Blank conveying device for automobile engine bearing cap

A technology of automobile engine and conveying device, which is applied in the field of mechanical equipment, can solve problems such as troublesome processing, and achieve the effects of avoiding wrong processing, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

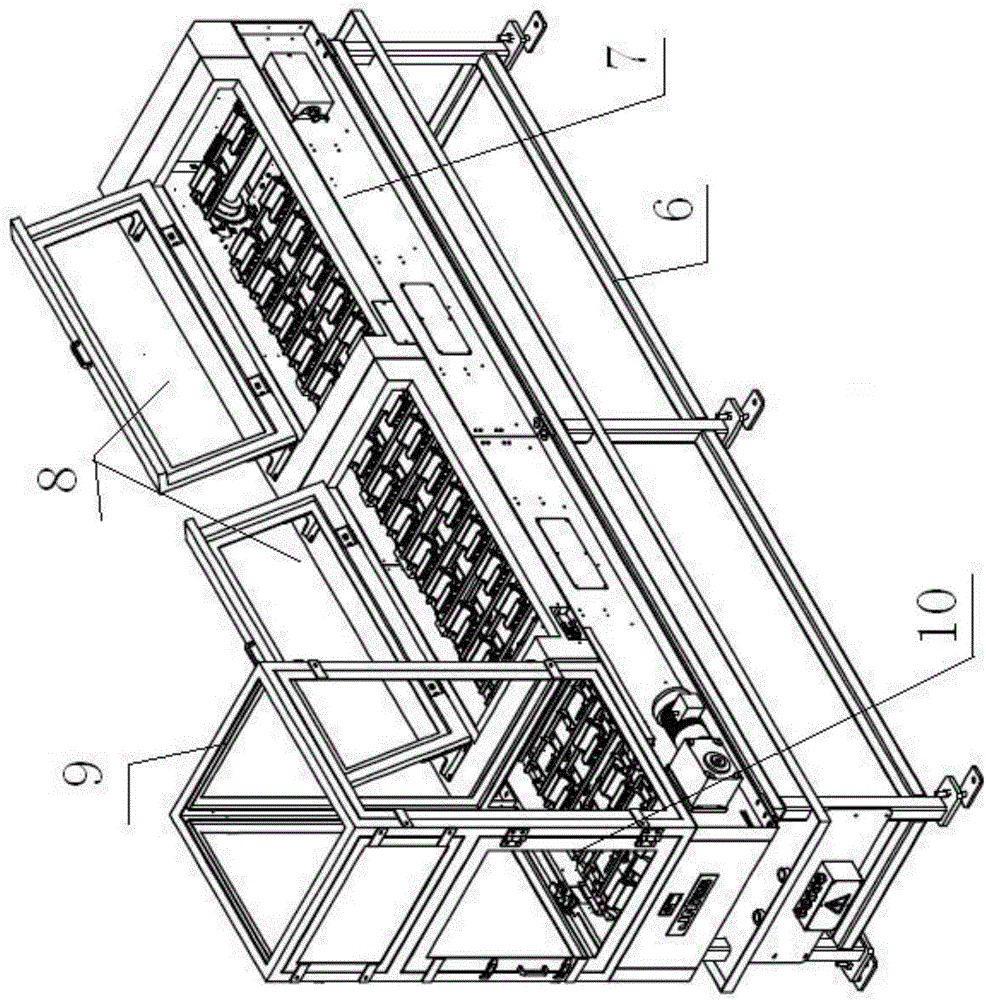

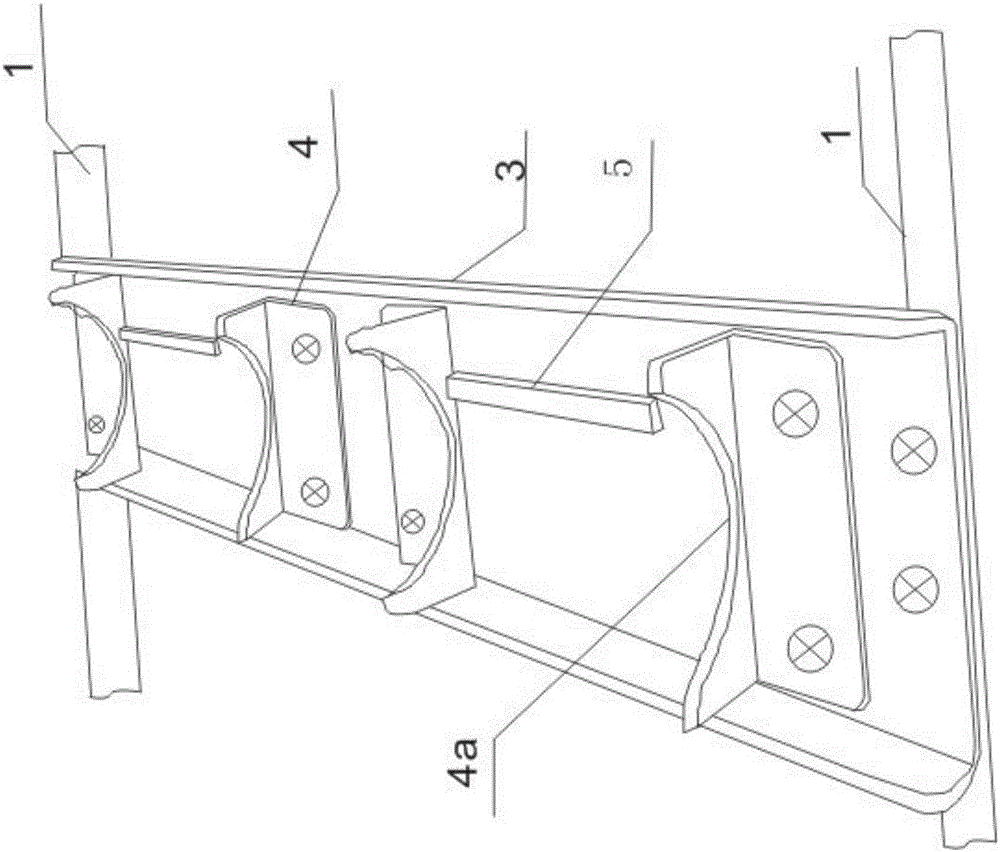

[0020] Such as figure 2 and 3 Shown: the anti-misplacement automobile engine bearing cover blank conveying device of the present invention is composed of a conveying chain 1, a steering knuckle blank tray 3, a blank limit plate 4, an anti-misplacement convex strip 5, a frame 6, a cabinet 7, and a case cover 8 , safe box 9, chamber door 10 forms.

