Automatic detecting method of breakage of elbow bulb of passenger vehicle exhaust system

An exhaust system and passenger vehicle technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor pipe bending, lower quality of finished products, unqualified rate, etc., to improve work efficiency and production. Utilization of resources, reducing economic losses, and ensuring the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

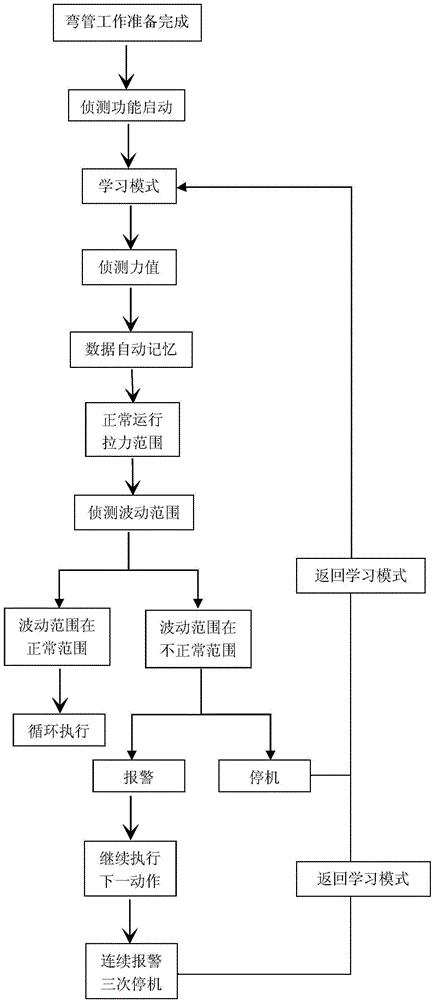

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] The automatic detection device for the breaking of the elbow ball head includes exhaust pipe bending equipment. The exhaust pipe bending equipment has a tension cylinder and a pipe bending mechanism. The tension cylinder is driven to connect with the tension shaft. The pipe mechanism is located outside the ball head of the elbow, and a tension sensor is arranged on the tension shaft, and the tension sensor is connected to the control detector through an electric signal.

[0026] Wherein the tension shaft is a through-core rod, the tension sensor is connected into the inside of the through-core rod, and the tension sensor is also connected with the tension oil cylinder through a circuit. The control detector includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com