Epoxy resin system and preparation method thereof

An epoxy resin system and epoxy resin technology, applied in the fields of chemical industry and materials, can solve the problems of difficulty in balancing mechanical properties, process operability, hardening process conditions, and poor carbon fiber infiltration effect, etc., to achieve good infiltration effect and low The effect of exothermic peak temperature and low viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

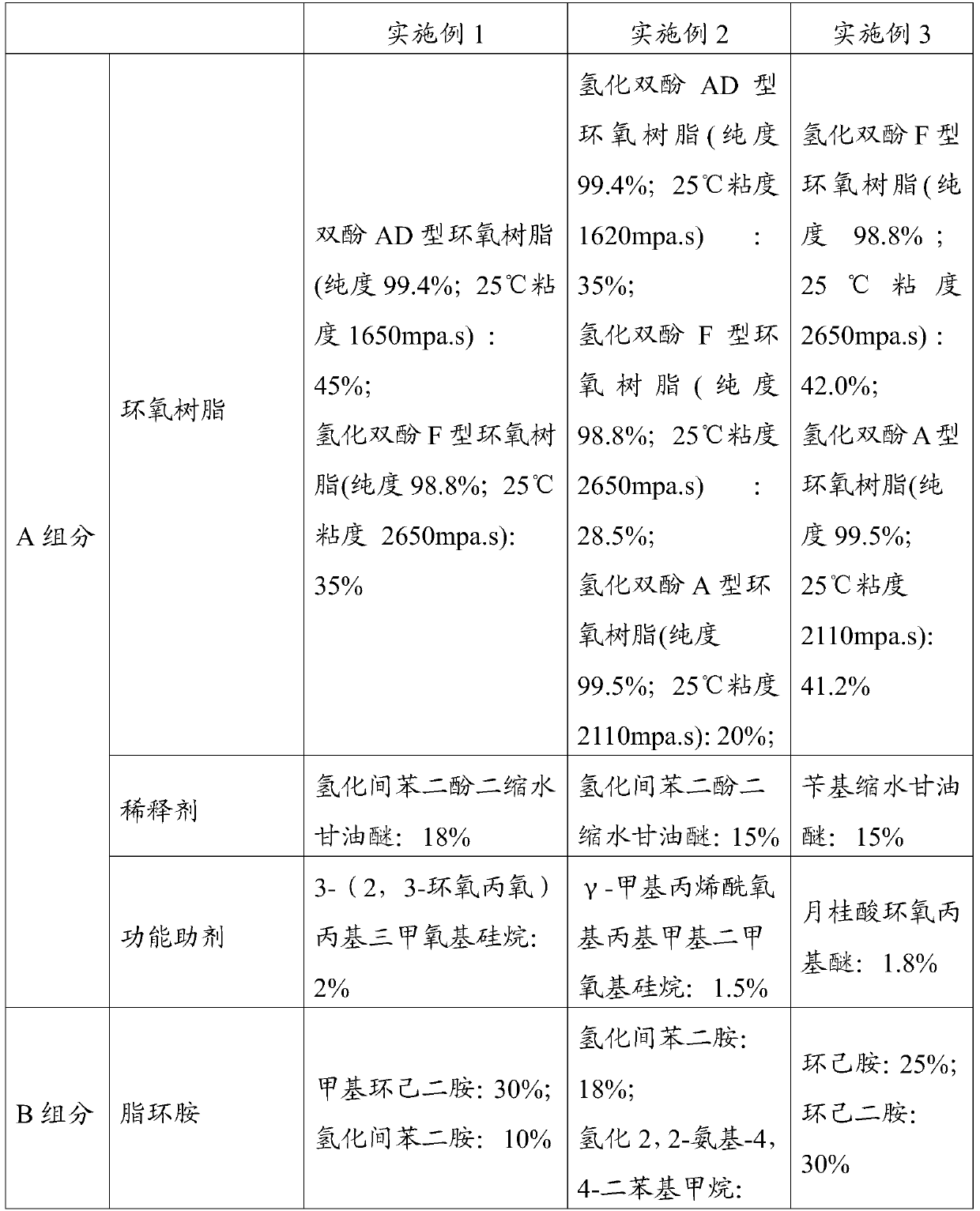

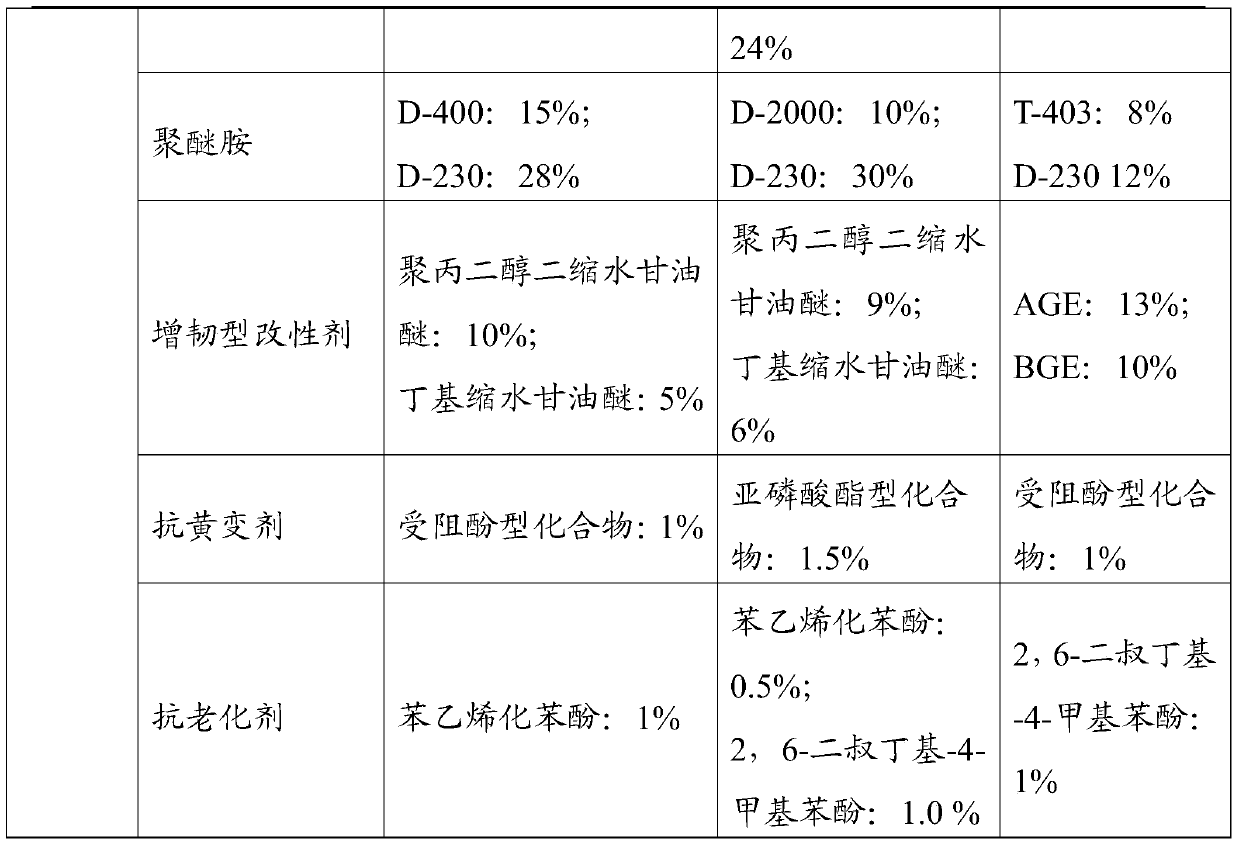

Embodiment 1

[0042] The preparation method of epoxy resin described in embodiment 1 may further comprise the steps:

[0043] (1) After mixing the epoxy resin and diluent, heat it to 45°C in a vacuum reactor, spray the functional additive at a spray speed of 20 g / min, and stir and react at a stirring speed of 200 r / min for 3 hours at the same time, Component A was prepared, the viscosity (25°C) was 870mpa.s, the epoxy value was 0.74, and it was a colorless and transparent liquid;

[0044](2) First, add hydrogenated m-phenylenediamine and methylcyclohexanediamine into the reactor and raise the temperature to 35°C, stir at 350r / min, then add the toughening modifier at a constant rate of 1.5kg / h In the reaction kettle, and control the maximum temperature not to exceed 75°C; then raise the temperature to 60-80°C after no obvious temperature rise, and react for 2 hours; then add the remaining alicyclic amine, and finally add polyetheramine, and keep it warm for 4 hours, Add anti-aging agent and...

Embodiment 2

[0047] The preparation method of epoxy resin described in embodiment 2, comprises the steps:

