards; the card catching power mechanism is connected to the driving mechanism; the sticking mechanism comprises a support, an adhesive tape releasing rotating disk, an adhesive tape recycling rotating disk, a pressing device for pressing the adhesive tape onto the instruction leaflet, a rotating power mechanism and a vertical power mechanism, wherein the pressing device comprises a pressing block. According to the smart card packaging machine, the cards are stuck onto instruction leaflets by the card and instruction leaflet overlaying and sticking device, the cards and the instruction leaflets are put into a packaging film at the same time, and therefore packaging time is reduced, production efficiency is improved and productioncost is lowered.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Method for quickly preparing diamond-silicon carbide electronic packaging material

InactiveCN102184873BReduce processing requirementsReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesCarbide siliconAdhesive

The invention provides a method for preparing a diamond-silicon carbide electronic packaging material fast. The method is characterized in that according to weight percentage, 10-15 percent of adhesive, 5-20 percent of graphite, 20-40 percent of ganister sand and 30-60 percent of diamond are wet-mixed for 16-24h, then a composite material blank is obtained through forming under 100 to 200 DEG C and 10-50MPa pressure; the composite material blank is fired for 16-24h under 1,000 to 1,100 DEG C in the argon atmosphere, and a diamond / silicon / carbon polyporous matrix having a certain strength andporosity is obtained after cooling; the diamond / silicon / carbon polyporous matrix prepared is placed in a graphite crucible and then is embedded through liquidphase infiltration infiltrated material,and then the crucible is placed in a high vacuum fritting furnace for vacuum liquidphase infiltration for 0.5-1h, and the infiltration temperature is 1,450-1,550 DEG C, and the vacuum degree is -0.08to -0.01MPa; and the compact diamond-silicon carbide electronic packaging material can be obtained after cooling.

Owner:UNIV OF SCI & TECH BEIJING

Efficient automatic spraying equipment

PendingCN114833011ANot easy to mixQuality improvementPretreated surfacesCoatingsElectric machineryEngineering

The invention discloses efficient automatic spraying equipment, and relates to the technical field of spraying devices.The efficient automatic spraying equipment comprises a main body, a clamping seat is arranged at the upper end of the main body, a spraying range adjusting device is arranged at the upper end of the clamping seat, a spraying head is arranged at the lower end of the main body, and a workbench is arranged below the spraying head; a drying device is arranged on one side of the workbench, a guide rod is arranged on one side of the main body, and a driving device is arranged at the upper end of the guide rod. Under the combined action of a fan, a dust remover, a blowing pipe, a spiral conveying pipe, an electromagnetic control valve and a gas collection and dust collection cover, dust in the spraying equipment can be cleaned up, the dust is not prone to being doped in spraying raw materials, the spraying quality can be improved, and through the combined action of a motor, a rotating shaft, an adjusting rod, a telescopic spring and a movable shaft, the dust in the spraying equipment can be effectively removed. And the spraying range of the equipment can be adjusted at any time, so that the spraying quality is improved, and the spraying can be more uniform by adjusting the spraying range.

