A kind of bearing processing technology

A bearing processing and process technology, applied in the field of bearing processing, can solve the problems of waste of power consumption and energy consumption, loss of repairability of bearings, etc., to save resources, improve production efficiency, and avoid subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

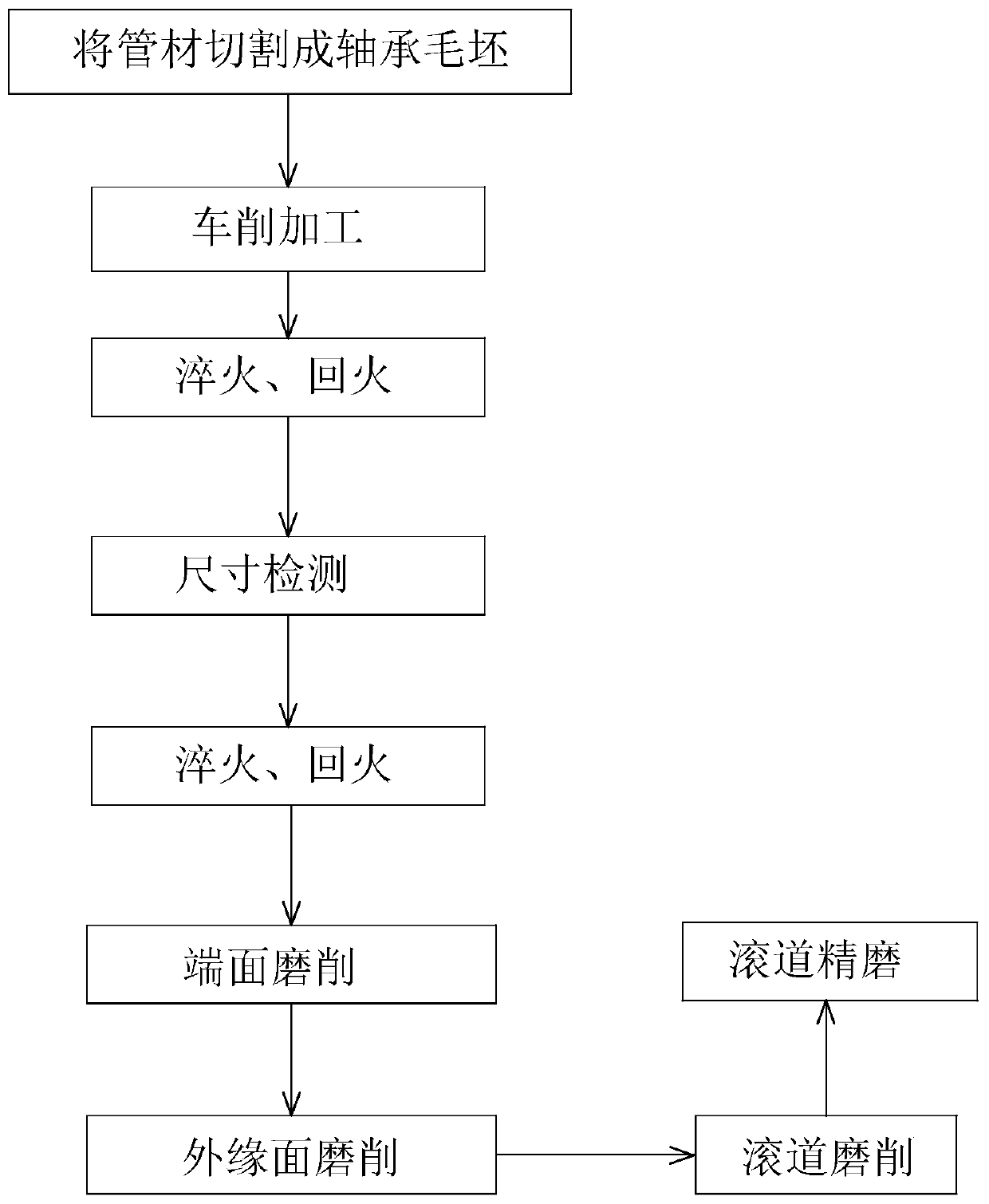

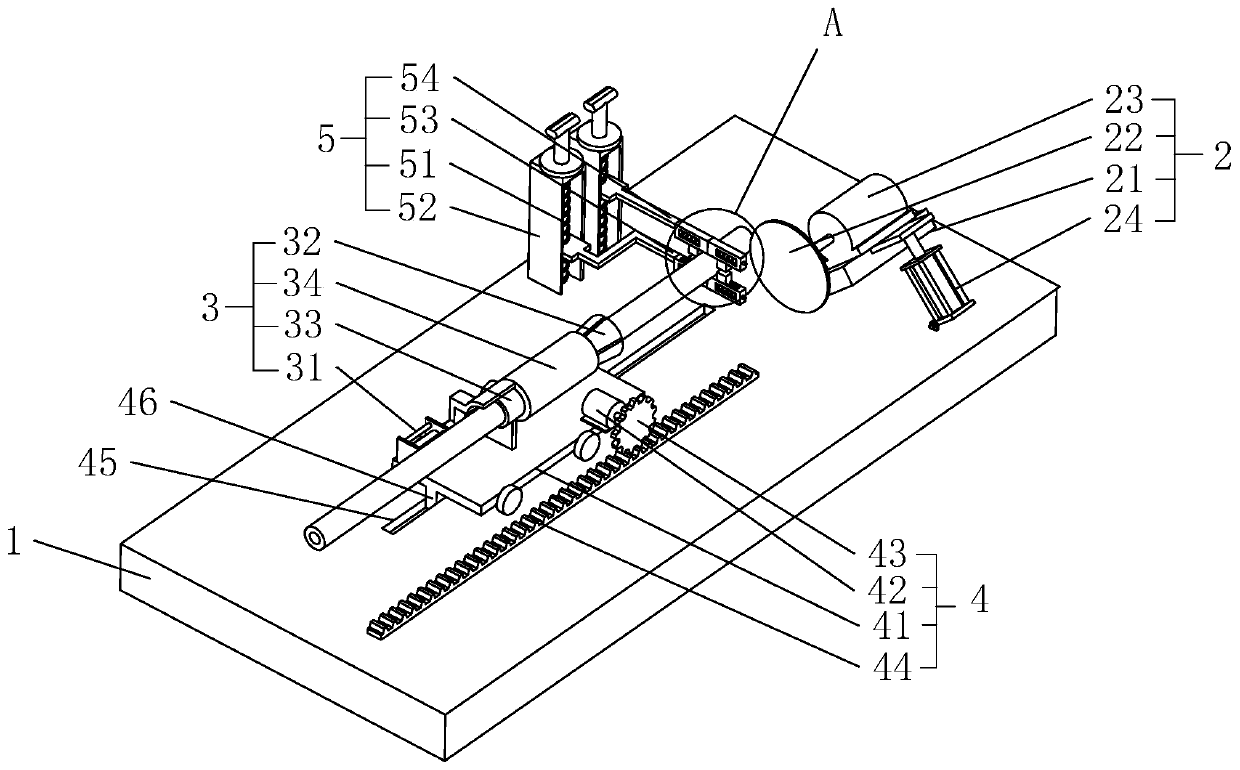

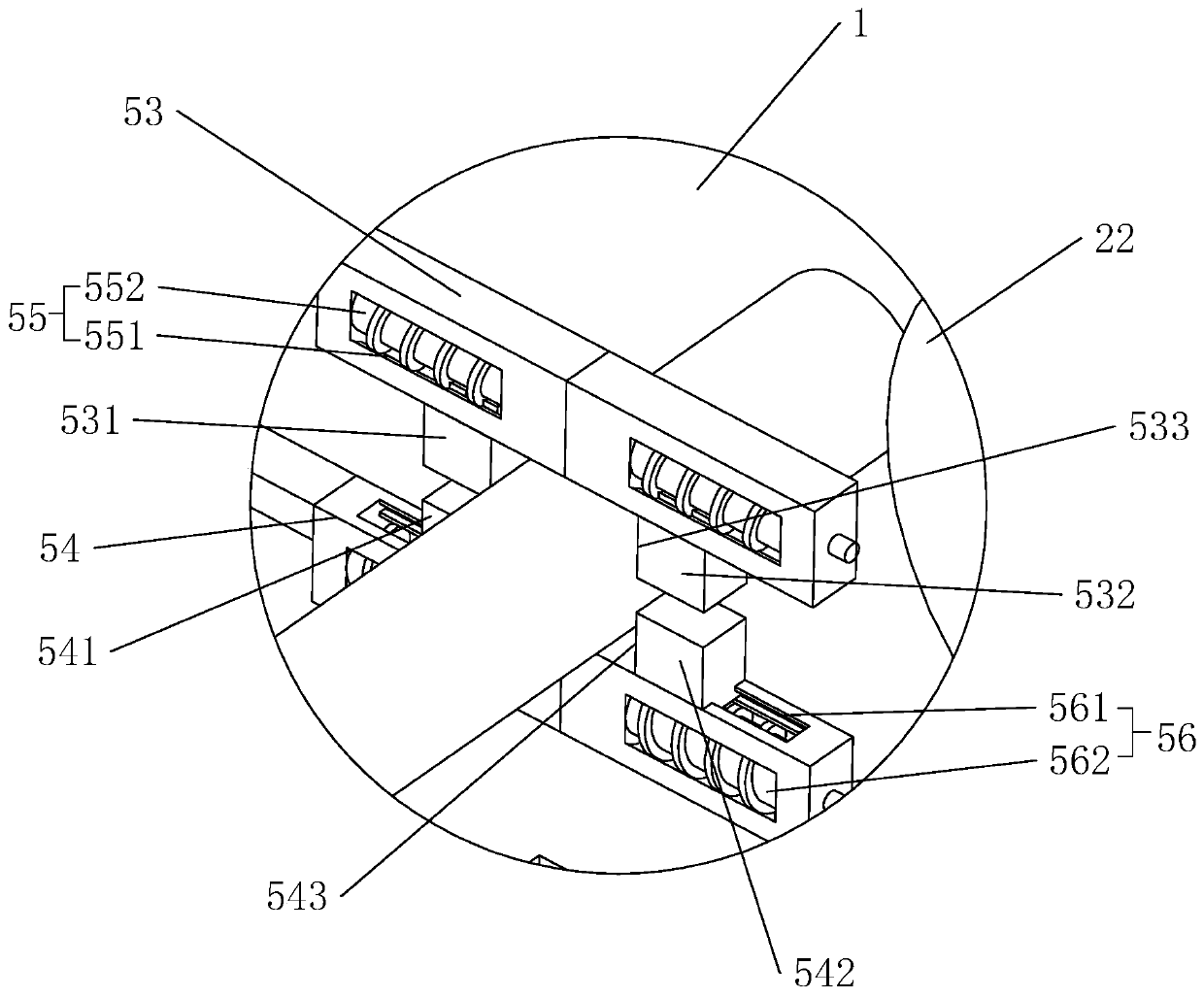

[0047] A bearing processing technology, comprising:

[0048] Step 1: Use bearing cutting equipment to cut the pipe into disc-shaped blanks;

[0049] Step 2: Turning the blank with a CNC lathe. The CNC lathe is an existing technology, so it will not be repeated here;

[0050] Step 3: Carry out heat treatment of quenching and tempering to the blank after turning, wherein quenching and tempering are existing heat treatment techniques in heat treatment, and will not be repeated here;

[0051] Step 4: Use the bearing automatic detection machine to detect the inner ring and outer ring diameter of the heat-treated bearing. This kind of bearing automatic detection machine was introduced by Cixi Tiantuo Automation Equipment Co., Ltd., and the model is TMPIDMEA-0840;

[0052] Step 5: Use a round table surface grinder to grind the end face of the blank. The round table surface grinder is imported from Yancheng Dafeng Xinda Machinery Manufacturing Co., Ltd., and the model is XD-306H;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com