[0048] (1) After mixing the epoxy resin and diluent, heat it to 50°C in a vacuum reactor, spray the functional additive at a spray speed of 15 g / min, and stir and react at a stirring speed of 300 r / min for 3 hours, Component A was prepared, the viscosity (25°C) was 830mpa.s, the epoxy value was 0.76, and it was a colorless and transparent liquid;

[0049] (2) First, add hydrogenated m-phenylenediamine and hydrogenated 2,2-amino-4,4-diphenylmethane into the reactor and raise the temperature to 40°C, stir at 350r / min, and then add the toughening modifier with Add the constant rate of 1.5kg / h into the reaction kettle, and control the maximum temperature not to exceed 75°C; then raise the temperature to 60-80°C until there is no obvious temperature rise, and react for 2 hours; then add the remaining alicyclic amine, and finally add Polyether amine, after heat preservation reaction for 4...

Embodiment 3

[0052] The preparation method of epoxy resin described in embodiment 3, comprises the steps:

[0053] (1) After mixing the epoxy resin and diluent, heat it to 40°C in a vacuum reactor, spray the functional additive at a spray speed of 10 g / min, and stir and react at a stirring speed of 150 r / min for 2 hours, Component A was prepared, the viscosity (25°C) was 700mpa.s, the epoxy value was 0.78, and it was a colorless and transparent liquid;

[0054] (2) First, cyclohexylamine: 10% (accounting for component B by weight) and cyclohexanediamine: 7% (accounting for component B by weight) are added to the reactor and heated to 45°C, at 150r / min Stir, then add the toughening modifier into the reactor at a constant rate of 0.5kg / h, and control the maximum temperature not to exceed 75°C; then raise the temperature to 60-80°C until there is no obvious temperature rise, and react for 1h; Then add the remaining alicyclic amine, and finally add polyetheramine, after heat preservation for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com