Owner:续可琴

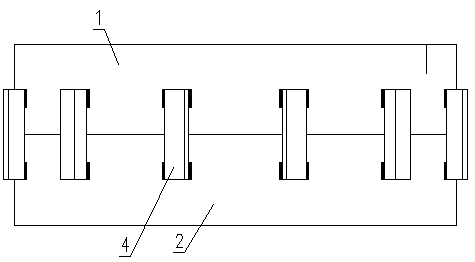

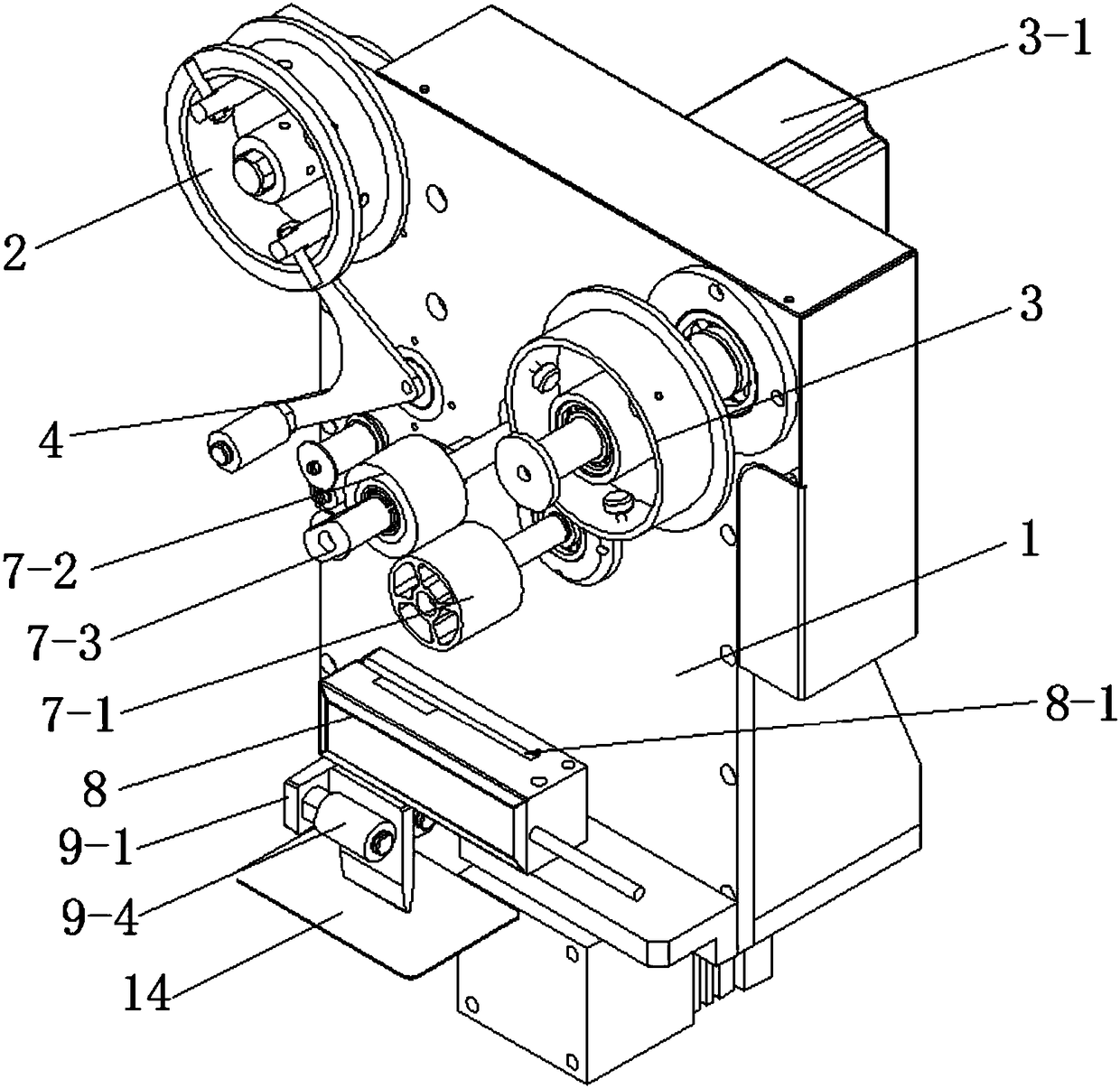

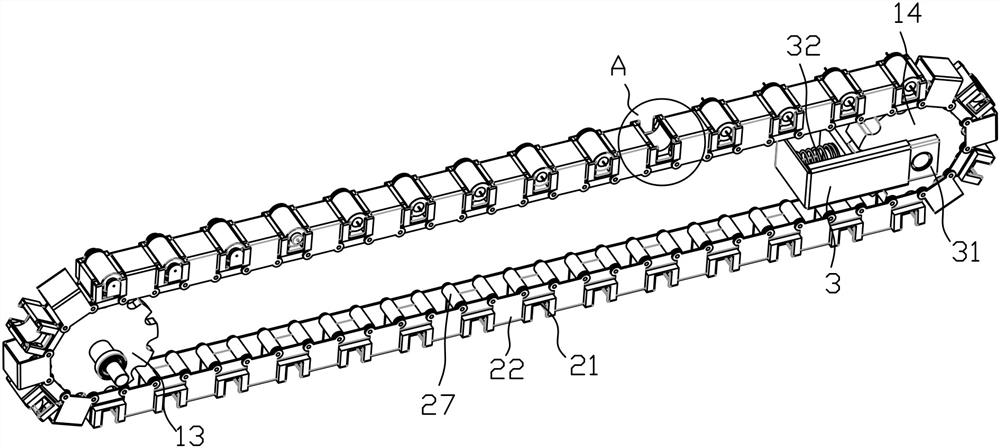

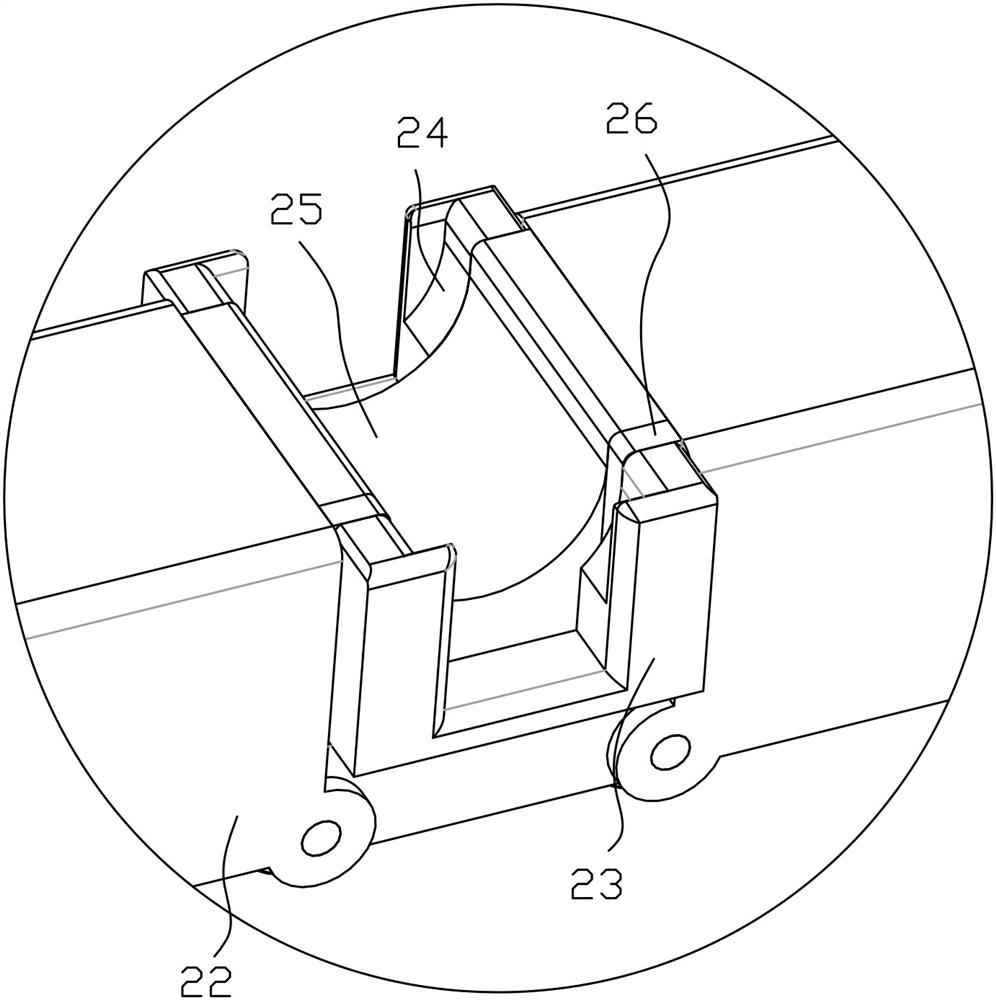

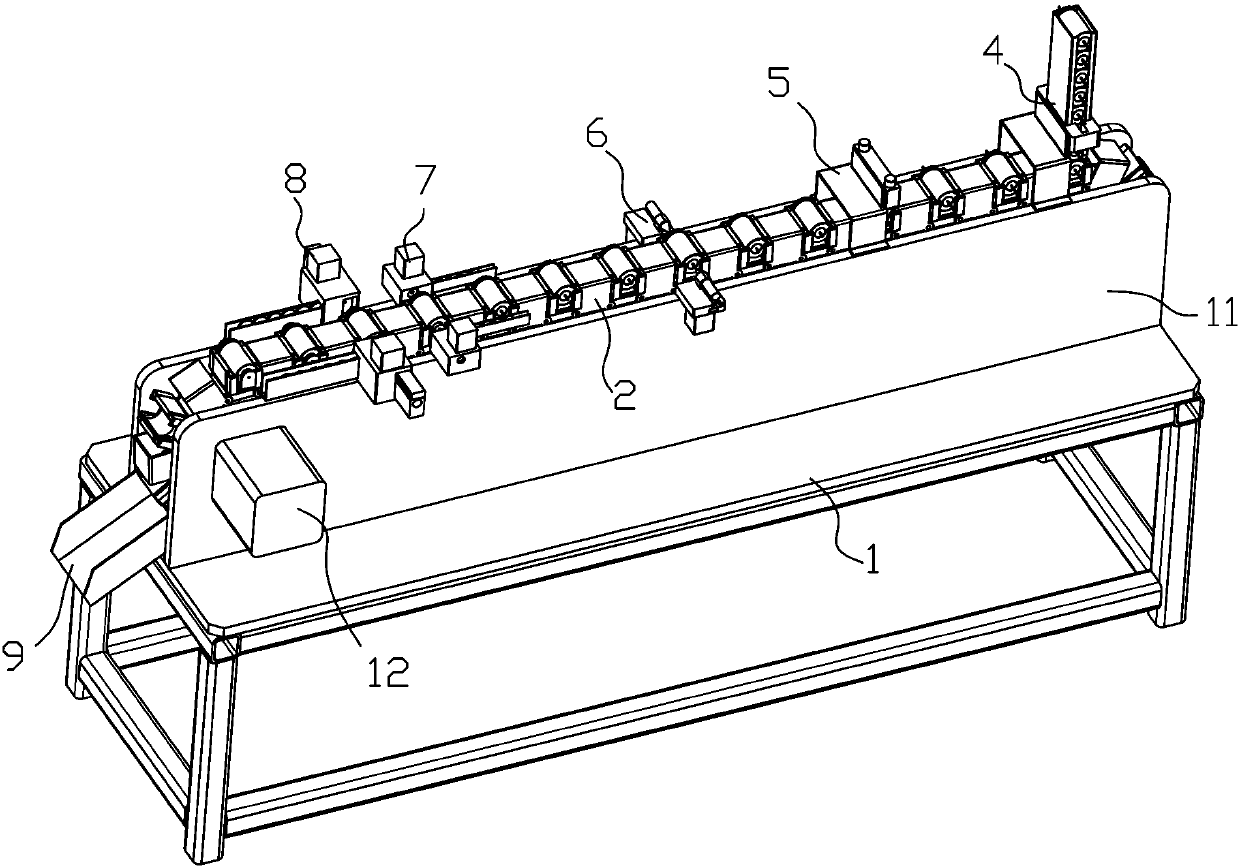

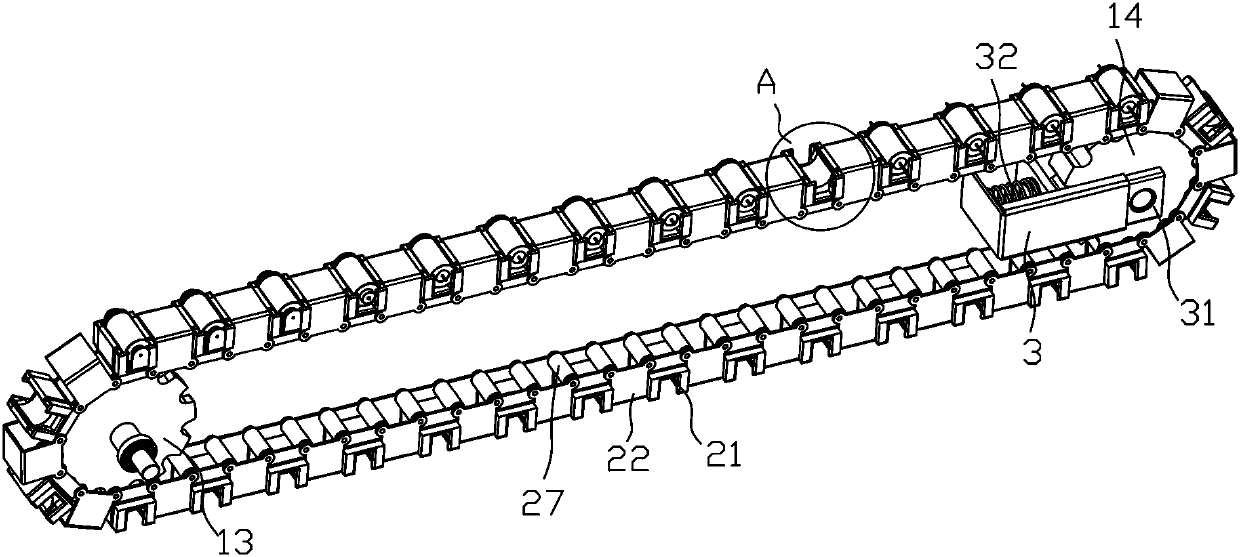

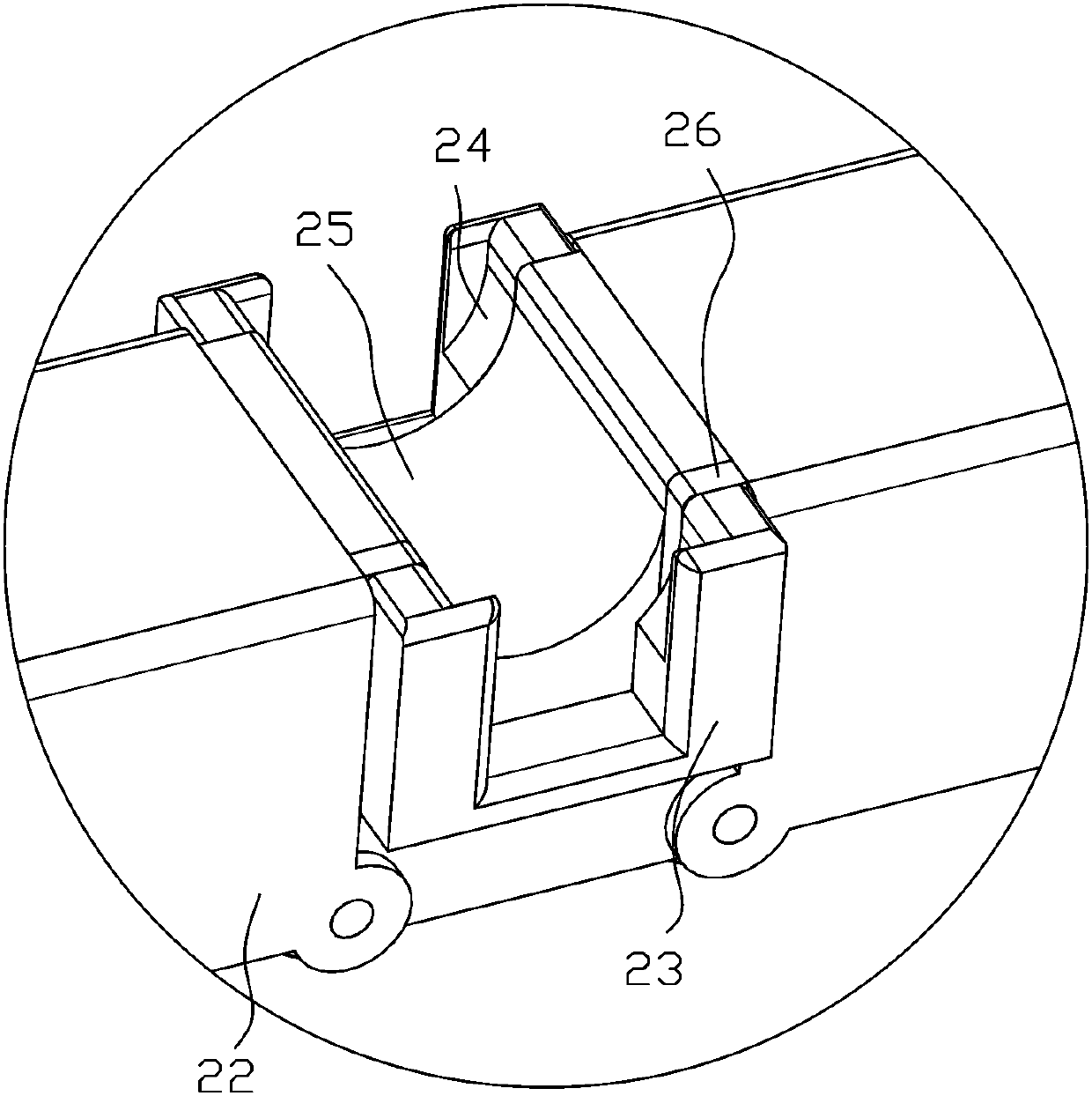

