Lithium ion battery diaphragm with high electrolyte wettability and preparation method of lithium ion battery diaphragm

A technology of lithium-ion batteries and ion batteries, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of poor electrolyte wettability and wrinkles, prevent the diaphragm from wrinkling, reduce the risk of short circuit, and improve The effect of wetting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

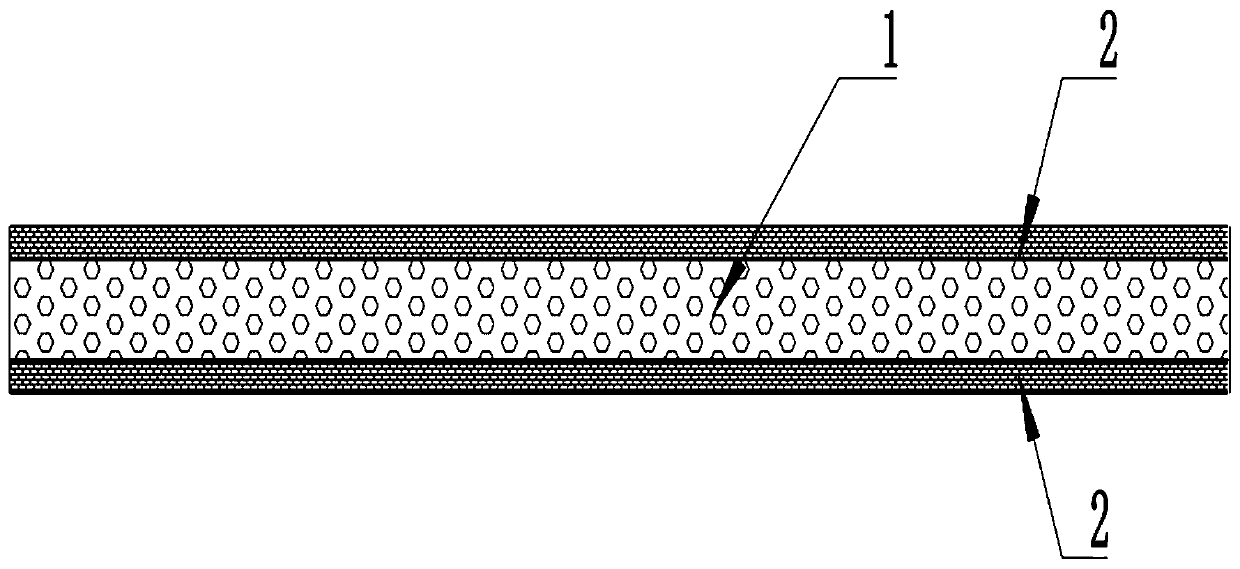

[0022] Such as figure 1 As shown, this embodiment 1 provides a lithium ion battery separator, comprising: a polyolefin microporous membrane substrate 1 , and a lipophilic polymer coating 2 coated on the surface of the polyolefin microporous membrane substrate 1 .

[0023] Optionally, the lipophilic polymer coating is a mixed liquid suitable for coating and curing on the surface of the polyolefin microporous membrane substrate. And the mode of described coating comprises: any one in dipping, spraying, roll coating; The mode of described curing comprises: any one in ultraviolet light irradiation, heat treatment, to improve lipophilic polymer coating and poly Olefin Microporous Membrane Matrix Bonding Degree.

[0024] The lithium-ion battery diaphragm of this embodiment 1 can greatly increase the wetting speed of the electrolyte to the diaphragm by coating a layer of lipophilic polymer coating on the surface of the polyolefin microporous membrane substrate, and improve the wetti...

Embodiment 2

[0039] On the basis of Example 1, this Example 2 provides a preparation method of a lithium-ion battery separator, including: preparing a cast cast sheet through a polyolefin resin; coating the lipophilic polymer coating on the cast cast and solidify on the sheet to prepare a polyolefin intermediate film; pre-laminate multiple polyolefin intermediate films to prepare a polyolefin pre-laminated film group; further bond multiple polyolefin pre-laminated film groups, Forming the laminated polyolefin intermediate film layer; performing recrystallization annealing treatment; and longitudinal stretching to prepare the lithium ion battery separator.

