Preparation method of single-crystal less-layer antimonene

An antimonene and single crystal technology is applied in the field of preparation of single crystal few-layer antimonene to achieve the effects of uniform size and thickness, preventing coagulation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, add 4g of antimony powder and 80ml of absolute ethanol to a 100ml wide-mouth bottle, mix well, then add 40mg of surfactant oleylamine; then, place the reaction vessel in an ultrasonic cleaning machine and ultrasonicate for 3 hours at a power of 80W; The final liquid was centrifuged at 2000r / min for 10 minutes, and the supernatant was taken out; finally, the taken out supernatant was freeze-dried for 18 hours, and the final product was antimonene.

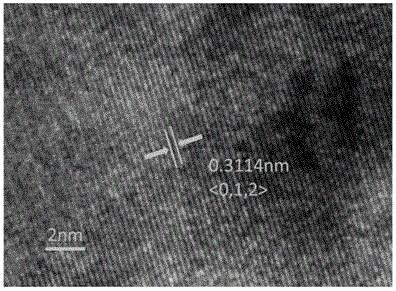

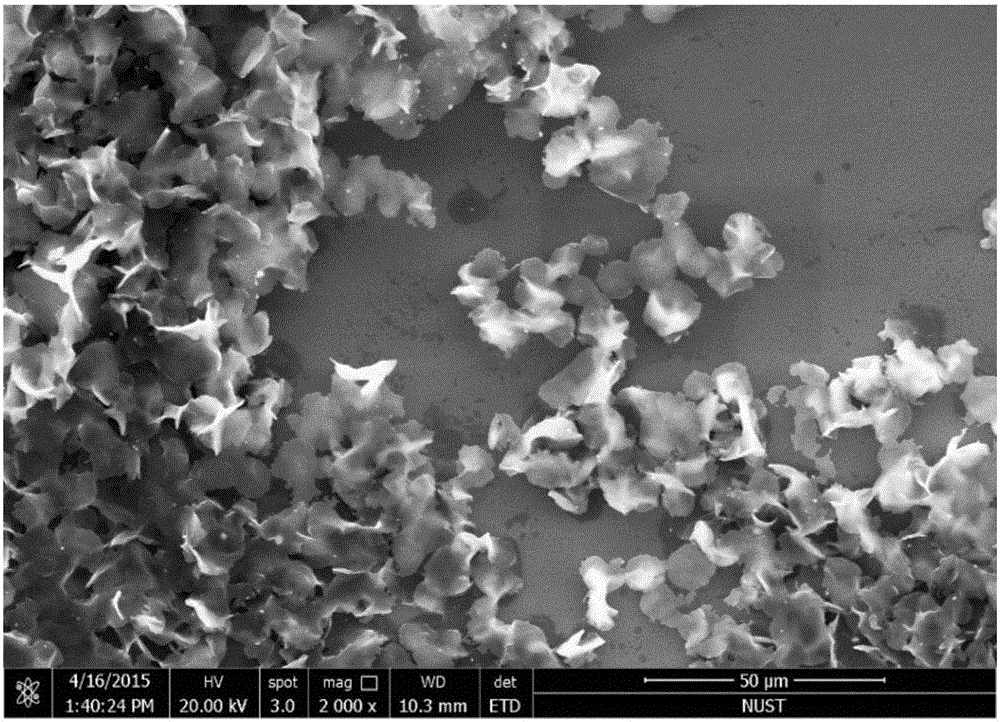

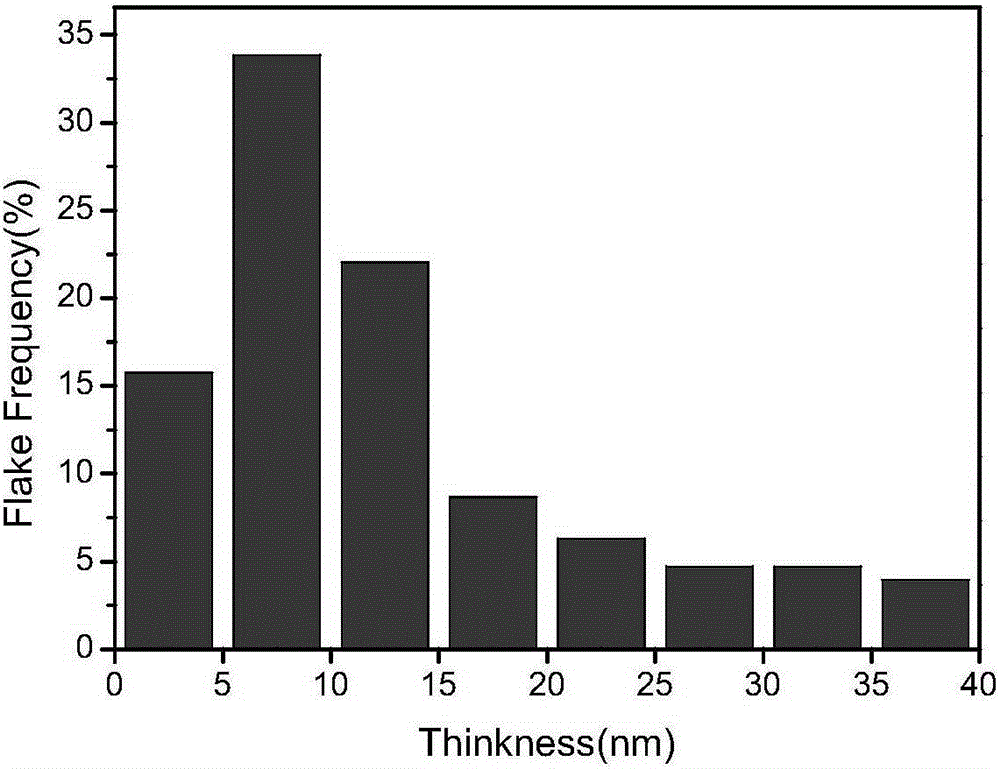

[0023] The prepared antimonene was characterized and analyzed, and the results were as follows: figure 1 , figure 2 with image 3 shown. figure 1 It is a scanning electron microscope image. It can be seen from the image that antimonene has a uniform shape and a uniform size, and the size is about 2.5 μm. figure 2 The antimonene thickness distribution statistical map obtained according to the test results of the atomic force microscope is obtained from figure 2 It can be seen that more than 75% of antimonene has ...

Embodiment 2

