Processing method of U-shaped through channels

A processing method and channel technology, applied in the direction of electrolysis, electroforming, etc., to achieve the effect of avoiding subsequent processing, improving production efficiency and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method of the present invention will be further described below in conjunction with the accompanying drawings.

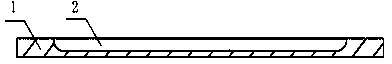

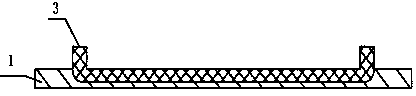

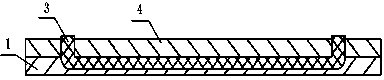

[0030] Please refer to Figure 1 to Figure 4 As shown, a workpiece with channels formed by grooves is composed of a base body 1 and an electroformed covering layer 4 . The base body 1 is generally made of copper, and the base body 1 is milled and turned to form grooves 2 or its array structure on the outer surface, so that its cross-section has the same groove structure as the channel cross-section. The width of the groove 2 is generally about 2 mm, and the thickness of the entire substrate 1 is 8-10 mm; the electroformed covering layer 4 is electroformed on the substrate 1, and the metal deposition layer is formed by electrodeposition, and the thickness is generally 3-5 mm. . The material of the electroforming covering layer 4 is nickel.

[0031] Please refer to Figure 1 to Figure 3 and combine Figure 4 to Figure 5 As shown, the processing method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com