[0021] The upper end of frame 6 is provided with the cabinet 7 of upper end opening, and cabinet 7 is rectangular casing, and the upper end of the front portion of cabinet 7 is provided with two case covers 8, and the afterbody upper end of cabinet 7 is provided with the safety box 9 of upper end opening, safe The side of the box 9 is provided with a box door 10 .

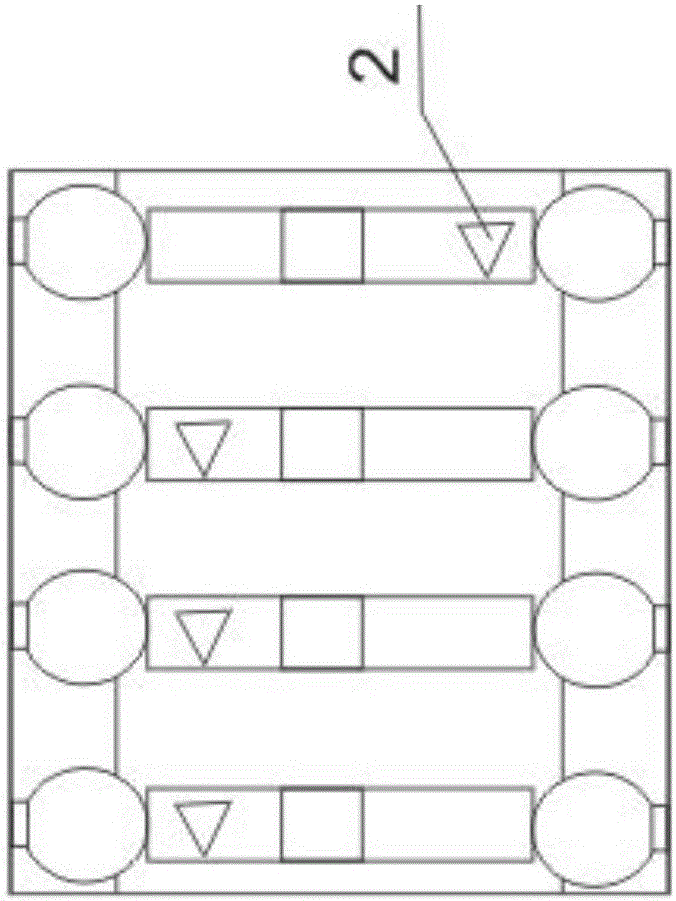

[0022] Conveyor chains 1 are installed symmetrically on the inner sides of the two long side plates of the chassis 7, and several steering knuckle blank trays 3 are connected between the two conveyor chains 1, and two sets of blank limit plates 4 are arranged in each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com