[0025] First, add 4g of antimony powder and 80ml of absolute ethanol to a 100ml jar, mix well, and then add 40mg of surfactant sodium lauryl sulfate; then, place the reaction vessel in an ultrasonic cleaner, and ultrasonicate with 80W power 3h; centrifuge the ultrasonicated liquid at 2000r / min for 10min, and take out the supernatant; finally, freeze-dry the taken out supernatant for 18h, and the final product is antimonene.

[0026] The prepared antimonene was characterized and analyzed, and the results were as follows: Figure 4 , Figure 5 shown. Figure 4 For the scanning electron microscope image, from figure 2 It can be seen that antimonene is uniform in shape and size, and the size is about 1 μm, which shows that the use of unused surfactants can effectively regulate the size of antimonene. Figure 5 It is an HRTEM image, which shows that the prepared few-layer antimonene lattice structure is complete and clear, and it is a good single crystal, and the crystal plane ...

Embodiment 3

[0028] First, add 4g of antimony powder and 80ml of absolute ethanol to a 100ml jar, mix well, then add 40mg of surfactant sodium lauryl sulfate; then, place the reaction vessel in an ultrasonic cleaner, and ultrasonically 5h; centrifuge the ultrasonicated liquid at 2000r / min for 10min, and take out the supernatant; finally, freeze-dry the taken out supernatant for 18h, and the final product is antimonene.

[0029] The prepared antimonene was characterized and analyzed, and the results were as follows: Image 6 shown. It can be seen that the shape and size of antimonene are uniform, and the size is about 400nm. It can be seen that increasing the ultrasonic power and ultrasonic time can significantly adjust the size and shape of antimonene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com