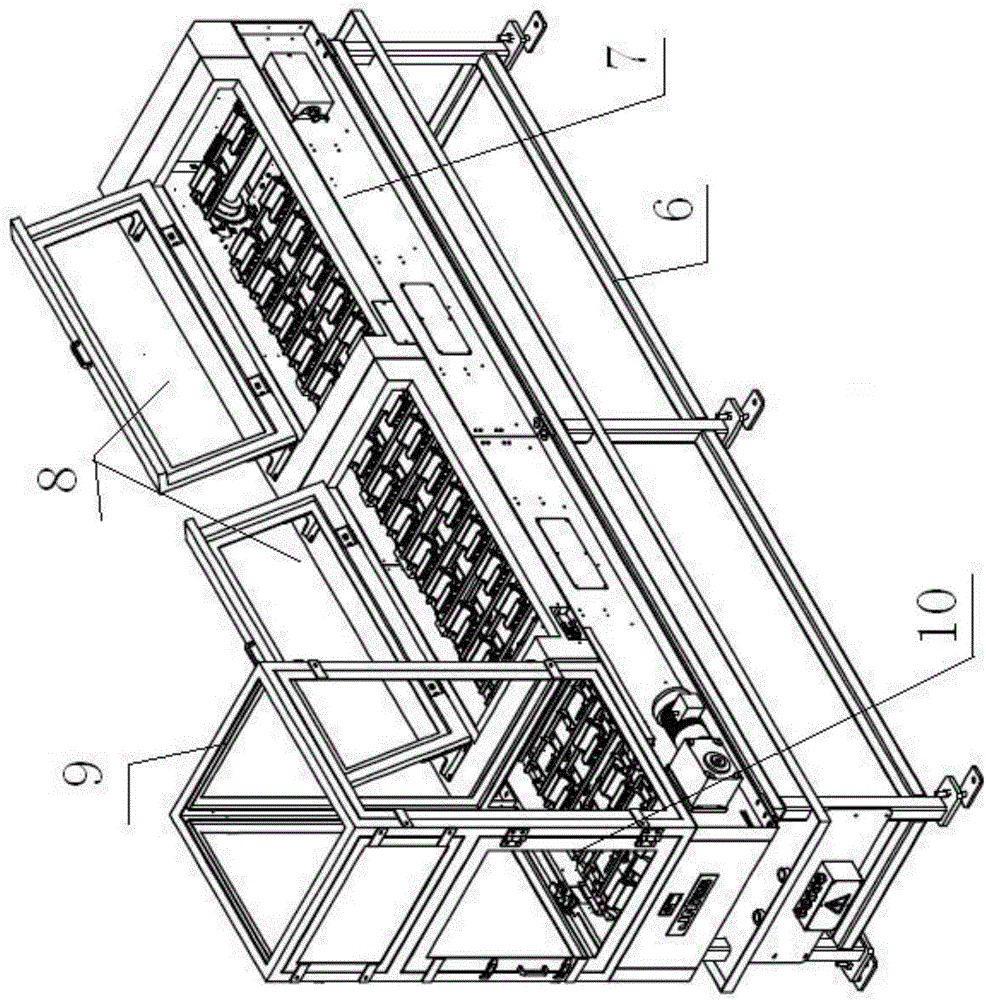

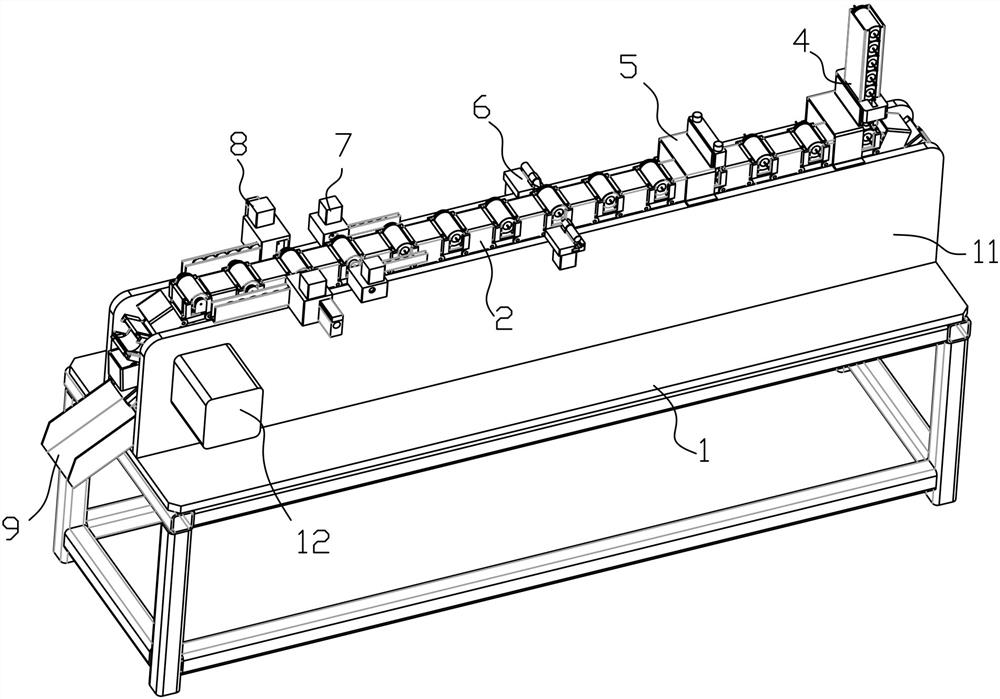

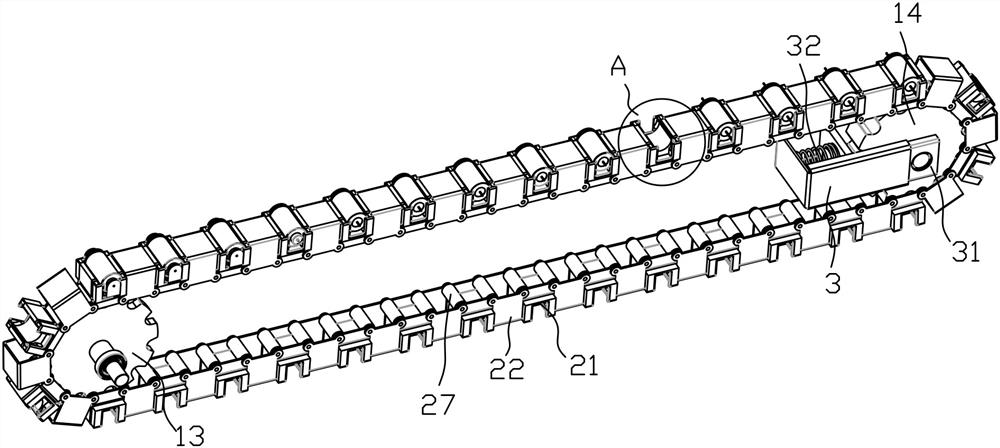

Linear capacitor welding machine

ActiveCN110744196AAvoid subsequent processingHigh precisionLaser beam welding apparatusCapacitancePiezoelectric microactuator