[0040] Generally, in the production process of lithium-ion battery separators, in order to increase production capacity and reduce production costs, multi-layer polyolefin cast sheets are often stretched at the same time, which involves wrinkles when laminating the multi-layer cast sheets question. The root cause of wrinkles is mostly ...

Embodiment 3

[0044] On the basis of Example 2, this Example 3 provides the first optional implementation of preparing lithium-ion battery separator, as follows:

[0045] (1) The polypropylene microporous membrane is melt-extruded to prepare a casting sheet, and the melt-extrusion temperature is 180°C-260°C.

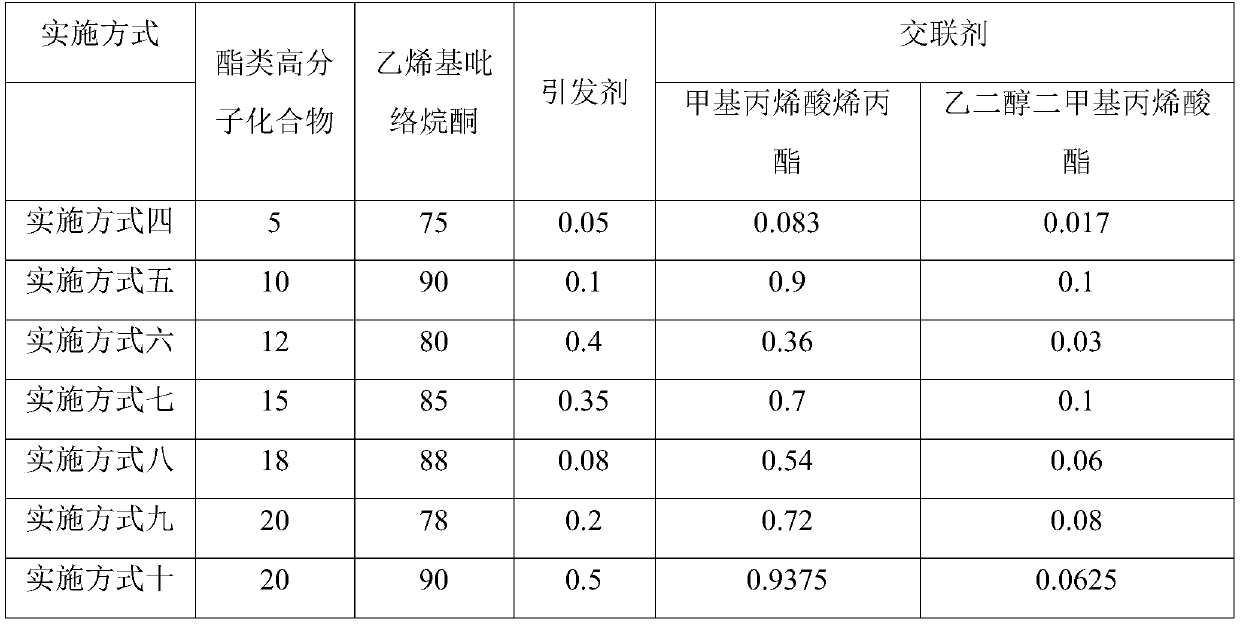

[0046] (2) Methyl methacrylate, vinylpyrrolidone, dibenzoyl peroxide and cross-linking agent are formulated into a mixed liquid in a mass ratio of 5:75:0.05:0.1, and are coated by dipping, spraying or roller coating The process is sprayed on the casting sheet, and then cross-linked and cured by ultraviolet light irradiation or heat treatment, so that the surface is covered with a layer of lipophilic polymer coating; among them, allyl methacrylate and ethylene glycol in the cross-linking agent The mass ratio of dimethacrylate is 5:1.

[0047] (3) The polyolefin intermediate film is pre-laminated every 2-6 layers through a composite process to prepare a polyolefin pre-laminated film gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com