Preparation method of electrostatic-assist nano-titanium polymer coated by graphene intercalation

A titanium nanopolymer and graphene technology, applied in coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of large cathode and small anode galvanic corrosion, electrode potential higher than iron, and limited number of functional groups, etc., to improve the resistance Chemical properties, improved compactness, and low viscosity of the material system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

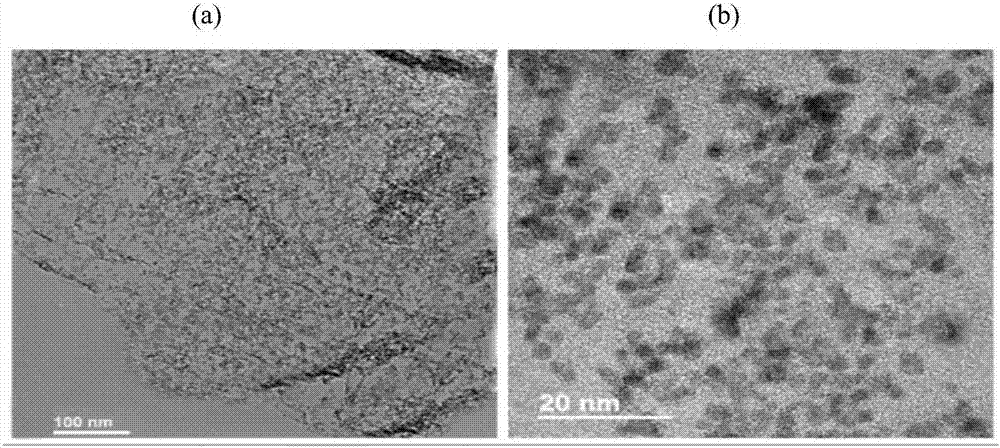

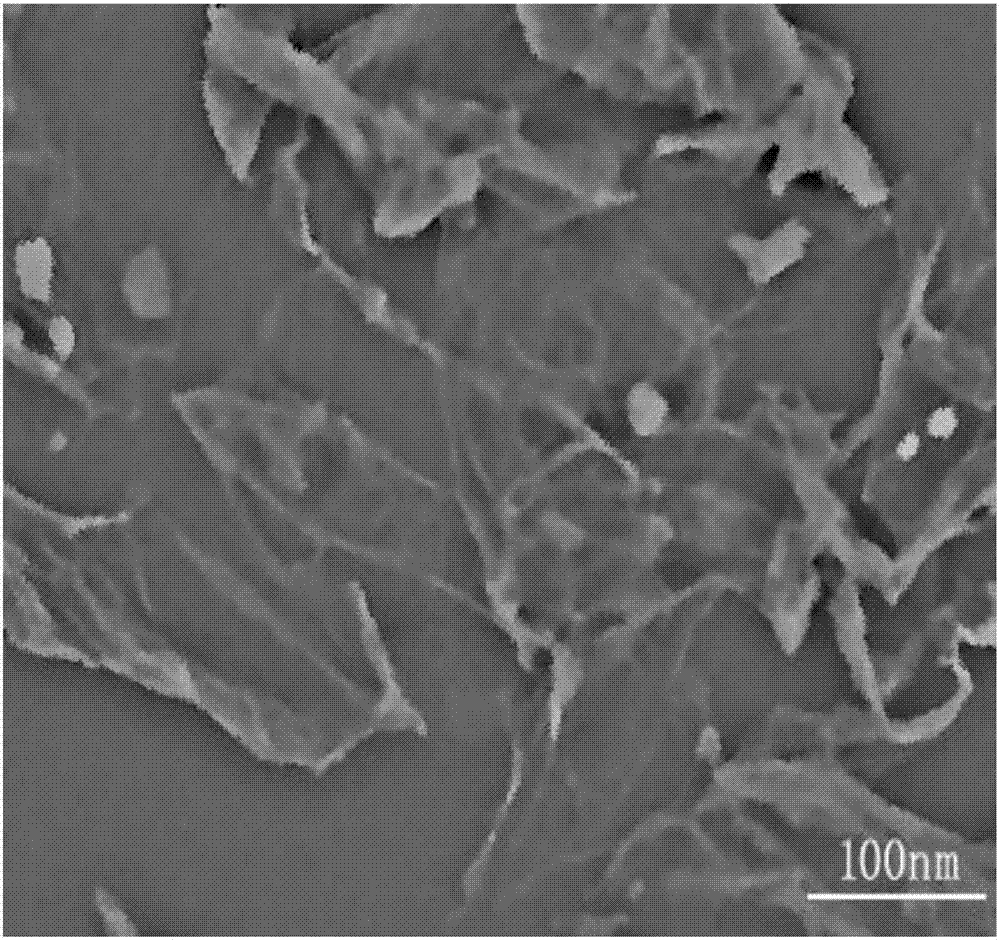

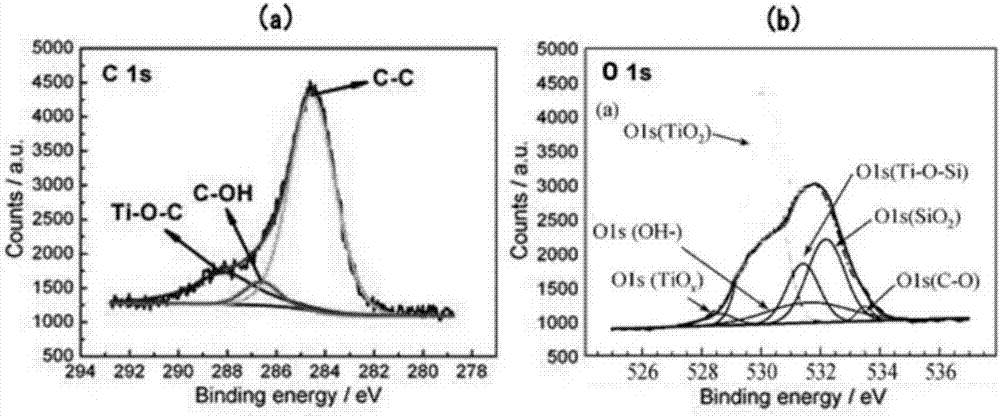

Image

Examples

Embodiment 1

[0029] All raw materials are fed according to the following mass percentages

[0030]

[0031] The specific operation steps are as follows: (1) In a glass or transparent engineering plastic box with small filter holes (greater than 5000 meshes), spray graphite powder by electrostatic powder spraying and titanium powder by ordinary air spraying. For spraying, the flow ratio of titanium powder and graphite powder is controlled according to the formula. The graphite powder and titanium powder are electrostatically mixed and then used for standby. At this time, the graphite powder has completed the uniform adsorption of titanium powder, and there is no need to maintain process insulation;

[0032] (2) Then prepare 2KG of the mixed powder material and other formula materials and put it into a 4L stainless steel reaction kettle, and add The weight ratio is 3:2:3, a total of 12KG high-hardness stainless steel beads. After sealing, place the kettle in a planetary ball mill to fix ...

Embodiment 2

[0042] All raw materials are fed according to the following mass percentages

[0043]

[0044]