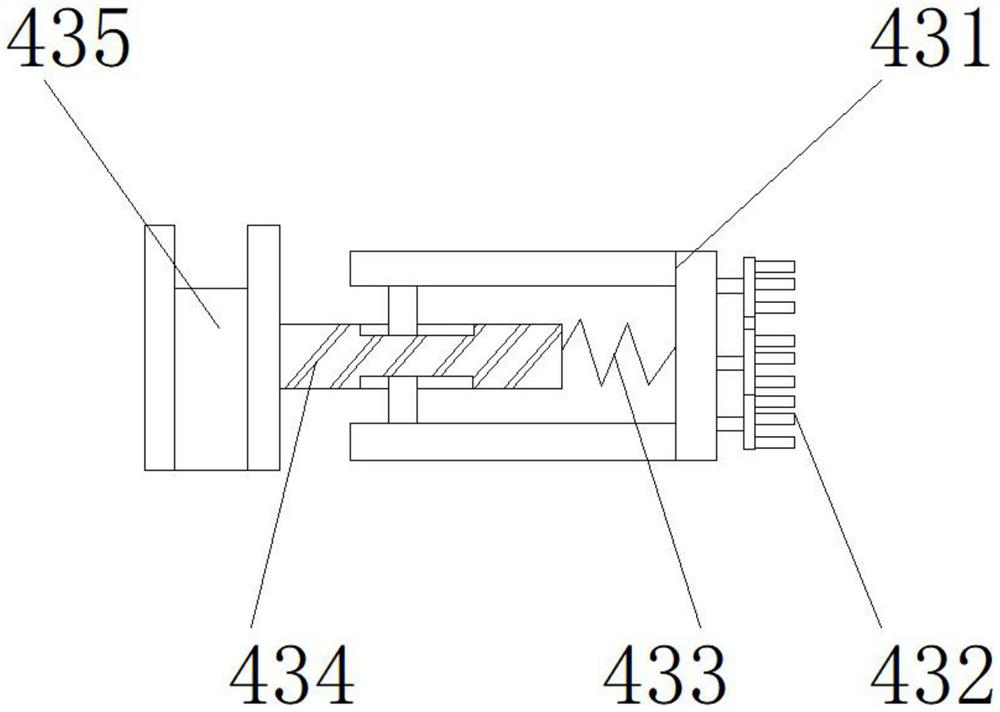

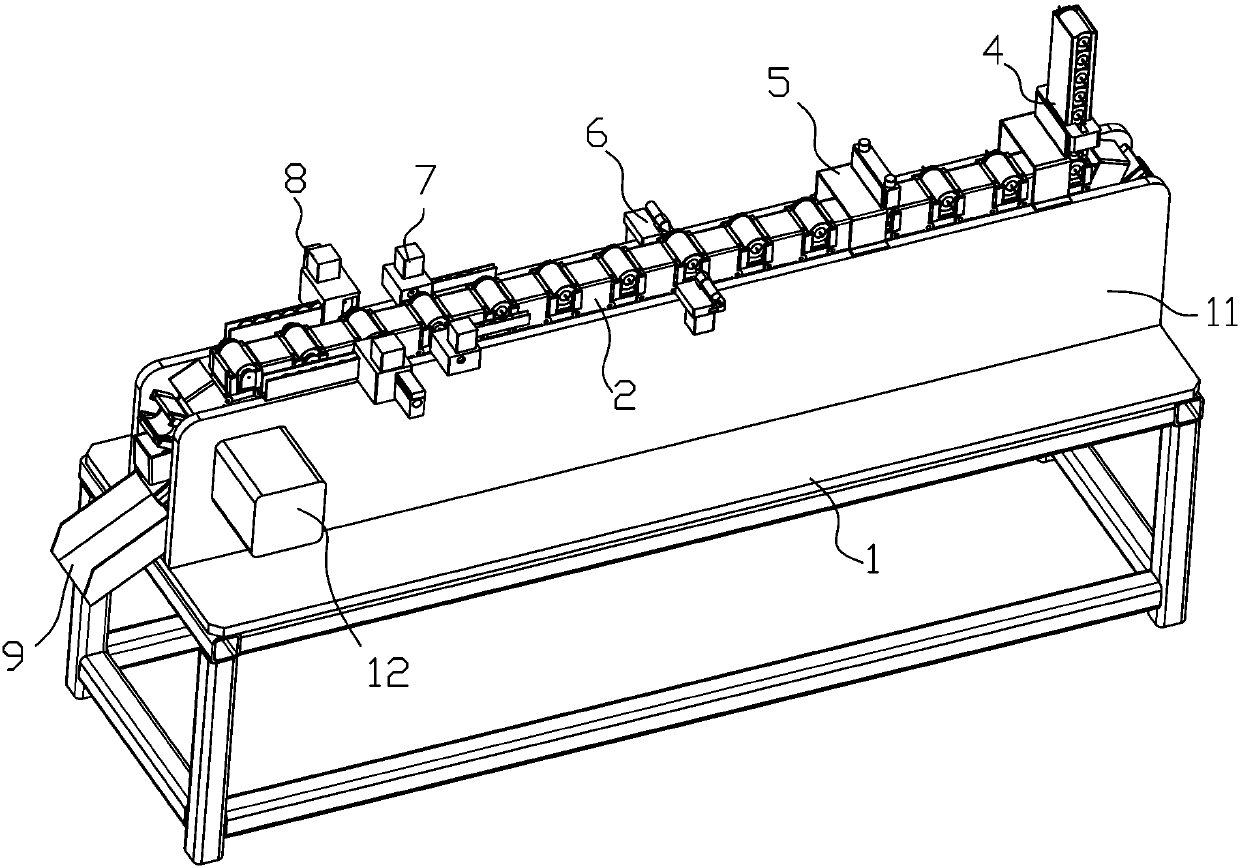

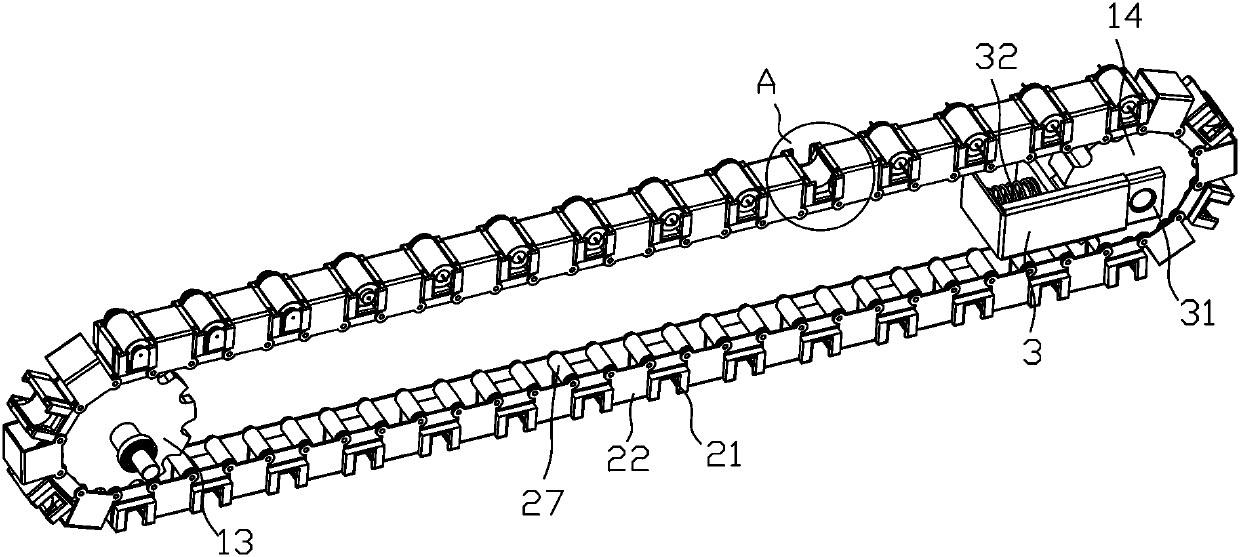

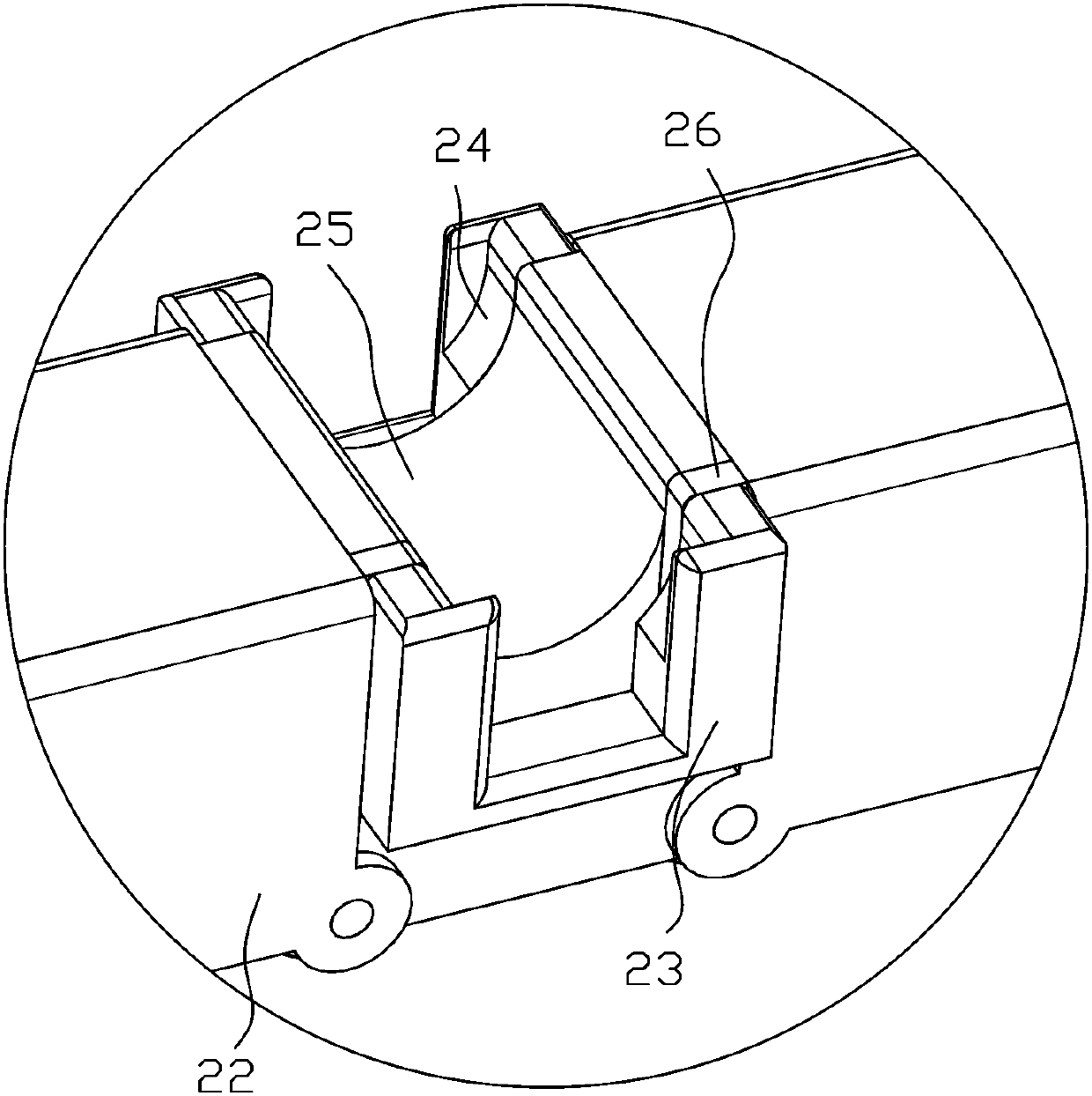

The invention relates to the technical field of capacitor design manufacturing, in particular to a linear capacitor welding machine. The machine comprises a rack, a vertical plate, a driving part, a driving chain wheel, a driven chain wheel, a chain and a tensioning mechanism, wherein the vertical plate is sequentially provided with a capacitor feeding mechanism, a laser cutting mechanism, a ballwelding mechanism, an insulating pad sleeving mechanism, an electrode piece feeding welding mechanism and a discharging mechanism in the moving direction of the chain, the chain comprises a pluralityof clamp chain links and flat chain links connected alternately, one sides of the clamp chain links are provided with first stop edges, the other sides of the clamp chain links are provided with second stop edges, positioning grooves are formed between the first stop edges and the second stop edges, and piezoelectric microactuator pieces are arranged between the positioning grooves and the first stop edges. According to the machine, full-electric-driving is adopted, the high-rigidity chain is automatically tensioned, high-precision and high-speed of a system are ensured, and a lead is cut offin a laser cutting mode, so that the situation that the subsequent machining is influenced by the deformation of the lead caused by mechanical cutting is avoided.

