A kind of preparation method of carbon particle reinforced metal matrix composite material

A composite material and carbon particle technology, applied in the field of metal matrix composite materials, can solve various problems such as unsatisfactory properties and poor compactness, and achieve the effects of low cost, improved sintering compactness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

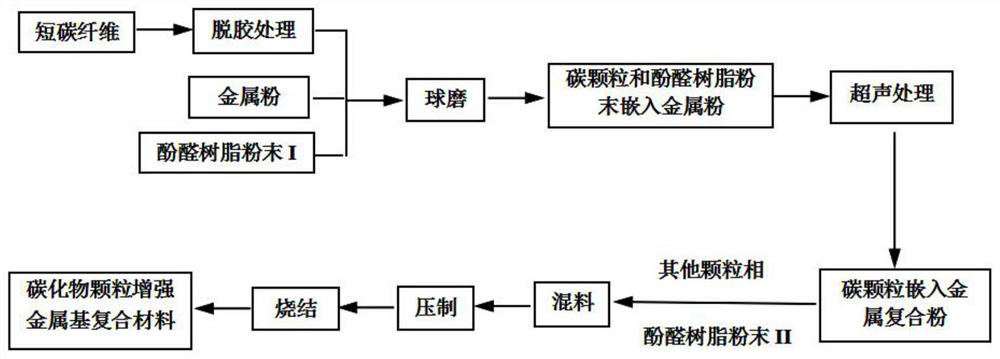

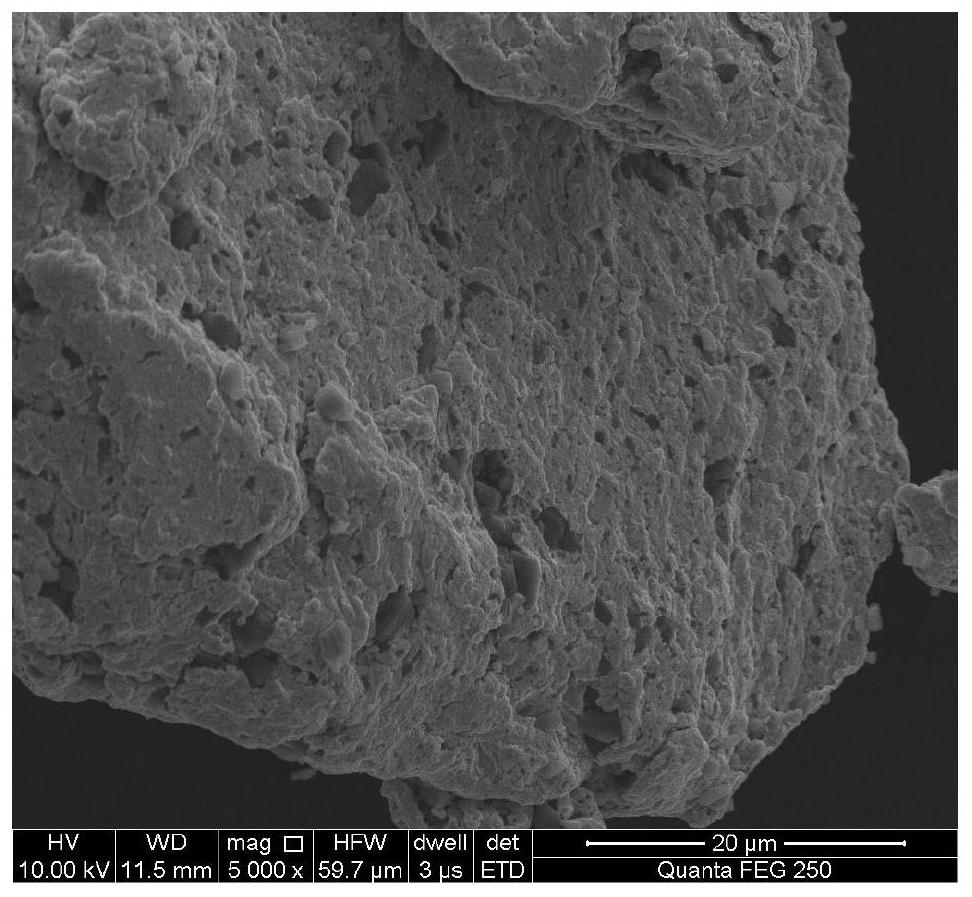

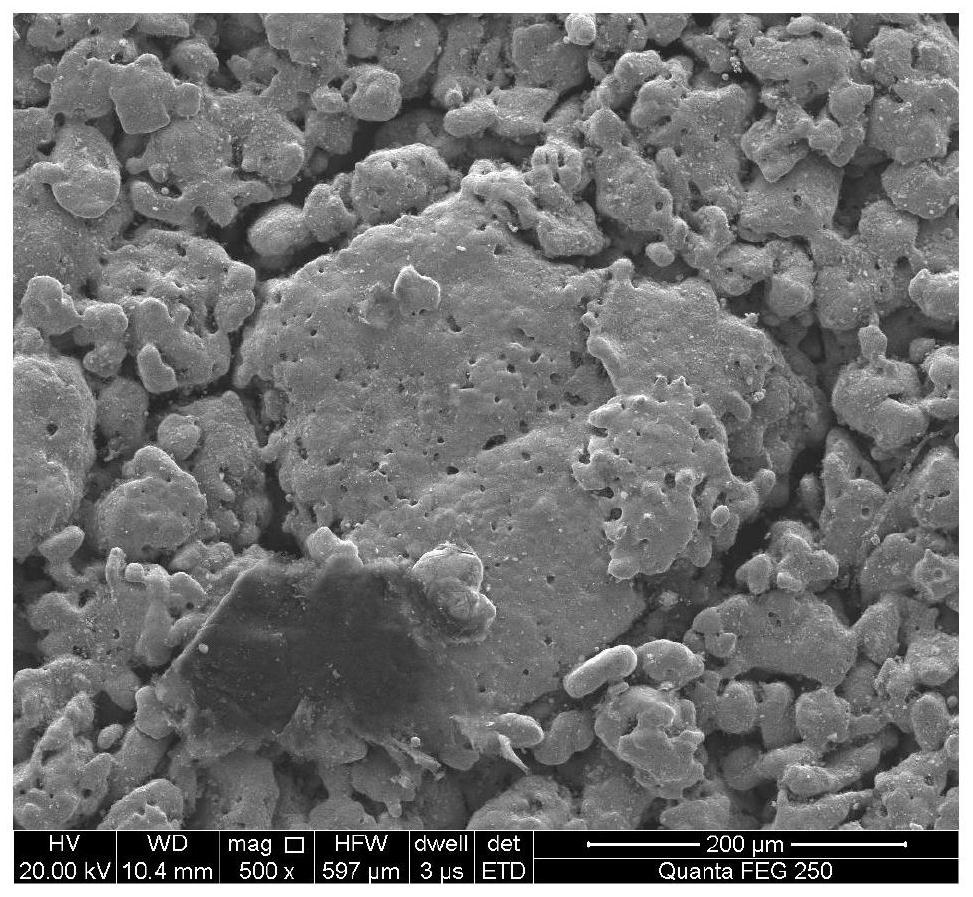

[0080] Step (1): In Example 1, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 7 μm and a length of 1 mm. The short carbon fiber bundles are heat-treated at 700°C for 50 minutes under an inert atmosphere or vacuum condition. The short carbon fiber bundle, phenolic resin powder I and copper powder are mixed according to the volume ratio of 9:1:90 and then ball milled. The particle size of the electrolytic copper powder is 150 μm, and the particle size of the phenolic resin powder I is 80 μm to obtain a mixed powder; The condition parameters of ball milling are: rotating speed is 280r / min, ball milling time is 6h, ball milling balls are stainless steel balls and hard alloy balls, ball diameter is 3mm~10mm (ball milling ball diameters are 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, The mass ratio of 9mm is 4:8:11:20:12:8:6:1). Then sieve 400 mesh sieves, get the undersieve, as standby material (SEM figure sees figure 2 ), the mas...

Embodiment 2

