Sulfur-containing waste residue environment-friendly building material product and preparation method thereof

An environmentally friendly and building materials technology, applied in the field of building materials, can solve problems such as low strength and poor durability, and achieve the effects of large specific surface area, improved bonding performance, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

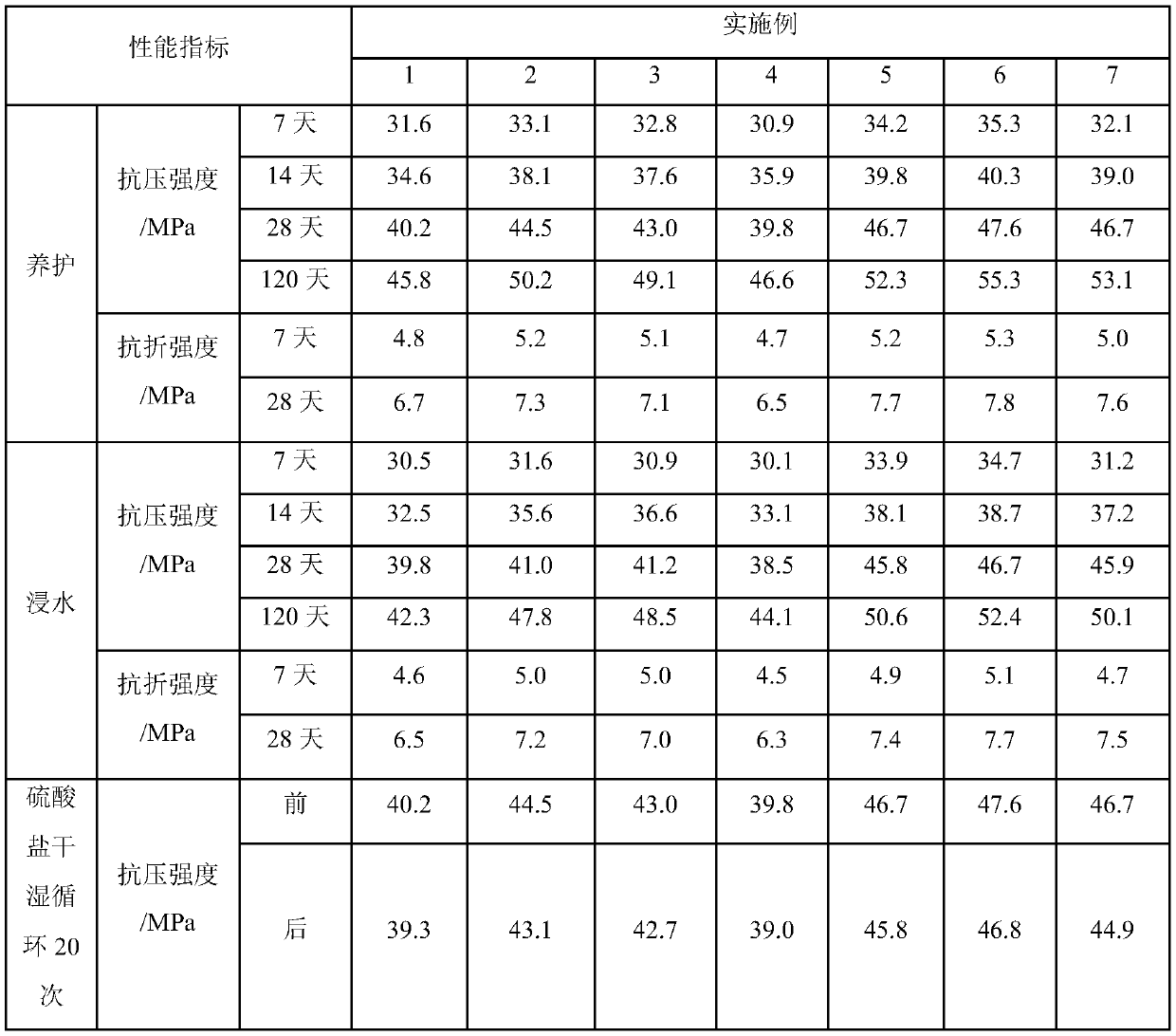

Examples

preparation example Construction

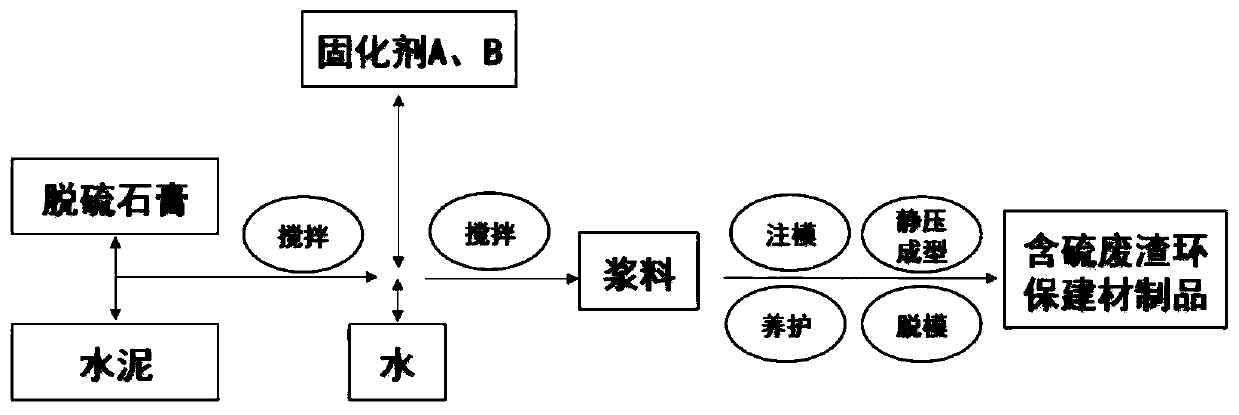

[0035] The present invention also provides a method for preparing an environmentally friendly building material product containing sulfur waste residue, comprising the following steps:

[0036] S1. Stir cement and desulfurized gypsum in a mixer according to the weight ratio of raw materials, and mix uniformly to obtain a dry mixture;

[0037] S2. Add water, curing agent A, and curing agent B to the dry mixture prepared in step S1 according to the weight ratio of raw materials, and mix and stir for 2 to 7 minutes to prepare a slurry;

[0038] S3. pouring the slurry prepared in step S2 into a mold, and performing static pressure molding to obtain a green body, the molding pressure is 10-60MPa, and the pressure holding time is 10s-3min;

[0039] S4. Put the green body prepared in step S3 into a standard box for curing, and demould, and obtain the sulfur-containing waste residue environmental protection building material product.

[0040] As an optional implementation, in step S4...

Embodiment 1

