Intelligent wire printer

A printing machine and electric wire technology, applied in the field of electric wire intelligent printing machine, can solve problems such as waste, difficulty, and hidden dangers in the use of electric wires, and achieve the effect of avoiding material waste and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

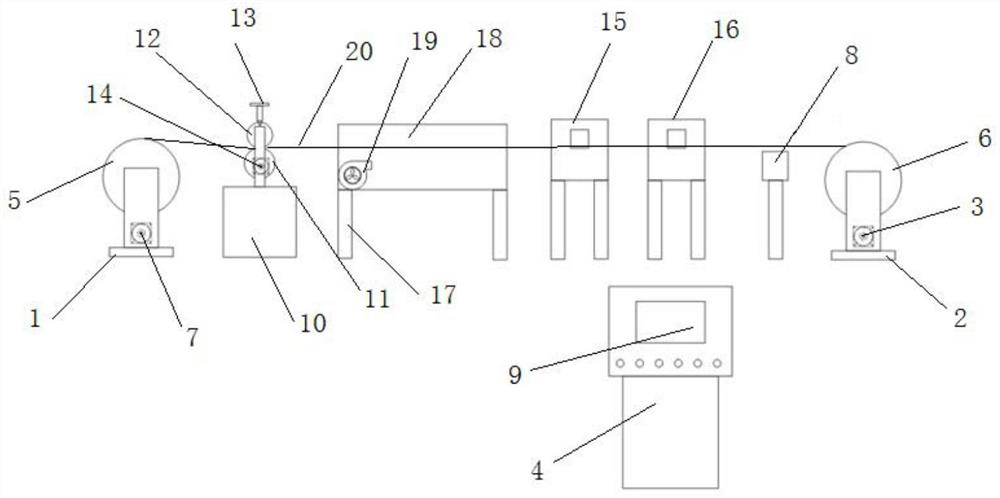

[0016] Embodiment: A kind of electric wire intelligent printing machine, comprises pay-off stand 1, take-up stand 2, printing equipment, drying equipment, electric wire defect detection equipment, take-up driving device 3 and control system 4, described pay-off stand 1 and The take-up rack 2 is provided with a pay-off reel 5 and a take-up reel 6 which can be rotated respectively. After the electric wires 20 are drawn out from the pay-off reel 5, they enter the printing equipment, drying equipment and wire defect detection equipment in sequence, and finally the take-up reel 6 Winding and take-up, the take-up driving device 3 drives the take-up reel 6 to rotate, the printing equipment can print on the surface of the wire 20 passing through it, the drying equipment can dry the printing ink on the surface of the wire 20, and the wire defect detection equipment can Defects on the surface of the electric wire 20 are detected and transmitted to the control system 4, and the control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com