A Robot-Assisted Intelligent CNC Turning Processing System

A robot-assisted, processing system technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as poor dimensional accuracy, easy turret crawling, poor surface finish, etc. Full, smooth oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

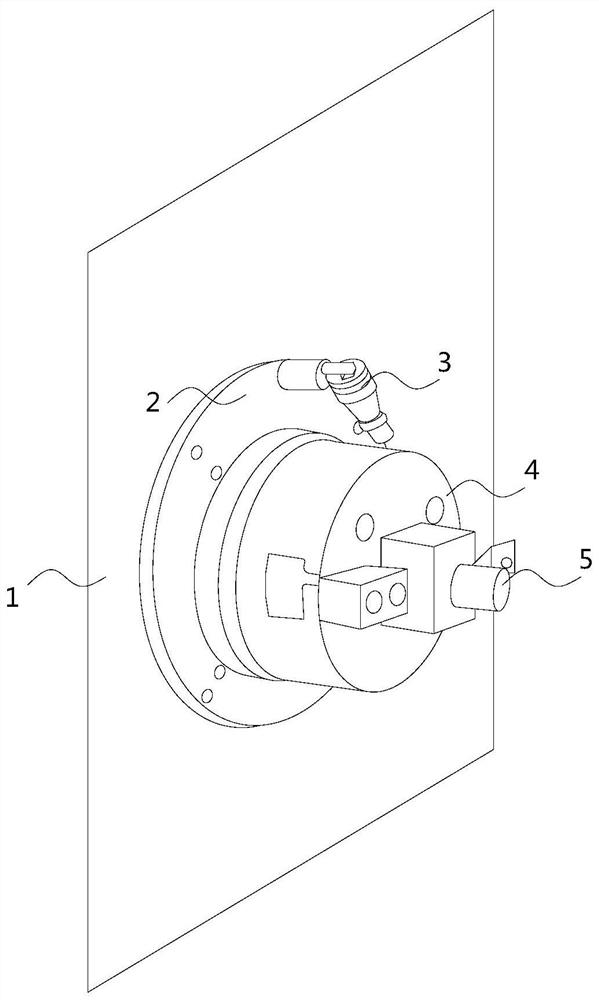

[0030] see Figure 1-Figure 4 , a robot-assisted intelligent numerical control turning processing system, the present invention provides a robot-assisted intelligent numerical control turning processing system, including a digital control system, a servo power system, an imported power turret, and a fully automatic chip removal system. The turret includes a frame 1, a tool seat 2, a lubrication mechanism 3, a turret seat 4, and a drill 5. The frame 1 is provided with a tool seat 2 horizontally, and the other end of the tool seat 2 is provided with a turret seat 4. , the turret base 4 and the turret base 2 are horizontally fixed, the other end of the turret base 4 is equipped with a drill 5, the drill 5 and the turret base 4 are fixed horizontally, and the knife above the turret base 4 A lubricating mechanism 3 is installed on the seat 2.