[0045] The specific operation steps are as follows: (1) In a glass or transparent engineering plastic box with small filter holes (greater than 5000 meshes), spray graphite powder by electrostatic powder spraying and titanium powder by ordinary air spraying. For spraying, the flow ratio of titanium powder and graphite powder is controlled according to the formula. The graphite powder and titanium powder are electrostatically mixed and then used for standby. At this time, the graphite powder has completed the uniform adsorption of titanium powder, and there is no need to maintain process insulation;

[0046] (2) Then prepare 2KG of the mixed powder material and other formula materials and put it into a 4L stainless steel reaction kettle, and add The weight ratio is 3:2:3, a total of 12KG high-hardness stainless steel beads. After sealing, place the kettle in a planetary ball ...

Embodiment 3

[0050] All raw materials are fed according to the following mass percentages

[0051]

[0052] The specific operation steps are as follows: (1) In a glass or transparent engineering plastic box with small filter holes (greater than 5000 meshes), spray graphite powder by electrostatic powder spraying and titanium powder by ordinary air spraying. For spraying, the flow ratio of titanium powder and graphite powder is controlled according to the formula. The graphite powder and titanium powder are electrostatically mixed and then used for standby. At this time, the graphite powder has completed the uniform adsorption of titanium powder, and there is no need to maintain process insulation;

[0053] (2) Then prepare 2KG of the mixed powder material and other formula materials and put it into a 4L stainless steel reaction kettle, and add The weight ratio is 3:2:3, with a total of 12KG high-hardness stainless steel beads. After sealing, place the kettle on a planetary ball mill to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com