Owner:兰泽(荆门)智能科技有限公司

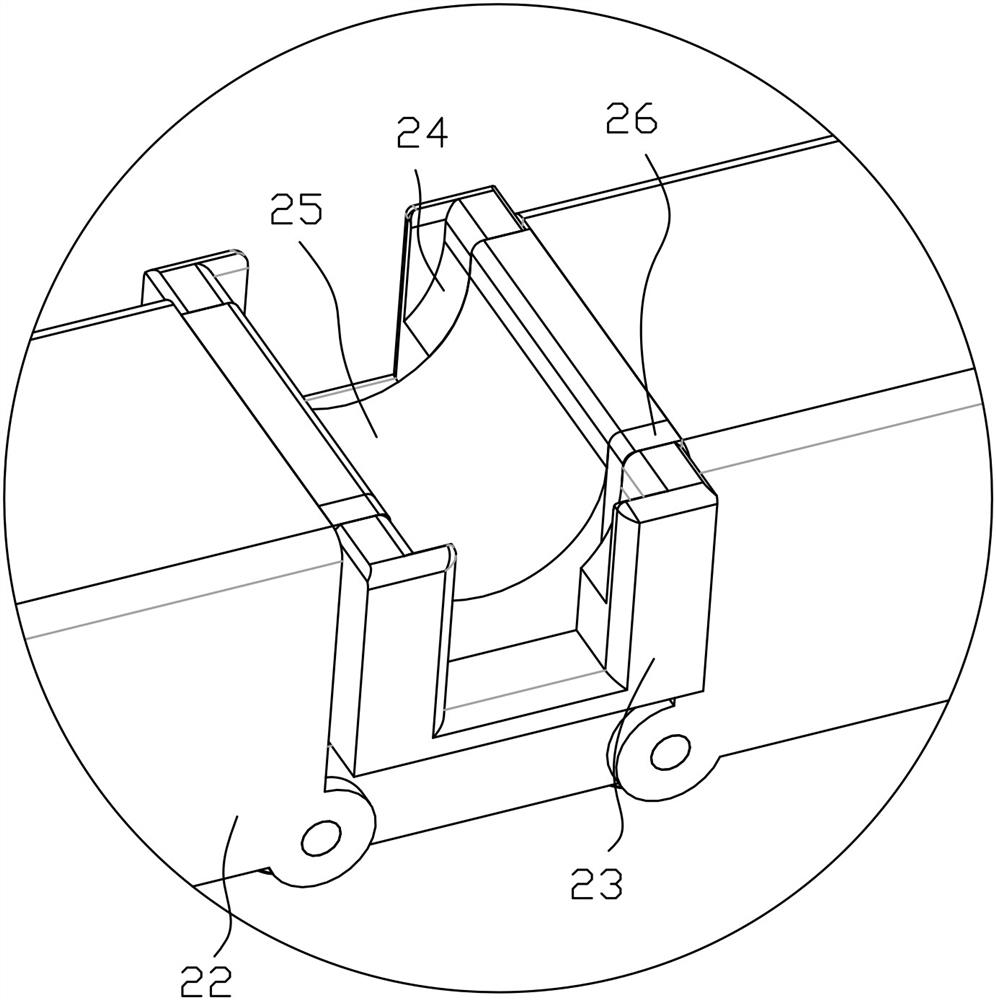

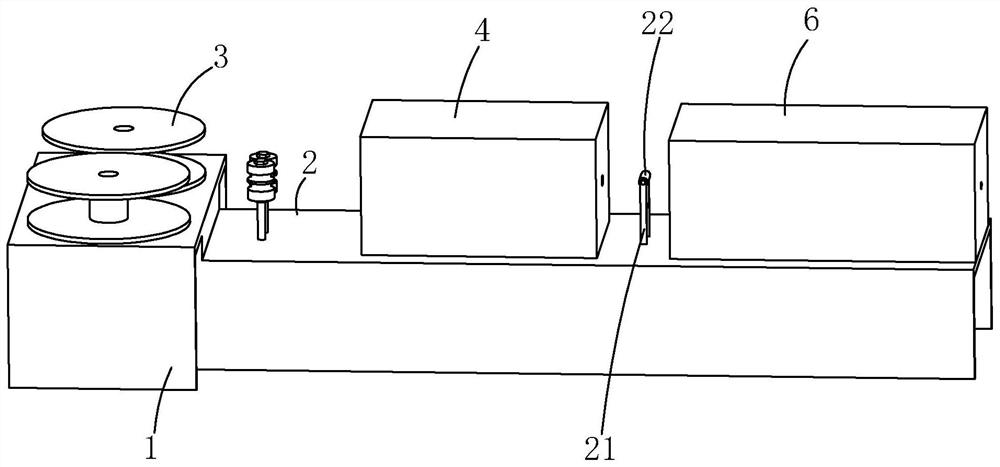

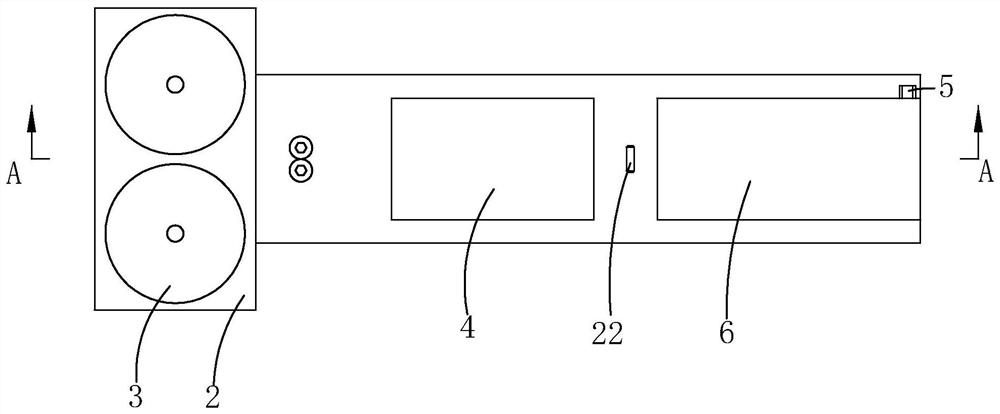

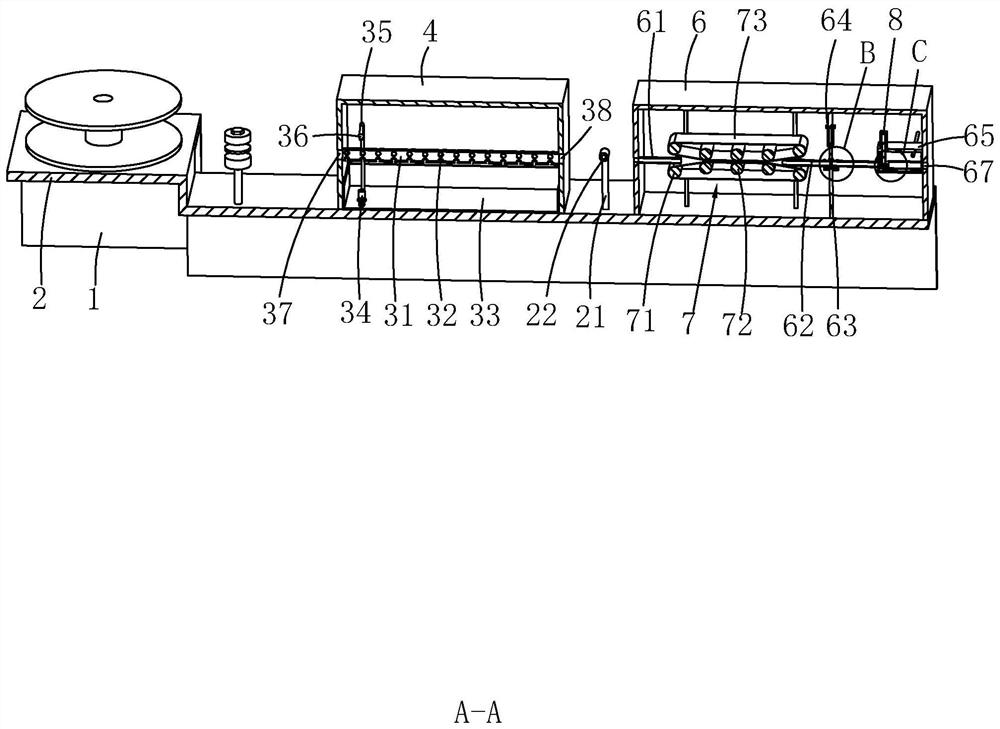

A kind of linear capacitor manufacturing method

ActiveCN110838417BAvoid subsequent processingHigh precisionCapacitor manufactureCapacitanceLaser cutting

The present invention relates to the technical field of capacitor design and manufacture, adopts a linear circulating flow production method as a whole, and a set of first ribs (23), second ribs (24), The capacitor fixing fixture composed of the positioning groove (25) and the piezoelectric micro-movement piece (26), the vertical plate (11) on both sides of the chain (2) is respectively arranged with a capacitor feeding mechanism (4), a laser cutting mechanism (5), The ball welding mechanism (6), the insulating pad socketing mechanism (7), the electrode sheet feeding and welding mechanism (8) and the discharging mechanism respectively complete the feeding and fixing of the capacitor, cutting the lead wire, ball welding, covering the insulating pad, covering the electrode sheet and In the welding process, the present invention adopts all-electric drive and automatically tensions the high-rigidity chain to ensure the high precision and high speed of the system; the laser cutting method is used to cut the lead wire, which avoids the influence of deformation caused by mechanical cutting on the lead wire. processing.