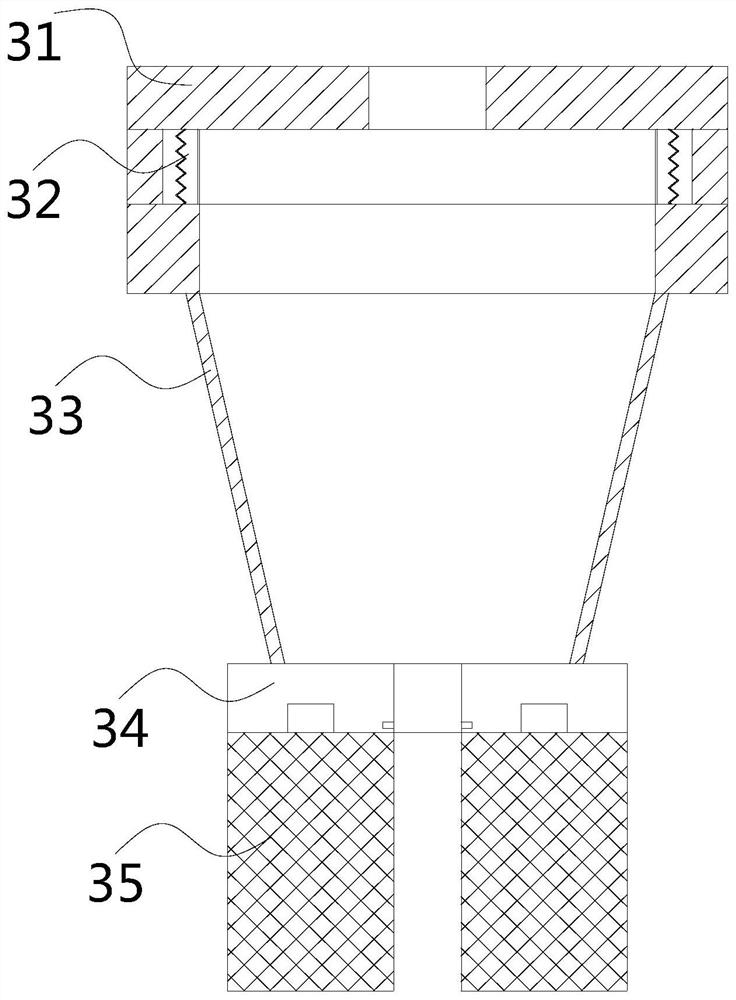

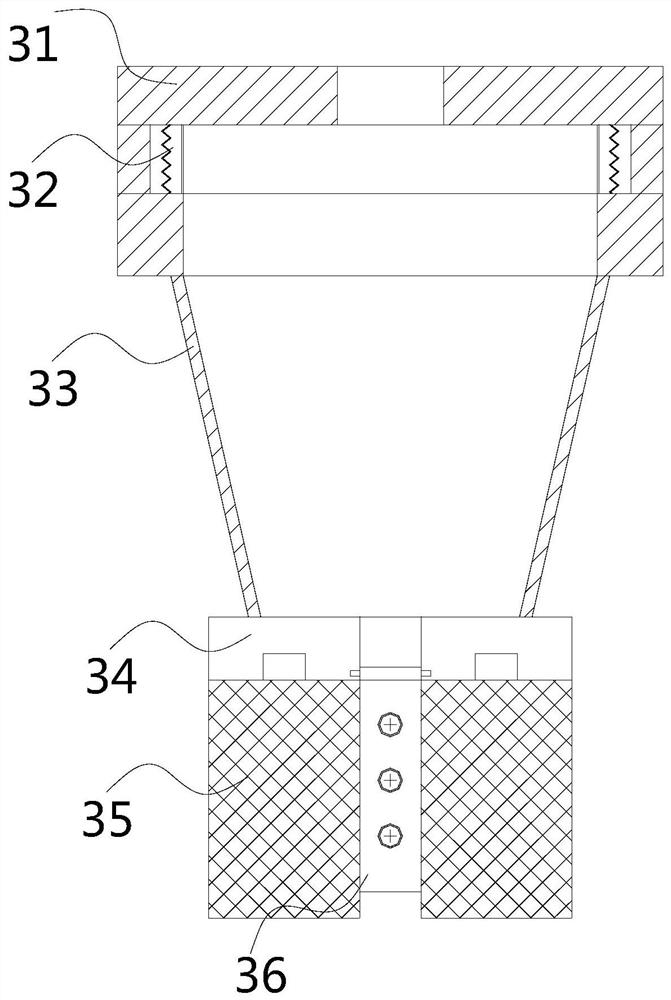

[0031] The lubricating mechanism 3 includes a connection top plate 31, an expander 32, a middle pipe 33, a chassis 34, and a sponge block ...

Embodiment 2

[0037] see Figure 1-Figure 6 , a robot-assisted intelligent numerical control turning processing system, the present invention provides a robot-assisted intelligent numerical control turning processing system, including a digital control system, a servo power system, an imported power turret, and a fully automatic chip removal system. The turret includes a frame 1, a tool seat 2, a lubrication mechanism 3, a turret seat 4, and a drill 5. The frame 1 is provided with a tool seat 2 horizontally, and the other end of the tool seat 2 is provided with a turret seat 4. , the turret base 4 and the turret base 2 are horizontally fixed, the other end of the turret base 4 is equipped with a drill 5, the drill 5 and the turret base 4 are fixed horizontally, and the knife above the turret base 4 A lubricating mechanism 3 is installed on the seat 2.

[0038] The lubricating mechanism 3 includes a connection top plate 31, an expander 32, a middle pipe 33, a chassis 34, and a sponge block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com