Silver contact chip automatic-welding equipment

A technology of automatic welding and silver tabs, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of quality problems affecting the normal sales of products, difficulty in controlling product quality, and damage to silver tabs, etc., to reduce the cost of enterprises The cost of manpower and material resources, simple structure, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

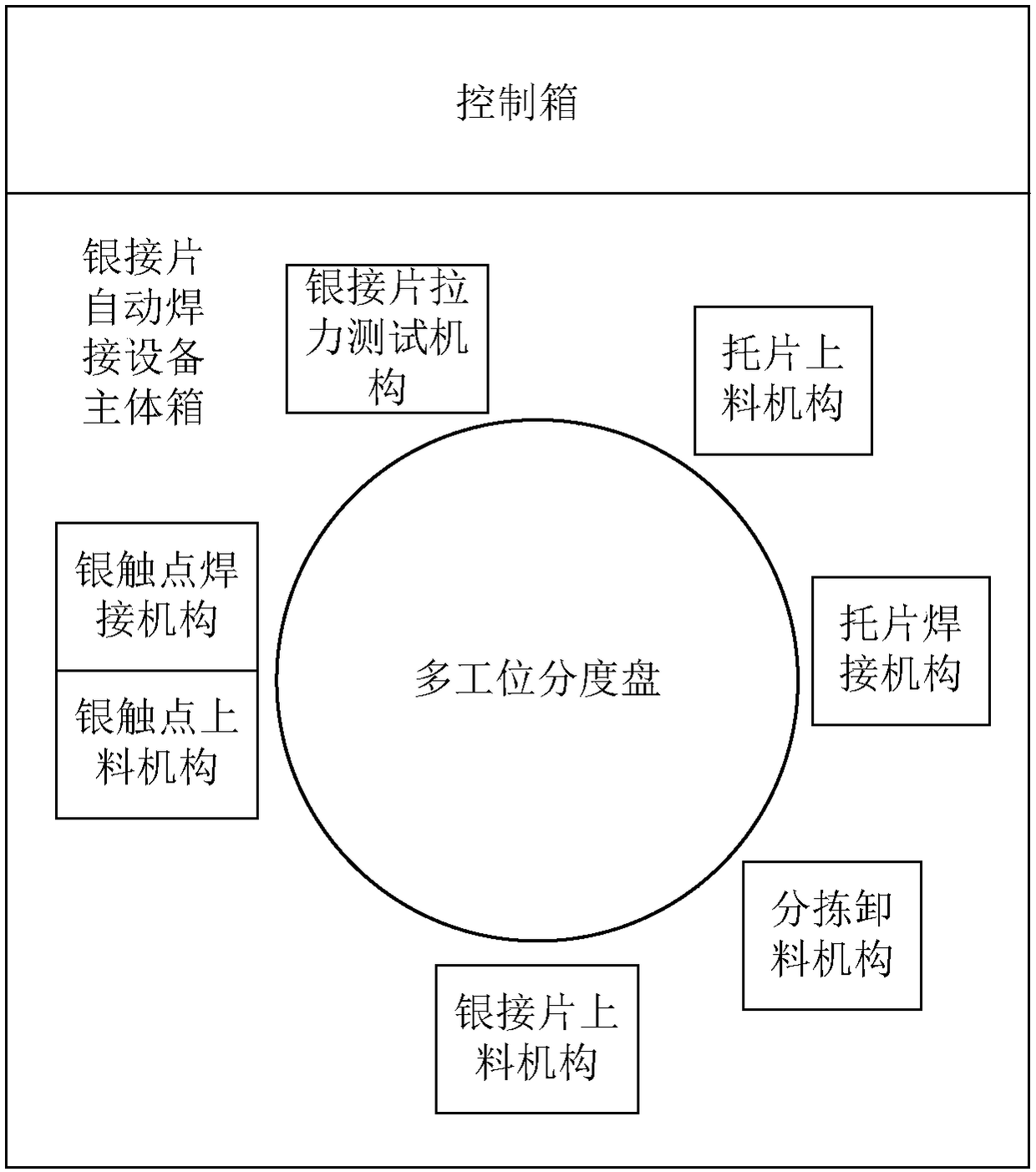

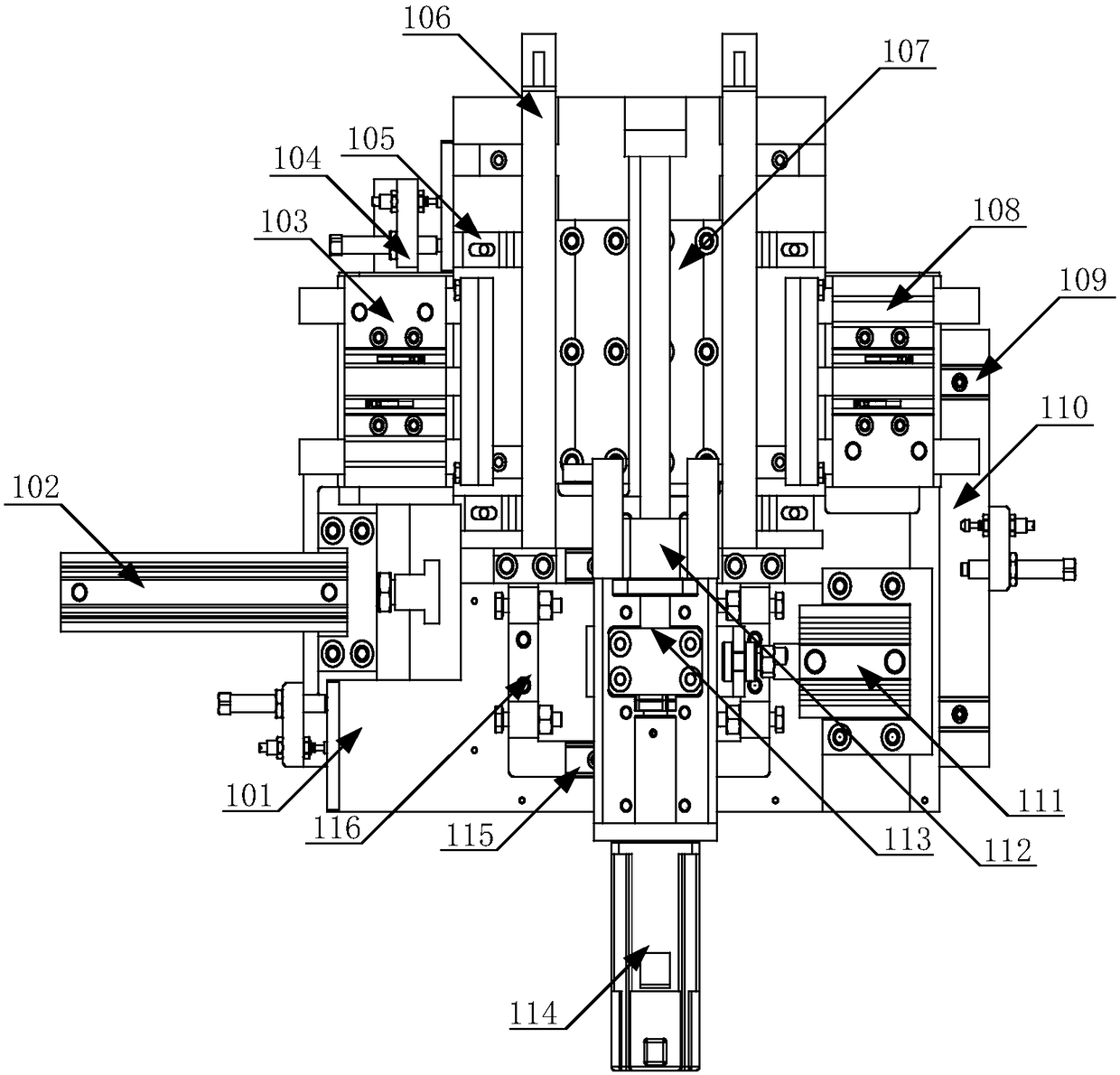

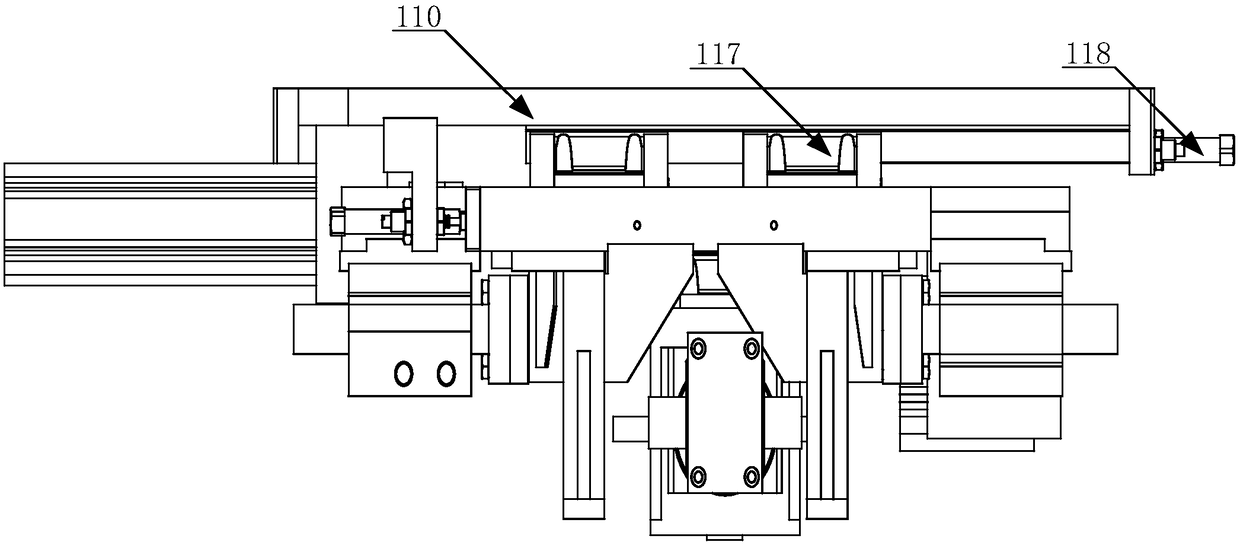

[0034] Such as figure 1 As shown, a kind of automatic welding equipment for silver tabs includes a main body box of automatic welding equipment for silver tabs, and a control box connected with the main box of automatic welding equipment for silver tabs; the main body box for automatic welding equipment for silver tabs is mainly composed of Multi-station indexing plate, silver tab feeding mechanism, silver contact feeding mechanism, silver contact welding mechanism, and silver contact tensile testing mechanism arranged clockwise around the multi-station indexing plate , supporting piece feeding mechanism, supporting piece welding mechanism and sorting and unloading mechanism; among them, the silver contact piece feeding mechanism and the supporting piece feeding mechanism both use the same feeding mechanism, and the silver contact welding mechanism and the supporting piece welding mechanism are both selected The same electrode spin welding mechanism.

[0035] The control box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com