Owner:深圳市三之佳电子有限公司

Rolling machine facilitating sand and stone stirring

InactiveCN108213333AStir wellGood mixing of sand and gravelMould handling/dressing devicesEngineering

The invention discloses a rolling machine facilitating sand and stone stirring. The rolling machine comprises a round casing, wherein support legs are fixedly connected with two sides of the bottom ofthe round casing, a shell is fixedly connected with the lower side between the two support legs, a motor is fixedly connected with the center of the top of the shell, an output end of the motor is fixedly connected with a cylinder, the top of the cylinder penetrates through the bottom of the round casing and extends into the round casing, connecting rods are fixedly connected with two sides of the cylinder, a rolling wheel is movably connected with one end, away from the cylinder, of each connecting rod through a bearing, the bottom of each rolling wheel is contacted with the bottom in the round casing. Through cooperated use of the round casing, the motor, long plates, compression springs, vertical plates, the cylinder, the connecting rods, the rolling wheels, sheet plates, tension springs, long blocks, rollers, long rods, thick rods and oblique plates, the rolling machine facilitating sand and stone stirring can well stir sand and stone, the sand and stone are uniformly rolled, andfollowing processing treatment for the sand and stone is avoided.

Owner:繁昌县金牛机械铸造有限责任公司

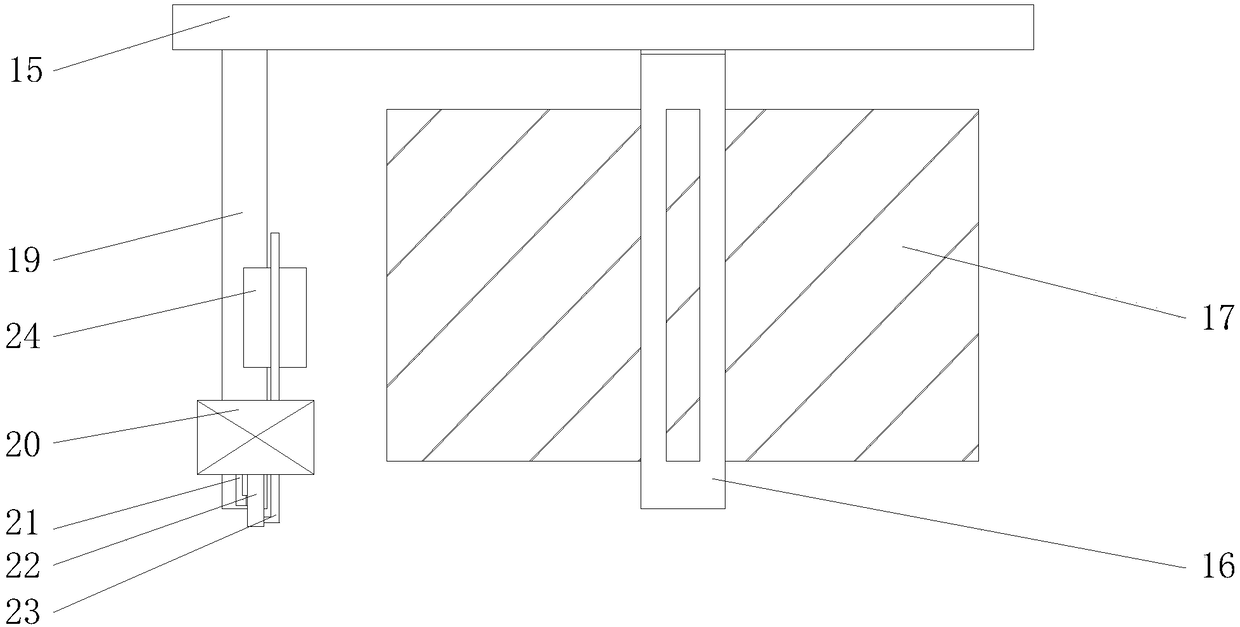

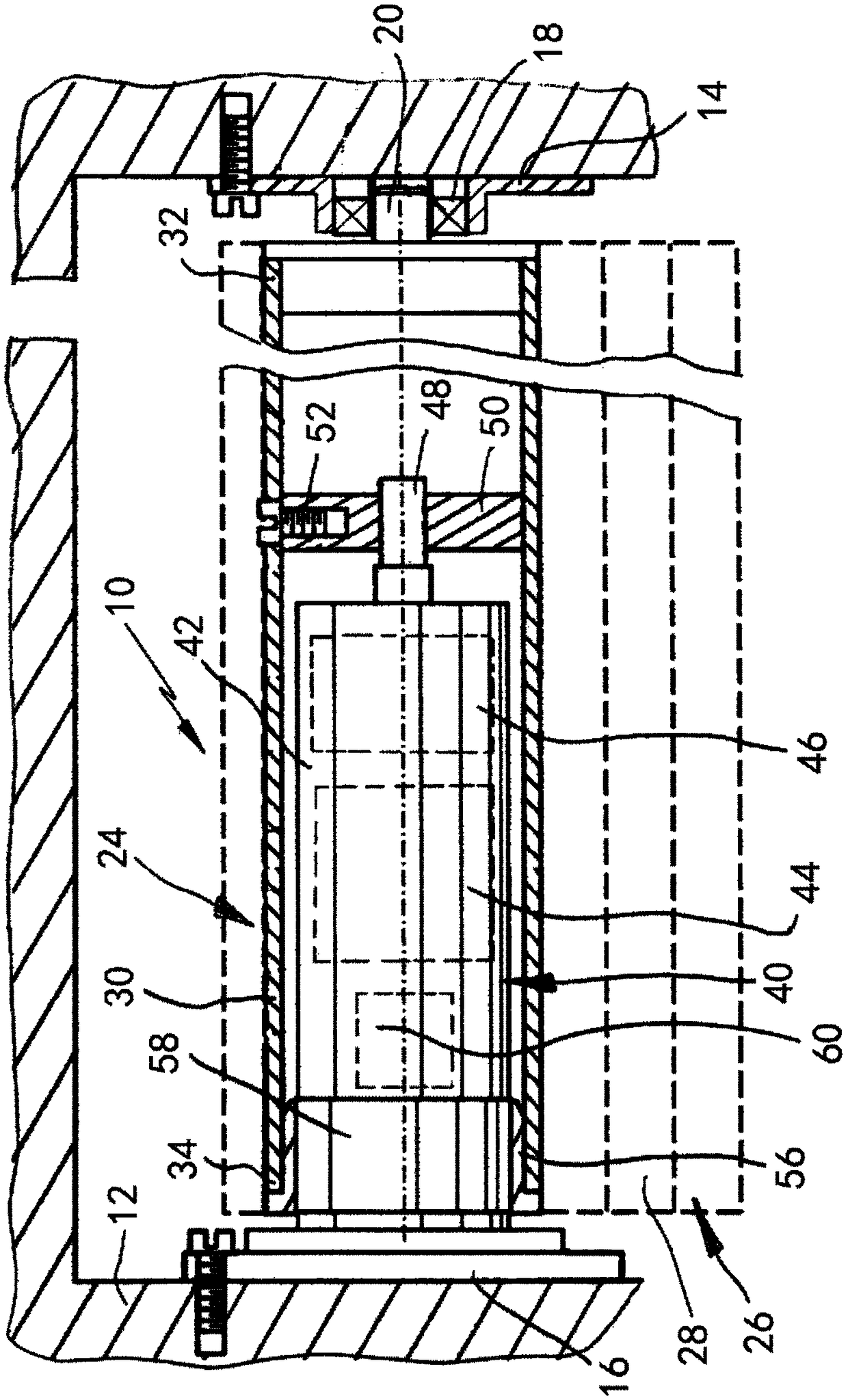

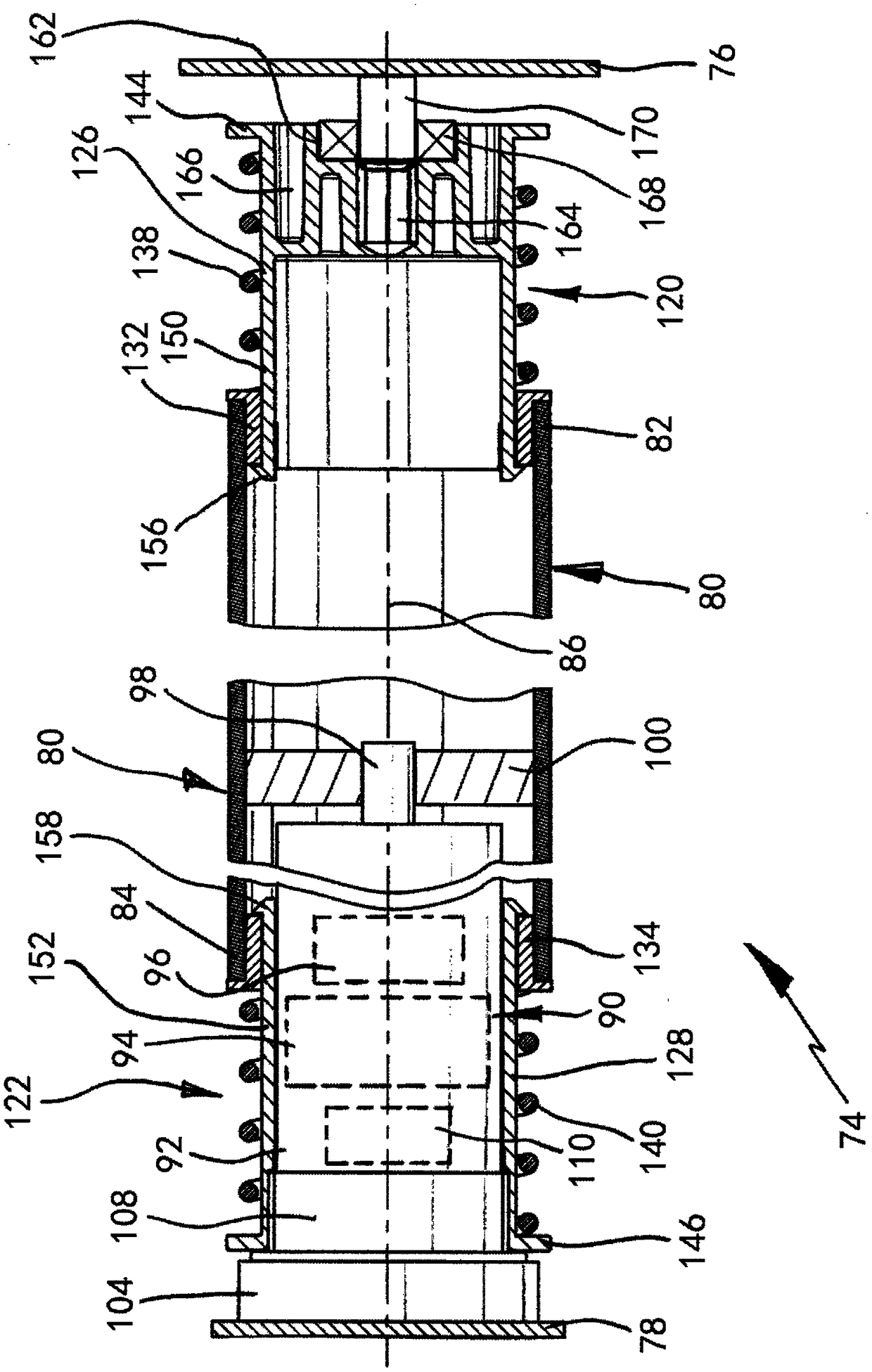

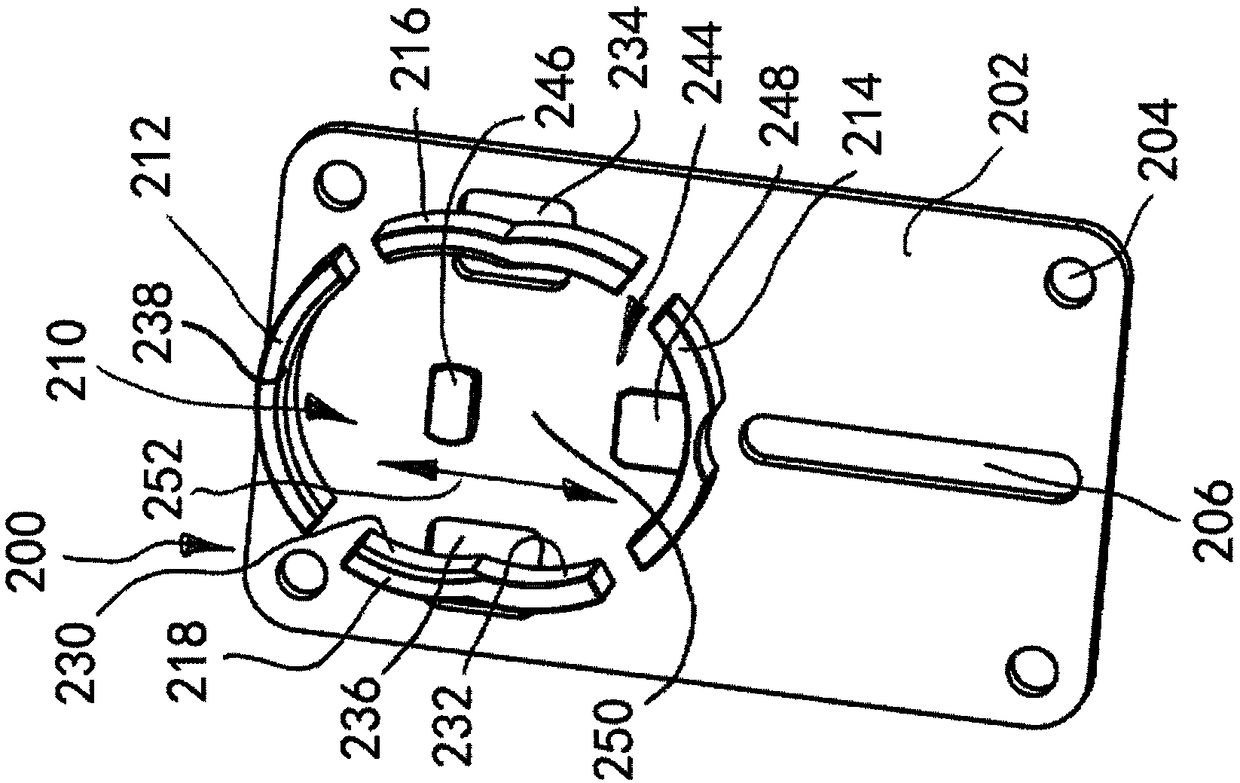

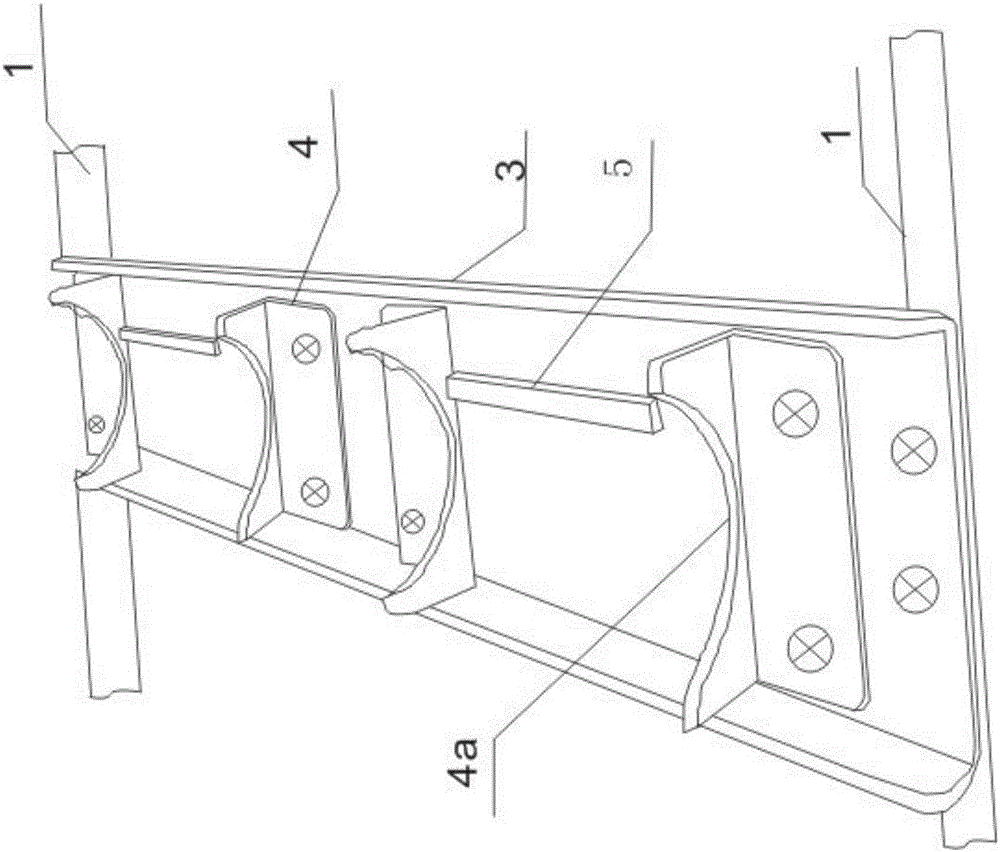

Support unit for a drive unit of a closing or protective device

ActiveCN109386220AEasy to manufactureAvoid subsequent processingShutters/ movable grillesLight protection screensElectrical and Electronics engineeringEngineering

The invention relates to a support unit for housing a drive unit of a closing or protective device in an anti-torque manner. The mounting unit has a retaining member having a special-shaped housing member; and a connecting member matching the special-shaped housing member, the connecting member being connectable to a driving unit. The retaining member provides a first housing position and a secondhousing position for the connector, so that the connector can be tightened in the first housing position relative to the retaining member in the second housing position to overcome the torque. Undera force for overcoming the retaining force, the connector is movable between the first housing position and the second housing position. The invention also discloses a closing or protective device anda tool-less method for stopping the anti-torque system of the drive unit of the closing or protective device.

Owner:ACOMAX GMBH

Linear capacitor manufacturing method

ActiveCN110838417AAvoid subsequent processingHigh precisionCapacitor manufactureCapacitanceProduction line

The invention relates to the technical field of capacitor design and manufacturing. A linear circulating production line mode is adopted as a whole; the top end of each clamp chain link 21 is providedwith a set of capacitor fixing clamps composed of a first flange 23, a second flange 24, a positioning groove 25 and a piezoelectric micro-motion piece 26; a capacitor feeding mechanism 4, a laser cutting mechanism 5, a ball bonding mechanism 6, an insulating pad sleeving mechanism 7, an electrode plate feeding and welding mechanism 8 and a discharging mechanism are arranged on the vertical plates 11 on the two sides of the chain 2 respectively, and the processes of feeding and fixing of the capacitor, lead cutting, ball welding, insulating pad sleeving, electrode plate sleeving and welding are respectively completed. Full-electric driving is adopted, a high-rigidity chain is automatically tensioned, and high precision and high speed of a system are guaranteed; and the lead is cut off ina laser cutting mode, and the situation that deformation of the lead caused by mechanical cutting influences subsequent machining is avoided.

Owner:深圳市三之佳电子有限公司

Blank conveying device for automobile engine bearing cap

The invention discloses a blank conveying device for an automobile engine bearing cap. A machine case which is open in the upper end is arranged at the upper end of a rack; conveying chains are symmetrically mounted inside two long side plates of the machine case; a plurality of steering knuckle blank trays are connected between the two conveying chains; two groups of blank limiting plates are arranged in each steering knuckle blank tray; each group of blank limiting plates is composed of two blank limiting plates; an anti-misplacing convex strip is arranged between every two blank limiting plates; one end of each anti-misplacing convex strip abuts against the blank limiting plate in the middle; the other end of each anti-misplacing convex strip has a distance from the blank limiting plate on the side; each anti-misplacing convex strip is positioned at the rear part of each steering knuckle blank tray; a box cover is arranged at the upper end of the front part of the machine case; and a safety box which is open in upper end is arranged at the upper end of the tail of the machine case. The blank conveying device disclosed by the invention is simple in structure, is convenient to use, can effectively avoids trouble, caused by steering knuckle blank misplacing of a worker, in follow-up processing, improves production efficiency, avoids wrong processing and can effectively reduce the occurrence of safety accidents.

Owner:重庆庆兰实业有限公司

A sealing safety detection device for beverage packaging cans

ActiveCN108036904BAvoid subsequent processingAvoid wastingMeasurement of fluid loss/gain rateVacuum levelFlow diverter

The invention relates to the technical field of sealing detection devices, and in particular relates to a sealing safety detection device for a beverage packaging can. The device comprises a packagingcan conveyor belt. A number of stand columns which are placed at equal intervals are fixed on the packaging can conveyor belt. A packing can is turned upside down on each stand column. A number of detection box bodies with downward openings are fixedly connected with the bottom of a support plate. A sealing plug is arranged in each detection box body, and a through hole is arranged in the middleof the sealing plug. A second shunt is connected with an air extractor. A first shunt is connected with an air blower. A vacuum level sensor is connected with a signal processor. The signal processoris connected with a controller. A first switch valve, the air extractor, a power telescopic rod, the air blower and a second switch valve are connected with the controller. According to the invention,the device can effectively detect air leakage of the packaging can, and can carry out batch detection; subsequent processing of unqualified products can be effectively avoided; the work efficiency ofthe whole process is improved; and beverage waste is avoided.

