Method for removing underground water hardness by combination of lime and ultrafiltration

A groundwater and lime technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of filter penetration, water turbidity, and increased effluent turbidity. To achieve the effect of simple separation, low operating cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

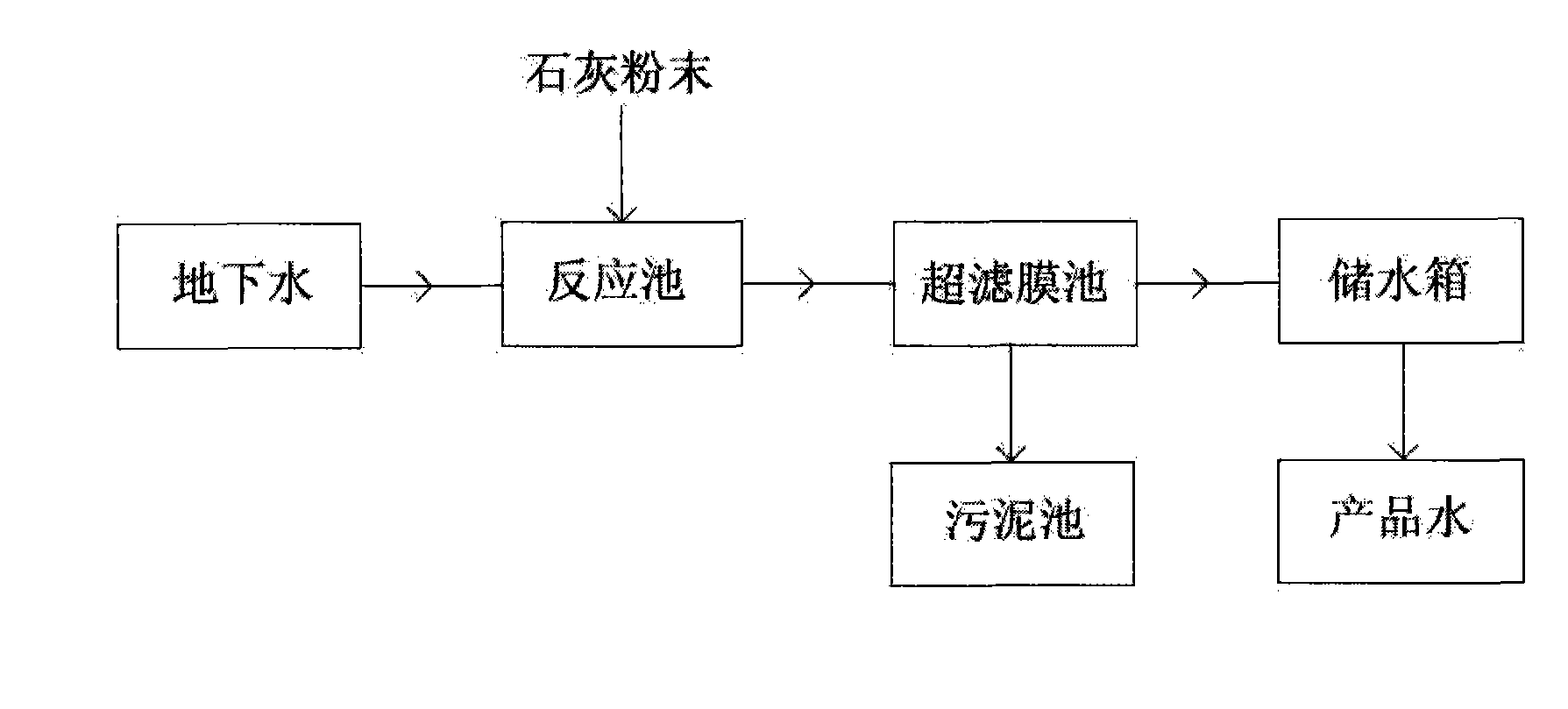

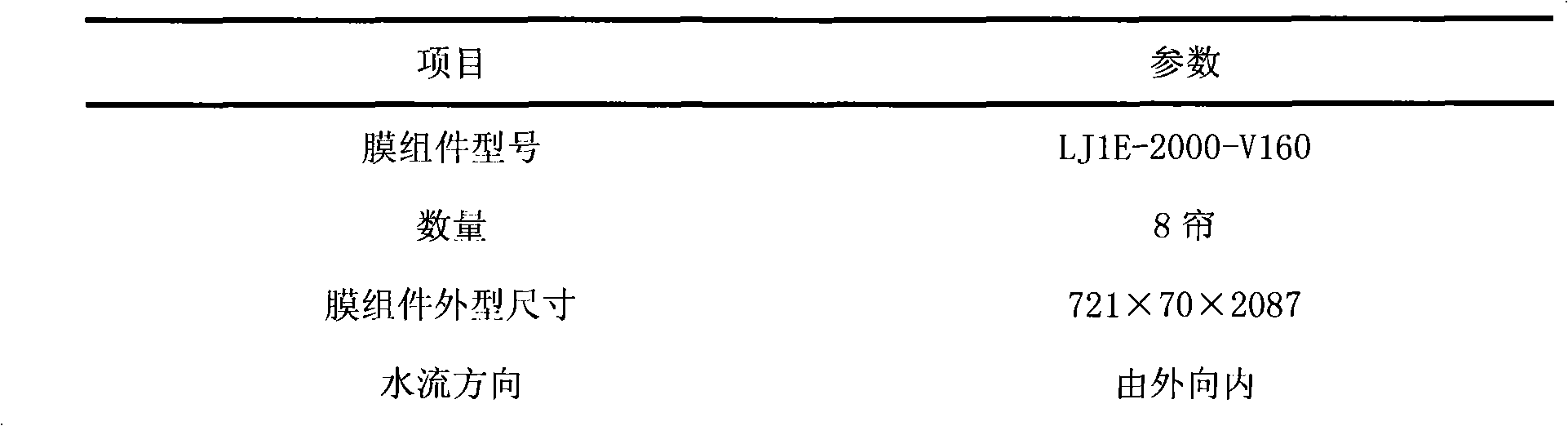

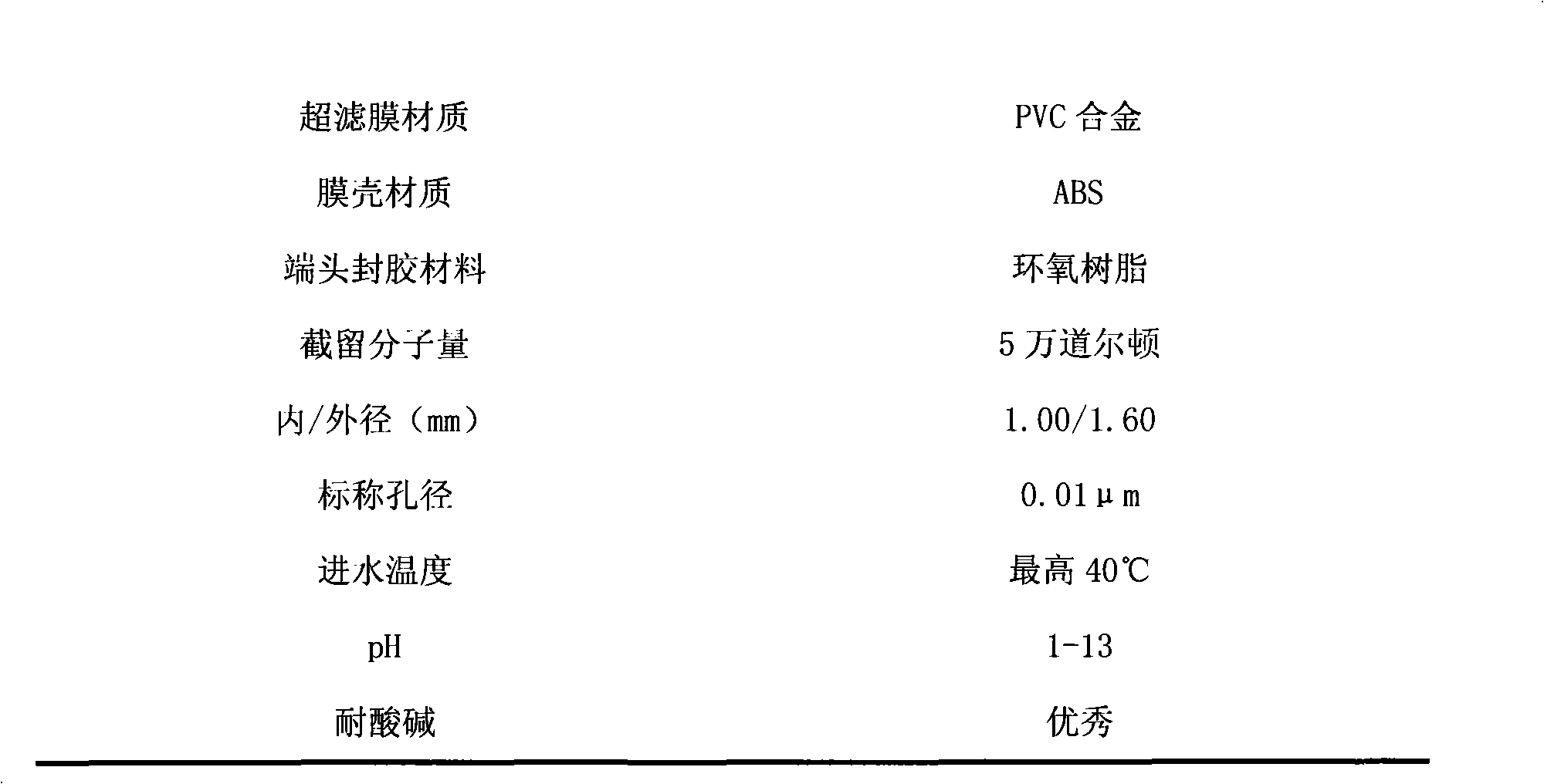

[0033]An embodiment of a method for removing groundwater hardness through lime ultrafiltration according to the present invention, the method includes the following steps: lift high-hardness groundwater into the reaction tank through a pump, and feed the reaction tank through a chemical dosing device while entering the reaction tank. Add lime powder (calcium hydroxide) into the pool, and fully stir it, and ensure sufficient reaction time to ensure that the lime powder (calcium hydroxide) chemical reacts fully with groundwater to generate CaCO which is insoluble in water. 3 , Mg(OH) 2 The floc turbid liquid; the floc turbid liquid flows to the ultrafiltration membrane tank, and the floc turbid liquid is filtered through the ultrafiltration membrane in the pool, and the CaCO trapped on the liquid inlet side of the ultrafiltration membrane is rapidly settled. 3 , Mg(OH) 2 And the insoluble compounds of Fe and Si in the original high hardness water body, the settled compounds ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com