[0043] An environmentally friendly building material product containing sulfur-containing waste residues in this embodiment is composed of the following raw materials in parts by weight: 75 parts of desulfurized gypsum, 5 parts of cement, 0.1 part of curing agent A, 0.1 part of curing agent B, and 6 parts of water; wherein: The cement is ordinary Portland cement; the curing agent A is composed of the following raw materials in parts by weight: 80 parts of fly ash, 5 parts of nano silicon dioxide, and 5 parts of sodium hydroxide; the curing agent B is inorganic The silica-alumina gel is specifically composed of 30 parts of inorganic aluminum gel and 50 parts of inorganic silica gel.

[0044] The preparation method of the above-mentioned sulfur-containing waste residue environmental protection building material products in this embodiment comprises the following steps:

[0045] S1. Stir cement and desulfurized gypsum in a mixer according to the weight ratio of raw materials, and...

Embodiment 2

[0052] A sulfur-containing waste residue environmental protection building material product in this embodiment is composed of the following raw materials in parts by weight: 80 parts of desulfurized gypsum, 10 parts of cement, 0.2 parts of curing agent A, 0.2 parts of curing agent B, and 8 parts of water; wherein: The cement is sulfoaluminate cement; the curing agent A is composed of the following raw materials in parts by weight: 82 parts of fly ash, 6 parts of nano silicon dioxide, and 6 parts of sodium hydroxide; the curing agent B is sodium water glass.

[0053] The preparation method of the above-mentioned sulfur-containing waste residue environmental protection building material products in this embodiment comprises the following steps:

[0054] S1. Stir cement and desulfurized gypsum in a mixer according to the weight ratio of raw materials, and mix uniformly to obtain a dry mixture;

[0055] S2. Add water, curing agent A, and curing agent B to the dry mixture prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com