Owner:GUANGZHOU DAYUE MACHINERY CO LTD

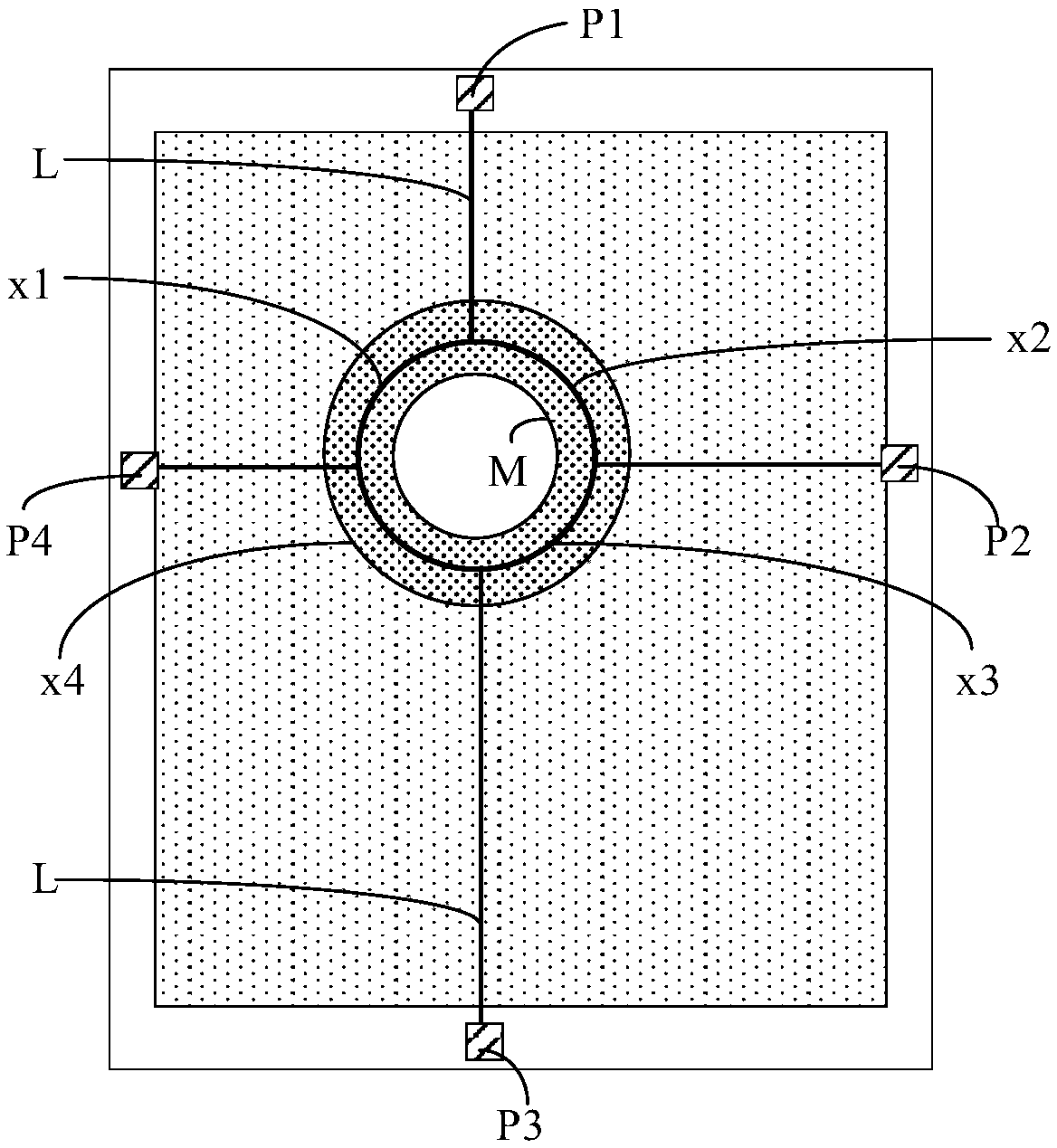

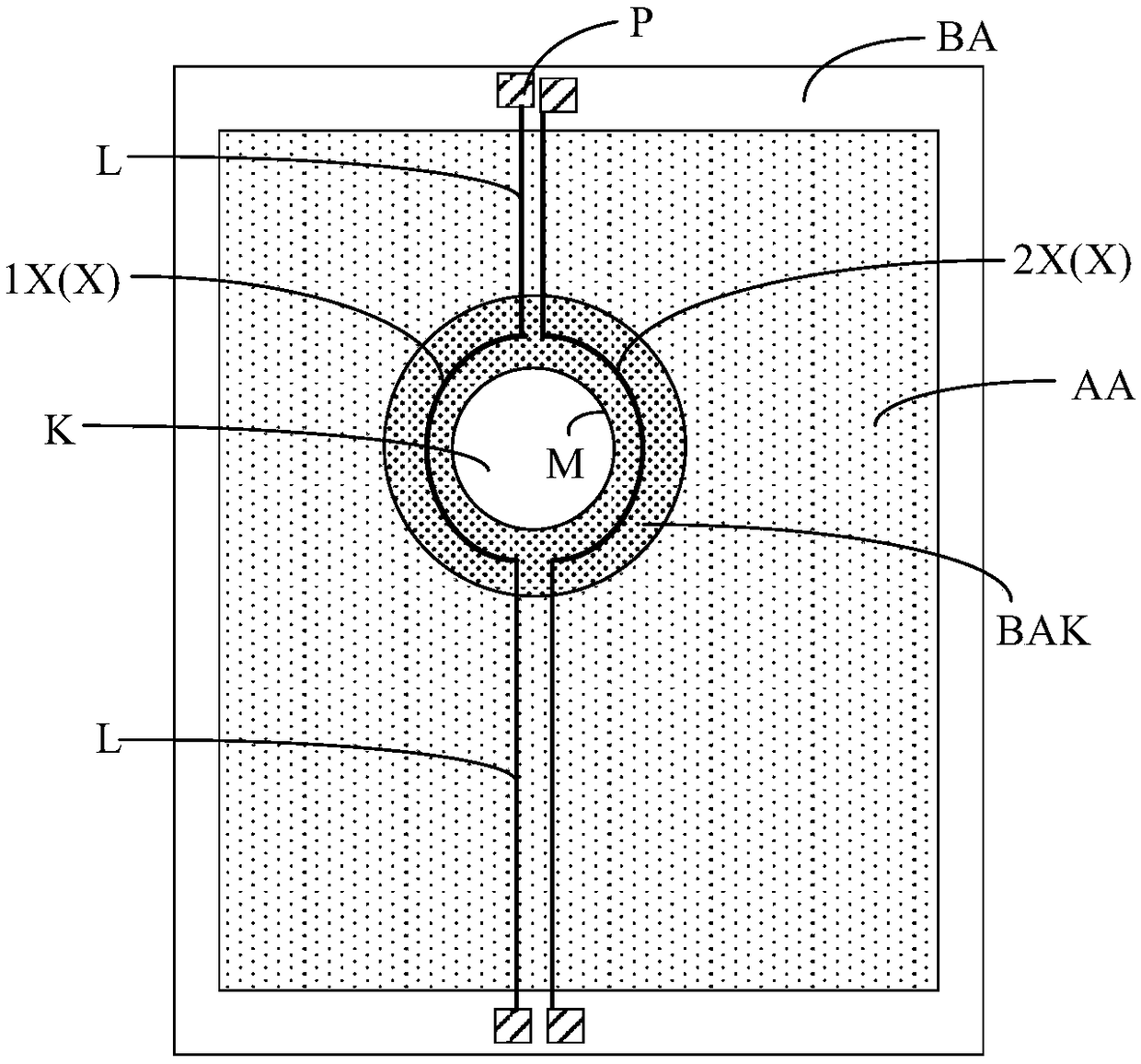

Array substrate, display panel and cutting control method for array substrate

ActiveCN109270758BAvoid subsequent processingSolid-state devicesNon-linear opticsElectrical connectionEngineering

The invention discloses an array substrate, a display panel and a cutting control method for the array substrate. The array substrate has a gap, and the array substrate includes a display area and a non-display area of the gap, wherein the non-display area of the gap surrounds the gap, and the display area surrounds the non-display area of the gap; it also includes: conductive traces, the conductive traces are located in the non-display area of the gap, and A conductive trace is arranged along the edge of the gap; the test board is electrically connected to the conductive trace through a connecting wire, wherein at least two test boards are electrically connected to the same conductive trace. The invention can realize the control of the cutting precision of the array substrate.

Owner:SHANGHAI AVIC OPTOELECTRONICS

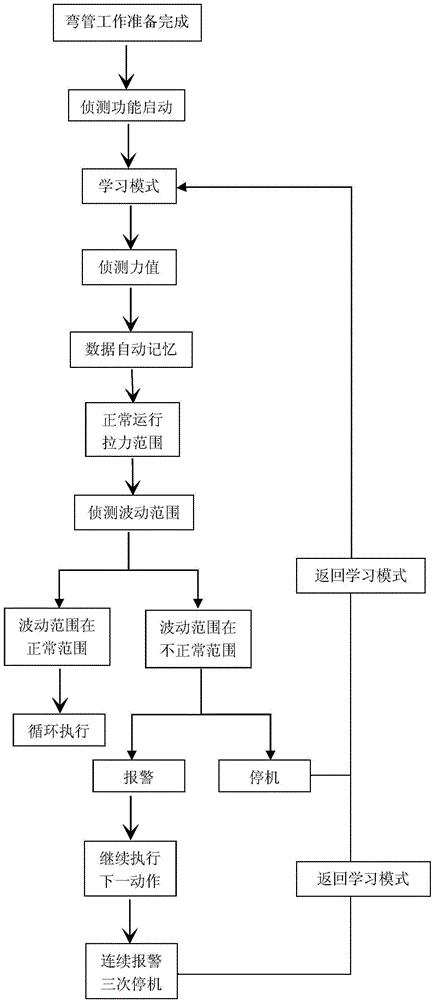

Automatic detecting method of breakage of elbow bulb of passenger vehicle exhaust system

InactiveCN104646453AAvoid missingAvoid it happening againShaping safety devicesMetal working apparatusWaste productDriving mode

The invention provides an automatic detecting method of breakage of an elbow bulb of a passenger vehicle exhaust system, and is used for solving the problem that an existing bulb is broken and enters a pipe body, and the state is difficult o observe. An exhaust elbow device is arranged, and is provided with a tension oil cylinder and an elbow mechanism, wherein the tension oil cylinder is connected with a tension shaft in a driving mode; the tail end of a tension shaft is provided with an elbow bulb; the tension shaft is provided with a tension sensor which controls a detector in a connecting mode by a circuit. The automatic detecting method comprises the following steps: (1) performing straight pipe bending operation; (2) starting an automatic detecting function; (3) implementing a learning mode so as to obtain the normal running tension range value; and (4) implementing the detecting stage of the tension oscillation range, judging that the elbow bulb is broken, and controlling the detector to alarm or stop. According to the method, waste products caused by stop of bulbs are prevented; further the subsequent processing of defective products is stopped; the yield of finished products is ensured; the economic loss is reduced; the working efficiency and the utilization ratio of production resources are improved.

Owner:FAURECIA QINGDAO EXHAUST SYST

A linear capacitor welding machine

ActiveCN110744196BAvoid subsequent processingHigh precisionLaser beam welding apparatusCapacitanceEngineering

The invention relates to the technical field of capacitor design and manufacture, in particular to a linear capacitor welding machine, which includes a frame, a vertical plate, a driving member, a driving sprocket, a driven sprocket, a chain and a tensioning mechanism; In the direction of movement, a capacitor feeding mechanism, a laser tangent mechanism, a ball welding mechanism, an insulating pad sleeve mechanism, an electrode sheet feeding and welding mechanism, and a discharging mechanism are arranged in sequence; the chain includes a plurality of clamp links connected at intervals and a plane chain. section; one side of the clamp link is provided with a first rib; the other side of the clamp link is provided with a second rib; a positioning groove is provided between the first rib and the second rib ; A piezoelectric micro-movement piece is provided between the positioning groove and the first rib. The invention adopts all-electric drive and automatically tensions the high-rigidity chain, which ensures the high precision and high speed of the system; the laser cutting method is used to cut the lead wire, which avoids the deformation of the lead wire caused by mechanical cutting and affects the subsequent processing.

Owner:兰泽(荆门)智能科技有限公司

A kind of harness threading equipment

ActiveCN110947878BImprove practicalityAvoid wastingTurning machinesMetal working apparatusEngineeringWorkbench

The invention relates to a wire harness threading device, which includes a frame body and a workbench. A winding column is rotatably connected to the surface of the workbench. A driving assembly is arranged on one side of the winding column. The first hollow wire tube and the second hollow wire tube are arranged on both sides of the casing, and a mounting hole is provided on the cover, and a hollow support tube is provided at the installation hole, and a shell is provided on the outer periphery of the hollow support tube, and a through hole is opened on the shell. hole, the second hollow wire tube, the through hole, the hollow support tube and the installation hole are arranged concentrically; The first air cylinder is connected on the handle portion of the knife. The wire harness threading equipment and its use method designed by the present invention realize the cutting of the wire harness, so that the wire harness protrudes out of the casing, which is convenient to use, and at the same time avoids the waste of the casing by secondary cutting of the casing, saves processing costs, and improves the production efficiency of the casing. Practical performance of wire harness through pipe equipment.

Owner:西咸新区吉亚汽车部件有限公司

Method for preparing diamond/silicon carbide ceramic matrix composite material

The invention discloses a method for preparing a diamond / silicon carbide ceramic matrix composite material, and belongs to the field of ceramic materials. The diamond / silicon carbide ceramic matrix composite material is characterized by being prepared from the following raw materials in percentage by weight: 5 to 15 percent of adhesive, 15 to 45 percent of silicon carbide powder, and 40 to 80 percent of diamond particle. The method comprises the following steps of: wet-mixing the raw materials for 8 to 24 hours, performing die forming under the pressure of 75 to 250MPa to obtain a blank of the composite material, oxidizing the blank in the air at the temperature of 200DEG C for 6 to 10 hours, sintering under the protection of nitrogen at the temperature of between 800 and 1,200DEG C for 8to 15 hours, and cooling together with a furnace; and performing vacuum impregnation, oxidation, sintering and cooling, and circulating for 3 to 7 times to obtain the compact diamond / silicon carbide ceramic matrix composite material, wherein the oxidation temperature is 200DEG C, the oxidation time is 6 to 10 hours, the sintering is performed at the temperature of between 800 and 1,200DEG C for 8to 15 hours under the protection of nitrogen, and the product is cooled together with the furnace. The method has low equipment requirement, is low in cost and can prepare the complicated-shaped compact diamond / silicon carbide ceramic matrix composite material.