[0093] Step (1): In Example 2, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 8 μm and a length of 2 mm. Under vacuum condition, 700 ℃ of insulations 60min, carry out degumming treatment; Then join in the ball mill equipment together with electrolytic nickel powder and carry out high-energy ball milling, the particle diameter of the electrolytic nickel powder added is 150 μ m, short carbon fiber bundle, phenolic resin powder 1 ( The particle size is 50μm) and the electrolytic nickel powder are mixed according to the volume ratio of 9.5:0.5:90, and then ball milled. The ball milling speed is 250r / min, and the ball milling time is 6h. 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, the mass ratio of 9mm is 4:8:11:20:12:8:6:1), the ratio of the quality of degummed short fiber, phenolic resin powder I and electrolytic nickel copper powder The mass ratio of sum to ball milling ball is 1:6.

[0094] Step (2): After ball milling, mix the...

Embodiment 3

[0111] Step (1): In Example 3, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 8 μm and a length of 2 mm. Under vacuum conditions, heat preservation at 720°C for 60min, and degumming treatment; Add the phenolic resin powder I to the ball milling equipment for high-energy ball milling, mix the short carbon fiber bundles, phenolic resin powder I and aluminum powder according to the volume ratio of 9:1:90, and then ball mill, the ball milling speed is 250r / min, and the ball milling time is 6h , the ball milling ball is a stainless steel ball, the ball diameter is 3mm ~ 10mm (the mass ratio of ball milling ball diameter 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1) , The mass ratio of the sum of the mass of degummed short fiber, phenolic resin powder I and aluminum powder to the ball milling ball is 1:6.

[0112] Step (2): After ball milling, mix the prepared aluminum powder embedded with carbon particles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com