Owner:UNIV OF SCI & TECH BEIJING

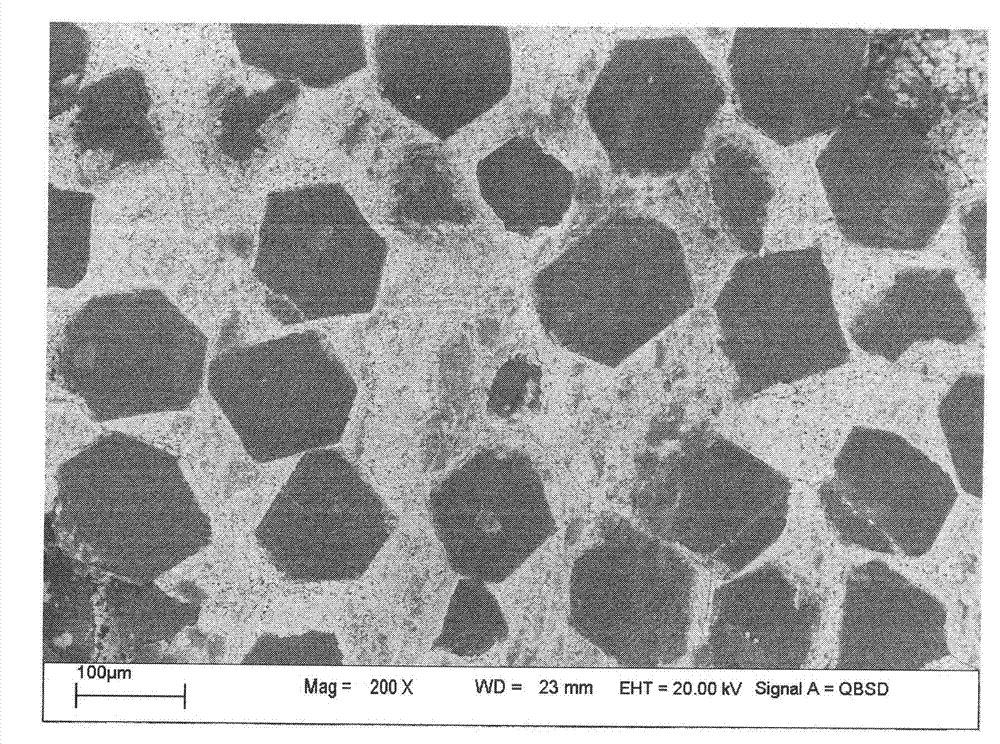

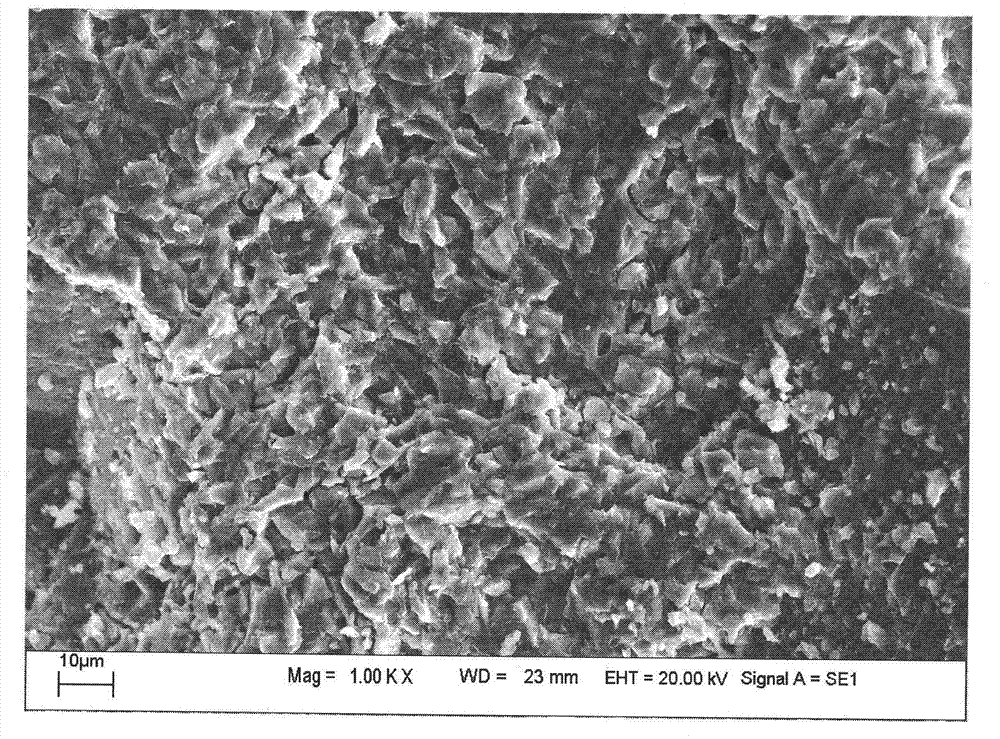

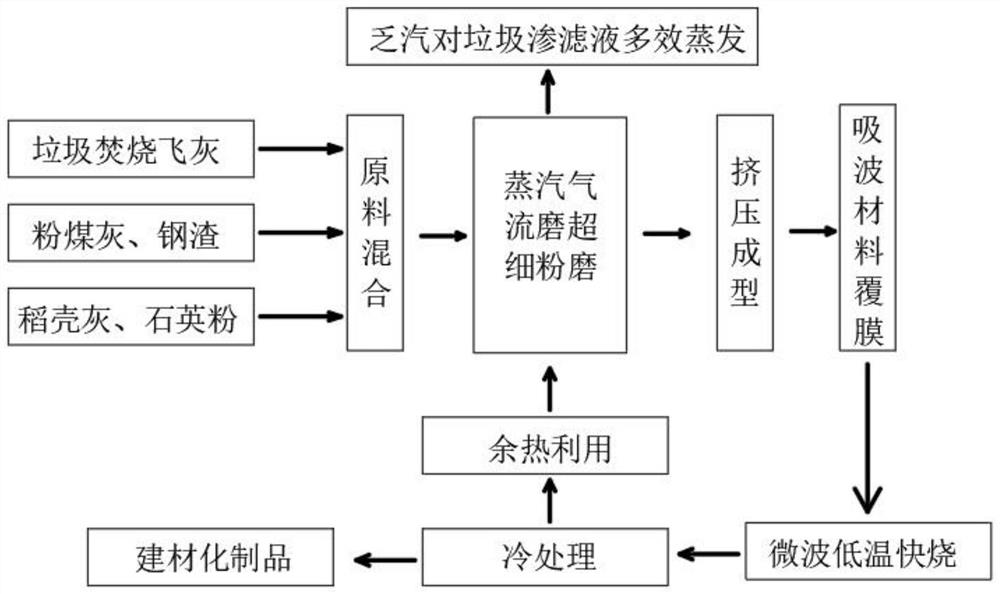

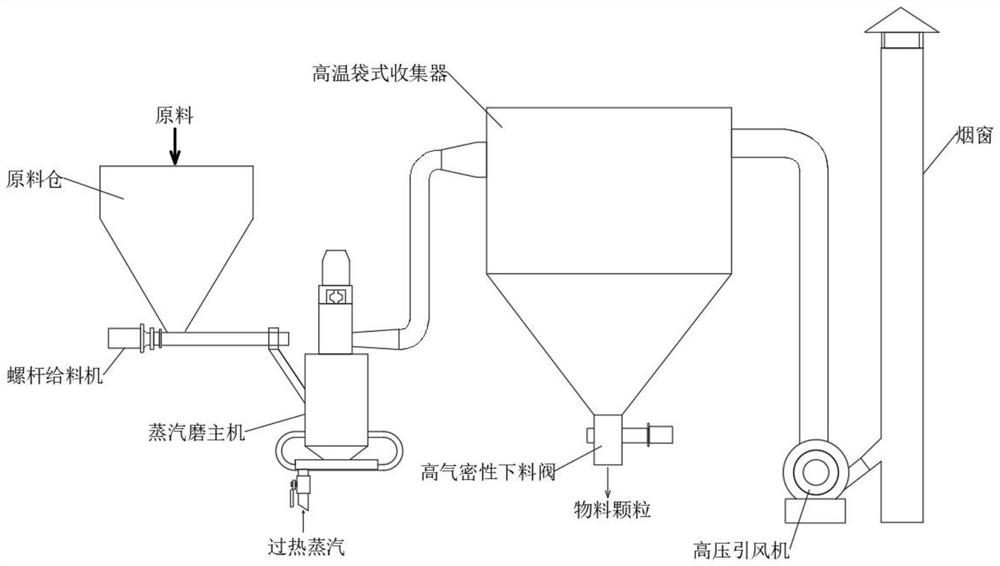

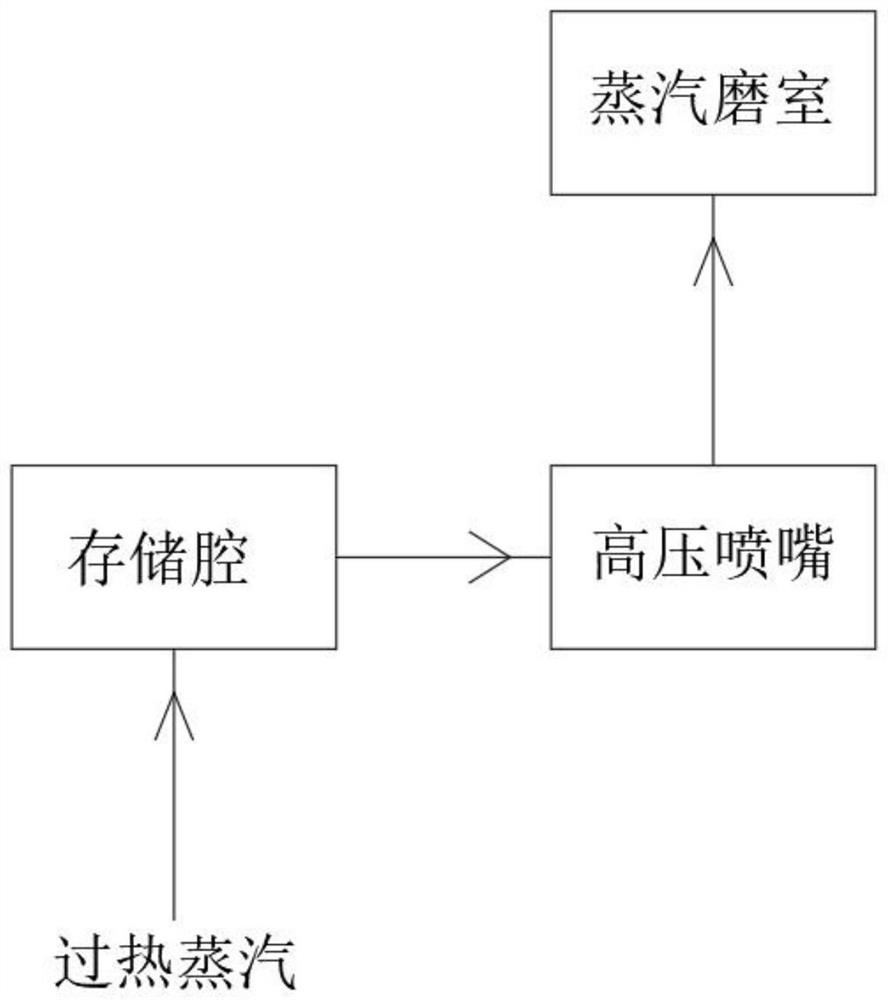

Garbage fly ash microwave sintering process based on superfine grinding technology

InactiveCN114453384AReduce consumptionLow filtrationSolid waste disposalTransportation and packagingWastewaterMicrowave sintering

The invention discloses a garbage fly ash microwave sintering process based on a superfine grinding technology, belongs to the field of fly ash microcrystal vitrification processes, and aims to solve the problem that water washing treatment is needed in traditional sintering by using a steam jet pulverization technology and a microwave sintering technology. According to the scheme, by adopting the microwave sintering technology, the treatment cost and the process difficulty are greatly reduced, volatilization of heavy metal is avoided through low-temperature sintering, the problem of subsequent treatment of secondary fly ash is avoided, landfill leachate is co-treated, zero discharge of wastewater is realized, and the economic benefit and the environmental protection benefit of a garbage power generation enterprise are effectively improved; compared with melting treatment, the sintering method is low in heat consumption, simple in chemical process and convenient to operate, the material and energy consumption in the curing process is low, the capacity increasing ratio is low, the raw materials are rich in source, low in price and easy to obtain, and the treatment cost is low.

Owner:谢飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com